In plumbing, the preparatory process is almost decisive. The slightest inaccuracies in measurement lead to errors in marking. This means that all further work, no matter how thorough it may be, loses its meaning. After all, a finished metal part, unlike a wooden one, cannot simply be “adjusted.” A part is either good or it's not.

When working with metal, measurements must be taken more accurately than a regular ruler allows. This is especially true for the manufacture of small parts. That is why the main measuring tool of a mechanic is a caliper, which allows you to take measurements with an accuracy of tenths of a millimeter.

Purchasing material

DIYers usually use blanks made of steel, brass, aluminum, copper or zinc. Lead is a soft metal that can be easily processed, but it is harmful to health, which is why it is increasingly being replaced by plastic. The shape of the workpiece also matters: it can be a pipe, a plate, a corner, etc. Since blanks of this kind are sold only in wholesale quantities, we advise you to purchase the necessary material from a mechanic or blacksmith.

Working with metal requires the highest precision - up to tenths of a millimeter.

metal marking compass

How to properly mark and mark a metal workpiece

For accurate measurements, it is necessary not only to install the caliper correctly, but also to look at it from a certain angle. To be completely sure, you can attach a square to the part and use it to straighten the position of the caliper (for example, when measuring the diameter of a pipe). The use of a square is even desirable when measuring depth, since the caliper scale must be strictly vertical to the surface of the part. A slight change in position may cause an error. A whole number of millimeters is read on the millimeter scale, fractions of a millimeter are read on the vernier from the place where its zero mark coincides with the division on the millimeter scale. In this case: 13mm and vernier 0.3mm. Exact size: 13.3mm.

Line Search

It is often difficult to find a marking line on metal sheets and plates covered with rust or scale. In order for you to be able to find such a line after some time, knock out two or three small holes with a center punch in the places where it passes. After this, it will be easy to restore the erased line.

Marking

| Marking is an operation in which contour lines (marks and recesses) are applied to the part being manufactured (or repaired), defining the boundaries of processing. The marking is called planar when all its lines lie in the same plane, and spatial when the marking lines are drawn in different planes. To carry out marking, you must have a marking plate and a set of special tools and accessories, including: an angle plate (setting square), prisms, measuring squares, a gauge with accessories or an ordinary gauge, i.e. a tripod with a scriber, a caliper with double-sided jaws, caliper with one-sided jaws, measuring ruler, calipers and bore gauge, protractor, marking compass, center punch, screw jacks, scriber, flat, prismatic and wedge-shaped pads, hammer, clamps. For particularly precise marking work, measuring (plane-parallel) end tiles are also used. |

Safety requirements during plumbing work

When performing metalworking work, which is carried out in a production area, and especially when metalworking is carried out at home, the following safety requirements must be observed:

- on the workbench you need to put only those tools and parts that will be necessary to complete this work;

- metalworking of metals should be performed only after they have been securely secured in a vice;

- remove shavings and dust from the workbench only with a brush;

- do not perform drilling work or sharpen tools with bandaged fingers or mittens to avoid them being caught by the drill;

- while the machine is operating, it is prohibited to open or remove protective covers, guards and safety devices;

- when chasing, riveting, chopping and other work in which there is a possibility of metal particles flying off, it is necessary to use safety glasses or a mask with safety glasses, while fencing off the workplace with nets and portable shields to avoid injury to people working nearby or passing by;

- pneumatic tools must be used with flexible hoses. It is strictly forbidden to use hoses that are damaged.

Application

Using a core, you can make marks on any surface. It is advisable to use it when working with smooth materials. These are tiles, polished surfaces. Most often it is used when drilling metal. Therefore, core samples are often referred to as metalworking tools.

Masons also actively use it. Special mason cores have been created for this purpose. They are not much different from locksmiths. They are often powder coated in a bright color to make them easier to find if lost.

Permanent connections

To obtain permanent connections from metal parts, metal processing methods such as riveting and soldering are often used. Riveting is a method of obtaining a permanent connection from two or more parts using rivets. Riveting can be done with a pneumatic hammer, a hand hammer or on special riveting machines.

Soldering parts

Soldering is the process of joining metal parts using a molten alloy called solder, which has a melting point much lower than the metal of the parts being joined. Metal processing at home often includes soldering - it is widely used for repair work, as well as for sealing cracks, eliminating liquid leaks from vessels, etc.

If you want to master artistic forging with your own hands, then you will need time and patience. There are different types of metal forming. You can read in detail about each of them in this article.

When welding high-strength steels, you need to have certain knowledge and skills - this is the only way to achieve success in this matter. You will find interesting information on this issue in our article at https://elsvarkin.ru/texnologiya/vysokoprochnye-stali-i-osobennosti-ix-svarki/ link.

Tools for flat marking

Work must be performed on a flat and comfortable surface. Marking tables are used for this purpose:

- woody;

- iron.

Key conditions for the quality and design of tables:

Read also: Metal balls in varnishes

- Strength and durability. To ensure strength, the table legs are connected by horizontal bars. It is recommended to place large-scale marking plates on jacks.

- Sufficient surface area for work. Conventional tables have dimensions: length 2000–3000 mm; width 4000–5000 mm; height 700–1000 mm. The surface area of the table should be suitable for the dimensions of the sheets, tapes, and strips of material.

- Convenience. Tables are equipped with different devices:

- weights for fixing sheets of light material;

- prisms for installing pipes;

- clamps for securing metal sheets;

- rectangular and wedge-shaped gaskets for installing profiles and other parts.

The work site must be guaranteed with all the tools necessary for flat marking. The table provides a list of the necessary tools and certain tips for working with them.

| Tool | Function | Design requirements | Tips for use | ||

| Scriber | drawing marked lines on workpieces | · thin steel rod; · one end is sharpened at 45 degrees, the other is bent into a ring; · the sharp end is hardened | · to obtain thin marks, the tip must be hard and sharp; · during operation, the scriber is deviated from the ruler in the direction of its movement; it should be regularly pressed against the ruler with its tip | ||

| Outline | drawing contours parallel to the edges of the sheet | · material: copper or steel; presence of a graphite pencil in the working part | Reismus | · checking the location of workpieces; · carrying out parallel risks | · stand with scriber fixed at the required height; · fixation height is measured with a square |

| Kerner | · construction of centers of circles or holes; · drawing holes on the marking lines | · material - hard steel; · dimensions: diameter 8-13 mm, length 90-150 mm; · the end is sharpened at 60 degrees; · there are manual and automatic (set marks of the same size) | The automatic center punch does not require a hammer to operate | ||

| Locksmith's hammer | percussion tool for punching | use hammers weighing 50 - 200 g | the work is performed with light movements conveyed by bending the hand “from the shoulder” | ||

| Squares | · construction and control of angles; restoration of perpendiculars | preferred material - metal | · it is advisable to have squares with angles of 30, 45, 60 degrees; · a square with a shelf is used to check the correct placement of parts on the plate | ||

| Protractor with protractor | marking corners and checking mark alignment | preferred material - metal | The position can be fixed with a hinge screw | ||

| Compass | · construction of circles, arcs; Transfer of dimensions from ruler to workpieces | It is recommended to harden the legs of the compass | the tip of the compass is installed strictly in the punched hole | ||

| Marking plate | Serves as a working surface; · used for equipment storage | · located horizontally; · must be clean and dry | placed on cabinets, stands with drawers, tables | ||

| Templates, stencils | simplification and acceleration of marking of similar parts | durable steel templates | ensure a tight fit of the template to the workpiece | ||

| Vise | tool for securing small parts | ensuring smooth tightening efforts | For fine work, a small step is recommended; for coarse clamping, a wide step is recommended. |

Inspection, measuring and marking tools

To mark and control the accuracy of processing workpieces and parts, various tools, instruments and devices are used. Processing accuracy means compliance of the shape and dimensions of the manufacturing part with the requirements of the drawing and technical specifications.

Correct marking ensures the necessary precision in processing workpieces and parts and economical use of materials. Linear dimensions are measured with a tape measure, tape measure, folding meter and various rulers with millimeter, centimeter, decimeter and meter divisions.

The square is used to check and set a right angle (90°) when marking and processing materials and workpieces. The Erunok is designed for marking and controlling angles of 45° and 135°. It consists of a base to which a wooden or metal linear line is rigidly attached at an angle of 45°.

The mark is used for measuring according to the sample and transferring them to the workpieces when marking. It has a hinged base and a ruler. Malka can be made of wood or metal.

Using a compass, they transfer the given dimensions and describe the circles when marking them. A bore gauge measures the internal diameter of a round hole. The outer diameter of a round part is determined using calipers and vernier calipers, which are used to measure the small linear dimensions of parts and elements of their connections. Use a caliper with double-sided jaws for external and internal measurements (width and thickness of parts, thickness of panels and ridges, width of eyes) and a ruler to determine the depth of sockets, grooves and holes. A caliper is a sliding metal tool that has a rod with a main scale, a frame with a clamping screw and an additional scale (cone) and a depth ruler. The frame can move along the rod depending on the size being determined. When measuring, first count whole millimeters that have passed along the bar along the leftmost line of the cone, and then tenths of a millimeter according to the complete coincidence of the division of the cone with any division of the bar. Vernier calipers can have a measurement accuracy of 0.1 to 0.05 mm.

The level is used to check the horizontal and vertical surfaces of joinery and carpentry products and structures (window and door blocks, beams and joists, floors, racks). It has a wooden or metal block in which an arched glass tube containing alcohol and an air bubble is placed. When the edge of the level bar coincides with the horizontal or vertical position of the elements being tested, the air bubble will be located between the two marks on the tube. The staples mark the spikes and eyes. It has a wooden block with a cross quarter at one end.

The thicknesser is used to apply marking marks parallel to one of the surfaces of the workpiece being marked and to each other.

Plumb line - used to check the vertical installation of joinery and carpentry products and structures. It consists of a cord with a cylindrical metal pointed weight attached to it at the bottom.

The micrometer with a scale division of 0.01 mm is equipped with a bracket with a measuring heel, a micrometer screw and a drum. The end surface of the screw facing the heel is the measuring surface. The ratchet is designed to achieve a constant measuring force. Hundredths of a millimeter are counted on the drum's circular scale. The indicator is longitudinal, drawn on the stem.

An inclinometer is used to measure the inclination angles of two adjacent surfaces. Goniometers come with a cone and optical. A protractor with a cone allows you to determine external angles from 0 to 180° and internal angles from 40 to 180° with an error of no more than ±5°. Optical inclinometers are used to measure the angular parameters of the cutting part of tools. They are equipped with a magnifying glass, which ensures the measurement of angle values with an error of no more than 10″ (arcseconds).

Marking boards

Marking plates have a ribbed design, which gives them rigidity with a relatively low weight.

The working surfaces of marking plates must be precisely machined. To avoid deformation of the slabs during their operation, the castings are subjected to aging (exposure to air for a long time) between roughing and finishing processing.

On the upper surface of the marking plate (Fig. 1, a), in the absence of machine grooves, longitudinal and transverse grooves with a depth and width of 1-2 mm are cut so that the entire surface of the plate is divided into square sections.

What you need to know about the center punch

When choosing a core sample, you need to remember several important points about this type of instrument.

Firstly, it does not matter at all what cross-sectional shape the tool rod has.

It is much more important to pay attention to its other characteristics. Secondly, you should buy a device based on the diameter and type of drill with which it will be used

Secondly, you should buy a device based on the diameter and type of drill with which it will be used.

Thirdly, if you plan to use a center punch when working with soft metals, it is better to choose one with a smaller sharpening angle and vice versa.

Applying marks

The standard regulates the procedure for drawing marking lines:

- horizontal;

- vertical;

- inclined;

- curvilinear.

Applying curved elements after straight ones provides another opportunity to check their accuracy. The arcs must close the straight lines, the interface must be smooth.

Tools for marking

Direct marks are carried out with a well-sharpened scriber, without tearing off, in one step. At the same time, the scriber is tilted away from the ruler or square so as not to introduce distortions.

Parallel lines are drawn using a square and moving it along the reference ruler to the required distance.

If the workpiece already has holes, then a special tool, a center finder, is used to attach marking lines to them.

Center finder

In order to mark inclined lines, use a marking protractor with a hinged ruler fixed at its zero point.

Marking protractor

For particularly precise markings in plumbing, calipers are used. They allow you to measure distances and scratch marks with an accuracy of hundredths of a millimeter.

Square

To make markings on sheet material extremely accurate, you need a good square. It should have as long a shelf as possible: the longer the supporting section will be. This is important, since the cut edge of a workpiece made of sheet material is rarely perfectly even and smooth, and the position of the square is smoother and more accurate, the longer the area of its support on the edge of the workpiece.

For plumbing work you need a high quality square. For those who intend to do such work regularly, we advise you to purchase a square made entirely of steel and with a long supporting section.

Place the square so that its supporting edge rests against the edge of the workpiece, and attach a steel ruler to the square at a right angle.

Check the accuracy of the angle with a mechanic's square (with a reference section) or - as in the picture - a combination square.

What is a marking operation?

It should be immediately clear that marking does not necessarily mean fixing the distance from one point to another when constructing a particular structure. As production and construction standards become more complex, the manufacturability of marking processes also increases. During this action, a foreman at a construction site or an operator on a production line can determine the parameters of the workpiece, the characteristics of its location relative to other objects, etc. A modern marking tool allows you to record indicators such as length, width, height and angle. Some models such as squares are also focused on initially determining how well an object, its parameters or location meet the requirements. As for the marking process, it mainly involves manual handling of measuring and marking devices. The user, in turn, is required to be attentive, accurate and thorough in removing and recording data.

Marking. Marking a workpiece or part

Marking is the operation of applying lines (so-called marking marks) to the workpiece being processed or the part being repaired, defining the contours of the part or the area to be processed.

Marking of parts is used mainly in small-scale production of parts and when carrying out metalwork repair work.

To carry out various marking work, a mechanic must have special measuring and marking tools (rulers, thickness gauges, scribers, punches, etc.).

To install, align and secure the marked parts, use a set of special devices (linings, prisms, squares, etc.).

Marking is done on marking plates, on which all fixtures and tools are placed.

Marking boards

Marking plates have a ribbed design, which gives them rigidity with a relatively low weight.

The working surfaces of marking plates must be precisely machined. To avoid deformation of the slabs during their operation, the castings are subjected to aging (exposure to air for a long time) between roughing and finishing processing.

On the upper surface of the marking plate (Fig. 1, a), in the absence of machine grooves, longitudinal and transverse grooves with a depth and width of 1-2 mm are cut so that the entire surface of the plate is divided into square sections.

Large marking plates are installed on special stands (pedestals) with drawers for storing tools. Small marking plates are placed on wooden stands and installed directly on workbenches.

The height from the floor to the working surface of a marking slab of small or medium sizes is 800–900 mm, and of large slabs – 700 mm.

The marking plate must have free space to walk around and to be able to work from either side.

Checking the flatness of the marking plates is carried out using an accurate ruler and feeler gauge. To do this, the ruler is placed with its working surface on the working surface of the marking plate. The gaps between these surfaces are controlled with a feeler gauge. The thickness of the probe, which passes into the gap between the ruler and the marking plate, should not exceed 0.03–0.05 mm.

The correctness of the working surfaces of scraped marking plates (Fig. 1, b), intended for precise marking and verification work, is checked for paint using a straight edge. The number of spots in a 25x25 mm square must be at least 12.

Rice. 1. Marking boards

Equipment

In order to install the part on the working plane of the marking plate, support pads, prisms, jacks, special devices, cubes and squares are used, which have precisely machined prismatic and vertical surfaces perpendicular to the surface of the plate. Shims are also used to protect the working surface of the marking plate from damage by the untreated (black) surfaces of the parts being marked.

Flat (Fig. 2, a) and prismatic (Fig. 3) pads are placed directly on the working surface of the marking plate.

Rice. 2. Pads for installing the part on the marking plate

Rice. 3. Prism (a) and square (b) for installing parts

Parts that have a flat base, a flat end, or three supports spaced at a maximum distance along the dimensions of the part must be installed for marking on three pads selected in height.

If it is necessary to orient the part in a horizontal plane, then select pads or a set of pads for the supports, in which the part will take a horizontal position. In this case, it is also convenient to use height-adjustable pads. In Fig.

2, b shows an adjustable lining, which is adjusted in height by rotating screw 1, which moves wedge 2 along wedge 3. On the side surface of the lower wedge there is a scale that allows you to more accurately set the height of the lining.

Cylindrical parts are placed on prismatic supports with triangular cutouts (Fig. 3, a). A set of auxiliary tools usually contains several of these pads with the same cutouts.

For ease of marking, the part can be fixed to a square (Fig. 3, b) installed on the marking plate. The shelves of the square have through holes through which the part can be attached to the square.

Spatial marking tools and devices

Categories

If it is necessary to punch the center holes at the ends of the shafts, it is convenient to use a special device for punching - a bell (Fig. 2.6, o). This device allows you to apply core recesses on the centers of the end surfaces of shafts without preliminary marking them.

For the same purposes, you can use a center finder square (Fig. 2.6, b, c), consisting of a square 1 with a ruler 2 attached to it, the edge of which divides the right angle in half. To determine the center, the tool is placed on the end of the part so that the internal flanges of the square touch its cylindrical surface and a line is drawn along the ruler with a scriber. Then the center finder is turned to an arbitrary angle and a second mark is made. The intersection of the lines marked on the end of the part will determine the position of its center.

Planar marking techniques

A prerequisite for the correct application of markings on flat surfaces is their high-quality preparation. Preparation procedure:

- Using steel brushes, remove dirt, scale, and traces of corrosion from the surface of the workpiece.

- Check the workpiece material for defects: cavities, cracks, blisters.

- If defects are identified, they should be measured and measures taken to remove them.

- If it is not possible to remove defects, then a marking plan should be drawn up so that they are removed from the surface during processing.

Before performing planar markings, it is recommended:

- Analyze the drawing of the part, its purpose, characteristics and dimensions.

- Develop a marking plan.

- Using reference books, determine processing allowances.

- Paint the surface.

The purpose of coloring is to ensure the clarity of the marks applied. When painting a small part, it is held at an angle in the left hand. Using a paint brush, apply paint thinly in cross movements. Large pieces are painted using a roller or spray.

Recommendations for staining are given in the table.

| Surface type | Coloring agents |

| any types of surfaces, except hot-rolled steel and non-ferrous metals | quick-drying water-based paints, alcohol varnishes |

| cast iron or steel workpieces | copper sulfate: · in pieces; solution (3 teaspoons per 200 g of water) |

| untreated black blanks | a solution of chalk in water (the consistency of thick milk) with the addition of drier or linseed oil |

The technique used for applying planar markings depends on its purpose, the material on which the lines are applied, and the shape of the parts being marked.

Marking work can be performed:

- according to the drawing - all elements of the part are transferred from the drawing to the material;

- according to a template - the contours of the part are outlined on the material along the contours of a pre-made pattern, template or stencil;

- according to a sample - used when there is no drawing and template, dimensions are taken from a sample of the part being replaced;

- in place - carried out during assembly or adjustment to the size of assembly units of dimensional parts.

If a drawing is used during work, the order of marking is as follows:

- Carefully study the drawing, find out the material of the part and the process of its manufacture.

- Establish methods and procedures for applying lines and cores to the material.

- The dimensions shown in the drawing should be marked using special marking tools and measuring instruments. It is not recommended to transfer dimensions from the drawing using compasses, even if the drawing is made on a scale of 1:1. This is due to the fact that the dimensions of the paper on which the drawing is applied may change as it dries.

- Set the base from which the marking will be carried out. The base can be:

- edges of the material to be marked;

- previously drawn lines, for example, axial, center.

- The order of drawing lines:

- in the horizontal direction;

- in the vertical direction;

- arcs, fillets, circles;

- slanted lines.

- Mark the lines.

- Check the presence of all lines from the drawing on the marked surface.

Techniques for high-quality marking:

- Marks on steel workpieces are made with a scriber. On sheets of aluminum-based alloys, all internal lines, to avoid damage to the coating, are drawn with a pencil, contour lines with a scriber. For cleanliness, the line is drawn only once. If the line is poorly drawn, then this area should be painted over, allowed to dry and the line drawn again.

- When working with a center punch, with your left hand, place it with its pointed end exactly in the required place, tilting it away from you and pressing it to the intended location. Afterwards, the punch should be quickly brought to a vertical position and lightly hit with a hammer. When applying the punch, the following nuances should be taken into account:

- the centers of the punches must be located clearly on the lines, so that after processing operations half of the hole remains on the workpieces;

- Be sure to mark the intersections of marks and roundings;

- on short marks, holes are made every 5-10 mm, and on long ones - 20-100 mm;

- the circle is marked at the intersection of the axes;

- on the treated surface, holes are placed at the ends of the marks;

- on cleanly processed surfaces, the lines are not marked; they are extended to the side edges, where the holes are placed.

- Perpendicular lines are drawn using a square. The workpiece is placed in the corner of the work table plate and secured with a weight. To mark the first line, the shelf of the square must be attached to the side surface of the slab. Then the square is moved to a perpendicular surface and a second line is drawn.

- When applying markings according to the template, you must use a properly sharpened scriber. It should be installed so that the generatrix of the cone moves smoothly along the contour lines of the template. The accuracy of the work is influenced by the conditions of contact of the template to the surface.

- When marking according to a sample, all dimensions are transferred from the used part to the workpiece. Before starting work, it is checked for sufficient allowances; the holes in the workpiece are closed with center plugs. The following is the sequence of actions:

- place the workpiece on the plate next to the part, taking into account the uniform distribution of allowances on the workpiece;

- gradually transfer all dimensions from the part to the workpiece;

- synchronously changing the positions of the workpiece and the part, transfer all dimensions with a thicknesser;

- using a square to check the compliance of the installation of the part and the workpiece along the lines drawn in the previous position;

- The marking should be completed by marking the marks.

Metal cutting

A special hacksaw or scissors (metal guillotine) can be used to cut metal. Sheet metal is cut with manual or mechanical scissors, pipes, and profile material is cut with manual or mechanical metal hacksaws. Pipe cutters, as well as circular and band saws are used for cutting pipes.

The technique of metal cutting includes an operation such as filing. This process consists of removing a layer of metal from the surface of the workpiece in order to give it more accurate dimensions and the required surface cleanliness. Filing is done with files.

When metalworking metals, an operation such as drilling can be performed - producing cylindrical holes using a drill. Drilling can be carried out on many metal-cutting machines: drilling, lathe, turret and others. The most suitable for this operation are drilling machines. During assembly and repair work, drilling is often performed using portable drills: pneumatic, electric and manual.

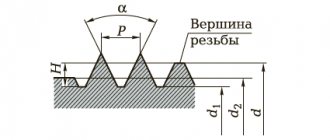

The manufacture of metal parts may include threading - the process of forming spirals on the internal and external cylindrical and conical surfaces of workpieces that serve to connect parts. Such parts form detachable connections. Threads on bolts, screws and other parts are cut mainly on machines. When assembling and repairing units, as well as during installation work, they resort to cutting threads manually using taps and dies.

Technologies for manual metal processing attach great importance to scraping - an operation for processing the surfaces of metal parts, during which a layer of metal is scraped off with a special cutting tool - a scraper. Scraping is used to ensure precise contact of rubbing surfaces without disrupting their lubrication. This operation is performed manually or on special machines.

In metalworking, metal finishing is often accomplished by lapping, which is done using hard grinding powders applied to special laps made of gray cast iron, copper, mild steel, and other materials. The shape of the lap must correspond to the shape of the surface being treated. By moving the lap over the surface being processed, a very thin (0.001-0.002 mm) layer of roughness is removed from it, which helps to achieve tight contact of the mating parts.

Marking techniques

The following techniques are used in plumbing:

- According to the template. Used in case of small-scale production. The template is made from rolled metal, the entire batch is marked (or even processed) through once marked slots and holes in this sheet. For parts with complex shapes, several templates can be made for different planes.

- Following the example. The dimensions are transferred from the part - the sample. It is used in the manufacture of a new part to replace a broken one.

- Local. Used in the production of complex multi-component products and structures. Blanks are placed on a plane or in space in the order in which they enter the final product and are marked together.

- Pencil (or marker). Used for workpieces made of aluminum alloys so that the scriber does not destroy the passivated protective layer.

- Accurate. It is done using the same methods, but special precision measuring and marking tools are used.

Techniques for marking metal parts

The selection of techniques is carried out in accordance with design and technological instructions.