The automatic machine ADG-502 (Fig. 9) is designed for direct current welding in a carbon dioxide environment of butt joints with and without cutting edges, fillet welds and overlap joints.

Rice. 9. Automatic ADH – 502

The machine is equipped with two parts: welding tractor 1 and arc power source 2 - rectifier VDU - 504. The operation of the machine is based on the principle of dependence of the electrode wire feed speed on the arc voltage. All control of the machine is carried out from a remote control located on the welding tractor. The control panel contains devices for monitoring the mode, regulators for arc voltage and welding speeds and electrode wire feed, as well as control buttons. The additional control panel mounted on the welding rectifier contains controls for the supply of shielding gas.

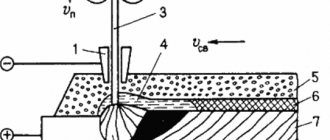

The welding tractor is similar to automatic machines of the ADF type, the difference is in the design of the current conductor, the presence of cooling water and shielding gas, the absence of a hopper for flux and a light indicator. The welding head is shown in Fig. 10.

Rice. 10. Welding head of the automatic machine ADG-502

One-sided welding by automatic machines on a copper moving slide.

This method was developed at the IES named after. Paton and was introduced into production in the form of the TS-32 assault rifle (Fig. 6.7.) and TS-44. This is a method of welding sheets along an increased gap using a movable cooled copper slider mounted on a trolley, which, using a special knife, was connected to a welding tractor through the gap between the sheets being welded. One of the requirements for this welding method is to maintain a constant initial gap between the sheets. This was achieved by the presence of assembly brackets installed across the future weld every 800 - 1200 mm and which must be removed during the welding process. Such machines made it possible to weld sheets of panels up to 12 mm thick. Later, at the Central Research Institute of TS, an analogue of these assault rifles was developed - a Brig type assault rifle. A significant disadvantage of this high-performance welding method was the presence of excess residual local welding deformations such as “waviness” (loss of stability) at thicknesses of 4-6 mm and “houses” at thicknesses of 8-12 mm at the ends of butt joints over a length of 800 - 1200 mm. Despite this drawback, the cost of assembling panel sheets decreased by 2 times, and the cost of welding by 1.5 times.

Semi-automatic devices. Installations for semi-automatic welding of the type PSh-5 (PSh-5U), PSh-54 under a layer of flux are currently not used in shipbuilding due to their disadvantages - significant weight of the holder (due to the hopper with flux), a small supply of flux, the impossibility of smooth regulation of wire feed speed.

The domestic industry has a large number of different automatic and semi-automatic machines for welding in shielding gases. In shipbuilding, automatic consumable electrode welding machines are used: ADPG-500, ADSP-1, TS-35 and non-consumable (tungsten) electrode – ADSV-2.

The ADPG-500 automatic machine is designed for welding with a consumable steel electrode in a shielding gas environment (CO2, Ar, He) butt and fillet welds in the lower position. The installation kit includes a welding arc power source (PSG-500 type converter), a control cabinet, a welding tractor and gas equipment. The welding tractor has parts that are unified with the ADF-500 automatic machine. The compact tractor is designed for welding with thin electrode wire with a diameter of 0.8 - 2 mm at current strengths of 150 - 500 A. The welding speed can be varied within the range of 15 – 70 m/h, and the wire feed speed is 90 – 960 m/h. The tractor can move around the product. Gas equipment consists (Fig. 6.8.) of a cylinder with protective gas, a reducer, a rotameter (gas flow meter) and connecting hoses. When welding in a CO2 environment, the gas system includes a dryer and a gas heater. The water-cooled heating pad provides protective gas supply within the range of 600 – 1500 l/h.

At shipbuilding plants, consumable electrode welding in shielding gases is most widely used as a semi-automatic method using semi-automatic machines PDPG-300, PDPG-500, A-537R, “Granit” and “Neva”, etc.

Semi-automatic machines PDPG-300 and PDPG-500 - the installation includes a welding power source (type PSG-350 or PSG-500), a control cabinet, a feeding mechanism with flexible hoses and welding guns and gas equipment (Fig. 6.8).

The feeding mechanism provides wire feeding with a diameter of 0.8-2.0 mm at a speed of up to 960 m/h. Semi-automatic machines are designed for welding with a consumable electrode in a shielded gas environment butt and fillet welds in any spatial position. Semiautomatic A-547R (A-547, A-547U) is designed for welding in a carbon dioxide environment; created at the IES named after. Paton. The peculiarity of the semi-automatic device is a lightweight pistol with a short hose from 0.8 to 1 m long (Fig. 6.9). The semi-automatic machine is designed for electrode wire with a diameter of 0.18 - 1.0 mm and is intended for welding thin-sheet steel up to 3 mm thick and fillet welds with a 4 mm leg in carbon dioxide.

For welding titanium alloys, automatic machines such as ADS-1000-2M, ADS-1000-2V, ASU-4MV and semi-automatic machines PGT-2, “Ri, etc.” are used.

Equipment for manual and mechanized welding with non-consumable electrodes in an inert gas environment. With this welding method, tungsten rods containing 1.5-2% lanthanum or yttrium oxide are used as a non-consumable electrode, which improve the emission of electrons from the electrode, which increases the stability of the arc. This method is most widely used for welding non-ferrous metals and alloys and stainless steels. In many cases, the welding arc is powered by an alternating current source, which is explained by the following.

Read also: How to make flux for soldering aluminum

When welding aluminum and its alloys based on it, as well as magnesium alloys, in order to destroy the refractory oxide film formed on the surface of the weld pool, reverse polarity (minus on the product) is necessary, since only with this inclusion the emission of electrons from the product (cathode) will destroy the surface film of oxides; Welding can be performed efficiently provided the weld pool is cleaned as specified. At the same time, with reverse polarity, the tungsten electrode heats up excessively. To avoid its melting, the welding current has to be reduced, and this reduces welding productivity.

When switching to alternating current, the weld pool is sufficiently cleaned during the half-cycle, when the product is the cathode; At the same time, alternating polarity allows you to increase the welding current and welding productivity. However, in this case, the appearance of a direct current component Iо (Fig. 6.10.) due to the fact that the electrodes are different metals (one electrode is tungsten, the other is aluminum).

More intense emission of electrons from the tungsten electrode causes the appearance of an asymmetrical alternating current sinusoid, from which a direct component can be separated. The direct current component has straight polarity, which worsens the quality of the welded joint (it makes it more difficult to destroy films, reduces the penetration depth, and worsens arc stability). Studies have shown [4,5] that the inclusion of ballast rheostats or a capacitance in a series welding circuit reduces or completely eliminates the direct current component. Therefore, when welding (mechanized or manual) aluminum alloys with a tungsten electrode, the welding circuit is usually powered with alternating current (Fig. 6.8b).

The installation includes: current source – welding transformer 1; choke for regulating the strength of welding current 2; oscillator for arc stabilization 3; ballast rheostat 4 to reduce the DC component; gas-electric burner 5 with a tungsten electrode, a gas system including a cylinder with argon 6, reducer 7, rotameter 8 and hoses for supplying argon. In the manual version, the gas-electric burner is moved manually. By attaching the control cabinet to the tractor and including the control cabinet in the installation, welding can be carried out automatically. Installations such as UDAR-300 and UDAR-500, as well as UDG-301 and UDG-501 are used in shipbuilding. To eliminate the DC component, capacitor banks are included in the welding circuit of these installations and there is an electronic voltage stabilizer. The diameter of the tungsten electrode is 2-6 mm. The ADSV-2 automatic machine is currently widely used in shipbuilding, which is designed for automatic welding of stainless steels and non-ferrous metals and alloys with a non-consumable tungsten electrode in an argon environment. Welding current is up to 400 A, welding speed is 10-80 m/h, filler wire diameter is 1-2.5 mm, its feed speed is up to 800 m/h.

Hybrid laser-arc welding. Basic principles. The use of an arc discharge as one of the most common and cheapest types of heat sources for welding encounters significant difficulties associated with insufficient energy concentration in the electric arc plasma and instability of the arc at high welding speeds [1, 3]. Therefore, at the moment, hybrid (mixed) welding methods, which include laser-arc welding, are increasingly being developed. This technology was obtained by combining laser welding and gas shielded welding technologies. Figure 6.11 shows the main methods for implementing hybrid arc welding.

The hybrid welding process can be implemented according to two schemes - in the first scheme, the laser beam and arc act from different sides, in the second scheme, the action of the arc and beam is carried out on one side in relation to the direction of welding and the normal to the metal surface. At the moment, due to the complexity of manufacturing equipment corresponding to the first scheme, the second scheme is used for welding. The laser-arc welding process can be carried out with both non-consumable and consumable electrodes. When using a non-consumable electrode, the arc is ignited ahead of the welding process. The arc heats the metal and melts its top layer, and the laser carries out deep penetration. When using a consumable electrode, an electric arc is ignited behind focused radiation, which melts only the parts of the metal in contact. The basis of the hybrid welding system is a special welding torch, which includes both laser optics and a gas-shielded welding torch (Fig. 6.12).

A schematic representation of the hybrid laser-arc welding method is shown in Fig. 6.13.

In hybrid welding, in addition to laser radiation, the weld pool is affected by the welding arc, which is an additional source of energy introduced into the weld pool. The minimum laser power should be more than 500 W [2, 3].

Hybrid laser-arc welding implements a technological process in which the advantages of each welding method are mutually enhanced and the disadvantages are reduced, which leads to an expansion of technological capabilities. The use of this type of welding is promising for shipbuilding.

Installations for mechanized welding of vertical seams. Application of EHS. With modern methods of constructing ship hulls from large sections or blocks, the most critical are the seams of assembly joints (intersectional joints), which are often welded manually in several passes (for thicknesses greater than 15 mm). This is a very labor-intensive and costly process. Currently, many shipbuilding plants use an A-433M type automatic machine (modernized for electroslag welding), designed specifically for shipbuilding. The A-820M, A-612, A-681 and others have also found use.

Read also: DIY boat winch

The A-433M automatic machine (Fig. 6.14.) is a single-electrode moving along a monorail on which a gear rack is mounted.

A welding head, a hopper with flux and a control panel are mounted on the machine’s carriage. The machine has an electric motor: one for vertical movement of the carriage at a speed of 2.5-20 m/h and the second for feeding electrode wire into the slag bath at a constant speed, which can be adjusted within the range of 68-430 m/h. To form the seam there are two copper sliders or a forming slider and a backing strip, cooled by water. The welding head of the machine is installed on a double support, which allows you to adjust the position of the electrode according to the width and thickness of the joint. The machine is designed to use wire with a diameter of 3 mm at a current strength of up to 12000 A and is intended for welding steel up to 60 mm thick. The PSM-1000 electric machine converter with a rigid external characteristic is used as a power source for the welding circuit. Currently, instead of this machine, machines of the A-820M type, which are intended for ESW of vertical metal seams with a thickness of 18-50 mm, have begun to be used more often. Due to the special responsibility of the housing assembly seams, the stability of the quality of the ESW is very important. A special feature of preparing such joints for welding is that their edges are not beveled. Assembly with a given gap is carried out using staples (Fig. 6.15.) after trimming the allowance along the assembly joint.

For welding cross-shaped joints of the set (flora and stringers) of high bottom sections, four-head (working simultaneously of four arcs) automatic machines of the “Baltia” type are currently used.

Didn't find what you were looking for? Use the search:

Automatic gas shielded welding

Simplification of welding technology, which does not lead to a deterioration in quality, helps make this type of metal connection even more popular. Automatic welding in shielding gases is currently one of the main options for mass production of welded products. This is fully justified by the factors that automation allows you to achieve high productivity, speed of creation of parts and decent quality. At the same time, the technology of using protective gases itself becomes a guarantee of quality, since this particular method is considered one of the most reliable. Although the cost of using gas protection is higher than that of manual arc welding, it provides a more reliable connection. This is especially true when working with thin sheets, non-ferrous metals and difficult-to-weld alloys.

Automatic gas shielded welding

Correctly setting the parameters of the machine makes it possible to eliminate the occurrence of defects due to human carelessness. After selecting the parameters, the equipment will carry out welding in the same way in all cases, which is required for mass production.

Application area

Automatic welding in CO2 of large thicknesses, as well as its other varieties, are used mainly in industry. For private use, such parameters are unclaimed. For mass production this is an indispensable thing, but for the manufacture of 1-2 parts it is better to use the ordinary manual method. Repairs are also impossible to achieve using this technology.

Shops for the production of metal structures, enterprises engaged in the production of metal products and other areas based on mass production necessarily use such equipment. Even the complexity of working with gas does not stop its development. After all, here it all comes down to preparatory work, which must be carried out at a high level, which ensures the same quality for each product in the batch.

Advantages

It is not for nothing that this technology has become widespread in industry, as it has a number of advantages:

- High productivity of the welding process when it comes to mass production;

- Everything is done the same according to the given settings, so there is no negative human factor;

- The seams are of high quality, as gas provides excellent protection;

- You can join difficult-to-weld and even dissimilar metals;

- A large number of people are not required to operate the machine.

Flaws

The following factors are worth noting as disadvantages:

- If there is an error in the parameters, the defect will spread to the entire series of products;

- The technique has a limited limit of settings, so not all parameters can be selected;

- The cost of the equipment makes this technique inaccessible to many people;

- It is not possible to create a seam in any position and with any parameters, since the system may not have sufficient parameters for this, whereas it is much easier to do it manually.

Operating principle and technology of mechanized welding

Automatic gas shielded welding is carried out using welding wire or uncoated electrodes and uses two basic operating principles. Electric welding refers to the heating of metal to a melting state using an electric arc. For this purpose, both fusible and non-fusible electrodes can be used. The lack of coating is compensated by a gas shell. The welding principle itself is practically no different from that used in manual welding with shielding gases.

Automatic gas shielded welding

The main difference is that the installation has a control system that helps carry out all procedures without human intervention. It has a number of parameters that need to be set to create the appropriate mode, and then everything is turned on for the stream. Setting up is one of the most difficult processes in this matter.

"Important!

Here you need to strictly adhere to the technology, since the slightest flaw can lead to the failure of the entire batch.”

Protective gases used

In this area, several types of protective gases can be used, each of which has its own properties and features. Among the main gases, the following should be highlighted:

- Argon - creates a high level of protection, but is harmful to human health, and also has a high cost;

- Helium - rarely used, but well suited for products with large thickness of welding;

- Carbon dioxide is a relatively cheap and safe option, but is mainly suitable for medium-thick carbon steels;

- Hydrogen - this type of gas is not often found in welding, but for special cases it is still used.

Welding materials and equipment

The following things are used as the main welding materials and equipment used:

- Uncoated welding wire or electrode;

- Infusible electrode;

- Burner;

- Shielding gas;

- Automatic system for feeding workpieces and controlling welding tools;

- Welding mask.

Equipment for automatic gas shielded welding

Safety precautions

In order for the process to proceed as safely as possible, it is necessary to check the integrity of the hoses connecting the burner and gas sources. You also need to check that nothing is poisoning, otherwise there will be a danger of explosion. All settings, repair work and other manipulations are carried out only when the equipment is disconnected from the network. During the welding process, it is prohibited to interfere with it.

Conclusion

Automatic welding is placed in a special category, since this technology stands apart. Human labor is not directly used here, since the main manipulations are assigned to the machine. A person only needs to monitor everything that is happening and set the settings. At the same time, this increases liability, since carelessness can create a situation where the entire batch of products turns out to be unsuitable for use due to existing defects. Otherwise it is a very efficient process.

Author: Igor

Date: 02/12/2017

Article rating:

svarkaipayka.ru

Protection options

Any welding work carries an increased degree of danger, so every worker must take care of the protection of the skin, eyes and respiratory organs. Even short-term overcooking in your own garage should be carried out with the following kit:

- mask;

- heat-resistant gloves;

- respirator.

Safety precautions

This is the only way to perform a high-quality operation without compromising your own health.

Application of welding in inert and active shielding gases

- November 28

- 37 rating

- Characteristics of electrodes

Gas shielded welding is carried out to prevent the influence of air on the molten metal in the joint area. To do this, special gases are supplied directly to the zone affected by the electric arc through the torch (FIGURE 1), or welding is carried out in a chamber from which air was first pumped out and then shielding gas was pumped in.

Figure 1. Gas shielded arc welding.

Range of protective gases

They are:

- chemically inert;

- active.

Welding in a closed environment is necessary to prevent air from interfering with the process.

The first group includes: argon (Ar), helium and argon-helium mixtures. They do not enter into chemical reactions with molten metals in the weld pool and do not dissolve in them. They are used for fastening aluminum, magnesium, titanium parts and for joining alloys of these metals (MIG welding - metal inert gas).

The second group (MAG welding - metal active gas), in turn, is divided into:

- having reducing properties (carbon monoxide and hydrogen);

- having oxidizing properties (carbon dioxide (CO2) and water vapor);

- with selective activity (nitrogen).

Of the group of active gases, carbon dioxide is the most widely used, since it has the lowest cost.

If we take the cost of 1 m3 of carbon dioxide as 1, then the cost of nitrogen will be 1.5625, oxygen - 3.2813, hydrogen - 4.0625, argon - 44.6875. Helium is the champion in price, it is 156.25 times more expensive than carbon dioxide! In addition, the density of helium is less than, for example, argon, and accordingly, more of it will be consumed.

Return to contents

| Type of metal | Its thickness, mm | Electrode used | |

| tungsten | melting | ||

| Low carbon, alloy and structural steel | 3 | argon grade B, mixture of Ar (70-80%) and CO2 (20-30%) | argon grade G, carbon dioxide, mixture of Ar (75-90%) with CO2 (10-25%) |

| Heat resistant pearlitic steel | argon grade B | argon grade G, carbon dioxide, mixture of Ar (75-90%) with CO2 (10-25%) | |

| High alloy, corrosion resistant, heat resistant and heat resistant steel | argon grade B, mixture of Ar (70-80%) and CO2 (20-30%), helium | argon grades V, G, helium, carbon dioxide, mixture of Ar (75-90%) with CO2 (10-25%) | |

| Heat-resistant chromium-nickel alloy | any | Ar grade B, helium | Ar grade B, helium |

| Aluminum and its alloys | 6 | argon grade B, helium, mixture of Ar (70-80%) with CO2 (20-30%) | argon grade B, mixture of argon grades B and B, mixture of Ar (35%) with helium (65%) |

| Titanium and its alloys | any | Ar grade A | Ar grade A |

| Copper and its alloys | argon grade B, helium, mixture of Ar (70-80%) with CO2 (20-30%), nitrogen | argon grade B, helium, mixture of Ar (70-80%) with CO2 (20-30%), nitrogen | |

| Magnesium alloys | argon grade B, helium | Ar grade B | |

| Zirconium, molybdenum, tantalum and other active metals | Ar grade A | Ar grade A |

Return to contents

Arc welding in a shielded gas environment is carried out using welding (transformer, power supply, cables, inverter, torch, mask) and gas (cylinder, hoses, flow meter) equipment.

The equipment is divided into manual welding machines, machines for semi-automatic work and fully automated devices.

Mechanized welding in shielding gas is used in industrial enterprises. The equipment allows us to produce large batches of similar products. For individual use, the use of such devices is impractical and very expensive.

Semi-automatic welding is widely used both in large factories and for individual use. Such equipment is much cheaper than full automatic machines, more mobile, and the quality of the seams is no less excellent. Semi-automatic devices have proven themselves excellent in small businesses. There is probably not a single service station where they are not used.

The operating principle of semi-automatic machines is that the process occurs manually, and the supply of electrode wire is automated.

Figure 2. Semi-automatic circuit diagram.

Scheme of the semiautomatic device in FIGURE 2, where 1 is a cylinder with protective gas; 2 - wire feed mechanism; 3 - wire; 4 - gas supply pipeline; 5 - burner; 6 - grounding; 7 - transformer.

Manual welding involves working only with non-consumable rods, where there is no need to constantly supply the electrode wire.

Schematic of the tungsten electrode welding process in FIGURE 3.

It should also be noted that according to the type of work, welding in shielding gas can be with a continuous and pulsed arc.

Return to contents

Gas shielded arc welding is performed with non-consumable and consumable electrodes.

The first ones for alternating current are made of pure tungsten, for direct current - from pure tungsten, lanthanum, thoriated and itrated tungsten. Such rods burn in air, so the protective gas protects against this as well.

Figure 3. Diagram of the welding process using a tungsten electrode.

Electric arc welding in a protective environment with tungsten electrodes is called TIG-DC with direct current, and TIG-AC with alternating current.

When using a fireproof rod, filler wire is used to fill the weld pool with metal.

Consumable electrodes for gas shielded welding are made from the same metal that is to be bonded. They are solid or tubular wire, which is fed automatically during operation. A powdered alloying, slag- and gas-forming component (cored wire) is placed inside the tubular electrode. The consumable electrode also functions as an additive.

Return to contents

Advantages:

- Using various operating modes, you can join almost any metal.

- High quality connections in a wide range of metal thicknesses.

- Visual control of the process.

- There is no dependence on the position of parts in space.

- The temperature effect is applied to a narrow area of the parts.

- High speed of work, the process can be easily mechanized and automated

- There is no need to remove fluxes and slags or clean seams.

Significant disadvantages:

- Protection from the harmful light and thermal effects of welding is necessary.

- The need to purchase expensive protective gases.

- The possibility of their negative effects on the human body.

- High cost of equipment.

- The need to take additional training courses.

High-quality welding in a shielded gas environment ensures high reliability of the resulting products and a long service life.

expertsvarki.ru

Modes

For these operations, semi-automatic class inverter units are often used. With their support, electricity and supply voltage are adjusted. These stations also serve as a basic power source, and their power and regulation options vary depending on the model. If there is a need to carry out standard activities (without handling thick and unpopular alloys), you can choose the simplest equipment.

Carbon gas welding modes

Automated gas shielded arc welding can vary in many quantities, most of which are determined by the following positions: 1st wire radius, 2nd wire diameter, 3rd electrical power, 4th voltage, 5th contact feed speed, 6 -e gas consumption. And it all looks like this:

- 15cm, 0.8mm, 120A, 19V, 150m/h, 6 units/min;

- 7mm, 1mm, 150A, 20V, 200m/h, 7 units/min;

- 2mm, 1.2mm, 170A, 21V, 250m/h, 10 units/minutes;

- 3mm, 1.4mm, 200A, 22V, 490m/h, 12 units/min;

- 4-5mm, 0.16cm, 250A, 25V, 680m/h, 14 units/minutes;

- more than 0.6cm, 1.6mm, 300A, 30V, 700m/h, 16 units/min.

These characteristics are standard and are calculated for processes with carbon dioxide.

Gas shielded welding

Topics: Gas shielded welding, MIG/MAG welding, Tig welding, Carbon dioxide welding.

When welding in a shielding gas environment, to protect the zone of the welding arc and the molten metal, a special gas is used, supplied as a stream into the melting zone using a torch, or welding is performed in chambers filled with gas.

The most common is jet local protection with a gas stream flowing from the nozzle of the welding torch (Fig. 1). The quality of jet protection depends on the size and design of nozzle 1, the distance L from the end of the nozzle A - A to the surface of the material being welded, and on the consumption of shielding gas. In the structure of the gas flow, two regions are distinguished: 2 - the core of the jet and 3 - the peripheral section. Reliable protection of the metal is guaranteed only within the core of the flow, the maximum length H of which is observed during laminar flow of gas from the nozzle.

Various shapes of the nozzle flow path are used: conical, cylindrical and profiled. To improve jet protection, porous materials, fine meshes, etc. are installed in the burner at the inlet of the nozzle, which further allows the gas flow to be equalized at the outlet of the nozzle. The gas flow rate must ensure laminar flow of the jet.

Rice. 1. Scheme of gas flow with local protection of the welding zone.

Inert gases that do not interact with the metal during welding (argon, helium, their mixtures), and active gases (CO2, N2, etc.) that interact with the metal, as well as their mixtures, are used as shielding gases. Shielding gas determines the physical, metallurgical and technological characteristics of the welding method.

Welding in a shielded gas environment can be performed with a non-consumable (usually tungsten) or consumable electrode (Fig. 2). In the first case, inert gases and their mixtures are used. The weld is formed by melting the edges of the product and, if necessary, filler wire fed into the arc zone.

In the second case, a welding wire is used, continuously fed into the arc zone, which melts during the welding process and participates in the formation of weld metal. To increase the stability of the arc, increase the depth of penetration or change the shape of the weld or increase the productivity of welding carbon and alloy steels, mixtures of inert gases with active gases are used, for example: a mixture of argon with 1 ... 5% O2, a mixture of argon with 10 ... 25% CO2, a mixture of argon with CO2 (up to 20%) and with the addition of ≤5% O2.

A mixture of carbon dioxide and oxygen (up to 20%) is used for welding carbon steel. This mixture has a high oxidizing ability, provides deep penetration and good weld shape, and reduces porosity.

Rice. 2. Schemes: welding in a protective gas environment with non-consumable (a) and consumable (6) electrodes, where 1 - weld metal; 2 - electrode; 3 - shielding gas; 4 — burner nozzle; 5 - filler wire.

Shielding gas can be supplied to the welding zone concentrically around the arc, and at increased consumable electrode welding speeds - from the side (Fig. 3). To save consumption of inert gases, protection with two separate gas flows is used (see Fig. 3, c); in this case, the external flow is usually carbon dioxide. When welding active materials, to prevent air contact not only with molten, but also with heated solid metal, elongated nozzle attachments are used (moving chambers, see Fig. 3, d).

The most reliable protection is achieved when the product is placed in stationary chambers, previously evacuated and then filled with protective gas. Shielded gas welding of large-sized products is carried out using portable chambers made of plastic, soft, usually transparent materials, installed locally above the joint to be welded.

The thermophysical properties of shielding gases affect the technological properties of the arc. Under equal conditions, an arc in helium, compared to one blown in argon, has a higher voltage, and the resulting weld has a smaller penetration depth and a larger width. Carbon dioxide occupies an intermediate position in its effect on the shape of the seam.

If metallurgical processing and additional alloying of the seam is necessary, a small amount of deoxidizing or alloying substances is supplied to the welding arc zone.

Fig. 3. Schemes for supplying protective gas to the melting zone: a - concentric; b - lateral; c - two concentric flows; g - with an additional nozzle.

Slag-forming substances are introduced in the form of dust or vapor along with a protective gas; as magnetic flux or flux poured into cutting edges; in the form of a coating applied to the surface of the electrode wire, and other methods. The composition of the weld metal can be changed by supplying additional filler wire to the welding zone, as well as double-arc welding in a common pool using wires of different compositions.

has the following main advantages:

- high quality of welded joints of metals and alloys of different thicknesses, low waste of alloying elements when welding in inert gases;

- possibility of welding in different spatial positions;

- the ability to monitor the formation of a seam and the ease of mechanization and automation of the process.

The disadvantages of the method include: the need to apply protective measures against light and thermal radiation of the arc, the possibility of violating gas protection when blowing off the jet, and in some cases the difficulty of water cooling of the burners.

weldzone.info