Semi-automatic welding is mechanized arc welding with a metal consumable electrode (wire) in a shielding gas environment. The method is also known as MIG/MAG welding. Depending on the type of shielding gas used, a distinction is made between inert gas (MIG) and active gas (MAG) welding. Welding in a carbon dioxide environment is predominantly used as active gases. Unlike manual arc welding with coated electrodes, in mechanized welding, the electrode is supplied to the welding zone using mechanisms, and the welder moves the torch along the axis of the seam and performs oscillatory movements with the electrode as necessary.

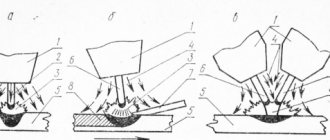

Rice. 1. 1 – torch, 2 – nozzle, 3 – current-carrying tip, 4 – electrode wire, 5 – arc, 6 – seam, 7 – bath, 8 – base metal, 9 – drop of metal, 10 – gas protection.

Description and principle of operation of semi-automatic welding

Welding is carried out in an atmosphere of inert gases to avoid unwanted oxidation of the material of the joints and seams. The welding unit pumps gas (most often argon) to the welding site under slight excess pressure, thus displacing air oxygen from the working area. The electrode is a thin wire stored on a drum inside the welding machine. Both gas and wire are supplied to the working area by a special mechanism through reinforced tubes and then through the pistol grip of the welding torch.

The mass is supplied to the part using a clamp, as in conventional manual electrode welding. Plus is fed to the welding wire. The welder opens the gas supply valve and regulates the pressure, after which he turns on the feed mechanism at the speed specified by the technical conditions and touches the part with the tip of the electrode protruding from the torch. An electric arc occurs, the electrode melts and is used as solder. The edges of the parts to be joined are heated by an electric arc and welded together. The inert gas forms a protective atmosphere, preventing unwanted oxidation.

It is also possible to use a semi-automatic machine without gas for welding ordinary ferrous metal, for which specially designed grades of welding wire are used.

Increasing CO2 welding productivity

Method of increasing the welding current

Welding in CO2 is often carried out in forced modes with an increased welding current. For a wire with a diameter of 1.2 mm, the current is 350-380A, and for a wire with a diameter of 1.4 mm - 400-450A. But a simple increase in current is only permissible when welding seams in the lower position.

When welding vertical and ceiling seams, the current can be increased only if the crystallization rate of the weld pool is increased. The rate of crystallization can be increased by imparting oscillatory movements to the welding wire along and across the seam, as well as by periodically turning off the wire feed. When the wire feed is turned off, the arc dies out, and by the time the arc is next ignited, the metal has time to partially crystallize.

Welding with increasing welding wire extension

This method of increasing productivity is especially effective if thin wire is used. Increased productivity is achieved due to the fact that the wire is fed into the welding zone already heated to a high temperature, so its melting rate increases and the volume of molten metal increases.

To avoid spontaneous movement of the end of the welding wire when it extends long, special tips made of porcelain or ceramic tubes are used. With an increase in the overhang length by 40-50mm, welding productivity and the volume of deposited metal increases by 30-40%. But the depth of penetration of the base metal is slightly reduced.

How to choose wire for a semi-automatic machine

To choose the right welding wire for semi-automatic machines, you need to take into account many important parameters:

- The main material to be welded.

- Material thickness.

- Welding method (gas or not).

- Welding machine power.

and some others.

So, for working with low-carbon steel, grades with low carbon and silicon content are suitable. They can be welded with copper-plated solid wire without the use of inert gas. This material is used for automatic and semi-automatic welding.

For alloyed, high-strength and stainless steels, materials with a similar content of alloying additives are selected, and the work is carried out in a gas atmosphere.

Gas welding process

Aluminum, due to its high chemical reactivity, should be welded in an argon atmosphere; the welding material should be of solid cross-section with a composition close to that of the specific alloy. To avoid the formation of an oxide film, aluminum wire should be stored in sealed packaging and unpacked immediately before loading into the machine and starting welding. Chemical or mechanical treatment of the welding area and welding material is often carried out.

Copper and its alloys are welded in an argon protective atmosphere

Copper and its alloys are also welded in an argon protective atmosphere. For copper, wire has the following subgroups:

- pure and low-alloy products;

- bronze;

- castings and rolled products.

Ferrous metals, cast iron or nickel have high heat resistance and corrosion resistance. For them, flux-cored wire of the rutile group with a sufficient nickel content will be optimal.

Self shielding cored wire

Surfacing grades of welding materials are used for welding different metals

The wire diameter for semi-professional semi-automatic machines is most often 0.3-2 mm. If you have sufficient experience and skill, it is possible to use the same diameter for different operations, but for a novice master it is better to stick to the reference table included with the semi-automatic machine.

Rules for working with a semi-automatic machine

We list a number of requirements, or rather rules, that should not be neglected when using an automatic welding machine:

- Before starting to operate the semi-automatic welding machine, you should carefully study the operating instructions;

- when welding, you need to ensure strict polarity - “plus” should be on the torch, and “minus” should be on the part being welded;

- To avoid unpleasant situations associated with human injury, when threading wire into the torch, you should not point the nozzle at yourself or other people. Here you need to be very careful, because the end of the wire can pierce your palm or other part of the body;

- It is strictly forbidden to move the semiautomatic device during operation by pulling it by the burner or cable; there are handles for this;

- in order not to damage the eyes and other parts of the face, you should work with a semi-automatic welding machine only in a special protective mask that has a light filter, the marking of which must correspond to the current range used in welding, and for additional protection you should use glasses with glass lenses, since glass does not transmit ultraviolet radiation;

- for long and trouble-free operation of the device, it is necessary to clean all its insides from dirt and dust twice a year;

- if, during an external inspection of the device, damage was discovered in the cable or burner sleeve, they must be immediately eliminated using insulating tape or heat-shrink tubing, and it is better to replace worn parts with new ones;

- the shape of the groove must clearly correspond to the electrode material: V-shaped smooth is used for solid steel wire, V-shaped with notches for flux-cored wire, U-shaped for alloys and soft metals;

- during operation, it is prohibited to touch the live parts of the semi-automatic welding machine, as well as to work with its covers removed;

- the room in which welding is performed must be well ventilated, since aerosols released during work are extremely harmful;

- Fire safety rules should be strictly observed;

- We must not forget that during welding the welding seam heats up to very high temperatures, so it is strictly forbidden to touch these places;

- It’s no secret that a semi-automatic machine, like any welding machine, is a source of electromagnetic radiation, which has an extremely harmful effect on human health. Not all people can work in such conditions, so you must first undergo a medical examination;

- It is strictly forbidden to weld vessels and pipelines together with liquids, as well as vessels in which flammable and flammable liquids were previously stored;

- do not overload the semi-automatic machine, work only under the conditions specified in the operating instructions, since this, firstly, is dangerous to the health of the operator, and, secondly, reduces the service life of the semi-automatic machine itself;

- since a person is a carrier of static electricity, touching the elements of the electronic board is strictly prohibited, in this case they may breakdown;

- The lid of the feed mechanism niche must be tightly and securely closed during operation so as not to become a source of injury to the operator;

- welding should not be performed in a continuous mode, it should be alternated with regulated breaks, the duration of which and the intervals between them should be selected in accordance with the manufacturers' recommendations;

- while operating the semi-automatic welding machine, it is strictly forbidden to switch the stages of the transformer installed on the welding power source;

- all welding work should be performed only in clothing specially designed for this purpose, in addition, clothing must be completely dry in order to protect yourself from possible electric shock;

- The flow rate of the shielding gas, which can be argon, helium, carbon dioxide or mixtures thereof, must be calculated optimally, since it forms a protective environment in the arc zone; in addition, the gas must be selected in accordance with the type of material being welded, as well as its thickness. The cylinder must be secured horizontally and securely enough.

Types of general purpose wire

Depending on the base material and type of coating, semi-automatic welding wire is divided into 4 main types:

- Copper-bonded is the most popular and is used for welding low-alloy structural steels of general grades.

Copper-plated filler wire

- Powder - does not require a protective atmosphere for use. The gas, which insulates the weld pool from air, is released during the evaporation of powdered additives.

Flux Cored Welding Wire

- Stainless steel - a solid section, obtained by cold drawing from high-alloy alloys.

Wire for welding stainless steel

- Non-ferrous – for welding non-ferrous metals such as aluminum or copper. Selected according to a composition close to the composition of the material being welded.

Colored Welding Wire

Other types of welding materials are also produced for semi-automatic machines, but they are used for highly specialized applications and are used relatively rarely.

Copper-plated product

Copper-plated semi-automatic welding wire is excellent for working with low-carbon and low-alloy steels in an atmosphere of inert gases. It has high corrosion resistance and allows you to get a strong and durable seam. Copper-coated wire is also used for surfacing. It has an affordable price and a constant chemical composition.

Copper-plated wire for semi-automatic welding

The disadvantage of copper-plated wire is the evaporation of copper during the welding process, which significantly worsens working conditions and requires the use of insulating masks with a forced supply of clean breathing air.

Settings for work

This method of metalworking involves working with machines. We are talking about both the use of a source of electricity and the operation of a semi-automatic device. Usually the well-known outlet works, but only when the power supply is uninterrupted.

There is a need to work with a device that is responsible for supplying wires. Pay attention to the choice of replacement structures. Let's talk about these moments.

Powder electrode

The main reason for the popularity of powder-cored welding electrodes is the ability to weld without the use of shielding gas. The wire is a thin-walled metal tube filled with specially prepared powder. Several more tubes may be formed within the tube to provide sufficient rigidity. The thickness of flux-cored welding wire varies from 0.9 to 1.5 mm.

Depending on the composition of the powder, several subtypes are distinguished:

- fluorite;

- carbonate-fluorite;

- rutile;

- rutile-fluorite;

- rutile-organic.

The principle of using such welding wire material is based on the evaporation of powder flux additives and the formation of protective gas bubbles from these vapors, protecting the weld pool from contact with atmospheric oxygen.

Flux-cored wire for semi-automatic welding

The main advantage of flux-cored wire is the ability to do without the supply of inert gas and work even in strong winds.

The disadvantages are the high price and increased fragility. If it breaks, the welding material has to be thrown away.

Features of semi-automatic welding in shielding gases

Well, we’ve come to the features of semi-automatic welding in shielding gases. First, let's finally define it... Semi-automatic welding is usually called PA or MIG. Such welding is an improved version, even a revolutionary solution. With its help, the quality of welds was improved in some cases. Moreover, work productivity has increased. Now, the same metal structures and products can be produced much faster, with the same quality of seams.

Also, among the features of semi-automatic welding in shielding gases, I would like to include the fact that there is no need to knock the slag off the seam. Which improves the aesthetics of the workplace. And also, during welding, much less combustion products are released. And this increases the health safety of the welder.

Attention! An important topic is safety precautions when performing welding work. Compliance with which is mandatory for everyone!

I would like to draw your attention to a few more features.

- The copper current-carrying tip is selected depending on the diameter of the wire used.

- The wire feed speed depends on the set current and per revolution.

- The operating gas pressure should be carefully adjusted so as not to overdo it. If a lot of gas is exposed, the welding will feel much harsher, and the seam will not be as beautiful and high-quality.

- When performing work outdoors, take into account the presence and strength of wind. If wind is present, add operating gas pressure. Or cover the welding area with a screen. Otherwise, the wind will blow the gas away. As a result, the weld pool will remain unprotected. And these are pores and other defects in the weld.

- Don't forget to clean the nozzle and tip of any dirt. Otherwise, problems with the quality of the seam will arise.

- The semi-automatic machine really does not like welding on painted surfaces, as well as rusty and dirty ones.

Conclusion

Semi-automatic gas shielded welding is an excellent solution for stationary work in a workshop. Provides high productivity and seam quality. If you have decent skills, there is no need for additional seam stripping.

The ease of mastering semi-automatic welding arouses the interest of amateurs. And it’s not in vain. After all, PA is perfect for garage and household work.

Don't forget to rate the article, repost and, if necessary, leave comments! Thank you for your attention and understanding!

Stainless flexible electrode

Flexible electrodes for welding stainless steel are produced by cold drawing from high-alloy steel alloys.

They have the following positive qualities:

- refractory;

- corrosion resistant;

- resistant to aggressive environments;

- long shelf life;

- provide excellent seam quality.

Stainless flexible electrode

A noticeable disadvantage is the high cost of such welding material. This hinders its widespread use.

Non-ferrous metals

It is not so easy to qualitatively weld non-ferrous metals or their alloys. It is necessary to carefully comply with the requirements of technical specifications and the correct selection of consumables and equipment.

Copper and its alloys

The welding process is strongly influenced by the following high properties of copper itself and its alloys - bronze and brass:

- thermal conductivity;

- reactivity with hydrogen;

- coefficient of thermal expansion.

These properties can lead to insufficient strength near the seam area and the seam itself, increased metal fluidity and the appearance of hot cracks. Therefore, when working on copper and its alloys, wires with a high tungsten content give the best results. This allows you to reduce the evaporation of zinc and tin and preserve the chemical composition and physical properties of the material.

Aluminum and magnesium alloys

The surface of parts and workpieces made of such alloys is constantly covered with a layer of refractory oxides, which prevent the melt from the weld pool from fusing with the base metal of the parts. The remains of this difficult-to-remove layer in the form of slag inclusions can get into the weld material, significantly deteriorating its quality.

When operating with reverse polarity current in the electric arc zone, cathodic cleaning of parts is carried out. But this technique allows you to remove only a thin layer of oxides. Therefore, before welding, the oxide layer should be removed by acid treatment or cleaning. It is also important to remember to remove the oxide layer from the surface of the welding wire.

Argon welding of aluminum

Alloys AB, AK6, AKV are especially susceptible to hot cracks during welding, so it is recommended to use wire containing about 5% silicon for them.

Welding is carried out in an atmosphere of pure argon, or in its mixture with helium.

Activated wire

This welding material is close in composition to flux-cored wire, but special additives are added to it, optimizing parameters in the weld pool area and preventing metal destruction during and after welding. Structurally activated wire is designed differently than flux-cored wire. The percentage of additives is significantly less and does not exceed 6-8% of the total linear weight. In this case, additives are not poured into the cavity, but are built into the body of the wire in the form of thin channels, and the material combines the advantages of solid wire and flux-cored wire. Due to the small proportion of additives, welding with such wire can only be carried out in an inert gas atmosphere.

Additives are easily ionized compounds of light metals and slag-forming components that improve the stability of the operating parameters of the weld pool. They increase the stability of the electric arc.

The following advantages of activated wire can be formulated:

- Wide range of compatible equipment. Wire, unlike flux-cored wire, allows bending and does not require specialized feeding devices.

- High quality of the seam due to lower surface tension of the workpieces being joined and low hydrogen saturation.

- Reduces current consumption by protecting the welding area from excessive heat loss.

Welding wire

The main disadvantage of activated wire is the need to use gas. This increases the complexity and cost of the operation.

The essence of the carbon dioxide welding process

The essence of welding is as follows. The carbon dioxide supplied to protect the welding zone breaks down into carbon monoxide and oxygen under the influence of the high temperature of the arc. The decomposition process occurs according to the reaction:

2CO2 = 2CO + O2

As a result of the reaction in the welding zone, a mixture of three gases is formed: carbon dioxide (CO2), carbon monoxide (CO) and oxygen (O2). The flow of these gases not only protects the welding zone from the harmful effects of atmospheric air, but also actively interacts with iron and carbon contained in the steel according to the reactions:

Fe + CO2 = FeO + CO 2Fe + 2CO2 = 2FeO 2C + 2CO2 = 4CO 2C + 2O2 = 2CO2

The oxidative effect of carbon dioxide can be neutralized by introducing excess silicon and manganese into the welding wire. Silicon and manganese are chemically more active than iron, therefore, they are first oxidized by the following reactions:

Mn + CO2 = MnO + CO Si + 2CO2 = SiO2 + 2CO 2Mn + O2 = 2MnO Si + O2 = SiO2

As long as more active silicon and manganese are present in a free state in the welding zone, oxidation of iron and carbon does not occur.

Good quality of welded joints when welding carbon steels is ensured when the ratio of the amount of manganese to silicon is: Mn/Si=1.5…2. The oxides of silicon and manganese formed during the welding process do not dissolve in the weld pool, but react with each other, forming a low-melting compound, which is quickly brought to the surface of the liquid metal in the form of slag.

Best Solid Welding Wire

Solid wire is used when working with high-carbon and low-alloy structural steels. Available in two versions

- Copper plated.

- Not copper-plated.

Copper-clad wire for welding

Copper plating significantly improves the corrosion resistance of the seam, but during welding it saturates the air with copper vapors that are harmful to health. In order to protect labor and create favorable working conditions, non-copper-bonded wire equipped with anti-corrosion coatings is increasingly being used.

Aluminum welding wire

Non-copper-clad solid wire is also divided according to purpose for:

- high-carbon and low-alloy steel grades;

- high-alloy and refractory steel;

- stainless steel;

- alloys of copper and aluminum.

Types and markings of welding wire

Russian Federation standards describe about 80 different grades of welded wire. However, in practice, no more than a dozen are widely used.

Welding wire marking

The remaining grades are highly specialized materials for special and rather rare applications, such as:

- manufacturing of nuclear reactors, internals and nuclear power components;

- aerospace industry;

- specialty shipbuilding, including submarine hulls and armor;

- equipment for production, transportation and processing of oil and gas;

- housings and equipment for chemical reactors;

- other high technology industries.

The wire designation consists of several groups of numbers and symbols:

- diameter in millimeters;

- destinations:

- actually for welding “St”;

- for surfacing - “Np”.

- carbon content in hundredths of a percent;

Symbols of alloying elements

- content of alloying additives as a percentage; if the content is less than 1%, then it is not indicated:

- X-chrome.

- N-nickel.

- M – molybdenum.

- C – silicon.

- N – nickel.

- X – chrome.

- C – zirconium.

- G – manganese.

- A - nitrogen.

- B - tungsten.

- T - titanium.

- Yu - aluminum.

- F - vanadium.

- B - niobium.

- D - copper.

- C - silicon.

- Requirements for material purity.

- A - purified.

- AA - special purity.

- Smelting method.

- VI - vacuum induction.

- VD - vacuum-arc. Sh. - electroslag.

- For the production of electrodes - letter E.

- Copper plated - letter O.

- Link to GOST.

So, for example, from the designation you can find out that the Sv-08G2S brand contains 0.08% carbon, 2% manganese and less than 1% silicon. This filler wire is suitable for gas welding of alloy steel.

Marking of the brand Sv-08G2S

The world's leading welding wire manufacturers - ESAB, Autrod and others - use their own designation systems that comply with American or European standards. Dealers of these companies always have at the ready tables of correspondence between their brands and the brands provided for by GOST.

Welding wire diameters

General purpose welding wire is available in diameters from 0.3 to 12 mm. The most widely used diameters are from 0.8 to 2 mm.

For example, a 2 mm wire allows you to weld metal from 3 to 5 mm thick. Another parameter to choose is the welding mode, primarily the current strength. There are special tables for selecting the thickness of welding wire.

Basic welding parameters

It is important to remember that if your power supply network has low or unstable voltage, then it is better to reduce the diameter of the welding wire to avoid under-welding.

Semi-automatic welding technique in various positions

Semi-automatic welding is quite simple. As you understand, workpieces and parts can be welded in various spatial positions. And for each position, there are its own nuances and features. First, let's look at what welding positions there are.

- Lower

- Ceiling

- Vertical

- Horizontal

- Angular

In the list above, you can familiarize yourself with the existing locations of the joints of the welded parts in space. Simply put, the spatial positions of the future or present seam.

Next, we should familiarize ourselves with the possible types of arrangement of welded joints in relation to the joints to each other.

- Tavrovoe

- Angular

- Overlapping

- Butt

- End

Semi-automatic welding butt joints

When carrying out welding work, the type of connection should be taken into account. So, if you are faced with a butt joint , pay attention to the thickness of the metal. If the metal is thin, from 1 to 3 mm, use a copper backing. With its help, we will prevent metal from dripping, and therefore minimize the risk of burn-through. Moreover, if possible, position the joint vertically and weld it from top to bottom. This makes it easier to weld thin metal. If, during butt welding of parts, the metal thickness is more than 3 mm, but not more than 5 mm, a small gap should be set. A gap of 1-2 mm will be enough for decent penetration. For thicker metal, whose thickness is more than 5mm, it is necessary to cut the edges. Only in this case will it be possible to achieve sufficient penetration of the welded joint.

Have you visited the consumables section yet? Be sure to visit, we have prepared more than one interesting article for you!

Semi-automatic welding of tee and corner joints

T-joints and corner joints if you arrange the parts in such a way that the corner joint is accessible for welding using the so-called “boat”. At the same time, it is necessary to increase the wire overhang by 9-14%. Moreover, the welding arc should be controlled so as not to make undercuts on the walls of the parts being welded.

Semi-automatic welding of lap joints

Overlapping parts with a thickness of 1 to 2 mm are easier to weld with a copper plate placed under them. This way we minimize the chance of burnout. Those parts whose metal thickness is more than 2 mm can be welded without a copper plate. For thicknesses greater than 5mm, it is recommended to weld in several passes.

Semi-automatic welding of horizontal seams

We smoothly move on to semi-automatic welding of horizontal seams . Welding is performed with the torch angle forward. Do not make oscillatory movements when welding thin metal. If you need to weld workpieces made of thick metal, cut the edges.

Vertical seams semi-automatic welding

Welding vertical seams . If the metal is thin, weld from top to bottom. With medium thicknesses, the same thing, from top to bottom, only with oscillatory movements. To weld parts made of thick metal, you should cut the edges and weld from bottom to top, with oscillatory movements.

Semi-automatic welding of ceiling seams

When welding ceiling seams, it is necessary to take into account the thickness of the metal. Thin metal is best welded with a backward angle, and thick metal with the torch angle forward. Also, do not forget about cutting edges with thick metal and oscillatory movements.

Welding wire consumption control

In order to manage the cost of welding work, it is necessary to control wire consumption.

The key factors determining consumption are:

- chemical composition of the metal;

- wire diameter and quality;

- characteristics of the welding unit;

- use of shielding gas.

A widely used standard for the consumption of welding material, depending on the length of the seams and the complexity of the product, is considered to be 1-2% of its total mass. To this amount add 6% for waste and wire loss

Modern mechanisms and welding wire feed speed

Modern semi-automatic units are divided according to the type of welding:

- in inert gases;

- using cored wire;

- submerged;

- universal.

Units for working with inert gas are equipped with an automatic valve that cuts off the gas supply when welding is stopped. Units for working under submerged arcs are equipped with a burner with a funnel. They use thicker wire, so they have a stronger feed mechanism.

Depending on productivity, duration of continuous operation and resource, units are divided into:

- Household.

- Semi-professional.

- Professional.

According to the degree of their mobility, semi-automatic welding machines are divided into portable, mobile and stationary.

Industrial units are equipped with three-phase power supply. They can work around the clock without shutting down for cooling and allow you to weld high-quality, durable and even seams.

Units for working with flux-cored wire are equipped with an improved feed mechanism that prevents deformation and creases of fragile wire. Universal semi-automatic machines have additional equipment:

- welding torches;

- special nozzles;

- improved feed rollers.

which allows them to be used in many operating modes

Feeding mechanism (broaching) of semi-automatic welding machine

The wire feed system includes:

- Electric motor.

- Transmission.

- Reinforced tube.

- Feed rollers.

In relation to the burner, the supply system can be pull, push or pull-push. In a push system, rollers are placed near the inlet of the torch hose and push the wire into the torch channel. With a pull feed system, the rollers are placed directly in the burner. This makes the torch heavier, but increases the stability of the wire feed and reduces the likelihood of deformation and creases. Pull-push feed is used for long lengths of reinforced hose in professional distributed welding stations.

There are two ways to adjust the feed speed. The first uses a three-phase asynchronous electric motor, and the speed is adjusted in steps by changing gears in a gearbox reminiscent of a car. The second option is used in cases where it is important to provide very fine adjustment of the feed speed, for example, when welding thin sheets of metal. The electric motor operates on direct current, and its rotation speed is controlled by an electronic circuit with an accuracy of several revolutions per minute.

Operating principle of semi-automatic machine

Semi-automatic welding machines are mostly simple equipment. Its main parts are an adjustable direct current source, which supplies the welding voltage, as well as a special mechanism designed to feed the welding wire into the welding arc zone, and the feed is performed at an adjustable speed.

The arc has reliable protection thanks to the gas flow created by the burner, where it enters from a cylinder with the same gas. The electrode feed speed and welding voltage are adjusted simultaneously.

As already mentioned, the welding wire must be fed into the arc zone at a strictly defined speed. Only in this case will the welding process proceed stably. Otherwise, at the slightest break in the wire feed, the arc breaks, and this leads not only to a decrease in the quality of the weld, but also to other more serious consequences, which include, first of all, burn-through of the seam, melting of the electrode tip and other failures and defects.

For high-quality feeding, it is necessary to check the drive rollers before work. It is necessary that the feed roller has a V-shaped groove, the size of which must match the size of the wire, and that this groove is in good condition, that is, not worn out.

Often when people experience poor feed, they will increase the clamping force on the drive rolls, which can only make the feed worse as the wire can become deformed. In addition, the burner guide channel can be damaged for the same reason.

During operation, the welding wire passes through the torch through a guide channel, which over time tends to become dirty and wear out. As a result, the resistance of the electrode feed increases, until the wire stops completely.

This should not be allowed; it is better to notice these changes in time and replace the guide channel with a new one, installing which you need to be very careful, since if its length, external and internal diameters do not match, serious feeding problems may arise. In other words, the whole point of replacement is lost and normal welding is still not possible.

In order to reduce wire contamination, as well as premature wear of the guide channel, it is better to choose a semi-automatic machine with a closed feed mechanism. This approach to wire feeding significantly better protects it from dust, moisture, oxidation, etc.

Now a few words about the contact tip of the torch, through which the actual welding current is supplied to the electrode (welding wire). It is clear that for high-quality welding, the wire must have high-quality and reliable contact with this tip. It is necessary to monitor the degree of wear of this part of the semi-automatic welding machine in order to replace it in a timely manner.

All these seemingly little things are of great importance for high-quality welding performed using a semi-automatic machine. Good condition of equipment is the key to success, and poor care of it is the first and surest step to the occurrence of all kinds of malfunctions.

Advantages and disadvantages

The main advantage of welding wire is the high quality of the resulting weld by a welder of average or even initial qualifications with little experience. To achieve comparable quality with traditional stick electrodes, a highly qualified welder with extensive welding experience is required.

The second indisputable advantage is the possibility of long-term work without interruptions to change the electrode, which ensures welding of long seams in one step and improves both the technical quality and the aesthetic impression of the seam.

Another important advantage is the simplicity and convenience of working in an atmosphere of protective gases. When welding with conventional electrodes, it would be necessary to place the product and the welder in an insulating gas mask in a sealed chamber, greatly increasing the labor intensity of the work and gas consumption.

The disadvantage of the method is the high cost of materials and equipment, however, taking into account the lower required qualifications of the welder and the lower labor intensity, the cost per linear meter of welding is lower.

Stainless steel welding

It is carried out in a protective atmosphere of argon due to the increased chemical activity of stainless steel in a heated and molten state.

In addition, large casting shrinkage, as well as reduced electrical and thermal conductivity of stainless steel, leads to the need to select special welding modes.

Wire for welding stainless steel

For welding stainless steel, full-section wire made of high-alloy steels is used, selected according to the similarity of the composition to the material being welded. For especially critical products, tungsten wire is used.

Wire for welding stainless steel

Flux-cored wire is also used for welding stainless steels without supplying shielding gas from a cylinder.

Gas selection

Either argon or carbon dioxide is used as a protective atmosphere.

Sometimes, to reduce the cost of the operation, acetylene is chosen as a gas, but it is explosive and requires a lot of experience from the welder.

The use of flux-cored wire allows you to do without gas, but this mode also requires high qualifications and is not recommended for particularly critical products.

Stainless steel welding technology in a carbon dioxide environment

When welding stainless steels, the following conditions must be met:

- Use reverse polarity mode.

- Do not allow the wire to fly out more than a centimeter.

- Monitor gas consumption, it should be from 6 to 12 m3 per minute.

- Use a desiccant - copper sulfate.

- Use chalk solution as splash protection.

- Operate the burner smoothly, without jerking.

- Move at least 5 cm from the edge of the part.

Metal preparation

- It is necessary to clean the welded edges and the surrounding area from contamination with a steel brush.

- Degrease surfaces with white spirit or a special solvent.

- Treat the surface with a special anti-metal splash agent. This will help reduce post-op stripping to a minimum.

- Achieve a welding gap sufficient to compensate for shrinkage.

Welding technical diagram

Due to the low thermal conductivity of stainless steel, in order to avoid overheating of the welding zone, operating current values are used that are 15-20% lower than when welding conventional structural steels.

Welding technical diagram

In addition, it is necessary to ensure a minimum welding gap sufficient to compensate for casting shrinkage

Semi-automatic welding

Metalworking in protective gases is possible under the control of a semi-automatic mechanism. The latter is considered a separate apparatus and at the same time a whole complex of mechanisms. We are talking about gas cylinders.

Work usually takes place either at a post, on a machine, or without a post. A typical semi-automatic machine for working in a protective nitrogen environment looks like this: a design consisting of an electricity source, a device for supplying wire, a light, a cable, a cooling apparatus, a gas supply system and other structures.

The purpose of the welding machine differs depending on the type of working gas. MAG welding uses active nitrogen, while MIG welding uses passive nitrogen. The first type of welding cannot use the second type of gas, and vice versa.

To avoid thinking, buy a universal device that can work with two types of gas. You will increase your welding capabilities.