Device and main components

A hand scythe consists of: a knife, a scythe, a handle, a wedge and a ring.

Did you know? The knife can make a sound reminiscent of a bell.

The blade is a long blade curved towards the bottom. Made of tool steel (U8, U7). There is a classification depending on the length of the knife: 50 cm - 5, 60 cm - 6 cm and up to 9. The most common is No. 5. Consists of: blade, butt, tip, spout, heel and beard. You can distinguish a high-quality blade from a scythe by the following characteristics:

- no damage or irregularities;

- equal blade thickness;

- deep sound upon impact;

- good elasticity.

Knives also have another name - Lithuanian or canvas.

Often gardeners and gardeners have to struggle with. There is a lot for mechanical removal of enemies of cultivated plants. Among them - . A flat cutter can be used to cut and pull out. Note that it is quite possible to make this manual cultivator yourself.

The braid, or scythe, handle, is the long wooden base of a hand-held scythe. Length - 1.7 or 2 m. Must be without damage, elastic, even. A good material is a spruce trunk at a height of 2 m. For production: remove unnecessary elements (knots, bark), give the desired shape, dry in a vertical position, sand, or soak in a wax solution.

For more convenient mowing, there is a handle or bow. For fastening: cut a square into the braid, hammer in the spike of the handle, wedge it, you can strengthen it with self-tapping screws or self-tapping screws. There are fixed and adjustable. The first ones are stable and reliable, the second ones are more convenient if used by many people.

A wedge is a wooden device for attaching a blade to a braid. Made from dry wood. It is important that the fastening is reliable, because integrity and safety depend on it.

The rings are the second element for attaching the knife to the handle in the form of a bolt fastening. Used together with a wedge. There are narrow and wide, with and without a key. Rings with adjustable bolts are called “clamps.”

Twine is a special type of strong thread. Required for adjustable handle. When bending, it or wire is used to tie the two ends of a beam made of a flexible type of wood and secure it using notches cut into them.

How to work with it?

There are several ways to prepare a hand scythe for work: sharpening, beating and finishing a loose surface; let’s look at each of them in more detail.

To know how to cut a braid at home, let's figure out what cutting is. Beating is a processing process, cutting off the blade with a special hammer with a sharp end to thin the knife along its entire length and create cutting serrations. Before beating, you need to leave the blade in the water to darken it, so that you can clearly see the cut-off zone. The beating is carried out at the heels of the canvas towards the nose.

New ones are usually already cut off at the place of production, but the braid can be cut off.

For convenience, use a special chair with legs of different heights. Near the high leg there is a headstock. The device for riveting braids is called a headstock - a narrow, small anvil. You can make it at home from a file or material with a hardness of 57 HRC. You can use a bias cutter - an improved headstock that is easier to use. The blows should not be strong, along the entire line of the knife.

The blade is fine-tuned using a sharpening block and musat - a special metal rod for leveling the knife. Only the part of the blade that is lighter needs to be sharpened.

Sharpening

Sharpening is done before beating. To do this, use a fine-grained abrasive wheel. Basic rules on how to sharpen a scythe: cool the blade with water, rotate the wheel slowly. Sharpening starts from the bottom side at 1.5-2 cm.

The sickle is one of the oldest agricultural tools. It is a kind of knife with a reverse bend; it has been used since ancient times for harvesting cereals and preparing feed for livestock. The antiquity of the tool is also confirmed by indirect data, for example, a comparison of the shape of the moon in some phases with the shape of this tool.

The technique of working with a sickle has been perfected over a long period of time. Harvesting with a sickle is described in many literary works and immortalized in the works of artists illustrating this process.

The features of the technique are determined by the presence or absence of teeth on the sickle blade. A smooth blade cuts the grass, while a serrated blade cuts it. In the second case, the capabilities of the tool are much wider. A smooth herbal sickle is suitable for harvesting succulent herbs. It is not suitable for dry or woody vegetation.

The process of working with the tool can be divided into three stages.

READ MORE: Growing mallow from seeds 16 photos when to plant What the seeds look like and how to collect them for seedlings

- Separating part of plant stems using the pointed end of a blade.

- Grasp the separated stems with your left hand at approximately the mid-length level.

- Cutting off stems caught in a bunch. The movement should be smooth, without sudden jerks; this will not speed up the work at all, it will only require excessive energy from the mower.

Cut grass or other plants do not fly away, as when working with a trimmer, but remain in the hand and can be placed as required. A serious disadvantage of working with a sickle is the worker’s constantly bent back; this factor once became an important motivation for the creation of the pink salmon scythe - a kind of sickle on a long handle, and then the litovka scythe, with which there was no need to bend over at all.

The sickle is a rather dangerous tool. In inept hands, it is capable of inflicting a serious puncture or cut wound, primarily on the mower himself. Since ancient times, in many countries, the sickle, along with a flail or an ax, was a weapon of the peasant militia. To avoid injury, it is recommended to mow only when the body is in a comfortable position, when the blade is visible and its position is known.

- The serrated blade of the sickle does not need sharpening; over time it becomes thinner and becomes even sharper with some reduction in weight.

- A flat blade requires more maintenance. Before starting work, it should be properly sharpened. In some cases, the sickle blade is beaten like a scythe blade. To do this, you need an anvil and a special hammer.

How to sharpen a sickle if it had sharpening in the form of teeth?

The fact is that the very teeth that cut grass so well when mowing when new are designed for a certain amount of work, that is, over time they will of course become dull, but do not rush to sharpen them with sandpaper.

The fact is that the notch is made in such a way that when the sickle becomes dull, it is simply riveted by lightly tapping the edge of the blade.

The tips of the teeth become sharp, and the spaces between them diverge and the teeth again acquire their original appearance. This operation can be repeated, of course, a limited number of times, since after all, a sickle is not even a scythe designed for large-scale work, and the pulling (unfastening) itself requires caution and skill.

Therefore, place the sickle with its flat side on a sledgehammer or anvil and, using a small hammer, lightly tap along the edge of the blade, trying to keep the striking plane of the hammer as even (horizontal) as possible.

If you can’t do this, ask someone who knows how, but if, as a result of several such procedures, the teeth are already inconspicuous, then, in principle, you can simply sharpen the sickle with a one-sided sharpening on an emery wheel, but the cut and sensations will of course not be the same.

www.remotvet.ru

Braids - pink salmon

The scythe, unlike the sickle, has an almost straight blade, slightly curved inward, and a much longer handle connected to it at a right angle. Pink salmon scythes (“gorbushki”) were used for mowing grass and harvesting grain crops, if they were not removed with a sickle. Pink salmon is the most ancient and primitive species of spit.

Its blade was slightly curved, and the relatively short (compared to the scythe-stand) handle had a rounded natural curve. The base of the scythe (heel) ended at the top with a sharp wedge driven into the end of the wooden handle - the braid. The handle in this place was wrapped with a strip of iron or bast.

At the end of the 19th and beginning of the 20th century, pink salmon braids, both factory-made and handicraft, were common. 12 braids from the Kizhi collection have marks. In particular, three copies from Zaonezhye bear the mark “Trepalin” - apparently the name of a local blacksmith.

Pink salmon were mowed in a bent position on either side. This is the main difference between the method of its use and a stand-up scythe with a long handle. The pink salmon scythe was used for cutting grass in forest or uneven (hummy, hilly) areas. Thanks to its small swing to the right and left, it was possible to mow the grass quite cleanly around every stump or tree, as well as on a hummock. That is why in the 19th century, pink salmon were mainly used in forest areas in the North of Russia, as well as in the northern provinces of the Urals and Siberia.

The collection of pink salmon braids in the collections of the Kizhi Museum includes 81 items. All of them date from the late 19th - early 20th centuries. It most fully presents samples from the villages of the Medvezhyegorsk region and the Onega region. Pink salmon from other regions of Karelia are represented by single specimens. The statistical characteristics of this collection are given in the table (see Appendix 2).

Pink salmon from the Medvezhyegorsk region (Zaonezhye) have short handles with a strong bend. The knives are narrow and long, but there are several scythes with wide and short blades. Only one braid has a handle wrapped in bast; the rest use other types of winding (see table). Pink salmon from the Onega region are somewhat different in appearance.

Classification

Such a long period of development of the instrument could not but affect its appearance and structure. Modern sickles can be classified according to a number of characteristics.

By type of handle

According to the sales results, sickles with a handle 11 cm long and 3 cm in diameter are absolutely in the lead. Handles are available in wood or plastic. A wooden handle is preferable: it does not slip or turn in the hand, is not “afraid” of sunlight and does not break when the tool is dropped. A handle that has dried out over time can be fixed by soaking the tool in water.

By shape

The length of the cutting edge of sickles varies from 25 cm to 50 cm. Accordingly, the width also changes - from 4 to 6 cm. The most commonly used are medium-sized tools - up to 35 cm in length and about 200 g in weight.

Based on the shape of the blade, all modern sickles are divided into three groups.

- The herbal sickle, designed for harvesting grass, has a smooth, serrated semicircular blade 4 cm wide.

- The classic sickle with a tapered end and a serrated blade was intended for harvesting grain crops. This form remains the most popular to this day.

- The reinforced sickle has a classic shape, but is distinguished by greater thickness and overall mass. This is a universal tool, the range of uses of which extends from harvesting to cutting off bushes.

READ MORE: Mobile split systems, features of portable air conditioners How to choose a model with a remote unit for your home

According to blade material

Steel is used to make modern garden tools, but its quality varies. For irregular and small-scale work, ordinary steel will do just fine. But tools that will have to do hard work should be made of more expensive hardened steel. For a multi-day harvest, such a high-quality sickle would probably be important, but there is practically no such work on modern summer cottages.

According to blade material

How to sharpen a hoe?

A hoe is an indispensable tool for creating irrigation furrows. This tool is also used when hilling plants, since thanks to the long handle it is possible to loosen the most remote areas.

A summer resident's kit always consists of several types of gardening tools, for example, a hoe and its hybrid (hoe, ripper), both factory-made and assembled with your own hands.

But it is also worth noting that with frequent use of this tool, it can become dull. But you can still get out of this situation; to do this, you need to sharpen the hoe. And we will look at how to do this in this article.

How to sharpen a hoe with a grinder?

Currently, a grinding machine is the easiest and fastest way to sharpen the working surface of garden tools. To do this, take a regular grinder and a thick grinding disc.

You cannot use thin discs, as if touched at an acute angle they will quickly grind and fly apart.

To sharpen a hoe with a grinding machine, you still need to fix it. For these purposes, you can use a vice in which we clamp the holder so that the blade “looks” up. Next, set the grinder handle up (in case it is replaceable) and switch to high speed. It is necessary to sharpen the hoe by gradually moving the disk from one end of the blade to the other, while also making sure that the metal does not overheat.

It is advisable to carry out this work in 2-3 approaches. But in cases where you need to do this quickly, you need to constantly cool the metal by immersing it in water or pouring it from a bottle every 2-3 minutes.

We sharpen from the end of the blade to the base. In this case, when working in the garden bed, friction will be significantly reduced. But when sharpening, you should also not overdo it. Of course, if the metal is too thin, the process of eradicating weeds will be significantly simplified, but the hoe blade will become dull in a couple of hours. Therefore, the whole process will have to start over again. The ideal sharpening angle is 25 degrees with a blade thickness of 3-4 mm.

When processing one-sidedly, in order to achieve the required sharpness, a lot of metal will have to be removed. But if the metal layer is removed from both sides, then the desired angle can be achieved much faster.

How to sharpen a hoe with an electric sharpener?

Today, an electric sharpener is often used to sharpen garden tools. But it is worth noting the fact that compared to the first option, in this case you will have to spend more effort and time. But you will definitely be satisfied with the result.

How is an electric sharpener superior to a grinder?

- The metal does not heat up so much, and therefore the material retains its physical and mechanical properties. Therefore, it will remain as strong as before treatment.

- The process is much slower, which makes it possible to control the thickness and direction of the impact angle of the sandpaper.

- It's much safer to work. There is no risk of the wheel breaking, and there are no metal chips.

To properly sharpen a hoe, the tool must be placed in such a way that the blade touches the sharpener at an angle of 35 - 40 degrees, no more and no less. If the tool is too sharp, it will quickly become unusable, especially on dry and dense soil. A large angle will allow you to work for a long time, but to knock down thick-stemmed weeds you will have to put in a lot more effort.

It is more convenient to sharpen from the center to the corners: first we touch the middle of the blade and smoothly move the tool to the side until the circle slides off the corner. This way you will be able to treat even hard-to-reach areas of the work surface. Of course, there will also be “blind spots”, places in the middle where there will be more or less removed metal. This means that after 5-6 transactions, separately, we process only the middle again.

You can determine the quality of sharpening both visually and by touch. The blade at the end should not be sharper than that of a small axe. If you overdo it with sharpening, then you don’t have to worry too much, since after a few days of work it will become dull again. The only thing is that you will have to do the whole process again. As a rule, the sharpener is sharpened on one side, since a chopper sharpened in this way will last much longer.

How to sharpen a hoe with whetstones?

Before the advent of power tools, garden tools were processed with ordinary emery stones. That is, saws, scythes, axes, and knives could be sharpened with ordinary whetstones. But in this case, as it was used, the metal wore out quite quickly, and therefore it was necessary to “renew” it.

It is also worth noting that at present this method, although not as often as before, is still used for sharpening tools. But at the same time, some people use fine-grained small stones for this work, and therefore cannot achieve the desired result.

In this case, it is recommended to use both coarse-grained and fine-grained sediment. We carry out “rough” processing with coarse-grained ones, and then bring the blade to the desired condition with fine-grained ones.

If possible, choose a large-grained whetstone - long and massive. In this case, it will be possible to erase the required amount of metal much faster. We sharpen from the base to the end of the blade, but with the help of a fine-grained whetstone we adjust the sharpness from the end of the blade to the base. In this case, when driving the tool into the soil, friction will be minimal.

The main advantage of the whetstone is its portability, that is, you can take it with you to the garden and, if necessary, work on the quality of the tool while working.

chudoogorod.ru

Scythe - stand (Lithuanian)

The main difference between the Lithuanian and the pink salmon is the long handle, which allowed the mower to make a significant sweep and cut the grass in a wide strip. They used them to mow grass and some grain crops. The Lithuanian knife was slightly curved. Approximately in the middle of the handle there was a device - a finger or a round handle for resting the right hand (the left hand of the mower held the upper end of the handle). Similar scythes, first made by a blacksmith and then made by a factory, were widespread throughout Russia.

The scythes were made of either cast or crucible steel. In the first case, a sharpening stone was sufficient for sharpening, but in the second, the scythe must first be beaten with a special hammer. Success in work depended on the quality of the scythe. Very hard and too soft braids are not suitable for work, despite the correct point: hard ones easily chip and are difficult to sharpen, while soft ones do not hold points and are easily and quickly worked.

In Russia in the 19th century, scythes with special devices were used: a hook, rakes, and a blade. The scythe with a hook (rake, feather) looked like a rake with long teeth (2-5 teeth) on a block, which was attached together with the scythe to the base of the handle. When mowing grain, the cut ears were collected in even bunches in the recess between the hook and the handle and thrown to the ground in the same order.

In the North of Russia, scythes with linen were used to harvest grain. Samples of such braids, in the amount of 6 pieces, are presented in the collection of the Kizhi Museum. A rounded curved rod was covered with linen (cloth), which was attached to the base of the braid. In some cases, the teeth of the rakes were covered with cloth and secured there.

The collection of the Kizhi Museum includes 11 Lithuanian brass women from the Medvezhyegorsk, Olonetsky and Kalevalsky regions. They date from the late 19th to mid-20th centuries. The small number of items is obviously explained by the fact that in the regions of Karelia until the beginning of the 20th century, pink salmon scythes were mainly used, and stand-up scythes that appeared at that time were widely used in peasant farms in subsequent decades, right up to the present day. The museum's collections contain only scythe blades, and only two objects have a handle. One scythe has a factory mark on the blade.

Thus, we examined the collection of harvesting and mowing tools in the collections of the Kizhi Museum, represented by three types of objects - sickles, pink salmon scythes and stand-up scythes. In general, the collection allows us to get a fairly complete picture of the composition and species diversity of traditional tools, which in the late 19th and early 20th centuries were used by peasants of Karelia in agricultural work related to harvesting grain crops and mowing grass.

Annex 1

Statistical table of the pink salmon collection

Appendix 2

Footnotes to the article

Karelians of the Karelian Autonomous Soviet Socialist Republic. Petrozavodsk, 1983.

Complete encyclopedia of Russian agriculture. T.8. St. Petersburg, 1903. P. 1027.

Ibid., p.1026.

What does a sickle consist of?

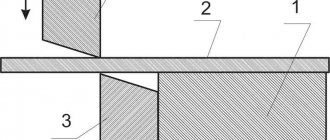

This tool consists of a curved knife with a handle (Fig. 1), but the shape of the cutting part is determined by the need to ensure equal force at any point on the blade that occurs during cutting.

Sickle: 1 - sickle knife; 2 - handle

In turn, the constancy of forces at any point of the cutting edge is ensured by the constancy of the angle, and at any point of the knife blade (angle a - the angle between a straight line drawn from point O, located on the axis of symmetry of the handle, to any point of the knife blade, and the tangent at this point to the curve of the blade).

Long-term practice of using sickles has shown that the angle a=51° is optimal. A notch 0.4 mm deep is made on the cutting edge of the blade (Fig. 2), as a result of which the knife blade consists of teeth. The notch is made either perpendicular to the edge of the blade (type 1), or at an acute angle to it (type 2).

. Varieties of the cutting edge of the sickle: 1 - blade of the knife; 2 - chamfer; 3 - teeth

The most common are sickles with type 2 notches.

How to use a sickle?

When reaping, the reaper holds a sickle in his right hand, uses it to separate part of the stems from the main mass, squeezes this part of the stems with his left hand and cuts them off with a quick movement of the sickle. At the same time, to compress one bunch of stems, the reaper makes three swings with a sickle.

He separates the compressed stems from the standing ones by raising his left hand up and places the stems on the prepared sheaf. Cutting occurs with sliding. In this case, the sliding of the sickle relative to the stems is greater, the smaller the height of the teeth on the blade of the blade. Therefore, the effort required to cut a bundle of straw is less.

The cutting process with a sickle is similar to the sawing process. The shallower the depth of the notch, the easier it is to work with the sickle. If the cut is too deep, the cutting force increases, and the reaper, as they said, jerks his hand. But the service life of a sickle with deeper notches from one serration process to another is much longer, since as the cutting edge wears out, the sharpness of the blade (with teeth on it) can be restored by sharpening the blade from the smooth, non-serrated side of the blade using a sharpener (with water ).

Design features

The sickle is popular due to the simplicity of its design and the operating technique used.

Depending on the experience gained, in one hour of operation the device can “mow” vegetation over an area of 100-150 sq.m. The peculiarity of the structure allows you to first collect (rake) a small bunch of grass that fits in the palm of your hand, and then cut it off with one movement of the hand. Thus, the grass does not scatter across the surface of the earth, but remains with the reaper. This is convenient when preparing, for example, hay or bedding for animals and poultry.

READ MORE: Dressing room dimensions 47 photos optimal for a narrow room and a large wardrobe system standard shelf sizes

Depending on the crops being cut, age, physical development and skills, the tool in different parts of the world had a different structural structure, blade shape with sharp sharpening or serrations.

You can work with the tool in a half-bent or squatting position. The user chooses which pose to take. Bending down speeds up the speed of harvesting plants; squatting requires less effort. The choice of sickle model depends on the buyer's preferences.

When purchasing, pay attention to ergonomics and convenience specifically for the buyer. As they say, the instrument should “fit into your hand.” It is this factor, as well as skills, that underlie safety precautions when working, in which you can inflict lacerations on your hand or forearm.

Important details and characteristics to pay attention to are:

- weight;

- blade bending geometry and length;

- length and thickness of the handle;

- shape and pitch of teeth.

For the average user, sickles with a mass of about 200 g and a total length of 33-35 cm will be preferable. A handle with a length of 11 and a diameter of 3 cm is considered the most convenient. Choose a sickle with a tooth pitch of 2 mm and an inclination of 60 degrees.

Such parameters allow you to perform most of the functions assigned to it.

Sharp blades are used for cutting single plants. Serrated sickles easily handle tufts of grass or grains, cutting them off like a saw.

The classification of agricultural implements is carried out according to several criteria.

By type of handle

There are two types of products on sale with a wooden or plastic handle. Classic models have a wooden handle. It does not slip in the hand when working in rainy weather, will not crack when a sickle falls, and is not subject to destruction under the influence of sunlight.

Plastic handles have an attractive appearance, but the choice must be made carefully. Smooth handles glide into brushes. Great efforts will have to be made so that the sickle does not rotate around its axis under load, and if it falls out, it does not cause a puncture injury to the feet. Under the influence of the sun or frost, low-quality material begins to deteriorate - the blade remains without a handle, while wooden handles are resistant to such impacts.

Cheap models are made from ordinary steel. A tool that has undergone heat treatment is more reliable and durable. At the same time, it makes sense to overpay for quality if you plan to give the tool a regular heavy load.

By shape

There are three main varieties:

- The herbalist is equipped with a semicircular smooth blade 40 mm wide and is designed for cutting grass in small areas.

- A sickle with an elongated tapering end (classic version) is designed for harvesting cereal crops. The narrow edge of the blade carefully separates the ears being cut from those that will be removed in the next movement. This reduces the likelihood of ripened grains falling off.

- The reinforced model with a wide semicircular blade is universal and is used for most technological operations - harvesting, foraging, removing weeds, including dry ones.

How to easily sharpen a saw

A simple and accessible way for everyone to sharpen a saw or hacksaw for wood with your own hands. There is no need to explain how important a good tool is for a true master. And in order for the saw to be constantly in use, the master must not only be able to use it, but also be able to sharpen it if it suddenly becomes dull. In some cases, the saw is supplied by the manufacturer without any sharpening at all:

Sharpening the saw with a file

To sharpen the saw you will need a triangular file. We clamp the hacksaw blade in a vice and at an angle of approximately 45 degrees, we begin sharpening each tooth one by one. First, we sharpen through one on one side, then we turn the blade over and sharpen the teeth on the other side. This is the most common and accessible way to sharpen saw teeth. If you do not have such wealth as a vice, then you can easily hold the saw in your hand. All Perform sharpening operations in mittens or protective gloves. The work is painstaking and requires skill. But you will get the hang of it very quickly and will not even notice how you will be finishing the last tooth of the saw. Now the saw is sharpened: This can be clearly seen with the naked eye. We check the sharpness in an accessible way - by sawing off the board. It cuts well, the saw cut is even. You can also use needle files for sharpening. I repeat, the work is very painstaking, it requires perseverance. I recommend getting rid of all distracting sources so that nothing distracts you from your work. Of course, when using a power tool, the effort and time required can be significantly reduced, but as already mentioned, this is the simplest and most affordable way to sharpen a hacksaw blade.

Watch the video

If for some reason you don’t understand what and how to do, watch the video, which describes in more detail and detail what and how to do.

sdelaysam-svoimirukami.ru