Cutting a profile pipe with a miter saw with a metal disc - is it possible?

IMHODom › Forums › hands from shoulders › Cutting a profile pipe with a miter saw with a metal disc - is it possible?

This topic has 9 replies, 7 voices, and was last updated by kaifsheg 5 years, 11 months. back.

Greetings. I don’t have a pendulum saw and/or a band saw at hand, so a question has arisen, but I need to make a cut on a profile pipe (ferrous metal, 50x50x2).

Accordingly, the question is: is it realistic to use miter saws with a metal (cutting) blade and, if so, what should the speed/power be?

Is it realistic to use a jigsaw with metal files and, accordingly, what should be the power?

clarification to the question:

1. The purchase of a band saw/pendulum does not fit into the budget of this design; cutting to order, again, is excluded - it’s too tedious with delivery, etc.

2. The problem with the grinder is to get more or less close to 90g. cut, that’s why I want to use a miter saw (on which 90 degrees are set) or a jigsaw along the guide.

- village of Dzerzhinskoye

Budget-friendly, here’s a pendulum for a simple angle grinder.

You can put a metal disc on a crosscut saw, but you can’t put a wood disc on a grinder, the speeds are different, everything can end badly...

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone, one disc lasts for a year or two.. at a price of 300-500 rubles, it pays for itself every 10-20...

There are cutting machines for metal. The price of Interskolovsky and other Chinese is about 2.5 thousand... (probably). They are just right for abrasive discs. I wouldn't spoil the trim. There is a lot of plastic on it, and as you know, it burns from sparks. There are also metal discs for trimming with carbide tips (a disc with teeth but a different shape compared to wood). It costs about 6 thousand.

- Tomsk

For some reason, my friend, you charged 6 thousand for the disk. At these prices, it’s easier to buy an angle grinder complete with a pendulum.

- Rainbow

jigsaw - definitely not considered, nonsense, sawing pipes with a jigsaw...

cross-cutting with a cutting disc - the saw will not last long, the disc will not fit, you need to tinker with the adapter, and the speed and power are not the same... also not an option

The stand for the grinder is flimsy, uncomfortable, the corners are floating, it is very advisable to mount it permanently, otherwise the grinder may behave unpredictably. If you need to cut a little, you can get by with it. the lesser of evils. but if you need to cut in the future, I strongly advise you to buy a cutting machine. 6-8 thousand, but it's worth it.

- The science

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone

And which one exactly? I tried several - they get very hot. I tried solid ones for waterless cutting

I had the matrix for a year, in daily use, until the car was opened, and the grinder didn’t do a leg... Of course it saws more slowly than an abrasive, but on roofs it beats itself off in 2-3 days... I sawed tiles, pipes and fittings...

And he really turned it down. Apparently the manager deceived me at the store.

I saw how a corner with a 5 mm flange was cut with such a disc. thick. It's sawing!

- Rainbow

With a miter saw in the usual sense, you can cut wood, plastic and soft metals (aluminum profile). such saws usually have a power of 1.3-1.8 kW, a blade of up to 200-300 mm, and a speed of 4000-5000 rpm.

pipes and other metal are sawed using cutting machines. they look roughly the same as trimmers, but have differences in characteristics. power from 2.2 kW, disc from 350 mm, speed up to 4000 rpm.

with seemingly small differences in characteristics, the linear speed of the disk of a crosscut saw will be approximately 1.5 times less than that of a cutting saw, with the latter having a higher power. thus, the crosscut tool simply will not carry the load when sawing metal.

We also must not forget about the problems associated with the compatibility of tools and disks (thicknesses, diameters, mounting dimensions).

How to cut laminate with a jigsaw correctly

Let’s say right away that this is the most optimal and fastest way to trim lamellas; after all, the manual method is quite labor-intensive and inaccurate. If you plan to continue to carry out all kinds of repair work in the house, it is worth having an electric jigsaw in your arsenal.

Using this electrical device, it is easy to make a cut along or across the slats, at any angle. There are devices that will allow you to make cuts located at the same distance from the edge of the board, even without marking.

Even with a single cut, such a tool shows excellent results. The answer to the question, what is the best way to cut laminate flooring using a shaped cutting line, becomes clear: with a jigsaw. This tool helps to obtain rounded cuts necessary when meeting heating pipes. To do this, you just need to choose the right file with fine teeth, which will improve the quality of the cut.

Of course, this tool also performs straight cuts efficiently. The advantage of an electric jigsaw is that even a novice builder can achieve excellent results with it.

The disadvantages of the device include

- noise during operation;

- a lot of dust is generated.

Note that other power tools also have these disadvantages. How to properly cut laminate flooring with a jigsaw:

- The tool is equipped with a file with a fine reverse tooth. If one is not included with the jigsaw, you need to purchase it. This is the answer to the question of which jigsaw file should you use to cut laminate flooring.

- Markings are applied to the panel that requires trimming. the cutting line is drawn on the back of the panel.

- The board is laid on a solid base with the decorative surface up, after which trimming begins along the intended mowing line.

Using a miter saw to cut metal.

I read somewhere that it is absolutely impossible. And it turns out you can” > I wonder what diameter of the circle he used.

I think 200x32 mm through the adapter washer. Everything is possible in our country)))

In some TV program I saw how men cut a steel profile with a circular saw, only not like a pendulum, but one that moves along a bar. They had a metal disk there and it seemed like they were even leaking coolant.

Yeees. Our people apparently have a lot of health.

2 BEARDED What risks do you think exist?

acrobat wrote: What risks do you think exist?

Burning of the edges of the workpiece, an increased probability of destruction of the disk at such speeds, and as a result, unfinished work and possible injuries, shaking or complete failure of the tool, waste of time and effort (which we don’t like to count) on remaking and fine-tuning an obviously poorly made tool .

It’s possible, there are special discs; usually partition installers often cut duralumin profiles with such a tool.

Serg wrote: duralumin profiles are often cut with such a tool.

Duralumin profile, aluminum profile - another story. I'm talking about steel - pipes and angles, for example.

General information about the tool

Along with jigsaws, circular and circular saws, the miter is capable of cutting metal sheets, profiles, and various types of pipes. The design of the device is simple - the main elements are a frame (base), a handle with a start button, a saw blade, a gearbox and a motor. The latter comes in two types:

The advantage of the first is ease of maintenance, the second is a long service life and less noise during operation.

The motor is connected to the saw blade via a belt or gear drive. They have advantages and disadvantages. For example, a belt is almost silent and eliminates vibration of the disk, but can slip during long-term operation, forcing the user to stop the process. The toothed one is free from this disadvantage, but it is noisy and vibrates slightly.

The working body of a miter saw is a disc. It is made of durable metals, since it bears a serious load. There are wavy lines or cuts on the surfaces of some removable elements. This is done to reduce noise during operation, as well as to compensate for temperature deformation.

Choose the right saw blade

Choosing the right blade for your saw and not missing is a whole art. Of course, at first glance, what’s so complicated about it? But the quality of work and productivity, as well as personal safety, depend on the disk. After all, circular saws are perhaps the most dangerous tool.

Saw and grinding discs are divided into all-alloy and with welded inserts made of vanadium alloys.

All-alloy ones, regardless of the quality of the material from which they are made, dull quickly enough. But you can sharpen them yourself at home and many times. They are inexpensive and designed strictly for working with wooden workpieces.

With welded inserts they are much more expensive, but last longer. If carbide is sharpened, the cost of this operation will be almost equal to a new disk. But the service life and quality of cutting the material justify the price. In addition, this blade can be used not only for cutting metal, but also for laminate boards or hard plastic.

Before purchasing a disc, pay attention to the following symbols:

Types of pendulum saws

It is easier to classify a miter tool than, for example, an electric jigsaw, which can be mechanical or electric. The products under consideration are divided according to the following criteria:

- appointment;

- the presence of a broach function;

- saw blade parameters.

Household and professional equipment and machines are distinguished by purpose. The former are distinguished by low power (up to 1500 W), compactness, and cost up to 20-25 thousand rubles. Example - Bosch GKM 18 V-LI 0 L-BOXX (battery model for 15 thousand rubles), Kolner KMS 210/1400 for 4000 rubles, domestic Caliber PTE-900/190M with a power of 900 W at a price of 4500 rubles.

A cross-cutting machine is equipment not for home work, used only in enterprises that produce rolled metal products and are engaged in cutting or other processing on a daily basis. Such machines cost tens and hundreds of thousands of rubles, their power exceeds 1000 W, and they weigh several centners. An example is domestically produced machines TsT 10-4 (3 kW, 360 kg, 105 thousand rubles) or TsKB-40 K (5.5 kW, 700 kg, 340 thousand rubles).

Professional trimmers for sheets, profiles and pipes occupy an intermediate position according to the specified parameters. For example, Makita LF 1000 (1650 W, from 60 thousand rubles), DeWalt 27111 (1500 W, from 50 thousand rubles).

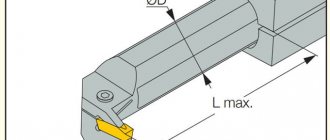

Having a drawing option gives the user a slight advantage when processing long sheets or pipes. The models have two parallel slats on which the cutting disc is mounted and moves freely along them. A tool with a broach is distinguished by a large cutting width of the part, as well as particularly small teeth on the disk. Also, the tool sometimes has a laser pointer for easy marking and process control. Metal trimming with broaching weighs more than usual, and the presence of the option increases the cost by 20-30%.

The parameters of the cutting blade are the most important classification criterion. They have two diameters - external (at least 20 cm) and internal (also known as landing; about 3 cm). The size of the teeth determines the depth and width of the cut, and the material determines the ability to work with a particular metal.

Now, a few words about manufacturers you can trust.

Specifications

When choosing, it is worth analyzing a whole range of parameters that will help you get an idea of the best choice. The main list of characteristics can be presented as follows:

Power. The average value is in the range of 1000-3000 W. If you rely only on metal, then it is advisable to purchase a device with a potential of at least 1500 W. At reduced power it will be possible to work only with thin-leaved soft workpieces. Rotation frequency. This indicator does not affect performance. Peak thrust is still determined by power. But the ability to change the speed can be useful precisely in cases where you plan to process workpieces of different types. The maximum frequency reaches 5000 rpm. Disk size. The diameter varies on average from 150 to 355 mm. Moreover, the metal cutting disc is distinguished by the presence of solderings made of hard-state alloys. They increase processing efficiency and quality. Sharpening type

It is important to keep in mind that the tooth shape of a saw blade can have a positive or negative angle. For metals, only the opposite, that is, negative sharpening, is used.

Recommendations for choosing a product brand

The best miter saw in terms of safety, manufacturability and work comfort is a product from one of the following companies:

Most of them offer table expansion for the workpiece, but cutting large parts sometimes requires additional supports. These are found in, for example, the LF 1000 model. This simplifies the user’s work. In this case, the moving part of the makita metal saw enters a stable frame, in which there is an area for setting the cutting angle.

The best trimmers in terms of reliability and stability are those whose frame is made of aluminum or magnesium alloy. They are durable, stable, but at the same time they weigh acceptable. An example is the Bosch GCM 10, popular among professionals, weighs only 15 kg.

The leader among saws with a possible inclination of the cutting edge to the workpiece is Hitachi. While Bosch, Metabo or Makita mostly allow you to set the cutting angle to only 0, 90 or 45 degrees, the Japanese concern offers the user the ability to rotate by 15; 22.5; 30 degrees. This option forces you to add a rotating device to the design, due to which, however, the weight of the installation for cutting profiles, sheets or pipes will still not exceed 30 kg. The price increases by 15-25%.

Tips for choosing a miter saw

The tips below are a must read before purchasing a tool.

- For rare and short-term work, choose household equipment (low power, compactness, price no more than 15 thousand rubles), for regular work - professional equipment (price 15 thousand and above, power - more than 1 kW).

- The more powerful the engine, the less it will heat up during operation, the higher the performance of the tool and the larger the disk you can install yourself if replacement is necessary.

- Many discs indicate the manufacturer's recommendations regarding the material to be cut or its type (for sheets/pipes/profiles); pay attention to this.

- Models with a spacious blade for work are more expensive, but they are much more convenient for cutting metal.

- The design welcomes the presence of a cutting depth limiter - this way you can select a groove for processing the workpiece in width.

- Evaluate whether you need laser illumination, broaching and similar options. If not, don't overpay.

- If the blade guard does not cover the blade during operation, it is a poor tool and dangerous to operate.

- The wider the workpieces will be cut with a miter saw, the larger the diameter of the disk should be.

- The heavy weight of the device will cause fatigue when cutting, although its cost is higher than its compact counterparts.

This material briefly examines the types of miter saws for metal and tips for choosing. You can describe your experience using devices or give advice on choosing a tool to visitors to our site.

Premium models

| Model | Characteristics |

| Bosch GCM 8 SJL Professional Professional “trimming” with an excellent set of functions that significantly speed up the process of high-quality processing of various materials with a small cross-section. Main characteristics: power - 1.6 kW, saw blade rotation speed - 5500 rpm, maximum blade diameter - 216 mm. The cutting depth at an angle of 90° is 70 mm. Cutting width - 312 mm. Equipment: broach, cutting depth limiter, head tilt to the left 47° and to the right at an angle of 2°, table rotation left/right - 45°/45°. Functionality: laser marker, two-point dust removal system, work table extension and clamp for fixing the workpiece. Weight - 17.3 kg. The average cost is 32,700-39,900 rubles. Advantages:

The disadvantage is the relatively small power and diameter of the saw blade. | |

| Makita LS 1216 Professional miter saw with excellent functionality and high cutting quality. Power - 1.65 kW, spindle speed - 3200 rpm, maximum disk diameter - 305 mm. The cutting depth at an angle of 90° is 107 mm. Cutting width - 363 mm. Features: broach with double guides on linear ball bearings, tilt of the cutting unit to the right/left at an angle of 45°, rotation of the table to the left 52° to the right - 60°. Functionality: maintaining speed under load, soft start, cutting depth adjustment, dust extraction pipe, work table extension and clamp for fixing the workpiece. Weight - 26.1 kg. The cost ranges from 44,900 to 50,700 rubles. Advantages:

Flaws:

| |

| Dewalt DWS 780 Professional model with a large saw blade with adjustable speed. Main characteristics: power - 1.675 kW, saw blade rotation speed 1900-3800 rpm, maximum blade diameter - 305 mm. The cutting depth at an angle of 90° is 112 mm. Cutting width - 349 mm. Equipment: broaching, head tilt left/right at an angle of 49°, table rotation to the left - 45°, to the right 60°. Functionality: electronic adjustment of the rotation speed of the equipment, adjustment of the cutting depth, dust removal system, illumination of the work area, XPS cutting line positioning system, work table extension and clamp for fixing the material. Weight - 24.8 kg. The average cost is 53,900-65,390 rubles. Advantages:

The disadvantage is the high cost. |

Can a miter saw cut metal?

cutting

profile pipe 50x50x2 with a miter saw and a metal disc. May be?

Greetings. I don’t have a pendulum saw and/or a band saw at hand, so a question has arisen, but it is necessary to make a cut on a profile pipe (ferrous metal, 50x50x2).

Accordingly, the question. Is it realistic to use miter saws with a metal (cutting) blade and, if so, what speed/power should it be?

Is it realistic to use a jigsaw with metal files and, accordingly, what should be the power?

clarification to the question:

1. The purchase of a band saw/pendulum does not fit into the budget of this design; cutting to order, again, is excluded. very troublesome with delivery, etc.

2. cutting metal with a miter saw with an abrasive disc? 1. cutting metal at a crosscut machine. The problem with the grinder. get more or less close to 90g. cut, which is why I would like to use a miter saw (on which 90 degrees are set) or a jigsaw along the guide.

What, some kind of special miter saw, only for wood? I saw these exclusively in sets for children's creativity,

so it seems that the trimmings are universal. Cutting a profile pipe 50x50x2 with a miter saw with a disk for the load when sawing metal. Here:

Model "Makita LS1040F"

This tool is universal. Its main advantage lies in its ability to efficiently handle the cutting of soft metal, wood and plastic. The power potential of the model is average (1650 W), but it is enough to provide a cutting depth of more than 90 mm. It should be emphasized that this metal trim is hardly suitable for professional cutting of material in construction or large-scale production. The lack of power and endurance will affect when working in continuous mode. But this disadvantage is compensated by the following advantages:

- A wide range of equipment, including a 255 mm disc, guides, a lamp for lighting, a bag for a vacuum cleaner, etc.

- Additional functionality in the form of a spindle lock and a soft start system.

- Reliability of the design.

Wood miter saw assembly saw

Anyone who has cut a large corner with a manual grinder knows how stressful and unsafe this work can be. https://imhodom.ru/node/14492 (write in PM)

There are cutting machines for metal. Cutting metal with a miter saw. Cutting metal with a band saw, miter saw and circular saw. The cost of Interskolovski and other Chinese is about 2.5 thousand (for sure). Cutting metal with a miter saw. They are just right for abrasive discs. I wouldn't spoil the trim. There is a lot of plastic on it, and as you can imagine, it glows with sparks. There are also metal discs for trimming with carbide tips (a disc with teeth but a different shape compared to wood). It costs about 6 thousand.

For some reason, my friend, you charged 6 thousand for the disc. At such prices, it is easier to purchase an angle grinder complete with a pendulum.

jigsaw It’s definitely not considered, it’s absurd, to cut pipes with a jigsaw.

Dependence of cutting speed on material

In this regard, there is the following pattern:

- for soft wood, it is recommended to use a speed of 50–90 m/s;

- cutting of hard rocks occurs at a speed of 50–80 m/s;

- cutting exotic types of wood – at 50–85 m/s;

- for MDF panels the speed is 30–60 m/s;

- for laminate panels – 40–60 m/s;

- for simple carpentry work and chipboards - 60–80 m/s.

When choosing a tool, it is necessary to take into account that saw blades for wood have different sizes and shapes of teeth and can be used at several operating speeds.

It should be remembered that all tool manufacturers indicate the required parameters, so you can easily decide which equipment you need to choose to complete the planned work. In addition to speed, speed, thickness and other indicators, it should be taken into account that circular saws can be not only hand-held, therefore, first of all, you should determine for which tool a particular disk is intended.

Why is it important to choose the right saw blade?

On the question of how to choose a saw

wood disc for a clean cut, you need to take into account parameters such as the shape and size of the teeth. Manufacturers offer several models:

Post Views: 6

Adjusting the Carburetor of Husqvarna Chainsaw 435 435e 440e

How to Remove the Air Filter of a Husqvarna 135 Chainsaw