TIG, or WIG, is the name of the same type of welding work - welding with a W-electrode in a protective environment, only in different languages. In German, WIG is translated as Wolfram-Inertgasschweißen. TIG (tungsten - tungsten) - in English-speaking countries.

To produce a high-quality weld, it is necessary to remove hydrogen, oxygen and nitrogen from the melt. This avoids the formation of bubbles or pores. TIG welding solved this problem.

TIG classification

According to the arc ignition method:

- By touching the product.

- On terminal strips.

- Using an oscillator.

By type of shielding gas supply:

- With laminar flow.

- In the gas chamber.

According to the inert gas used:

- Argon is used more often than other gases because it is heavier than air and does not form explosive mixtures . The first grade is used for welding steel and aluminum. The highest is used for alloys, non-ferrous, rare and active metals.

- Helium is lighter than air . Two grades: technical and special purity. More rare and expensive. In its environment, an electric arc releases 1.5-2 times more energy.

- A mixture of argon and helium in proportions up to 40% argon and up to 65% helium . Advantages: arc stability and high degree of penetration.

- Nitrogen is used only for copper welding . Available in four varieties.

According to technical characteristics.

- Submerged arc.

- Penetrating arc.

- Several W-electrodes.

General information

Helium is an inert gas that is colorless and odorless.

This gas is practically insoluble in most metals. It is much lighter than air. Helium density is 0.179 kg/m3. Its liquefaction temperature is -269 °C. Helium is non-flammable, non-toxic, non-explosive. However, at high concentrations in the air it can cause suffocation and oxygen deficiency. Liquid helium is a colorless liquid that can cause eye damage and frostbite to the skin. Helium is obtained from natural gases by fractional condensation (liquefaction). In this case, impurities that have a higher liquefaction temperature than helium are converted into liquid. After a series of accompanying chemical purifications, the final purification of the helium is carried out, which consists of passing it through activated carbon. The helium used for welding retains small amounts of hydrogen, nitrogen, oxygen, neon, hydrocarbons and moisture.

State standards

There are quite a lot of state standards for organizing welding work, which provide explanations and requirements for the work and determine methods for safe welding.

Here are the most suitable documents characterizing gas shielded welding:

- GOST 19521-74;

- GOST 2601-84;

- GOST 14771-76;

- GOST 23518-79;

- GOST 14806-80;

- GOST 27580-88.

Helium

Helium is a chemical element, atomic number 2, atomic weight 4.0026, classified as an inert gas, colorless and odorless.

The volumetric content of helium in air is 0.00052%. Helium is much lighter than air, density 0.1785 kg/m3 at zero temperature and normal pressure. Boiling point -268.9°C. Ionization potential 25.4 V. Colorless, non-toxic, non-flammable and non-explosive gas, diffuses well through solids. Chemical formula - He. Helium is obtained from helium-containing natural gases, minerals and air (see Methods for producing helium)

The possibility of welding in an inert gas environment was first explored by the American Charles L. Coffin at the end of the 19th century. However, even at the beginning of the 20th century, welding materials such as aluminum and magnesium was difficult due to their high activity in atmospheric oxygen.

In the early 1930s in the United States, inert gases filled into vessels began to be used for welding. A little later, the DC magnesium welding process was introduced into the aircraft industry. This process was refined and refined by Russell Meredith of Northrop Aircraft.

Russell Meredith developed the torch design and patented the Heli-Arc welding process under number 2274631 for welding magnesium and its alloys. Thus, 1941 is the year of birth of TIG welding. Russell Meredith later sold all rights to use the HELIARC patent and trademark to Linde Division.

In the article Welding in inert gases with a tungsten electrode (TIG), we have already given a description of argon arc (TIG) welding, but as they say, “instead of a thousand words,” we recommend watching this video.

weldering.com

Working principle of argon TIG

The most common arc welding with a W-electrode is in a protective environment of argon or its mixture. Argon is much heavier than air, so it safely displaces it from the area of the parts being welded.

There are three types of starting welding work:

- Passing a needle through metal.

- Spot touch.

- Contactless ignition.

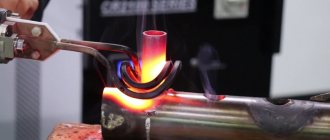

During the welding process with a non-consumable electrode, an inert gas environment is created in which an electric arc is ignited between the tungsten electrode and the materials being joined. The applied heat melts the edges of the parts being joined and the filler strip. A filler strip is not always required: only if the parts being joined cannot be connected tightly.

According to technology, the working length of the arc should be short - 1.5 ... 5 mm. At the same time, the electrode is not allowed to touch the surfaces being welded.

To start TIG, after striking the arc, the welder sets the correct position of the holder, tilting it to 150 from the vertical. With this method you need to work with both hands. The torch is operated with one hand, and the filler rod is supplied with the other as needed.

If the filler strip is made of a low-melting material, such as aluminum, the welder should keep it at some distance from the arc, but not remove it from the inert gas zone. If such a rod is brought closer to the arc, it may melt earlier without coming into contact with the weld pool.

To prevent cracks, it is recommended to gradually reduce the arc current when completing TIG welding. This will allow the weld to harden gradually and evenly.

Impact of clean gases on quality and productivity

The pure gases used in welding are argon, helium and carbon dioxide. They can have both positive and negative effects on the arc.

Welding using argon

Argon (Ar) is a monatomic chemical element that is widely used in its pure form and as part of many welding gas mixtures. Argon is completely inert, which makes it suitable for working with refractory and chemically active materials. It has low thermal conductivity and ionization potential, thereby providing low heat transfer to the environment surrounding the arc. This creates a narrow arc column, which in turn results in the usual penetration profile for argon - deep and relatively narrow. When working with argon, there is a slight tendency to undercut the fusion zone and enlarge the weld, which is due to the lack of heat at the outer edges of the weld pool in both TIG and MAG. In MAG, pure Ar promotes jet transport of metal.

Read more about the features of this gas in the article: argon gas - chemical properties and scope of application.

Helium (He) is a monatomic inert gas most often used for welding non-ferrous metals with a non-consumable electrode. Unlike argon, helium has high conductivity and ionization potential, which contributes to the opposite results. Helium gives a wide profile, good wetting at the weld edges and higher temperatures than pure Ar. High ionization potential can make it difficult to initiate an arc unless high-frequency or capacitive arc initiation methods are used to work with the tungsten electrode. In addition, a higher gas flow rate is recommended since helium tends to rise in the air. Pure helium promotes large droplet transfer of the electrode material and is rarely used for GMAW, with the exception of pure copper.

Carbon dioxide (CO2) is a two-component gas used in MAG and FCAW. CO2 is a complex molecule with rather complex interactions in an arc. At arc temperatures, carbon dioxide breaks down into CO and O2. This creates the potential for oxidation of the base material and decomposition of the weld pool or weld alloy. CO/O2 recombination gives a fairly broad penetration profile at the weld surface, while the low ionization potential and thermal conductivity creates a hot region in the center of the arc column. This gives the entire joint a well-balanced width-to-depth penetration profile. In the case of electric arc welding, pure carbon dioxide cannot create a jet transfer of metal, but only large droplets, which can lead to a large amount of spatter.

Power supplies

DC sources:

- Universal welding rectifier VDU.

- VSVU series sources.

- Specialized source TIR-300D.

- Specialized installations : UDG-161, UDG-501-1.

AC power source: transformer for manual arc welding.

Approximate cost of machines for TIG welding on Yandex.market

Inverter power supplies:

- Source DSU200AU.

- Source DS200A.3.

Specifics of electrodes

The most used electrode brands:

- EHF – pure tungsten. Use only on alternating current.

- EVL – tungsten with lanthanum oxide.

- EVI – tungsten with yttrium oxide.

- EVT – tungsten with thorium oxide.

The diameter of the electrode is selected from a reference table depending on the power source and brand of electrode. Such an electrode has a melting point of about 40,000C, so it is convenient to use for welding metals in which melting occurs at a much lower temperature.

The tungsten electrode is not thrown away, but only cleaned and sharpened in a certain way.

Approximate cost of tungsten electrodes on Yandex.market

Properties of the welding arc in inert gases - argon and helium

The article “Electric Arc” explains in detail what a welding arc is. This article will discuss the properties of a welding arc in an inert gas environment - argon or helium .

The characteristics of the welding arc vary depending on the selected shielding gas. Any arc charge is maintained due to the fact that an ionized space is enclosed between the electrodes, in which the movement of ions and electrons from one electrode to another is observed.

In the environment of diatomic gases, electrons lose more energy during their movement than when moving in the environment of argon or helium, since many inelastic collisions occur in this case. This leads to a large loss of energy; the ionization of molecules is accompanied by their dissociation. This process simultaneously causes a lower mobility of free electrons. Their mobility in an inert gas environment is several times greater than in an active gas environment, which increases the likelihood of excitation and ionization of neutral gas particles. During a discharge in a diatomic gas environment, negative ions are formed in the arc gap, which impede the movement of electrons due to an increase in electrical resistance, which is not observed in an inert gas environment.

The absence of negative ions reduces the recombination coefficient, which leads to increased discharge stability. In argon and helium, the probability of spontaneous termination of the discharge is less than in other gases, since the former have lower ignition potentials for a spontaneous discharge. The cathode voltage drop is minimal, so a minimum voltage is required to maintain the discharge. The presence of argon and helium atoms in a metastable state facilitates the stepwise ionization of gases, and this leads to the fact that the arc combustion potential is lower than the ionization potential of the gases.

Typically, the excitation and ionization potential of inert gases is higher than the corresponding potentials of metal vapor, nitrogen and oxygen, which makes it difficult to ignite an alternating current arc when powered by conventional transformers. During welding in a helium environment at the same current strength, the arc voltage on electrodes consisting of W - Me (metal), Al - Al, Ti - Ti is significantly higher than the arc in argon. When welding steel, the voltage between the iron electrodes is very low, approximately 8 - 10 V.

An arc in helium has a greater melting capacity and is less concentrated; it creates a more uniform form of penetration than an arc in argon, and the latter provides a greater depth of penetration in the center. The voltage drop across the arc column in helium is greater than in argon, so changes in arc length in helium have a more noticeable effect on the voltage and overall thermal efficiency.

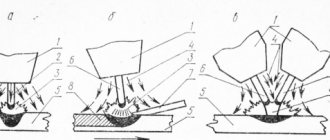

Change in the form of penetration depending on the properties of the inert gas

Depending on which inert gas is used, the surface tension at the metal-gas phase interface changes. Thus, the surface tension of liquid chromium-nickel steels with an austenitic structure when welding in helium is noticeably lower than in argon. This circumstance affects the formation of the weld reinforcement surface. In helium, there is a smoother transition of reinforcement to the base metal , which sometimes leads to a decrease in stress concentration in this area and improved performance of the welded joint. Therefore, in some cases it becomes advisable to use argon-helium mixtures in different mixing proportions.

The arc burning between a tungsten electrode and a metal in an argon environment has its own characteristics. The static characteristics of such an arc in argon, like the arc under a layer of flux, are positive. This is explained by the cooling effect of the gas jet and the high current density on the tungsten electrodes, which is 10-90 A/mm 2. The figure below shows the static characteristics for a tungsten arc burning in argon. It can be seen that at high currents and small arc gaps, the arc voltage Ud is less than the ionization potential Up.

- for argon Up = 15.7 V

- for helium Up = 25.4 V

The minimum arc voltage approaches the excitation potential of argon, the metastable state of which probably plays a significant role in this case. The voltage gradient in helium for large arc gaps is greater than for small arc gaps. The opposite phenomenon is observed in argon. Here, gas flow and electrode diameter have little effect on the nature of the dependence of the arc voltage on its length, but in helium, on the contrary, the arc voltage can be changed by changing the gas flow. The properties of the arc burning in argon between the tungsten electrode and the metal can vary depending on the properties of the metal and the composition of the gas mixture.

Static characteristics of a tungsten arc in argon for various arc lengths

The technological properties of a tungsten arc during welding deteriorate due to the rectification of alternating current (if used) and the appearance of a direct current component in the circuit.

Analysis of this phenomenon, carried out using oscillograms, shows that the degree of current rectification in the arc depends on the difference in the thermal time constants of the electrode material (heat capacity multiplied by the reciprocal of thermal conductivity). The greater the difference between these constants, the greater the degree of current rectification in the arc. For different electrode materials, the difference in their temperatures during arc burning is proportional to the difference in thermal time constants. However, the difference in cathode temperatures in different half-cycles of arc combustion leads to the appearance of a direct current component, and the degree of rectification turns out to be proportional to the difference in the thermal time constants of the electrode materials. Along with the difference in the thermophysical properties of the electrodes, the rectifying effect of the arc in argon is also affected by a change in the geometric shape of the electrodes. The highest value of the direct current component, due to the difference in thermophysical properties, is observed for the arc that occurs when using electrodes of the W - Al system.

Uхх – no-load voltage Uд – arc voltage Iд – welding current strength

DC component in the AC welding circuit for the W – Al system arc in argon

In half-cycles, when the cathode spot is located on the tungsten electrode (straight polarity), due to the powerful thermionic emission of the cathode, favorable conditions are created for the initiation and burning of an arc at low voltage. In half-cycles, when the cathode spot is on aluminum (reverse polarity), the cathode is cold and thermionic emission is difficult. In this case, higher maximum (peak) voltage values are required to initiate the arc, and the arc will burn at a higher voltage value than in the previous half-cycle. When welding at low currents, excitation of the arc during half-cycles of reverse polarity may not occur at all, and the arc will become a “rectifier valve”. This leads to a sharp deterioration in the stability of its combustion. In the presence of a constant component, the resistance of the transformer magnetic circuit increases significantly and the power given to the arc decreases. When the current decreases during half-cycles of reverse polarity, cathodic cleaning of the welded edges and the surface of the weld pool from refractory oxide films becomes more difficult. Therefore, installations for tungsten arc welding (especially aluminum and its alloys) must contain special devices (stabilizers, pulse exciters, capacitor banks, semiconductor valves), or supply pulses in a half-cycle of reverse polarity to facilitate arc ignition or partial (complete) suppression of the resulting DC component current.

source

Features of making a high-quality seam

The torch moves only along the axis of the seam, which gives a narrower and higher quality seam.

The end of welding and filling of the crater is accomplished by decreasing the current value. Under no circumstances should you stop welding by extending the arc.

The additive and the welding site must always be in a shielding gas environment.

Correct movement of the electrode:

- Horizontal seams are made from right to left, “away from you”, “toward you” . The W-electrode is aimed exactly at the corner. The filler wire is fed in front of the torch.

- Vertical seams : the electrode is directed precisely into the corner at an angle. The additive is supplied from above.

- Ceiling seams lead towards themselves . The burner is located almost vertically. The wire is fed in front of the torch.

Areas of application of argon arc welding

It is effective to use argon arc welding to create a transition between pipes of different diameters and when welding fixed pipe joints, for which various designs of automatic welding machines have been developed.

Although the aerospace industry is the main user of TIG welding, the technology is also used in a number of other areas, including in everyday life.

At your request, we will produce two or three-component mixtures for TIG welding with different ratios of incoming gases, for example:

- The gas welding mixture Ar /5 O ₂ ( 95% argon - highest grade (99.993%) and 5% oxygen GOST 5583-78, grade 1 (99.7%)) is used for welding thin metal with a consumable electrode, which increases the stability of the arc , the fluidity of the weld pool increases, metal fusion improves, which allows you to increase the welding speed compared to welding in argon.

- The gas welding mixture Ar/30He (70% argon - highest grade (99.993%) + 30% helium grade "A" (99.995%)) is used for:

√ semi-automatic and argon arc welding of stainless steels;

√ semi-automatic welding of aluminum alloys;

√ welding of non-ferrous metals and alloy steels.

The use of an Ar/30He mixture reduces the porosity of the metal in the welded zone and increases the strength of the joint.

Compared to welding in argon, penetration and welding speed increase, a more even surface of the weld is obtained, which significantly reduces the cost of welding wire.

- Gas welding mixture 50Ar/50He (50% Ar - highest grade (99.993%) + 50% He grade “A” (99.995%)) is used for:

√ argon arc welding of non-ferrous metals and alloy steels;

√ welding materials of almost any thickness;

√ welding materials of almost any thickness.

- Gas welding mixture He/30Ar (70% He grade “A” (99.995%) + 30% Ar - highest grade (99.993%)) is used for:

√ argon arc welding of non-ferrous metals and alloy steels;

√ TIG welding of thin materials, which can significantly reduce porosity, increase welding speed and reduce (possibly eliminate) the need for preheating.

A high helium content in the welding mixture produces a more productive welding arc.

LLC "Technical Gases" produces protective gas mixtures for welding in accordance with TU 2114-003-49632579-2009, corresponding to the main quality parameters:

√ ratio of components of the welding gas mixture;

√ homogeneity - the exact ratio of the layers of the constituent parts of the gas mixture;

√ purity – absence of foreign impurities in the gas mixture;

√ stability – the proper state of the mixture as a result of temperature and time changes;

source

Advantages and challenges of inert gas welding

Advantages:

- Possibility of connecting various metals, such as : different types of steel, aluminum and its alloys with magnesium, titanium, zirconium, copper, molybdenum, nickel, bronze, brass.

- This type of welding produces high-quality connections.

- Minimal deformation in the parts being welded due to the small heating area.

- Welding speed.

- A technique that is not difficult to master.

- Possibility of complete automation of the process.

Flaws:

- Joining dissimilar materials , for example, carbon steel with stainless steel, can result in pores in the welds.

- Low productivity compared to consumable electrode arc welding , not to mention semi-automatic and automatic welding.

- Quite a difficult method for manual welding . The welder needs to simultaneously feed a rod of filler material and work with a gas torch.

- After ignition outside the welding zone, the remaining mark must be cleaned.

- It is not very convenient to weld parts at an acute angle.

- When working outdoors, especially in windy weather, the consumption of inert gas increases.

How are welding gas mixtures supplemented?

Oxygen (O2) is a diatomic active component commonly used in gas mixtures for the electric arc welding process in concentrations below 10%. Oxygen has a heat input potential arising from both its ionization energy and its dissociation energy (the energy released by breaking a molecule into individual atoms in an arc).

The picture shows the name of the chemical element and its properties.

Oxygen creates a very wide and relatively shallow penetration profile with a high level of heat input at the surface. Because the high level of heat reduces the surface tension of the molten metal, jet transfer is facilitated, as is moisture at the weld located at the edge of the outer surface of the weld. O2/Ar mixtures exhibit a penetration profile at the nailhead level in electric arc welding of carbon steel, which is the most common application. O2 is also used in trimixes with CO2 and Ar, where it provides metal wetting and jetting benefits.

Hydrogen (H2) is a diatomic active gas that is often used in protective welding compounds in concentrations less than 10%. Hydrogen is primarily used in austenitic stainless steels to facilitate the removal of oxides or to increase heat input. As with all diatomic molecules, the result is a hotter, wider weld. Hydrogen is not suitable for working with ferritic or martensitic steels due to cracking problems. At higher concentrations (30-40%) H2 can be used to plasma cut stainless steels to increase power and reduce dross.

Nitrogen (N2) is the least commonly used additive for protective purposes. Nitrogen is mainly used to produce austenite and to improve corrosion resistance in duplex and super-duplex steels. For a more detailed introduction to this chemical element, read the article: technical nitrogen and its demand in the industrial sector.

Safety precautions

Welder personal protective equipment:

- A suit made of special fabric , consisting of trousers and a jacket with long sleeves.

- Welding gloves - hand protection.

- Mask for protection against ultraviolet arc radiation . With this type of welding, the arc burns much brighter than with gas welding, and produces stronger UV radiation - solar radiation. This is one of the main harmful factors during welding work in shielding gases.

- Welding helmet with opaque dark glasses - eye protection from arc flashes. This helmet completely covers the head and neck, protecting against UV burns. Modern helmets have liquid crystal self-darkening glasses (photochromic), which themselves regulate the dimming depending on the brightness of the arc.

Welding workplace equipment:

- Ventilation is required . During the TIG welding process, there is a risk of the formation of poisonous gases and toxic compounds of the materials used to clean and degrease the welding site. The formation of ozone and nitrogen oxides is also possible.

- Application of transparent welding shield made of PVC film . This will protect people nearby from the ultraviolet radiation of the welding arc.

Helium - solar gas

Helium is obtained from helium-containing natural gases, minerals and air (see Methods for producing helium)

Helium was first discovered during a solar eclipse in 1868. Astronomers first used spectroscopy to study the solar atmosphere.

On October 24, 1868, the French Academy of Sciences received two messages - from Pierre Jules Cesar Janssen from India and from Joseph Norman Lockyer from London - about their discovery of a new bright yellow line in the spectrum of the solar corona , which was subsequently given the symbol D3. The coincidence of two independent reports from different parts of the world indicated the possibility of spectroscopy methods to penetrate the secrets of the solar atmosphere and other distant stars.

The question of what substance line D3 corresponds to remained open for a long time. It was only established that in the spectra of elements known on our planet, a spectral line similar to the bright yellow D3 line has not yet been detected. Lockyer mistakenly believed that the hot gas emitted by the mysterious D3 line was a modification of hydrogen not found on Earth.

In August 1871, Kelvin stated that the D3 line had not yet been identified with any terrestrial element. It is possible that it belongs to a new substance, which Lockyer and Jansen proposed to give the name helium (from the Greek word helios - sun).

In 1895, Sir William Ramsay was studying the gas he isolated from the mineral kleveite and unexpectedly discovered a bright yellow line in a Heusler tube. The outstanding spectroscopist of the time, William Crookes , determined the wavelength of the new line (5874.9 A) and established that it was the D3 line, on this basis Ramsay announced (March 23, 1895) his discovery of helium on Earth. This is the story of the discovery of the most important representative of the group of inert gases - helium, which was first discovered in the solar atmosphere, and then (27 years later) on Earth.

Helium was soon discovered in other minerals and rocks containing uranium. The presence of helium in the earth's crust allowed us to draw a conclusion about its content in the atmosphere, although many scientists argued that this light gas released from the earth's crust is completely carried away from the atmosphere into outer space. Soon, Heinrich Kaiser, and then Siegbert Friedländer (1896), as well as Edward Beley, as a result of analyzing the first evaporated fraction of liquid air, proved the presence of helium in the atmosphere .

In industry, helium is used on a smaller scale than argon. Most often it is used:

- coolant – cooling of superconducting magnets in medical MRI scanners;

- metallurgy – smelting of pure metals;

- underwater rescue - as part of breathing mixtures;

- welding production - shielding gas;

- in the entertainment industry - filling balloons.

Due to the fact that helium is approximately 10 times lighter than argon, which reduces the effectiveness of protection of the weld pool when welding in the lower position, but provides better protection when welding in the ceiling position, therefore, helium consumption during welding increases by 1.5-3 times.

It is used mainly for welding chemically pure and active materials and alloys, as well as alloys based on aluminum and magnesium.

Helium is becoming preferable to argon when additional seam protection is needed when welding in the ceiling position. Especially when welding titanium alloys and other chemically active metals that absorb nitrogen and oxygen not only in the molten state, but also in the solid state when heated above a certain temperature.

However, not only the protective properties of argon and helium are different. The characteristics of the arc in these gases are also different. Thus, at the same current strength, the arc voltage in helium is significantly higher than the arc in argon . Such an arc has a greater penetration capacity and is less concentrated (it creates a different form of penetration, more uniform, while an arc in argon when welding, for example, titanium alloys with a tungsten electrode gives a large penetration in the center and much less at the edges of the pool). The voltage drop in the arc column in helium is greater than in argon, so a change in arc length has a more noticeable effect on the voltage and its overall thermal efficiency (see the article “Properties of a welding arc in inert gases - argon and helium”).

Weld shape and penetration for various shielding gases

Depending on the use of argon or helium, the surface tension at the metal-gas phase interface also changes. Thus, for chromium-nickel steels of the austenitic class, the surface tension of the liquid metal when welding in helium is noticeably lower than in argon. This also affects the formation of the surface of the seams. Smoother transitions from the weld to the base metal when welding in helium also occur for other metals, in particular titanium alloys, and in some cases affect some performance characteristics of welded joints.

The cost of helium is much higher than argon, so it is used mainly for welding chemically pure and active materials and alloys, as well as alloys based on aluminum and magnesium.

Most often, helium is used to form inert gas mixtures . Having a higher density than helium, such mixtures better protect the metal of the weld pool from air and increase welding productivity in general. The mixture fully realizes the advantages of both gases:

- argon - ensures arc stability;

- helium - provides a high degree of penetration.

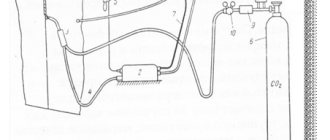

Methods for determining the proportion of impurities and helium supply conditions are regulated by GOST 20461. Helium is transported and stored in a gaseous state in steel cylinders at a pressure of 15 MPa or in a liquefied state at a pressure of less than 0.2 MPa.

Helium cylinders are painted brown with the inscription “HELIUM” in white letters . Cylinders must comply with the requirements of GOST 949.

source