How to sharpen a hacksaw yourself

A hacksaw for wood is one of the “eternal” values.

But, in order for a hand saw to always perform its functions, it must be sharpened correctly.

This is where basic knowledge about the type of cutting edge and its features will come in handy.

Of the existing methods, we will consider the safest and most popular ones, using available tools and available for home use.

Basic Rules

When sharpening a wood saw with your own hands, you need concentration, a good eye, and skills in working with a file. Despite the apparent complexity of the process, if you follow the recommendations, this manipulation can be done quite simply, although not quickly. To sharpen a hacksaw at home, you need to spend an hour or two, but you can do it faster if you get good at it.

Hacksaws are also sharpened with a grinder, but many craftsmen have a negative attitude towards this method. Firstly, it is unsafe, and secondly, you can damage the incisors more than sharpen them.

Preparation

The blade must be securely fixed in a vice. You can also sharpen on your knees or a stool, but holding the hacksaw is so inconvenient. The place where sharpening is carried out should be well lit; for safety reasons, gloves should be worn. Nothing extraneous, such as a TV, should distract from work.

To restore the performance characteristics of carpentry tools, it is necessary to use only a high-quality file. Usually a triangular file is used, and for the small teeth of a garden hacksaw a special tetrahedral file is provided.

The edges of the incisors must be cleaned with a needle file or a file that has a fine velvet notch. If you have to use a used file, then first clean it with a steel brush.

A small layer of coating is ground off the incisors. During their processing, the file should not slip, but cling to them well. If this does not happen, then the file is not suitable for processing or the blade cutters are overheated. For sharpening, you should take another tool. If the repeated attempt is unsuccessful, it is recommended to change the hacksaw.

Sharpening

To sharpen a hacksaw on wood with a file correctly, hold its handle with your right hand and hold the end with your left. The tool is directed at the teeth of the blade at an angle (like a bevel). The pressure should be uniform, smooth and only in a certain direction (usually away from you).

If possible, it is advisable to ensure that the removed layer of metal is of the same thickness. To do this, it is recommended to move the tool an equal number of times and with equal pressure. This way you can maintain the height, steps and angles of the teeth after processing.

It is necessary to remove burrs that appear on the edges of the tooth with a damp whetstone or with a file with a velvet notch. If left, they will reduce the sharpness of the teeth and chip when cutting wood materials, which will worsen the quality of the manipulations performed.

When sharpening is finished, check the sharpness of the teeth by sawing a piece of wood. If, when inspecting the saw blade, the cutters do not shine, then all actions were done effectively and the hacksaw is ready for use.

Teeth setting

The set of teeth is necessary so that the hand saw does not jam during the cutting process, so that it goes smoothly and easily. After using a hacksaw for a long time, you may need to set it before sharpening it. The essence of the process is to uniformly bend the teeth in different directions. After this procedure, free gaps should form on both sides of the canvas. The movement of a sharp-cutting tool in a cut will be much more efficient.

The greater the bend of the cutters, the less the risk of the saw getting stuck during operation. But you shouldn’t overdo it here, otherwise sawing will be extremely problematic.

Note! According to the standard, the wiring is made no more than 2 mm. If the hacksaw is intended for sawing dry wood, then the teeth are bent by 0.3-0.5 mm. To cut raw wood materials, the dilution should be 0.5-1 mm.

For ease of bending, it is recommended to use special devices. The hacksaw is clamped well in a vice, and the device is mounted on the work surface. The main thing is that the teeth should not protrude completely, otherwise they will break.

Why sharpen and when?

With constant use, the teeth lose their sharpness, the cutting edges wear out, deteriorating the quality of the cut and increasing the time it takes to complete the task.

Buying a new one will not correct the situation for long, and it will take no more than half an hour to restore the old canvas.

Timely sharpening of the hacksaw will restore the cutting ability of the incisors, and will always allow you to have a working tool at hand.

It is worth correcting the sharpness of the cutting edges at the first signs of wear, which can affect local areas and the entire working surface.

The dimensions of the cutter set also change, and this leads to jamming during operation.

How to determine when it’s time to sharpen a hacksaw?

How to determine when it's time to sharpen the teeth of the tool.

An experienced owner knows when and how to sharpen a hacksaw, but it is not difficult for the average person to determine this point on their own. As a rule, the sound produced during operation and the uniformity of the color of the cutting edge change.

Sharp cutters are characterized by uniform wear of the cutting edge.

The following signs indicate the need to “correct” the saw:

• sawing is difficult and uneven; • the cut is uneven; • the blade often gets stuck; • it becomes difficult to maintain a given trajectory.

In addition, a dull hacksaw often gets stuck and requires a lot of effort to complete the process.

A simple device to help

It is difficult to sharpen a hacksaw efficiently without special tools and a machine, by eye. You have to constantly inspect the teeth to make sure that they are not deformed, but become sharp.

We recommend: 3 simple ways to beat meat without a kitchen hammer

If the saw is used frequently, it makes sense to make a device that makes sharpening several times easier and faster.

You will need:

- old boards;

- screws and a screwdriver.

Progress:

- We connect two boards slightly larger than a hacksaw to each other at an angle of 37 degrees. To fasten the parts we use two corners.

- Place the hacksaw on the board so that the cutting edge protrudes.

- We fix it using 3 bosses, self-tapping screws and a screwdriver.

- We fix the device itself on the table using 2 clamps.

How to sharpen a hacksaw with your own hands

How to sharpen a hacksaw yourself if the need arises?

First you need to decide what material the work cloth is made of.

Ordinary steel can be corrected independently, but teeth with pobeditovy tips can only be processed on specialized industrial machines.

Some craftsmen, at their own peril and risk, undertake to sharpen a hacksaw using a grinder - but this is an unreliable and dangerous method.

To tidy up an ordinary manual hacksaw for wood at home, you will need to determine the shape of the teeth, prepare everything you need, and be sure to follow safety precautions.

Essential sharpening tool

To perform such a seemingly simple operation, you will need a rather impressive list of tools. However, if one of them is not at hand, you can try to find a replacement for it. What you cannot do without is a workbench with a vice, since only with their help can the saw be firmly fixed for work. The rest of the list looks like this:

- a “wiring” device, which, if missing, can be replaced with high-quality pliers. In this case, you will have to determine the approximate distance from the center for each tooth;

- a sharpening stone with sandpaper or a set of needle files and files;

- hammer;

- additional light source;

- In some cases, a caliper and protractor may be needed to take accurate measurements.

Special mention should be made of the method of sharpening hand saws using a grinder. In this case, you will need to have the angle grinder itself, a workbench and a pair of clamps, since the blade will need to be fixed horizontally.

General requirements for sharpening

Not every garage or workshop has a special machine for sharpening hacksaws, but it won’t hurt to sharpen the tool yourself.

There are, of course, exceptions - hardened teeth cannot be sharpened.

Diamond drills and other tricks will not help.

This saw has an increased service life and must not be repaired, but replaced with a new one.

It is easy to identify hardened steel - it is distinguished by its black color with a blue tint.

A grinder or a file and a needle file are usually used as a sharpener for a hacksaw.

A prerequisite is to first carry out the correct setting of the teeth, because the thickness of the hacksaw blade affects the width of the cut, so the edges must be bent to the required width.

Necessary tool

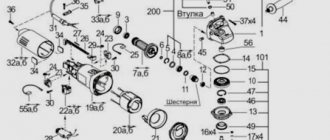

Sharpening a hacksaw using a grinder or grinder requires certain skills.

It is much safer and easier to sharpen a hacksaw mechanically.

Before you begin, prepare a vice or clamp, calipers, hammer and other necessary tools:

Crosscut saws are sharpened at an angle of 60 degrees using a triangular fine file.

Longitudinal with an angle of less than 60 degrees - use a large needle file or diamond file with fine abrasive.

For a mixed type, you will need a coarsely cut file or a finely cut diamond file.

For this operation, a special sharpening device is useful - a wooden block with a cut-out socket to protect your hands from cuts.

NOTE:

To sharpen a hacksaw using a grinder, you will need a cutting wheel with a thickness of 1.2 to 1.4 mm, with a diameter of 115 or 125 mm. The angle grinder must have a speed adjustment in the range of 5000 - 8000 per minute. Installing protection is a prerequisite for using this method. As a rule, a homemade shield made of transparent plastic is used.

Wood saw sharpening technology

Proper sharpening of a hacksaw should preserve the working profile of the teeth.

It is determined by the following parameters:

• pitch and height; • point angle; • radius of curvature.

The sharpening angle can be set in the range from 30 to 60 degrees, and depends on the material.

So, for soft wood, 50 degrees will be optimal.

It is important to secure the blade correctly in the vice - do not clamp it too hard, as the steel will vibrate under the file.

Using a workbench and a clamp, you can conveniently secure the hacksaw.

Sharpening is done by alternating double-sided sharpening - first, one row is passed along the left edges of all teeth.

Then the tool is turned over and the passage along the right half of the cutters is repeated.

The one-way method is not used for straightening hand saws - it is applicable only to certain types of knives.

Do-it-yourself saw sharpening

The saw is prepared for sharpening by fixing it in a vice, the jaws of which should ideally be made of wood so as not to damage the surface of the saw. Step-by-step instructions for sharpening a hacksaw on wood with your own hands are as follows:

- The hacksaw is fixed with its teeth as close as possible to the jaws of the vice, but so that their alignment is not disturbed while clamping the driver at an angle of 90° to the surface of the workbench.

- The file is taken into the working hand with the handle, and its tip is held on the reverse side with the other hand. This way the force will be distributed evenly.

- Sharpening a regular hand hacksaw is done at an angle of 15-30° to the tooth. If the wear is not too severe, the “original” sharpening angle will be clearly visible.

- The angle of the file to the blade should be about 30-45°. To do this, you need to stand so that the working hand is lower than the auxiliary one.

- The file should move only away from itself, with the same force and number of movements for each tooth. For a sharp file, 3-5 movements are usually enough to straighten the edge of an individual tooth.

- In this way, one side of the canvas is passed, after which it is turned over, fixed in a similar way, and the actions are repeated for the second side.

If, when performing sharpening work, you apply uneven force or make different numbers of movements with a file, this can lead to displacement of the teeth in relation to each other, distortion of their size and shape. Ultimately, such a hacksaw will require professional sharpening, or may even be completely unsuitable for further use.

How to properly sharpen a hacksaw with a file

Using a file is still relevant today, so let’s try to figure out how to properly sharpen a hacksaw at home.

Let's start by installing the canvas.

It must be secured, as already mentioned above, in a clamp or vice.

The jaws of the vice must be made of wood, with the width of the “jaws” not less than 200 mm.

The movement of the file should be uniform, and pressure on the teeth should only be applied when moving “forward”.

It is necessary to move the hand with the tool to the starting point freely, without force on the incisors.

In one working pass, a uniform layer of metal is removed, this will preserve the pitch, height and profile of the edge.

The sharpness of the cutter can be reduced due to the formation of burrs on the surface and irregularities after passing the abrasive.

A file cannot sharpen a hacksaw perfectly, but you can get high quality - after sharpening, the smallest file or needle file and whetstone will come in handy.

Burrs are removed by selective grinding with a fine abrasive, and the edges are leveled with a wet whetstone along the side base of the blade.

When you set out to sharpen a hacksaw correctly, pay attention to maintaining the tops of the teeth.

The same height of the cutters and correct setting affect the wear resistance of the tool and the quality of the cut.

Features of sharpening longitudinal hacksaws

In this case, a diamond file is used, also with a fine notch. The saw blade is installed strictly vertically. How to sharpen a wood hacksaw for longitudinal cutting? You can follow two approaches that differ in sharpening angle:

- Direct method. The tool is directed horizontally relative to the hacksaw blade and removes a small layer of material from the surface. The posterior and anterior edges of the tooth are subject to correction. As a result, the cutting edges become sharper.

- Oblique method. This technique differs from the first approach in the direction of the file relative to the hacksaw blade. The sharpening angle is selected with a slight bevel - about 75-80°.

Hacksaw teeth set

The movement of the blade must be free, for which the saw teeth are set apart by the same amount.

To reduce the coefficient of friction and the clamping of the hacksaw in the cut, its width must be greater than the thickness of the working blade, otherwise the metal heats up and expands, which leads to the saw jamming.

The teeth of the hacksaw are set by bending the cutters to the sides.

Using pliers does not allow you to obtain the same angle of inclination - with such a tool you can only cut firewood.

To spread the cutters evenly and get an even, neat cut, use a homemade device for setting the teeth.

To make it, you need a metal die of arbitrary shape with a thickness of 2-3 mm.

In a simple version, several slits are made to indicate the thickness of the canvas.

The tooth is grabbed into the hole and bent until the selected stop is reached.

In the second version, a cut is cut into the plank with a metal file, and two holes are drilled to install the limiter.

Rotating the sector to the sides allows you to adjust the bend angle.

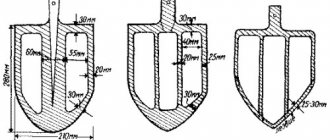

The figure shows a simple model and wiring with a stop.

The design of the device is intuitively easy to manufacture and use.

It is necessary to take into account that the width of the bend has its own parameters.

Requirements for the setting of hacksaw teeth

When bending the cutters one at a time on both sides of the canvas, maintain a certain value that can be set on a homemade device.

The width of the wiring depends on the type of wood.

Soft and damp wood requires a larger angle of inclination than dry wood.

As a rule, hand tools work effectively with an average value of 0.2-0.3 mm.

At the same time, the total value should not exceed the width of the canvas.

In addition, the same nature of the bend on each side is observed.

The wiring for the hacksaw is checked visually or using a caliper.

Pay attention to the size of the tooth - the height of the incisor is especially important.

Teeth setting

The teeth deviate from the plane of the blade in a checkerboard pattern, for example, all even ones to the left, all odd ones to the right. Only very experienced carpenters are able to set saws on wood “by eye”. This skill comes after several hundred diluted saws. Less experienced craftsmen are better off using a special tool - wiring. The simplest version of the tool is a flat plate of durable metal with a slot into which the blade fits tightly, with minimal clearance. The saw blade should be clamped in a bench vice. The teeth should protrude slightly from the jaws. The teeth, one after another, are clamped into the groove of the plate tool and bent in the middle part. The wiring angle must be constantly monitored. First, bend all the even-numbered teeth in one direction, then all the odd-numbered teeth in the other. Once the wiring is complete, you can spread the jaws to the width of the wiring and stretch the fabric between them. If any of the teeth are bent more than necessary, they will hit the vice. They need to be fixed.

Teeth setting

Canvases with hardened teeth are not subject to routing.

Leveling the height of the links

All teeth must be the same height.

An uneven edge results in uneven loading and significantly reduces work efficiency.

Checking the height of the hacksaw teeth

It is necessary to check the height of the teeth before sharpening the tool.

To do this, place a sheet of plain paper on a hard and flat surface, and press the cutters tightly until a clear imprint is obtained.

If there are teeth protruding from the general row, traces of them will be reflected on the print.

If there are higher teeth, they are carefully cut down with a flat file to the general level.

Alignment of teeth

During operation, the teeth of a hacksaw can not only deviate from the correct geometry, but also become completely deformed in height. Curvatures also need to be restored, but strictly after sharpening and setting. And again the question arises - how to sharpen a hacksaw correctly so that the result is straight teeth? During this procedure, you can only reduce the likelihood of aggravating the situation with the same file. To do this, the pressure when sharpening should be moderate and directed strictly at the edges and edges. And at the end of the hacksaw maintenance process, a separate leveling procedure follows, which is performed with pliers or a vice by firmly gripping the problem teeth.