- 1 Purpose

- 2 Varieties 2.1 HIT-RE 500

- 2.2 HFX

- 2.3 HIT-ICE

Hilti chemical anchors are fastening elements for all structures in construction; they are dowels. Today, their use is popular for many consumers, because they are quite effective fasteners. But until recently, anchors were considered a luxury and an easily replaceable exotic item.

Scope of application of chemical anchor

Chemical anchors for concrete are used when connecting critical structural elements at all stages of construction, building construction, laying subway lines, fastening mine arches in the mining industry and in everyday life during the construction of houses, cottages with porous concrete, fastening doors, windows, and furniture to walls.

- When constructing foundations of buildings and structures at high humidity and low temperatures,

- Construction of high-rise buildings, skyscrapers, exhibition centers, production workshops,

- Connecting bridge spans, arches, beams, trusses,

- Fastening metal parts to concrete bases,

- An auxiliary element for tying reinforcement under the foundation,

- When laying subway tunnels, strengthening mines in the mining industry,

- Installation and installation of high-voltage power lines, especially in areas of rivers, lakes, swamps, permafrost areas,

- Repair and construction of roads, highways, runways, construction of ports, shipyards, underground bunkers,

- Entertainment industry, installation of prefabricated foundations, industrial buildings, shopping centers, water parks, ski lifts,

Installation of equipment, machines, transformers, conveyors, loading equipment,

The use of chemical anchors is advisable in the construction of any facility, from the infrastructure of pipelines, stations and ending with the arrangement of plots, cottages, houses and living rooms.

Advantages of the Hilti HIT-RE-100 adhesive anchor

When using HIT-RE-100 adhesive for anchors in concrete, consumers can count on the following advantages of this product:

- Possibility of use indoors and outdoors with the base material, regardless of its current state (dried, moistened, filled with moisture, etc.).

- Large selection of additional accessories (metal brushes, electric dispenser, injection pistons).

- High level of efficiency for use in solid concrete foundations without cracks.

- Long curing period, due to which you can make the necessary adjustments during installation.

- Easy to clean, making installation much easier.

The cost of adhesive for anchors in concrete Hilti HIT-RE-100 starts from 1,500 rubles for a 330 ml container.

Fastener design

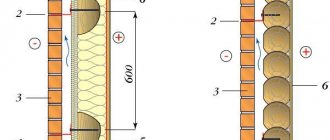

There are two types of anchorage depending on the location and method of applying the adhesive:

- The himanker is attached using an injection glue gun, which is loaded with two capsules of resin and hardener. Using piston pressure, their contents are squeezed out of the containers and mixed into a homogeneous mass in the nozzle of the gun using a spiral. The adhesive composition is fed into a drilled hole with an anchor rod fixed in it. The solution fills the entire volume of voids around the fasteners, including voids in brick or foam block.

- The glass capsule contains the active component of glue and hardener, separated by a partition. The mounting hole is drilled along the diameter of the capsule. The container is inserted into the prepared recess and a pin is inserted using a drill or hammer, which breaks the wall of the capsule. The adhesive and hardener are mixed to firmly secure the stud into the wall. Glass shards additionally reinforce the fastening.

Important! The capsule anchor is not used for vertical fastening in ceilings. The glue may leak and the connection will not form.

A chemical anchor consists of several parts that form a connection:

- Adhesive based on phenol-formaldehyde, polyurethane or polystyrene resin,

- The hardener accelerates the drying process of the adhesive composition,

- Fillers increase the strength and reliability of the connection, usually quartz sand or cement is used,

- A metal rod in the form of a bolt, pin, nail or piece of reinforcement.

Himanker for aerated concrete

The porosity of aerated concrete blocks used for the construction of building walls ranges from 40 to 85%. This material is not suitable for attaching heavy hanging structures, furniture elements, suspended ceilings, cabinets to it using nails, dowels or expansion anchors. It uses a chemical anchor for aerated concrete.

Types of fastening depending on the adhesive composition:

- In addition to strong, reliable fixation, epoxy-acrylic adhesive is fire-resistant, frost-resistant, and has a hardening time of 15 to 180 minutes.

- Polyester or polyester reagent is used at room temperature, curing time is from 25 minutes.

- Based on vinylester resin. The reagent is safe for metal, does not cause corrosion, is used in conditions of high humidity, hardening time is up to 24 hours.

- Epoxy adhesive is used when working with all types of concrete. Used for interior and exterior work, moisture-resistant, non-corrosive, used when using smooth fittings and studs without threads.

Adhesive anchor Hilti HIT-RE-100

This type of Hilti glue for anchors is made on the basis of epoxy resin and hardener, and is two-component (the components are mixed during installation).

Using these products, the following construction and installation work is performed:

- installation of additional metal structural parts;

- installation of load-bearing metal structures (beam, column and other types);

- replacing incorrectly installed reinforcing bars or installing missing reinforcement;

- installation and connection of concrete reinforcement bars.

The Hilti anchor HIT-RE-100 has a wide operating temperature range: from -40 to +70° C. These products can be stored and transported at temperatures from +5 to +25° C. Tools for its installation are: HDM, HDE 500-A22.

Liquid nail for hollow bricks

A chemical anchor for hollow bricks reliably fixes the stud in the hole, filling all nearby voids with adhesive. A strong connection is obtained due to the large area of adhesive, which seeps through the pores, cracks and voids in the base of the material.

For these purposes, injection formulations are used, which are loaded into an injection gun. Use the cartridges until they run out of substance. Tubes have a volume of up to 400 ml. Polyurethane, acrylic, phenol-formaldehyde and other types of glue are used as fillers.

Varieties

On the building materials market, Hilti dowels are presented in two samples; these are compositions that obtain the characteristics described above only after injection and ampoules. And also such types of anchors as: HILTI HVU, HILTI HIT-HY, HILTI HIT-MM PLUS, HILTI HFX, HILTI HIT-RE 500, HILTI HIT-ICE.

Return to contents

HIT-RE 500

This type of chemical dowels has all the advantages of a conventional anchor. It differs from the others in its scope of application. It is used in holes with moisture, in water-saturated concrete, when gluing outlets of working reinforcement, fastening load-bearing and auxiliary structures, and reconstructing bridges. If you choose this type of dowel, it will be easy to control due to its color, it does not emit an unpleasant odor and is easy to use.

Return to contents

HFX

This anchor is well suited for renovating living spaces, installing mounts for household appliances, various shelves, and plumbing fixtures. It is easy to use and hardens quickly. You also don’t need to buy a special dispenser, and you can take a break from work when the capsule is opened.

Return to contents

HIT-ICE

The main advantage of this chemical dowel for concrete is the ability to install even at minus twenty-three degrees Celsius. Simple and quick dosing is possible even at sub-zero temperatures. And also you will not lose time, because you will be able to work in the winter.

Return to contents

Technology of use

Do-it-yourself installation of chemical anchors does not require special equipment or training. It is easy to do it yourself if you have a tool that every owner has.

Mark the intended location for fastening. Using a hammer drill with a diamond tip drill, drill holes that should be 2 mm larger than the diameter of the anchor pin or bolt.

Carefully remove dust from the middle.

- Insert an ampoule of glue into the hole, tighten the bolt or pin with an electric drill or hammer it in.

- If a cartridge is used, squeeze out the adhesive until the hole is completely filled, and insert the pin.

- Wait until the components specified in the attached instructions are completely dry and proceed with further installation.

Each type of anchorage is supplied with detailed instructions by the manufacturer, which explain in detail all stages of the work. The instructions must be strictly followed.