Carbides are compounds of metals and non-metals with carbon. Typically, in such compounds, carbon has a greater electronegativity than the second element, which allows oxides, halogens, and other carbon compounds to be excluded from the group.

These are solid, refractory substances, non-volatile and insoluble. Basically, they have a variety of properties: some, for example, gold carbide, can explode if you try to pour it, and some of the compounds, for example, boron, zirconium, titanium, silicon and tungsten, are harder than diamond and are resistant to acids and solvents.

Historical reference

The first unusual carbon compound, similar to carbide, was obtained at the beginning of the 19th century by the Englishman Davy. It was potassium carbide. Then, in 1863, unstable copper carbide was found, and 15 years later, iron carbide.

Officially, the connections “appeared” only at the end of the 19th century.

- Frenchman Henri Moisson put his hand to them. He made connections using a voltaic arc in an electric furnace, which he himself invented. For this purpose, charcoal heated to a red-hot state, pure metals and their oxides were used.

However, several years before Moisson, the mineral cohenite was discovered in meteorites - a mixture of cobalt, iron and nickel carbides. In a sense, this find helped answer the question “What are carbides?”

Intermediate/metallic carbides

Tungsten Carbide End Mills.

Transition metal carbides of groups 4, 5 and 6 (except chromium) are often described as interstitial compounds.[2] These carbides have metallic properties and are fire retardant. Some exhibit a range of stoichiometries, representing a non-stoichiometric mixture of different carbides resulting from crystal defects. Some of them, e.g. Titanium carbide, TiC and tungsten carbide are important in industry and are used to coat metals in cutting tools.[3]

It has long been believed that carbon atoms fit into octahedral spaces in a close-packed metal lattice when the radius of the metal atom is greater than about 135 μm:[2]

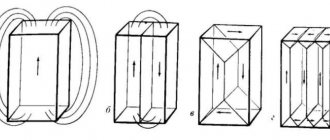

- When the metal atoms are cubic close packed, (ccp), then the filling of all octahedral voids with carbon reaches a 1:1 stoichiometry with the structure of rock salt.

- When the metal atoms are hexagonal close packed, (hcp), because the octahedral spaces lie directly opposite each other on either side of the layer of metal atoms, the carbon occupancy of only one of them achieves a 2:1 stoichiometry with the CdI2 structure.

The following table[2][3] shows the actual structures of metals and their carbides. (Please note: the body-centered cubic structure adopted by vanadium, niobium, tantalum, chromium, molybdenum and tungsten is not a close-packed lattice.) The designation "h/2" refers to the M2 Type C structure described above is only an approximate description real structures. The simple idea that a pure metal lattice "absorbs" carbon atoms can be seen as incorrect, since the lattice packing of metal atoms in carbides is different from that in pure metal, although it is technically correct that the carbon atoms fit into the octahedral voids of a close-packed metal lattice.

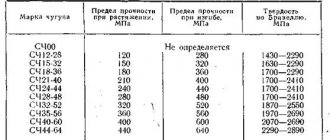

| Metal | Pure metal structure | Metal radius (pm) | MC packing of metal atoms | MC structure | M2C packing of metal atoms | M2C structure | Other carbides |

| titanium | hcp | 147 | ccp | rock salt | |||

| zirconium | hcp | 160 | ccp | rock salt | |||

| hafnium | hcp | 159 | ccp | rock salt | |||

| vanadium | hidden copy | 134 | ccp | rock salt | hcp | h/2 | V4C3 |

| niobium | hidden copy | 146 | ccp | rock salt | hcp | h/2 | Nb4C3 |

| tantalum | hidden copy | 146 | ccp | rock salt | hcp | h/2 | Ta4C3 |

| chromium | hidden copy | 128 | Cr23C6, Cr3C, Cr7C3, Cr3C2 | ||||

| molybdenum | hidden copy | 139 | hexagon | hcp | h/2 | Mon3C2 | |

| tungsten | hidden copy | 139 | hexagon | hcp | h/2 |

For a long time, nonstoichiometric phases were thought to be disordered with random filling of voids, but short- and long-range ordering was discovered.[4]

Iron forms a series of carbides, Fe3C, Fe7C3 and Fe2C. The best known is cementite, Fe3C, found in steels. These carbides are more reactive than interstitial carbides; for example, Cr, Mn, Fe, Co and Ni carbides are all hydrolyzed by dilute acids and sometimes by water to produce a mixture of hydrogen and hydrocarbons. These compounds share features with both inert inserts and the more reactive salt-like carbides.[2]

Some metals, such as lead and can, are not believed to form carbides under any circumstances.[5] However, there is a mixed titanium and tin carbide that is a two-dimensional conductor.[6]

Application

The elements are used to give cast iron and various types of steel hardness and increase their wear resistance. Tungsten and titanium carbides, as the hardest and most refractory options, are used for the manufacture of cutting tools, as well as for the production of superhard materials. Due to their good chemical and physical properties, the substances are used as a component of refractory materials, resistance rods of electric heating devices and as an abrasive material.

Calcium carbide is also called welding carbide. This is an ideal substance for welding: upon contact with water, it releases acetylene, a volatile gas that is the basis for oxygen welding, metallization, cutting and soldering.

There are many different chemical compounds known in the world: about hundreds of millions. And all of them, like people, are individual. It is impossible to find two substances that have the same chemical and physical properties with different compositions.

One of the most interesting inorganic substances existing in the world are carbides. In this article we will discuss their structure, physical and chemical properties, applications and analyze the intricacies of their production. But first, a little about the history of the discovery.

Story

Metal carbides, the formulas of which we give below, are not natural compounds. This is due to the fact that their molecules tend to disintegrate when interacting with water. Therefore, it is worth talking here about the first attempts to synthesize carbides.

Since 1849, there have been references to the synthesis of silicon carbide, but some of these attempts remain unrecognized. Large-scale production began in 1893 by the American chemist Edward Acheson using a method that was later named after him.

The history of the synthesis of calcium carbide is also not very rich in information. In 1862, the German chemist Friedrich Wöhler obtained it by heating fused zinc and calcium with coal.

Now let's move on to more interesting sections: chemical and physical properties. After all, they contain the whole essence of the use of this class of substances.

Carbon compounds

At the beginning of the 19th century, substances were divided into inorganic and organic. The second group includes hydrocarbons (methane, ethylene and acetylene series), proteins, carbohydrates, fats. Organic chemistry studies these substances.

Inorganic chemistry studies other carbon compounds: halides, cyanides, carbides, oxides. The most significant are oxygen-containing substances - CO, CO2. There is also C2O (dicarbon monoxide) and C3O2 (suboxide), but these are not yet well-studied substances.

Monoxide or carbon monoxide

Carbon monoxide 2 (another name for monoxide) - is formed during incomplete combustion of C or products containing it. Its main properties:

- It liquefies at a temperature of - 192 °C.

- Hardens at t=-205°C.

- Molecular weight - 28.01 g/mol.

- The structure of the molecule is linear (within the framework of the theory of valence bonds it can be written as “:C==O:”).

- It is practically insoluble in water.

Monoxide is a poisonous gas that is colorless and odorless. Its toxic effect is that it irreversibly interacts with hemoglobin in the blood, as a result of which the ability to transfer oxygen from the lungs to the tissues is completely lost.

In industry, monoxide is produced during the gasification process of solid fuel. In the laboratory, the compound can be synthesized by reacting concentrated sulfuric acid with oxalic acid (C2H2O4) or formic acid (HCOOH). The reaction occurs when heated:

- HCOOH → CO + H2O.

- C2H2O4 → CO + CO2 + H2O.

According to its chemical properties, divalent oxide is a good reducing agent. It burns well, releasing a large amount of heat: 2CO + O2 → 2CO2. Other characteristic features:

- The ability to “remove” oxygen from its compounds with metals: FeO + CO → Fe + CO2.

- In the presence of activated carbon, which acts as a catalyst, carbon monoxide with an oxidation state of +2 is capable of adding chlorine (Cl), thereby forming phosgene (COCL2), a chemical warfare agent. It is a colorless, highly toxic gas with the smell of rotten hay. The reaction equation for the production is: CO + Cl2 → COCl2.

- At high temperatures (above 400°C) and elevated pressure (300 atm) it reacts with hydrogen. As a result of the process, methyl alcohol (methanol) is formed: CO + 2H2 → CH3OH.

- At elevated temperatures, it reacts with alkalis, forming salts of formic acid (HCOOH): CO + NaOH → HCOONa.

- When interacting with ammonia, hydrocyanic acid is formed - a very toxic substance: CO + NH3 → HCN + H2O.

Carbon monoxide has wide practical applications. It is part of artificial gaseous fuel. In addition, it is indispensable in organic synthesis processes.

Carbon dioxide or CO2

It is a colorless gas with a weak sour odor and taste. The molar mass is 44.01 g/mol.

Note: carbon monoxide 4 is one and a half times heavier than air, so it can be “poured” from test tube to test tube.

Carbon dioxide (another name for carbon dioxide) does not support combustion. In addition, it makes breathing impossible: in a room where the concentration of the substance is high, a person will suffocate. What properties are inherent in the connection:

- Some substances that form a stronger bond with oxygen than carbon (for example, magnesium) can burn in carbon dioxide: 2Mg + CO2 → 2MgO + C.

- Combustion reaction with hot coal: CO2 + C → 2CO.

- Interaction with water: CO2 + H2O → H2CO3 (carbonic acid).

- Forms acidic oxides when interacting with basic oxides: Na2O + CO2 → Na2CO3 (sodium carbonate).

- With a lack of alkali, it forms hydrocarbonates: CO2 + NaOH → NaHCO3.

In industry, carbon dioxide is synthesized by thermal decomposition of limestone or chalk (sometimes dolomite, magnesite): CaCO3 → CaO + CO2. This substance can also be isolated from coke oven gas when burning coal, peat, oil products, and wood. In addition, it is also found in natural sources: for example, it “appears” as a result of volcanic activity, during the decay of organic substances.

In laboratory conditions, it is obtained by the interaction of CaCO3 and hydrochloric acid: CaCO3 + 2HCl → CaCL2 + CO2 + H2O (the reaction is carried out in a Kipp apparatus). Another way is to calcinate sodium bicarbonate: NaHCO3 → Na2CO3 + CO2 + H2O.

Carbon dioxide is of industrial importance: it is necessary in soda production, in the food industry (production of carbonated drinks), and for the synthesis of organic acids. Dry ice (solid dioxide) is used as a refrigerant - the carbon dioxide environment prevents food from decomposing. In addition, CO2 is also used in medicine (carbon dioxide baths to activate metabolic functions). It is also indispensable for agriculture - carbon monoxide IV is involved in photosynthesis, so its deficiency negatively affects plants.

Physical properties

Absolutely all carbides are distinguished by their hardness. For example, one of the hardest substances is tungsten carbide (9 out of 10 possible points). In addition, these substances are very refractory: the melting point of some of them reaches two thousand degrees.

Most carbides are chemically inert and react with small amounts of substances. They are not soluble in any solvents. However, dissolution can be considered interaction with water with the destruction of bonds and the formation of metal hydroxide and hydrocarbon.

We will talk about the last reaction and many other interesting chemical transformations involving carbides in the next section.

Chemical properties

Almost all carbides react with water. Some - easily and without heating (for example, and some (for example, silicon carbide) - when water vapor is heated to 1800 degrees. The reactivity depends on the nature of the bond in the compound, which we will talk about later. In reaction with different hydrocarbons are formed with water. This happens because the hydrogen contained in the water combines with the carbon found in the carbide. You can understand which hydrocarbon you will get (and you can get both a saturated and an unsaturated compound) based on the valence of the one contained in the original carbon substance. For example, if we have calcium carbide, the formula of which is CaC 2, we see that it contains a C 2 2- ion. This means that two hydrogen ions with a + charge can be attached to it. Thus, we get the compound C 2 H 2 - acetylene. In the same way, from a compound such as aluminum carbide, the formula of which is Al 4 C 3, we obtain CH 4. Why not C 3 H 12, you ask? After all, the ion has a charge of 12-. The fact is that the maximum amount hydrogen atoms is determined by the formula 2n+2, where n is the number of carbon atoms. This means that only a compound with the formula C 3 H 8 (propane) can exist, and that ion with a charge of 12- decays into three ions with a charge of 4-, which, when combined with protons, give methane molecules.

The oxidation reactions of carbides seem interesting. They can occur both when exposed to strong mixtures of oxidizing agents, and during ordinary combustion in an oxygen atmosphere. If with oxygen everything is clear: two oxides are obtained, then with other oxidizing agents it is more interesting. It all depends on the nature of the metal that is part of the carbide, as well as on the nature of the oxidizing agent. For example, silicon carbide, whose formula is SiC, when interacting with a nitric mixture, forms hexafluorosilicic acid with the release of carbon dioxide. And when carrying out the same reaction, but with only nitric acid, we also obtain carbon dioxide. Oxidizing agents also include halogens and chalcogens. Any carbide interacts with them; the reaction formula depends only on its structure.

The metal carbides, the formulas of which we have examined, are far from the only representatives of this class of compounds. We will now take a closer look at each of the industrially important compounds in this class and then talk about their applications in our lives.

Chemical classification of carbides

Carbides can generally be classified by type of chemical bond as follows: (i) salt-like (ionic), (ii) covalent compounds, (iii) interstitial compounds, and (iv) “intermediate” transition metal carbides. Examples include calcium carbide (CaC2), silicon carbide (SiC), tungsten carbide (WC; often called simply, carbide

when it comes to machine tools), and cementite (Fe3C),[2] each are used in key industrial applications. The name of ionic carbides is not systematic.

Salt/salt/ionic carbides

Salt carbides are composed of highly electropositive elements such as alkali metals, alkaline earth metals, and Group 3 metals, including scandium, yttrium, and lanthanum. Aluminum is a Group 13 carbide, but gallium, indium, and thallium are not. These materials have isolated carbon centers, often described as "C4−" in the methanides or methides; diatomic units, C2− 2″, to acetylides; and triatomic units, "C4− 3", in allides.[2] The graphite intercalation compound KC8, prepared from potassium vapor and graphite, and alkali metal derivatives C60 are not generally classified as carbides.[7]

Metanides

Methanides are a subset of carbides that have a tendency to decompose in water to form methane. Three examples: aluminum carbide Al 4C 3, magnesium carbide Mg 2C[8] and beryllium carbide Be 2C.

Transition metal carbides are not salt carbides, but their reaction with water is very slow and is usually neglected. For example, depending on surface porosity, 5–30 atomic layers of titanium carbide hydrolyze to form methane within 5 minutes at ambient conditions, followed by saturation of the reaction.[9]

Please note that methanide in this context is a commonplace historical name. According to the IUPAC naming rules, a compound such as NaCH3 would be called a "methanide", although the compound is often called methyl sodium.[10]

Acetylides/Etinides

Calcium carbide.

Some carbides are believed to be salts of the acetylide anion C22– (also called percarbide), which has a triple bond between two carbon atoms. Alkali metals, alkaline earth metals, and lanthanide metals form acetylides, such as sodium carbide Na2C2, calcium carbide CaC2, and LaC2.[2] Lanthanides also form carbides (sesquicarbides, see below) with the formula M2C3. Group 11 metals also tend to form acetylides such as copper(I) acetylide and silver acetylide. Carbides of actinide elements, which have the stoichiometry MC2 and m2C3, are also described as salt-like derivatives of C2− 2.

The CC triple bond length ranges from 119.2 pm in CaC2 (similar to ethine), to 130.3 pm in LaC2 and 134 pm in UC2. The bonding in LaC2 was described in terms of LaIII with an extra electron delocalized to an antibonding orbital on C2− 2, explaining metallic conduction.[2]

Allylides

The polyatomic ion C4− 3 is sometimes called an allylide

, is found in Li4C3 and Mg2C3. The ion is linear and is isoelectronic with CO2.[2] CC distance in mg2C3 133.2 pm.[11] Mg2C3 gives methyl acetylene, CH3CCH and propadiene, CH2CCH2, upon hydrolysis, which was the first indication that it contained C4− 3.

Covalent carbides

Silicon carbides and boron are described as "covalent carbides", although virtually all carbon compounds exhibit some covalency. Silicon carbide has two similar crystalline forms, both related to the diamond structure.[2]Boron carbide, B4C, on the other hand, has an unusual structure that includes icosahedral boron units linked by carbon atoms. In this respect, boron carbide is similar to boron-rich borides. Both silicon carbides (also known as carborundum

) and boron carbide are very hard materials and fireproof. Both materials are industrially important. Boron also forms other covalent carbides, such as B25C.

Molecular carbides

[Au6C (PPh3)6]2+ complex containing a carbon-gold core.

Metal complexes containing C are known as metal carbide complexes. The most common are octahedral clusters with a carbon center, such as [Au6C (PPh3)6]2+ and [Fe6C (CO)6]2−. Similar species are known from metal carbonyls and early metal halides. Several terminal carbides have been isolated, for example [CRuCl2{PK6CHAS11)3}2].

Metallocarbohedrins (or “metavozes”) are stable clusters with the general formula M 8C 12 where M is a transition metal (Ti, Zr, V, etc.).

What types of carbides are there?

It turns out that carbide, the formula of which is, say, CaC 2, differs significantly in structure from SiC. And the difference is primarily in the nature of the connection between atoms. In the first case, we are dealing with salt-like carbide. This class of compounds is named so because it actually behaves like a salt, that is, it is capable of dissociating into ions. This ionic bond is very weak, which makes it easy to carry out many other transformations involving interactions between ions.

Another, probably more industrially important type of carbides are covalent carbides: such as, for example, SiC or WC. They are characterized by high density and strength. They are also refractory and inert to diluted chemicals.

There are also metal-like carbides. They can rather be considered as alloys of metals with carbon. Among these we can highlight, for example, cementite (iron carbide, the formula of which varies, but on average it is something like this: Fe 3 C) or cast iron. They have a chemical activity intermediate in degree between ionic and covalent carbides.

Each of these subtypes of the class of chemical compounds we are discussing has its own practical application. We will talk about how and where each of them is used in the next section.

Related materials

In addition to carbides, there are other groups of related carbon compounds:[2]

- graphite intercalation compounds

- alkali metal fullerides

- endohedral fullerenes, where the metal atom is enclosed in a fullerene molecule

- metallacarbohedrenes (methcarbons), which are cluster compounds containing C2 units.

- tunable nanoporous carbon, where gas chlorination of metal carbides removes metal molecules to form a highly porous, nearly pure carbon material capable of high-density energy storage.

- carbene complexes of transition metals.

- two-dimensional transition metal carbides: MXenes

Practical application of carbides

As we have already discussed, covalent carbides have the widest range of practical applications. These include abrasive and cutting materials, and composite materials used in various fields (for example, as one of the materials included in body armor), and auto parts, and electronic devices, and heating elements, and nuclear energy. And this is not a complete list of applications of these super-hard carbides.

Salt-forming carbides have the narrowest application. Their reaction with water is used as a laboratory method for producing hydrocarbons. We have already discussed how this happens above.

Along with covalent carbides, metal-like carbides are widely used in industry. As we have already said, the metal-like type of compounds we are discussing are steels, cast irons and other metal compounds interspersed with carbon. As a rule, the metal found in such substances belongs to the class of d-metals. That is why it tends to form not covalent bonds, but, as it were, to be embedded in the structure of the metal.

In our opinion, the above compounds have more than enough practical applications. Now let's take a look at the process of obtaining them.

Preparation of carbides

The first two types of carbides that we considered, namely covalent and salt-like, are most often obtained in one simple way: the reaction of the element’s oxide and coke at high temperature. In this case, part of the coke, consisting of carbon, combines with an atom of the element in the oxide and forms a carbide. The other part “takes” oxygen and forms carbon monoxide. This method is very energy-intensive, as it requires maintaining a high temperature (about 1600-2500 degrees) in the reaction zone.

To obtain some types of compounds, alternative reactions are used. For example, the decomposition of a compound that ultimately produces carbide. The reaction formula depends on the specific compound, so we will not discuss it.

Before concluding our article, we will discuss several interesting carbides and talk about them in more detail.

Sodium carbide. The formula of this compound is C 2 Na 2. It can be thought of as an acetylenide (that is, the product of the replacement of hydrogen atoms in acetylene with sodium atoms) rather than a carbide. The chemical formula does not fully reflect these subtleties, so they must be looked for in the structure. This is a very active substance and upon any contact with water it very actively interacts with it to form acetylene and alkali.

Magnesium carbide. Formula: MgC 2. Interesting ways to obtain this fairly active compound. One of them involves sintering magnesium fluoride with calcium carbide at high temperature. As a result, two products are obtained: calcium fluoride and the carbide we need. The formula for this reaction is quite simple, and you can read it in specialized literature if you wish.

If you are not sure of the usefulness of the material presented in the article, then the next section is for you.

Composition and types of carbides

Carbides are not a separate substance. It is a compound of carbon with metals and non-metals. Moreover, it should be taken into account that carbon must have greater electronegativity in the resulting substance compared to other elements used. This makes it possible to avoid the production of halogens, oxides and other carbon compounds.

Today there are three types of carbide:

, the composition of which is different from each other:

- Acetylenides - upon hydrolysis they form ethylene or acetylene. Calcium carbide belongs to this type of compound.

- Methanides - when reacting with water or dilute acids, they form methane. Most often colorless. These include aluminum, magnesium, and beryllium carbide.

Carbon compounds: carbides, salts, dioxide, carbonic acid

Task 368 What compounds are called carbides and silicides? Write the equations for the reactions: a) aluminum carbide with water; b) magnesium silicide with hydrochloric (hydrochloric) acid. Are these reactions redox? Why? Solution: Carbides are compounds of carbon with metals. Silicides are compounds of silicon with metals. Reaction equations:

a) aluminum carbide with water:

Al4C3 + 12H2O = 4Al(OH)3↓ + 3CH4↑;

b) magnesium silicide with hydrochloric (hydrochloric) acid:

Mg2Si + 4HCl = MgCl2 + SiH4↑

These reactions are not redox reactions because there is no change in the oxidation states of the elements.

Task 389 How is carbon dioxide produced in industry and in the laboratory? Write the equations for the corresponding reactions and reactions that can be used to carry out the following transformations: NaHCO3 → CO2 → CaCO3 → Ca(HCO3)2 Solution: In industry, carbon dioxide is obtained by burning limestone:

CaCO3 CaO + CO2↑

In the laboratory, carbon dioxide is produced in a Kipp apparatus by the reaction:

CaCO3 + 2HCl → CaCl2 + H2O + CO2↑

Equations of the corresponding reactions and reactions with which the following transformations can be carried out:

NaHCO3 → CO2 → CaCO3 →Ca(HCO3)2:

a) 2NaHCO3 Na2CO3 + H2O + CO2↑; b) CO2 + Ca(OH)2 = CaCO3↓ + H2O; c) CaCO3 + CO2 + H2O = Ca(HCO3)2

Task 390 Which carbonic acid salts have the greatest industrial use? How to get soda from metallic sodium, hydrochloric (hydrochloric) acid, marble and water? Why does litmus turn blue in a solution of soda? Confirm your answer with the equations of the corresponding reactions. Solution: Of the salts of carbonic acid, the following salts are of great practical importance:

1.Na2CO3 – sodium carbonate or soda. Used for the production of aluminum, glass, production of detergents, etc. 2.CaCO3 - calcium carbonate or limestone. It is used in the production of lime and carbon dioxide, as a flux in metallurgy, and large quantities in the form of chalk are used in the production of building materials and for purifying substances. 3.K2CO3 – potassium carbonate or potash. Used for the production of building materials. 4.NaHCO3 – sodium bicarbonate or baking soda. Used in the food industry. 5.MgCO3 – magnesium carbonate or magnesite. Used in the production of building materials.

Getting soda. When sodium metal is dissolved in water, sodium hydroxide can be obtained, which, when reacted with hydrochloric acid, produces sodium chloride. The reaction of sodium chloride and calcium carbonate produces soda. Process reactions:

a) 2Na + 2H2O = 2NaOH + H2; b) HCl + NaOH = NaCl + H2O; c) 2NaCl + CaCO3 = Na2CO3 + CaCl2

A Na2CO3 solution turns litmus blue because soda, a salt of a strong monoacid base and a weak polybasic acid, is hydrolyzed at the CO32- anion, which binds to the H+ ion to form the acid salt anion HCO3–. H2CO is not formed because dissociation of HCO3- is more difficult than H2CO3. Hydrolysis proceeds in the first stage. Ionic-molecular hydrolysis equation:

CO32- + H2O ⇔ HCO3- + OH-

Molecular equation of the reaction:

Na2CO3 + H2O ⇔ NaHCO3 + NaOH

Since the hydrolysis of salt produces an excess of OH– ions, the solution will have an alkaline environment, pH > 7. In an alkaline environment, litmus gives a blue color.

Properties

Due to their properties, these compounds are widely used in mechanical engineering.

, as well as in construction.

- High hardness of the material. It varies for different compounds, but always remains above average. They are the hardest minerals.

- Melting temperature

. Almost always it is higher than the melting point of the metal included in the connection and can exceed 2000 degrees. - Corrosion resistance. Many compounds do not react with various acids and are quite resistant to external aggressive factors.

- Interaction with water. Almost all carbide compounds react with water; for example, when interacting with calcium carbide, it can explode. The terms of interaction may vary and depend on the nature of the connection in the connection.

Basic properties

Carbon is inert towards all common solvents. The exception is some molten metals. However, after cooling it again crystallizes into graphite.

Under normal conditions, only black carbon is more chemically active. It can combine with fluorine, and with increasing temperature - with hydrogen, silicon, sulfur, boron and some other metals. As a result of the reaction, carbides are formed:

- 4Al + 3C → Al4C3.

- Ca + 2C → CaC2.

When carbides react with water or acid, methane or acetylene is formed:

- Al4C3 + 12HCl → 4AlCl3 + 3CH4 (methane).

- CaC2 + 2H2O → C2H2 (acetylene) + Ca (OH)2 (calcium hydroxide).

A number of carbides have a composition that does not obey the “generally accepted” idea of valence. These include, for example, Fe3C.

Carbon does not combine with nitrogen, but in the presence of hydrogen it forms hydrogen cyanide (substance formula HCN). In reactions with oxygen, it forms monoxide and dioxide, which releases a large amount of heat:

- C + O2 → CO2.

- Monoxide is most often released when dioxide is passed over hot coal: CO2 + C → 2CO.

Carbon is one of the most powerful reducing agents known in chemistry. When interacting with metal oxides, it “takes away” oxygen from them, thereby restoring the substances to a free state:

- ZnO + C → Zn + CO.

- SiO2 +2C → Si + 2CO.

When excess carbon interacts with silicon dioxide (quartz, sand), in addition to pure Si, carborundum (silicon oxide) is formed - a very hard substance: SiO2 + 3C → SiC + 2CO.

“Pure” carbon does not interact with halogens. Compounds with them are formed from other substances (for example, hydrocarbons).

Carbide production

Covalent and salt-like compounds are obtained by a simple method. A mixture of crushed coke and metal oxide is placed in an electric furnace and heated. At high temperatures, the element's oxide reacts with coke. With this method, part of the coke, which consists of carbon, combines with the atoms of the element included in the oxide. As a result, the required carbide and carbon monoxide are formed. The finished molten mixture is poured

in special forms, and after hardening, they are crushed and sorted by granule size. Despite the simplicity of this method, producing carbide using it is quite energy-intensive, since it requires maintaining high temperatures (1600-2500 degrees) throughout the reaction.

There are alternative ways to obtain some types of substances. As a rule, this is the decomposition of a compound as a result of which the required element is obtained. The breakdown formula will differ depending on the specific compound.

CARBIDES

CARBIDES (from Latin carbo - coal), conn. carbon with metals, as well as boron and silicon. By type of chem. carbides are divided into ionic (salt-like), covalent and metal-like (ionic-covalent-metallic) bonds. Ionic carbides (see Table 1) form metals of groups I and II. (respectively M2S2 and MS2), rare earth elements and actinides (MS, M2S3, MS2), as well as Al. In these connections the C atom, depending on the type of hybridization (sp3, sp2 or sp), forms C4-, (C=C4-, (C=C=C)4-, (C=C)2- ions. Covalent carbides (see table. 2) form B and Si; the C atom in these compounds is in a state of sp-, sp2- and sp3-hybridization. Metal-like carbides form transition metals of groups IV-VII, Co, Ni and Fe. In these carbides the metal-carbon bond ionic-covalent, and the C atom is negatively charged, the metal-metal bond is purely metallic, the C atoms are not connected to each other. Alkali metal carbides crystallize in graphite-type lattices, metal atoms are placed between carbon layers built from hexagonal networks. Alkali carbides - earth metals crystallize in a face-centered tetragonal lattice of the CaC2 type, rare earth carbides, monocarbides of actinides and transition metals in a face-centered cubic lattice of the NaCl type, sesquicarbides of actinides M2C3 in a body-centered cubic lattice of the Pu2C3 type. Ionic alkali metal carbides decompose at a temperature of approx. 800 °C, carbides of alkali-earth metals in the range of 1800-2300 °C, covalent carbides and metal-like carbides decompose and melt at higher temperatures. In periodic system within a group, the melting temperatures of carbides increase with increasing serial number of the metal and are usually 1.5-2 times higher than the melting temperatures of the corresponding metals. This is due to the high strength of the M-C bond. Metal-like carbides have metallic properties. conductivity, they are characterized by positive. temperature coefficient r. For sesquicarbides, the value of r (reaches 500 µOhm.cm) is approximately an order of magnitude higher than for dicarbides and monocarbides (20-50 µOhm.cm). REE dicarbides also have metallic properties. Holy you. Carbides B and Si, as well as Be, Mg and Al are semiconductors. Fur. The properties of carbides depend on the chemical strength. bond, the degree of its covalence and interatomic distance. max. Carbides of B, Si, Be, as well as monocarbides of rare earth elements and transition metals have high hardness; the hardness of the latter decreases upon transition from carbides of subgroup IVa to carbides of subgroup VIa. All carbides at room temperature are brittle substances, they are plastic. deformation is possible under conditions of all-round compression at very high stresses. Ionic carbides decompose with water to form methane, acetylene, methyl acetylene or a mixture of hydrocarbons and metal hydroxide, for example:Al4C3 + 12H2O : 4Al(OH)3 + 3CH4;

Na2C2 + 2H2O : 2NaOH + C2H2;

Mg2C3 + 4H2O : 2Mg(OH)2 + C3H4.

Covalent and metal-like carbides are not decomposed by water and most minerals. compounds and alkalis. Carbides are obtained from elements by reduction of metal oxides, gas-phase method, metallothermic method. Synthesis from elements is carried out at high temperatures in a vacuum or inert atmosphere. Depending on technology process parameters, powders with particle sizes from 0.5 microns to 2 mm are formed. Synthesis can be carried out in combustion mode, since as a result of the reaction a large amount of heat is released, or in plasma at 5000-10000 K in arc, high-frequency and microwave plasma torches. As a result of rapid cooling, ultrafine powders with particle sizes of 10-100 nm are formed from the vapor-gas mixture of elements in the plasma-forming gas (Ar or He). The reduction of metal oxides produces the most. important connections — boron carbides, silicon carbides, as well as tungsten carbides, titanium carbide, etc. Transition metal carbides. The gas-phase method produces carbides from chemicals. connections, which evaporate, decompose, and then are restored and interact. with each other, for example:

2MCl + 2CCl4 + 5H2: 2MC + 10HCl.

Most often, this synthesis is carried out in plasma, producing dispersed powders. According to metallothermic method, metal oxides are reduced with metals (Mg, Al or Ca) in the presence. carbon, eg:

MO + C + Mg: MC + MgO.

Particularly pure carbides, free of oxygen and nitrogen, synthesize interaction. C and metal in the melt of another metal or alloy, for example. TiC is obtained in an alloy of Fe Ni. Of ionic carbides, most Calcium carbide CaC2, from covalent B4C and SiC, is important. Metal-like carbides strengthen cast iron and steel [Fe3C, (Fe,Cr)3C, Fe2W2C, (Fe,Cr,Mo)23C6], they are the basis of hard tungsten alloys (WC, TiC, WC, TiC, TaC, WC), etc. hard alloys (TiC, VC, Cr3C2, TaC) used for metal cutting. Carbides are also used as reducing agents, deoxidizers and catalysts; they are part of heat-resistant and heat-resistant composite materials, including cermets. === Use. literature for the article “CARBIDES” : Storms E., Refractory carbides, trans. from English, M., 1970; Goldshmidt X., Interstitial alloys, trans. from English, V. 1-2, M, 1971, Toth L., Carbides and nitrides of transition metals, trans. from English, M, 1974. Samsonov G.V., Upadhaya G.Sh., Neshpor V.S., Physical materials science of carbides, K., 1974, High-temperature carbides, ed. G.V. Samsonova, K, 1975, Carbides and alloys based on them, ed. G.V. Samsonova, K, 1976, Properties, preparation and application of refractory compounds, Handbook, ed. T. Ya. Kosolapova. M, 1986, P. S. Kisly.

“CARBIDES” page was prepared based on materials from the chemical encyclopedia.

Industrial Applications

Calcium carbide is an important compound for the production of acetylene, a gas used in oxy-fuel welding and metal working.

. When burning with oxygen, acetylene can reach 3150 degrees Celsius. This allows you to work with refractory metals that require a temperature twice as high as the melting point of the metal itself.

Boron carbide is used as a refractory material, since the melting point of such a compound is above 2400 degrees. At the same time, it is also found in body armor, as it can protect not only from bullets and shrapnel, but also from radiation. Titanium carbide is used to coat industrial and construction tools. Its strength allows you to increase the wear resistance of parts and process even the most durable materials.

Storage and transportation

Since carbide, when reacting with moisture, leads to the release of large amounts of heat and explosive acetylene gas, this substance is stored in sealed tanks or drums. Working with such tanks requires special care. Acetylene gas is lighter than air and is capable of self-ignition, while it has a narcotic effect

. When opening drums with carbide, a special tool is used to prevent the occurrence of sparks, and if the substance gets on the skin, you must immediately rinse the affected area with water and lubricate it with a rich cream.

Storage areas must be well ventilated, and keeping other substances in the vicinity is prohibited. This may lead to dangerous reactions. Improper storage can either explode the carbide or render it unusable.

The shelf life is only up to six months.

Transportation is carried out only by covered transport. Air delivery is prohibited.

Price

Calcium carbide can be purchased on the market at a price of 80 rubles per kilogram. This mixture is sold in barrels or special bags. The substance with silicon is not much more expensive. Its cost is 82 rubles per kilogram. But tungsten carbide will cost 1,400 rubles per kilo. Moreover, a minimum purchase weight can be set, for example, from 10 kg. Boron carbide will cost even more - from 2000 rubles, and packaging starts from 35 kilograms. The cost of connections with hafnium or molybdenum is negotiated with the supplier separately.

Carbide

(Carbidkohie, carbone de recuit) - is a certain chemical compound of iron with carbon, corresponding to the formula Fe 3 C 4, found in well-tempered steel. It has been known since ancient times that carbon in cast iron is in two different forms: a) in the form of graphite, released during the slow cooling of cast iron, and b) in the form of carbon chemically bound to iron. Thanks to the work of Rinman, Carsten, Caron, Ockerman and others, who studied the properties of hardened and unhardened steel, it turned out that the combined carbon in these different states of steel is in two forms. One of them, found in well-hardened steel, when treated with cold and dilute sulfuric or hydrochloric acid, almost all gives hydrocarbons or dissolves; the other, located in well-tempered steel, leaves, during such treatment, a rather significant deposit of amorphous carbon, which disappears only with prolonged boiling. The first of them is called hardening carbon

(Hartungskohle), and the second -

cementing carbon

(Cementkohle).

Caron argued that cementing carbon is free carbon, which combines with iron, i.e., turns into hardening carbon, only under the influence of rapid cooling or hammer blows. Professor Müller, exposing steel to the action of dilute sulfuric acid in an atmosphere of illuminating gas, found that the quenching carbon was converted into hydrocarbon, and the residue was a special solid substance with magnetic properties and consisting mainly of iron and carbon; in addition, from ½ to 1% water and a small amount of phosphorus. The carbon content of these residues ranged from 6.6-7.7. At the same time, the English scientists Abel and M. Dering were studying this issue and also came to similar results. In their research, they used a solution of chromic acid consisting of 90 g. sulfuric acid mixed with 100 gr. dichromopotassium salt. They came to the following conclusion: a) that in unquenched or well-tempered steel, carbon is distributed evenly throughout the entire mass in the form of a certain chemical compound with iron, carbide,

whose composition is Fe 3 C 4;

b) that in hardened steel the carbon is in an amorphous state and does not form any specific compound with iron. If you release the hardened steel, then the carbon from the amorphous state goes back into combination with iron in the form of K. When a piece of steel heated to a high temperature cools slowly, K is formed and is distributed evenly throughout the rest of the iron mass. When steel is cooled rapidly, this connection cannot form. Finally, Osmond and Werth, although in a different way, also came to the same result. By isolating a carbon compound from steel using the Weils method, i.e., decomposing a piece of steel using a galvanic current, they obtained a precipitate that consisted of small microscopic sparkles attracted by a magnet and, as analysis showed, consisted of iron, carbon and a certain amount of water. This is the same compound of carbon with iron that Abel called K., Caron - cementing carbon,

Osmond and Werth -

annealing carbon

(Glühkohle), Ledebur -

carbon of a normal carbon compound

(gewöhnliche Carbidkohle);

Sorby in his microscopic studies - pearl constituent

of iron, and Howe -

perlite

(Perlyte), and finally, Wedding -

crystalline iron

(Krystalleisen).

From their microscopic studies, Osmond and Werth came to the conclusion that carbon, distributed evenly in steel, forms a continuous mesh in the mass of metal, in the spaces of which metallic iron is placed. In their opinion, steel is formed from small multifaceted granules of soft iron surrounded by carbon iron, i.e., from individual cells, the core of which is soft iron, and the shell is K. This K. also serves as cement,

i.e. binder for adjacent cells. In hardened steel, the sparkles of carbon are found in small quantities and in a separated state, and in this case the carbon does not play the role of a shell, but is evenly distributed throughout the entire mass of the steel. As with most chemical phenomena, here too, during the formation of carbon or its transition to hardening carbon, we notice the absorption or release of heat (see Recalescence), which occurs at approximately 700°. Thus, K. represents a certain compound that is released during the slow and gradual cooling of steel (heated to a light red heat) between 700° and 600°; according to Osmond, it is distributed in the form of a network bordering the grains of soft iron, although, according to Wedding and Ledebour, on the contrary, this carbonaceous iron is distributed in the mass of steel in the form of grains.

Literature:

"Comptes Rendus" (vol. LVI, pp. 43-211); "Zeitschrift des Vereins deutscher Ingenieure" (vol. XXII, p. 385); "Stahl und Eisen" (1888, vol. VIII, p. 291); "Metallurgy of Steel"; M. Howe; "Stahl und Eisen" (1885, vol. V, p. 489; 1886, p. 379; 1887, p. 448; 1888, p. 369); "Mining Journal" (1886, vol. III, p. 138; 1886, no. 9; 1888, no. 2 and 1889, no. 1); Osmond, “Transformation du Fer et du Carbonne dans les fers”; Osmond et Werth, "La théorie cellulaire des proprietés de l'acier" (in Ann. des Mines, 1885, vol. 8, p. 5); F. Abel, "Carbon in Steel" (in "Engineering", 1886, vol. XXXIV, p. 150).

A. Rzheshotarsky.

Δ

.

Encyclopedic Dictionary F.A.

Brockhaus and I.A. Efron. - St. Petersburg: Brockhaus-Efron. 1890-1907. Synonyms

:

See what “Carbide” is in other dictionaries:

- A foul substance with an extremely strong suffocating odor; a compound of iron and carbon. A complete dictionary of foreign words that have come into use in the Russian language. Popov M., 1907. carbide carbide, m [lat. carbo charcoal + gr. species] (chemical). Connections ... Dictionary of foreign words of the Russian language

carbide

- a, m. carbide m. <lat. carbo + gr. eidos type special A combination of metal and carbon. Iron carbide. Calcium carbide. BAS 1. Carbide aya, oh. ♦ Carbide lamp. A lamp in which acetylene burns is obtained by the action of water on calcium carbide. BAS 1.… …Historical Dictionary of Gallicisms of the Russian Language

Depending on the context means: Calcium carbide, a compound used to produce acetylene Carbide, as a compound of metal with carbon, see Carbides ... Wikipedia

Cementite Dictionary of Russian synonyms. carbide noun, number of synonyms: 1 cementite (1) ASIS Dictionary of Synonyms. V.N. Trishin. 2013 ... Dictionary of synonyms

CARBIDE, carbide, many. no, husband (from Latin carbo coal) (chemical). Connection of elements, preferably metal with carbon. Ushakov's explanatory dictionary. D.N. Ushakov. 1935 1940 ... Ushakov's Explanatory Dictionary

CARBIDE, huh, husband. A chemical combination of carbon with metals and certain non-metals. | adj. carbide, oh, oh. Ozhegov's explanatory dictionary. S.I. Ozhegov, N.Yu. Shvedova. 1949 1992 ... Ozhegov's Explanatory Dictionary

- (Carbidkohle, carbone de recuit) is a certain chemical compound of iron with carbon, corresponding to the formula Fe3C4, found in well-tempered steel. It has been known since ancient times that carbon in cast iron is found in two... ... Encyclopedia of Brockhaus and Efron

Carbide

- - a combination of metals and some non-metals with carbon. Used in technology... Oil and gas microencyclopedia

carbide

— A chemical compound of carbon with one or more metallic elements. Subjects metallurgy in general EN carbide ... Technical Translator's Guide

carbide

— [کربيد] yu. moddai khimiyavi iborat az omezishi filiz bo carbon; charogi carbide charoge, ki bo carbide mesuzad... Farhangi tafsiriya zaboni togiki

Carbide Carbide. A chemical compound of carbon with one or more metal elements. (Source: “Metals and alloys. Directory.” Edited by Yu.P. Solntsev; NPO Professional, NPO Mir and Family; St. Petersburg, 2003) ... Dictionary of metallurgical terms

Being in nature

In nature, carbon is found both in pure form and in the form of compounds. In the free crystalline state it is found in the form of two allotropic modifications:

- Diamond is an extremely hard substance that is a poor conductor of heat and electricity. In appearance, they are colorless crystals that strongly refract light. If they are cut accordingly, they will be diamonds; their weight is measured in carats: 1 carat = 0.205 g. The largest stones are given names: for example, Cullinan (more than 3 thousand carats), Star of Yakutia (232 carats), and others. Dull diamonds (bort) are used in industry. When heated without access to air, diamond turns into graphite. Currently, artificial diamonds are created from graphite (long-term heating at t=3000°C and a pressure of 70-100 thousand atmospheres). Synthetic products are widely used in technology.

- Graphite - forms powerful deposits. In appearance it is a gray-black mass that is greasy to the touch. It has a layered structure. Conducts heat and electricity well, refractory. Used in industry in the production of electrodes and pencil leads.

There is another modification - amorphous carbon. It is a porous black substance. Its “known representatives” are coke, soot, charcoal and bone charcoal. It is not found in its pure form and always contains impurities.

In a bound state, carbon is found in carbonates (calcite, limestone, chalk, marble, iron spar FeCO3, manganese spar MnCO3, zinc spar ZnCO3, magnesite, dolomite, malachite, and others). In addition, carbon is the main component of coal and other coals, oil, combustible natural gases, and all living organisms.