The welding arc has been used by mankind for the permanent, hermetically sealed connection of metals for more than a century. The physicist Volt studied it. Then welding devices appeared. An electrical discharge occurs when there is a short circuit between the electrode and the part being welded. Electrical energy is converted into thermal energy and a melt pool is formed. A diffuse homogeneous layer of metal is created at the site of the welded joint.

Having studied the current-voltage characteristics of the process, scientists improved the welding process and created welding machines that support stable arc burning.

What is a welding arc, definition

What can be called a welding arc is, in fact, a long-lasting conductor consisting of ionized particles, existing in time thanks to a supporting electric field. An arc discharge is characterized by a continuous form, high temperature, and occurs in a gas environment capable of ionization.

In welder's textbooks, the definition of a welding electric arc is as follows: this is a long-term electrical discharge in a plasma consisting of a mixture of ionized air or shielding gases, as well as evaporated components of the filler and base metal.

Nature and structure

In a short time, the metal can be heated to its melting temperature using a powerful welding arc. Its properties are characterized by current density and current-voltage indicators. From the point of view of electrical engineering, an arc column is an ionized gas conductor between the cathode and anode with high resistance and the ability to glow. A detailed examination of the structure of the welding arc will help to understand the essence of temperature effects. The average length of the electric arc is 5 mm, it is divided into main zones:

- anodic, it is no more than 10 microns;

- cathode, it is 10 times smaller than the anode;

- pillar - a visible luminous strip.

The temperature of the welding arc is determined by the flow of free electrons. They are formed at the cathode spot. It heats up to 38% of the plasma temperature. In an arc column, electrons move towards the anode and positive particles move towards the cathode. The column has no charge of its own; it remains neutral. Inside, the particles are heated to 10,000°C, while the metal is heated on average to 2350°C, the standard temperature of the melt bath is 1700°C.

The place where electrons enter and are neutralized is called the anode spot. Its temperature is 4–6% higher than that of the cathode.

The voltage in the anode and cathode zones is significantly reduced, and no glow occurs. Only plasma that emits ultraviolet, infrared and light waves is visible. They are harmful to the organs of vision and skin. Therefore, welders use personal protective equipment.

Welding arc structure

For direct and reverse polarity

DC welding can be performed in 1 of 2 ways:

- “Plus” is connected to the workpiece, i.e. it becomes the anode. This polarity is called straight.

- A minus is connected to the workpiece, so that it becomes the cathode. This is reverse polarity.

DC welding can be done in a variety of ways.

When welding with a refractory electrode, the anode spot is hotter than the cathode spot, so the first method is used to join parts of medium or large thickness. Strong heating ensures deep penetration and, as a result, high strength of the seam.

Reverse polarity connection is used to connect thin-walled workpieces. Otherwise they will burn out.

When welding with a consumable electrode, the anode spot is colder, so they do the opposite.

Types of welding arc

There are several criteria for classifying a welding arc. Based on the type of welding current and the position of the electrode relative to the elements being welded, the following varieties are distinguished:

- direct action, the discharge is perpendicular to the workpiece, parallel to the electrode;

- indirect action, the discharge occurs between two electrodes inclined to each other at an angle of 40 to 60°, and the metal.

Column plasma composition classification:

- open type occurs in the air atmosphere due to components evaporating from the coating and metal;

- closed, arising under the layer of flux due to the gaseous phase formed from particles of the electrode, metal, and flux components during the passage of the discharge;

- with the supply of a gas mixture or one-component protective gas.

Types of welding arc

The division of the welding electric arc into types is carried out on the basis of several characteristics. Thus, according to the criterion “Type of electric current and location of electrodes in the working area,” the following groups are formed:

- direct action. This is when the discharge is located parallel to the longitudinal axis of the electrode and perpendicular to the metal surface being processed;

- indirect action. Here the electrode is inclined to the workpiece surface at an angle of 40.0°-60.0°. The discharge passes between this consumable element and the metal;

- combined. It is a combination of the above arcs. An example is a 3-phase arc. Its 2 arcs provide electrical connection between the electrodes and the welding object. The third burns between two electrodes isolated from one another.

Depending on its composition, the plasma column can be:

- open. Formed in atmospheric gases. The feeding medium is the chemical compounds evaporating from the welding object and electrode coating;

- closed. Produced under flux. A prerequisite is the presence of a gaseous phase formed by particles that are the products of evaporation of the flux, the consumable element - the electrode, and the metal itself, which is in a liquid aggregate state;

- with the supply of a protective mixture. It can be a gas with inert properties, etc.

Another sign on the basis of which experts divide the electric arc into types is the type of electrode. The following consumables are used for welding:

- steel, the coating of which contains inclusions that ensure gas ionization;

- made from coal or graphite;

- refractory, made of tungsten metal (element W).

According to the “exposure time” criterion, the welding electric arc can be pulsed or constant.

Combustion conditions

The essence of the welding process is the conversion of electrical energy into thermal energy.

To maintain the welding column, it is necessary to create conditions for rapid ionization of the gas: the parts are heated so that the air around them is warm, or a gas capable of ionization is supplied to the working area. Particles of alkali and alkaline earth metals are most easily ionized. When current is passed through the rod, their particles become active.

To prevent the arc column from extinguishing, it is important to maintain a constant temperature in the cathode region. It directly depends on the chemical composition of the cathode and its area. The required temperature is maintained by a current source; in industrial conditions it reaches 7 thousand degrees.

Selecting a Power Source for Arc Welding

Of course, in addition to power characteristics, welding equipment is selected based on mobility, size, and weight. Speaking about the advantages and disadvantages of power sources, it is worth starting with the very first type of welders.

Transformer

Equipment with a secondary winding converts the voltage; due to inductive fields, the voltage from 80 volts can be lowered to 20. This is the simplest and most cumbersome type of welding machine. But it is very reliable, depends little on environmental conditions, and is not afraid of humidity or dust. You can build a transformer yourself; the required voltage is obtained by a certain number of turns of the secondary winding. The efficiency of the equipment is quite high, the cost is low. When the amount of work is small, welders with experience prefer to purchase transformers for the garage or home.

Rectifier

Already from the name it is clear that we are talking about a direct current source. Semiconductors are used for conversion; they transmit electricity only in the upper range of the sine wave. Due to the use of semiconductors and the presence of an electrical circuit, the capabilities of rectifiers are wider than those of transformers. When changing the polarity, you can adjust the temperature at the contacts: with direct polarity, the electrode heats up more, with reverse polarity, the metal heats up more. The efficiency of rectifiers is higher than that of transformers, and there are low no-load losses.

The big disadvantage is that welding machines get very hot, they periodically need a break to return to normal or an additional cooling system.

Generator

Electricity is generated by rotating the shaft in a constant magnetic field. The devices operate on gasoline and diesel fuel; there are stationary installations on coal and briquetted fuel. Main advantages:

Cons: large dimensions, low efficiency, plus exhaust gases, noise, vibration.

How does an electric welding arc occur?

Like any electrical discharge, a welding arc appears when a circuit is closed. The occurrence of current when the electrode touches the metal being welded leads to the generation of a large amount of heat. At the point of closure, a melt appears, it reaches behind the tip of the electrode, a neck is formed, which instantly sprays due to the strong current. Ionization of air molecules and the protective cloud occurs; they carry a flow of electrons.

The direction of the flow depends on the type of current. The arc is ignited using direct current of reverse and direct polarity, and alternating current. The frequency of extinction and ignition of the electric arc depends on the parameters of the operating current.

Exam tickets to test the knowledge of welding specialists level 1

TICKET 4

QUESTION 1. Name the main external defects of the seam in RDS.

1. Violation of the size and shape of the seam, undercuts, burns, sagging, fistulas, unwelded crater.

2. Violation of the size and shape of the weld, cracks, pores, slag inclusions.

3. Burns, sagging, fistulas, tungsten oxide inclusions, lack of fusion.

QUESTION 2. Within what limits does the standard edge bevel angle change when V-shaped cutting of steel structure elements according to GOST 5264-80

QUESTION 3. What letter of the Russian alphabet denotes aluminum and copper in steel markings?

1. Aluminum - A, copper - M.

2. Aluminum - B, copper - K.

3. Aluminum - Y, copper - D.

QUESTION 4. Indicate a way to eliminate the influence of magnetic blast

1. Increasing the parameters of the welding mode, mechanically cleaning the welded edges.

2. By changing the location of the current supply, the angle of inclination of the electrode, and replacing direct current with alternating current.

3. By changing the angle of separation of the edges, reducing the gap at the joint.

QUESTION 5. What is the no-load mode of a welding transformer?

1. The primary winding of the transformer is connected to the supply network, and the secondary winding is closed by the consumer.

2. The primary winding of the transformer is connected to the supply network, and the secondary winding is disconnected from the consumer.

3. The primary winding of the transformer is not connected to the network, and the secondary winding is short-circuited by the consumer.

QUESTION 6. Which of the following affects the choice of electrode diameter and welding current?

1. Brand and thickness of the metal being welded.

2. Ambient temperature.

3. Everything listed in paragraphs 1 and 2.

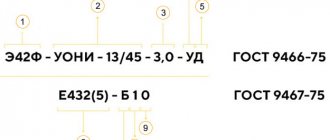

QUESTION 7. Indicate the correct division of electrodes by type of coating according to GOST 9466?

1. Silicon-containing, manganese-containing and neutral coatings.

2. Oxidizing, reducing and passivating coatings.

3. Acid, basic, cellulose and rutile coatings

QUESTION 8. For welding what class of steels are electrodes of types E70, E85, E100, E125, E150 used?

1. For welding heat-resistant steels.

2. For welding structural steels of increased and high strength.

3. For welding carbon and low-alloy structural steels.

QUESTION 9. Which of the following causes the appearance of slag inclusions?

1. Poor protection of the welding site from wind during installation.

2. Traces of moisture and oil on the welded edges.

3. Low quality of electrode coating during manual arc welding.

QUESTION 10. When is fine-droplet metal transfer observed during gas-shielded welding?

1. At low values of welding current density.

2. At high values of welding current density.

3. At average values of welding current density.

QUESTION 11. Which of the listed factors most influences the width of the seam in RDS?

1. The magnitude of the welding current.

2. Transverse vibrations of the electrode.

3. Arc voltage.

QUESTION 12. Specify the requirements for the heating mode when welding dissimilar pearlitic steels

1. The mode corresponding to the more alloyed steel being welded is set.

2. The mode corresponding to the less alloyed steel being welded is set.

3. The average heating mode is set.

QUESTION 13. Indicate how an increase in the diameter of the electrode (at a constant current) during manual arc welding affects the spatial stability of the arc

1. Increases as the wandering of the active spot decreases.

2. Decreases, as wandering of the active spot across the cross section of the end of the electrode increases.

3. Has no effect.

QUESTION 14. What current-voltage characteristic should the power source for the RDS have?

QUESTION 15. Specify the requirements for the quality of preparation of the surface of the edges before welding

1. It is allowed to use metal in the delivered condition.

2. The interface between the edges of the part and the area adjacent to them must be clean, free of scale, rust, oil, grease and dirt.

3. The interface between the edges of the part and the area adjacent to them must be free of traces of moisture.

QUESTION 16. Indicate how to choose the density of protective glass in a welding helmet during arc welding

1. Depending on the welding method.

2. Depending on the magnitude of the welding current.

3. Depending on the visual acuity of the welder.

QUESTION 17. When do temporary welding deformations appear?

1. Formed during welding.

2. Occur after welding.

3. Appear after cooling of the metal being welded.

QUESTION 18. What defects are allowed to be eliminated by a welder (without involving the work manager)?

1. Any defects, including defects such as lack of penetration and cracks.

2. Cracks and lack of fusion between rollers.

3. Surface pores, slag inclusions, lack of fusion between rollers, undercuts.

QUESTION 19. What is the minimum amount of current that can be fatal to a person when exposed to electrical voltage?

1. Current strength is 1 mA.

2. Current strength is 10 mA.

3. Current strength is 50 mA.

QUESTION 20. What line represents an invisible weld in the drawing?

1. Solid main.

3. Stroke – dotted.

To move to the next page, use the page navigation below.

Source

How is the power of a welding arc determined?

The power parameters of the electric arc are influenced by several factors:

- voltage, increasing leads to an increase in power only in a small range, there are restrictions on the size of the electrode;

- current strength, high amperage ensures stable combustion;

- The magnitude of the plasma voltage is proportional to the power.

The length of the welding arc is the distance from the weld crater to the tip of the electrode. The volume of heat released depends on this value.

The power of the welding arc determines the melting rate of the metal. The time required for welding work depends on this characteristic. The current intensity is adjusted to adjust the temperature in the working area; even on a long pole, the electric arc will not die out with a large amperage. The voltage is rarely changed during the welding process.

Volt-ampere characteristics

The current-voltage characteristic describes the dependence of current parameters. Using this graph determine:

- arc power;

- burning time,

- extinction conditions.

Dynamic current-voltage characteristic describes the unsteady state of an electric arc when its length fluctuates. The static current-voltage characteristic reflects the dependence of voltage on amperage at a constant arc length. The graph is divided into three areas:

- falling - as the current increases, the voltage drops sharply, this is due to the formation of a column: the cross-sectional area of the plasma flow increases, the electrical conductivity of the plasma changes;

- hard, this is a section of stable current density and voltage drop, with an increase in amperage from 100 to 1000 A, the diameter of the arc column increases proportionally (the anode and cathode spots change, respectively);

- increasing, characterized by a constant size of the cathode spot, it is limited by the diameter of the electrode; with increasing amperage, according to Ohm's law, U, R of the arc column increases.

Static current-voltage characteristics of the welding arc: 1 - falling; 2 - hard; 3 - increasing.

The current-voltage characteristic of the process of conventional manual welding using consumable and non-consumable electrodes in air or in a cloud of shielding gas is limited to the first two areas; the amperage does not reach the third. Mechanized welding using fluxes corresponds to the schedule of regions II and III, welding with a consumable electrode in a cloud of a protective atmosphere - III.

To main§ 8. WELDING PROPERTIES OF ARC

A welding arc is a powerful, stable electric discharge in a gas environment formed between the electrodes, or between the electrodes and the product. The welding arc is characterized by the release of a large amount of thermal energy and a strong light effect. It is a concentrated heat source and is used to melt base and filler materials. Depending on the environment in which the arc discharge occurs, there are: an open arc burning in the air, where the composition of the gas environment of the arc zone is air mixed with vapors of the metal being welded, the material of the electrodes and electrode coatings; a closed arc burning under a submerged arc, where the composition of the gaseous medium of the arc zone is a pair of base metal, wire and protective flux; an arc burning in an environment of protective gases (the gaseous environment of the arc zone includes an atmosphere of protective gas, pairs of wire and base metal). The welding arc is classified by the type of current used (direct, alternating, three-phase) and by the duration of combustion (stationary, pulsed). When using direct current, an arc of direct and reverse polarity is distinguished. With direct polarity, the negative pole of the power circuit - the cathode - is located on the electrode, and the positive pole - the anode - is on the base metal. With reverse polarity, the plus is on the electrode and the minus is on the product. Depending on the type of electrode used, the arc can be excited between consumable (metal) and non-consumable (carbon, tungsten, etc.) electrodes. According to the principle of operation, arcs can be of direct, indirect and combined action (Fig. 14).

Straight arc

called an arc discharge occurring between the electrode and the product.

An indirect arc

is an arc discharge between two electrodes (atomic-hydrogen welding).

A combined arc

is a combination of a direct and indirect arc. An example of a combined arc is a three-phase arc, in which two arcs electrically connect the electrodes to the workpiece, and the third burns between two electrodes isolated from each other. The arc is excited in two ways: by touching or by striking, the essence of which is shown in Fig. 15.

In a welding arc, the arc gap is divided into three main regions: anodic, cathodic and arc column. During the arcing process, there are active spots on the electrode and base metal, which are more heated areas of the electrode and base metal through which the entire arc current passes. The active spot located on the cathode is called cathode

, and the spot located on the anode is

anodic

.

The total length of the welding arc (Fig. 16) is equal to the sum of the lengths of all three areas:

L

d =

L

k +

L

c +

L

a,

where L

d - total length of the welding arc,

cm

;

L

k is the length of the cathode region, equal to approximately 10-5

cm

;

L

с - length of the arc column,

cm

;

Ld

is the length of the anode region, equal to approximately 10-3 ÷ 10-4

cm

. The total voltage of the welding arc is composed of the sum of the voltage drops in individual areas of the arc:

U

d =

U

k +

U

c +

U

a,

where U

d - total voltage drop across the arc,

in

;

Uk

is the voltage drop in the cathode region,

in

;

U

c is the voltage drop in the arc column,

in

;

U

a is the voltage drop in the anode region,

in

. The temperature in the welding arc column ranges from 5000 to 12,000° K and depends on the composition of the gaseous medium of the arc, material, electrode diameter and current density. The temperature can be approximately determined using the formula proposed by Academician of the Academy of Sciences of the Ukrainian SSR K. K. Khrenov:

T

st = 810

Ueff

,

where T

sm—arc column temperature, °K;

Ueff

—effective ionization potential.

Static current-voltage characteristics of the welding arc.

The dependence of the voltage in the welding arc on its length and the magnitude of the welding current, called the current-voltage characteristic of the welding arc, can be described by the equation

U

d +

a

+

bL

d,

where a

- the sum of the voltage drops at the cathode and anode (

a

=

U

k +

U

a):

b

- specific voltage drop in the gas column per 1

mm

of arc length (the value of

b

depends on the gas composition of the arc column);

L

d - arc length,

mm

.

At low and ultra-high current values, U

d depends on the value of the welding current.

The static current-voltage characteristic of the welding arc is shown in Fig. 17. In region I,

an increase in current to 80

A

leads to a sharp drop in arc voltage, which is due to the fact that with low-power arcs, an increase in current causes an increase in the cross-sectional area of the arc column, as well as its electrical conductivity.

The shape of the static characteristics of the welding arc in this section is falling. A welding arc with a falling current-voltage characteristic has low stability. In region II

(80 - 800

A

), the arc voltage remains almost unchanged, which is explained by an increase in the cross-section of the arc column and active spots in proportion to the change in the welding current, therefore the current density and voltage drop in all areas of the arc discharge remain constant.

In this case, the static characteristic of the welding arc is rigid. This arc is widely used in welding technology. When the welding current increases to more than 800 A

(region

III

), the arc voltage increases again. This is explained by an increase in current density without growth of the cathode spot, since the electrode surface is no longer sufficient to accommodate a cathode spot with a normal current density. The arc with increasing characteristics is widely used in submerged arc and shielding gas welding.

Processes occurring at the moment of excitation of the welding arc.

In the event of a short circuit, the end of the electrode comes into contact with the product. Since the end of the electrode has an uneven surface, contact does not occur along the entire plane of the end of the electrode (Fig. 18). At the points of contact, the current density reaches very high values and, under the influence of the released heat at these points, the metal instantly melts. At the moment the electrode is removed from the product, the zone of molten metal - the liquid bridge - stretches, the cross-section decreases, and the temperature of the metal increases. When the electrode is removed from the product, the liquid bridge of the metal breaks, and rapid evaporation occurs (an “explosion” of the metal). At this moment, the discharge gap is filled with heated ionized particles of metal vapor, electrode coating and air - a welding arc occurs. The arcing process lasts only a fraction of a second. Ionization of gases in the arc gap at the initial moment occurs as a result of thermionic emission from the surface of the cathode, due to structural damage as a result of sudden overheating and melting of the metal and electrode coating.

An increase in the electron flux density also occurs due to oxides and the formed surface layers of molten fluxes or electrode coatings, which reduce the electron work function. At the moment the bridge of the liquid metal breaks, the potential drops sharply, which contributes to the formation of field emission. A drop in potential makes it possible to increase the emission current density, accumulate kinetic energy for electrons for inelastic collisions with metal atoms and transfer them to an ionized state, thereby increasing the number of electrons and, consequently, the conductivity of the arc gap. As a result, the current increases and the voltage drops. This happens up to a certain limit, and then a steady state of the arc discharge begins - arc burning. Cathode region.

Processes occurring in the region of the cathode voltage drop play an important role in welding processes.

The region of the cathode voltage drop is a source of primary electrons, which maintain the arc gap gases in an excited ionized state and carry the bulk of the charge due to their high mobility. The removal of electrons from the cathode surface is caused primarily by thermionic and field emission. The energy spent on tearing electrons from the cathode surface and fusing the metal is, to some extent, replaced by energy from the arc column due to the flow of positively charged ions that release their ionization energy on the cathode surface. The processes occurring in the region of the cathode voltage drop can be represented according to the following diagram. 1. Electrons, emitted from the surface of the cathode, receive accelerations necessary for the ionization of gas molecules and atoms. In some cases, the cathode voltage drop is equal to the ionization potential of the gas. The magnitude of the cathode voltage drop depends on the ionization potential of the gas and ranges from 10 to

16

V. 2. Due to the small thickness of the cathode zone (about 10-5 cm

), electrons and ions move in it without collisions and it is approximately equal to the free path of an electron.

The values of the thickness of the cathode zone, found experimentally, are less than 10-4 cm

.

3. With increasing current density, the temperature of the cathode region increases. Arc pillar.

In the arc column there are three types of charged particles - electrons, positive ions and negative ions, which move to the opposite pole.

The arc column can be considered neutral, since the sum of the charges of negative particles is equal to the sum of the charges of positive particles. The arc column is characterized by the formation of charged particles and the reunification of charged particles into neutral atoms (recombination). The flow of electrons through the gas layer of the discharge gap causes mainly elastic collisions with gas molecules and atoms, as a result of which a very high temperature is created. Ionization as a result of inelastic collisions is also possible. The temperature of the arc column depends on the composition of the gases, the magnitude of the welding current (as the current increases, the temperature increases), the type of electrode coatings and polarity. With reverse polarity, the temperature of the arc column is higher. Anode region.

The anodic region has a larger extent and a smaller voltage gradient than the cathodic region.

The voltage drop in the anode region is created as a result of the extraction of electrons from the arc discharge column and acceleration as they enter the anode. In the anode region there is mainly only an electron current, due to the small number of negatively charged ions, which have lower velocities than the electron. An electron that hits the anode surface gives the metal not only a supply of kinetic energy, but also work function energy, so the anode receives energy from the arc column not only in the form of a flow of electrons, but also in the form of thermal radiation. As a result, the anode temperature is always higher and more heat is generated on it. Features of a welding arc fed by alternating current.

When welding with an alternating current arc (industrial frequency 50 cycles per second), the cathode and anode spots change places 100 times per second.

When the polarity changes, the so-called “valve effect” is formed, which consists in partial rectification of the current. Current rectification occurs as a result of continuously changing electron emission, since when the direction of the current changes, the conditions for the release of emission currents from the electrode and from the product will not be the same. With the same materials, the current is almost not rectified; the rectification of the current in the welding arc is called the direct current component

, which during argon-arc welding of aluminum has a negative effect on the process. The combustion stability of a welding arc fed by alternating current is lower than that of an arc fed by direct current. This is explained by the fact that as the current passes through zero and changes polarity at the beginning and end of each half-cycle, the arc dies out. At the moment of arc extinction, the temperature of the arc gap decreases, causing deionization of the gases of the arc column. At the same time, the temperature of active spots also drops. The temperature especially drops at the active spot, which is located on the surface of the weld pool, due to heat dissipation into the product. Due to the thermal inertia of the process, the temperature drop is slightly behind the phase of the current passing through zero. Ignition of the arc due to reduced ionization of the arc gap at the beginning of each half-cycle is possible only with an increased voltage between the electrode and the product, called the ignition peak. If the cathode spot is located on the base metal, then in this case the magnitude of the ignition peak is slightly higher. The magnitude of the ignition peak is influenced by the effective ionization potential: the higher the effective ionization potential, the higher the ignition peak should be. If there are easily ionized elements in the welding arc, the ignition peak decreases and, conversely, it increases if there are fluorine ions in the arc atmosphere, which, when combined with positive ions, easily form neutral molecules. The main advantages of an alternating current arc include: relative simplicity and lower cost of equipment, the absence of magnetic blast and the presence of cathode sputtering of an oxide film during argon-arc welding of aluminum. Cathode sputtering is the process of bombarding the weld pool with positive ions at the moment when the product is the cathode, due to which the oxide film is destroyed.

The influence of the magnetic field and ferromagnetic masses on the welding arc

In a welding arc, the arc column can be considered as a flexible conductor through which an electric current passes and which can change its shape under the influence of an electromagnetic field. If conditions are created for the interaction of the electromagnetic field arising around the welding arc with extraneous magnetic fields, with the own field of the welding circuit, as well as with ferromagnetic materials, then in this case a deviation of the arc discharge from the original own axis is observed. In this case, the welding process itself is sometimes disrupted. This phenomenon is called magnetic blast

. Let's look at a few examples showing the effect of an external magnetic field on a welding arc. 1. If a symmetrical magnetic field is created around the arc, then the arc does not deviate, since the created field has a symmetrical effect on the arc column (Fig. 19, a).

2. The welding arc column is affected by an asymmetrical magnetic field, which is created by the current flowing in the product; the arc column will deviate in the direction opposite to the current conductor (Fig. 19.6). The angle of inclination of the electrode, which also causes deflection of the arc, is also significant (Fig. 20).

A strong factor acting on arc deflection is ferromagnetic masses: massive welded products (ferromagnetic masses) have greater magnetic permeability than air, and magnetic field lines always tend to pass through the medium that has less resistance, therefore an arc discharge located closer to ferromagnetic mass, always deviates in its direction (Fig. 21).

The influence of magnetic fields and ferromagnetic masses can be eliminated by changing the location of the current supply, the angle of inclination of the electrode, by temporarily placing ferromagnetic material to create a symmetrical field and replacing direct current with alternating current.

Transfer of molten metal through the arc space

When transferring molten metal, the forces of gravity, surface tension, electromagnetic field and internal gas pressure act. The force of gravity manifests itself in the tendency of the drop to move downward under its own weight. When welding in the lower position, gravity plays a positive role in transferring the drop into the weld pool; when welding in vertical and especially in overhead positions, it complicates the process of transferring electrode metal. The force of surface tension is manifested in the desire of a liquid to reduce its surface under the influence of molecular forces, seeking to give it a shape that would have a minimum amount of energy. This form is a sphere. Therefore, the force of surface tension gives a drop of molten metal the shape of a ball and retains this shape until it comes into contact with the surface of the molten bath or the drop is torn off from the end of the electrode without contact, after which the surface tension of the bath metal “pulls” the drop into the bath. The force of surface tension helps to retain the liquid metal of the bath during welding in the ceiling position and creates favorable conditions for the formation of a seam. The strength of the electromagnetic field lies in the fact that the electric current passing through the electrode forms a magnetic force field around it, which has a compressive effect on the surface of the electrode, tending to reduce the cross-section of the electrode. The magnetic force field does not affect solid metal. Magnetic forces acting normal to the surface of a spherical molten drop have a significant effect on it. With an increase in the amount of molten metal at the end of the electrode, under the action of surface tension forces, as well as compressive magnetic forces, an isthmus is formed in the area between the molten and solid electrode metal (Fig. 22).

As the cross section of the isthmus decreases, the current density sharply increases and the compressive effect of magnetic forces, tending to tear the drop from the electrode, intensifies. Magnetic forces have a minimal compressive effect on the spherical surface of the droplet facing the molten pool. This is explained by the fact that the current density in this part of the arc and on the product is small, so the compressive effect of the magnetic force field is also small. As a result, the metal is always transferred in the direction from the small-section electrode (rod) to the large-section electrode (product). It should be noted that in the resulting isthmus, due to an increase in resistance during the passage of current, a large amount of heat is released, leading to strong heating and boiling of the isthmus. The metal vapors formed during this overheating at the moment of separation of the drop have a reactive effect on it - they accelerate its transition to the bath. Electromagnetic forces contribute to the transfer of metal in all spatial welding positions. The force of internal gas pressure arises as a result of chemical reactions, which proceed more actively the more the molten metal at the end of the electrode is overheated. The starting products for the formation of reactions are gases, and the volume of gases formed is tens of times greater than the volume of the compounds involved in the reaction. The separation of large and small drops from the end of the electrode occurs as a result of violent boiling and the removal of formed gases from the molten metal. The formation of splashes on the base metal is also explained by the explosive fragmentation of the drop when the drop passes through the arc gap, since at this moment the release of gases from it increases, and some part of the drop flies out of the weld pool. The force of internal gas pressure mainly moves the droplet from the electrode to the workpiece.

Main indicators of the welding arc

Melting coefficient.

When welding metal, a seam is formed due to the melting of the filler metal and penetration of the base metal. The melting of the filler metal is characterized by the melting coefficient

where αр is the melting coefficient; G

the electrode metal

melted during time

t g ; t

is the arc burning time, h;

I

is the welding current,

and

.

The melting coefficient depends on the composition of the wire and electrode coating, the weight of the coating, as well as the type and polarity of the current. Loss ratio.

The coefficient characterizes the loss of electrode metal due to splashing, evaporation and oxidation.

where ψ is the loss coefficient; G

n—weight of deposited metal,

G

;

G

r - weight of molten metal

,

G. The loss coefficient depends not only on the composition of the wire and its coating, but also on the welding mode and the type of welded joint. The loss factor increases with increasing current density and arc length. It is somewhat smaller when welding tees, with cutting edges, than when surfacing. Deposition factor.

To evaluate the surfacing process, the concept of surfacing coefficient is introduced:

where αн is the deposition coefficient; G

n—amount of metal deposited during time

t

,

g

(including losses).

The deposition rate depends on the type and polarity of the current, the type of coating and composition of the wire, as well as on the spatial position in which welding is performed. Dependence of the welding current on the electrode diameter.

In manual arc welding, the welding current and the diameter of the electrode are related by the following relationship:

I

=

K d

,

where I

is the magnitude of the welding current,

and

;

K

- coefficient depending on the brand of electrode (

K

= 40 ÷ 60; 40 - for alloy electrodes, 60 - for carbon electrodes)

d

- electrode diameter,

mm

.

The given formula is applicable for electrodes with a diameter of 8 - 6 mm

. The relationship between the diameter and the welding current is also expressed by the following experimental formula:

I

= (

m

+

n d

)

d

,

where m

= 20;

n

= 6 (for manual welding with steel electrodes).

Productivity of the arc welding process.

Welding performance is determined by the amount of deposited metal

G

= αн ·

I · t

,

where G

— weight of deposited metal

,

G. The higher the current, the higher the performance. However, with a significant increase in the welding current for the applied electrode diameter, the latter can quickly be heated by Lenz-Joule heat, which will sharply reduce the quality of the weld, since the weld metal and the fusion zone of the base metal will be overheated. It should be noted that overheating the electrode increases metal spattering. Running energy.

The ratio of the effective thermal power of the arc (source)

q

n to the speed of movement of the arc

v

is called

heat input

.

where v

— arc movement speed (welding speed),

cm/sec

. Heat input is the amount of heat in calories introduced per unit length of a single pass weld or bead. The total thermal power of the welding arc is approximately equal to the thermal equivalent of its electrical power

Q

= 0.24

U

d

I cal/sec

,

where Ud is the voltage drop across the arc, in

;

I

is the magnitude of the welding current,

and

;

Q

is the thermal equivalent of the electric power of the welding arc,

cal/sec

.

The amount of heat introduced by the welding arc into the product during its heating per unit time is called effective thermal power of the welding arc

, which is the sum of the thermal energy released in the arc spot on the product, introduced into the product during heat exchange with the arc column and the spot on the product, and entering with drops of molten flux, electrode metal and coating:

q

u = 0.24

U

d

I h

and

cal/sec

,

where q

and is the effective thermal power of the welding arc

cal/sec

;

h

and is the effective efficiency. process of heating metal with a welding arc, From

Efficient efficiency process of heating metal with a welding arc

is the ratio of the amount of heat introduced into the metal to the thermal equivalent of the electric power of the arc. This coefficient characterizes the efficiency of the processes of heat release and heat exchange in the arc gap in relation to the heating of the metal of the product and depends mainly on the welding method. In Fig. Figure 23 shows the thermal balance of the heat generated by the arc, from which it can be seen that the heat of the arc is used more fully in automatic submerged arc welding.

As the arc length increases, the effective efficiency falls and increases as the arc deepens into the bath. When welding with metal electrodes, this coefficient depends little on the type, polarity and magnitude of the welding current.

Self-test questions

1. What is an electric arc?

2. Name the main sections of the electric arc. 3. As a result of what phenomena does ionization of the air gap between the electrode and the product occur? 4. How to determine the melting, deposition and loss coefficients? 5. What is heat input called? Previous page

| table of contents | Next page |

Arc Features

Due to its special properties, the electric arc is used when welding with refractory and consumable electrodes. It quickly heats the metal, forming a melt pool. Electric current is efficiently converted into thermal energy with minimal losses.

By the nature of its origin, the electric welding arc can be compared with other types of electric charges. The main distinctive characteristics of the arc:

- high temperature created by a dense current (amperage depends on the length of the column, reaches thousands of A per cm2);

- small values of the anode and cathode voltage drop, weakly dependent on the initially specified voltage;

- uneven distribution of electric field voltage between the poles;

- spatial stability;

- self-regulation of power, current-voltage characteristic;

- clearly defined boundaries that are clearly visible in the environment.

Ignition is carried out in two ways:

- short touch (the electrode is placed end-to-end, increasing the risk of sticking);

- by striking (impossible in hard-to-reach places).

The nature of the phenomenon

The arc formation process is as follows:

- The welder touches the metal workpiece with the electrode for a split second.

- At the moment of contact, a short circuit occurs, accompanied by the flow of high current and, as a consequence, a powerful release of heat.

- The metal melts at the point of contact. It becomes viscous and viscous.

- At the moment the consumable is separated from the workpiece, a drop of melt trails behind it.

- Lengthening, it becomes thinner with the formation of the so-called. cervix. At some point, it evaporates and turns into a cloud of charged particles. At the same time, due to the high temperature in this zone, the air or shielding gas is ionized.

- Under the influence of an electric field, negative charge carriers rush to the anode, positive charge carriers - to the cathode. The process of current flow in the plasma begins.

At the moment of contact, a short circuit occurs and the metal at the point of contact melts.

Each stage lasts milliseconds, the discharge occurs almost instantly. The current is then maintained by the emission of electrons at the cathode. On their way to the anode, they ionize gas and metal vapor, increasing the number of free charge carriers.

Modern welding machines are equipped with a high-frequency vibration generator (oscillator). This device allows you to excite the arc in a non-contact manner.

Under what conditions does combustion begin?

An electric welding arc occurs at a current strength of 10 to 1000 A and a potential difference of 15-40 V. In cold air, ignition is difficult because it is weakly ionized. Under such conditions, the workpiece is heated or warm shielding gas is supplied.

Arc Power Supplies

To create a discharge, both direct and alternating voltages are used. In the first case, the weld is of higher quality, and the metal spatters less.

The current from the 220 V network is converted by a transformer, giving an output of 15-40 V.

In order to reduce its dimensions, modern welding machines use a circuit consisting of the following units:

- Input rectifier.

- An inverter is an electronic device with fast-switching transistors controlled by a microcircuit.

- Transformer.

- Output rectifier.

The inverter is the arc power source.

The inverter converts direct current into alternating current with a frequency of up to 80 kHz. This allows not only to reduce the size of the transformer, but also to increase the efficiency of the device.

The source parameters are selected taking into account the method of performing the work. For example, during manual welding, the arc length fluctuates, so you need a device with a steeply falling current-voltage characteristic. Thanks to it, the discharge does not go out when stretched, and when it is shortened, the current does not become too large.

When welding with a consumable electrode, drops of metal flow from it onto the workpiece. At such moments, a short circuit current occurs that exceeds the arc current by 20% -50%. It burns out the formed metal bridge, and the plasma discharge is formed again. These fluctuations occur in short moments of time, so the source must quickly respond to them, stabilizing the potential difference.

We recommend reading: Job Description Items for Electric and Gas Welder

What and how power is determined

Plasma is a conductor with electric current flowing through it. This means that the question of how the power of a welding arc is determined is given the same answer as for any resistor: voltage and amperage. The rate of heat release is equal to the product of these quantities.

The power varies with the current strength, which depends on the length of the arc.

Increasing the potential difference allows you to increase power only within small limits. In addition, the possibility of such adjustment is limited by the size of the electrode.

More often, the power is varied by the current strength, which, in turn, depends on the length of the arc. At the same time, the heating temperature of the metal changes, and with it the speed of work.