Arc welding modes (ARC) are a set of measures, indicators and parameters that must be maintained and observed for the correct implementation of a manual arc connection.

Manual arc welding modes can be defined as the conditions for the normal functioning of the process of joining parts under various circumstances. Depending on different parameter indicators, the correct choice of modes for a specific type of welding joint and the choice of welding mode in general is carried out. Conventionally, the parameters of the manual arc welding mode can be divided into two types: basic and additional. The main parameters of the welding mode for manual arc welding include the diameter of the electrode, the properties and magnitude of the welding current, and the arc voltage. Additional parameters include the position of the seam on the product, the composition and thickness of the metal, the speed of joining the product and the electrode coating. Let's consider each of them separately.

Welding current

Current has defining properties: type, polarity and strength. By type, current is divided into direct and alternating. Polarity can be direct or reverse.

Most welding machines operate on direct current. The difference between direct current and alternating current is that direct current does not change in direction or magnitude. Thus, it ensures the stability of the arc. The only disadvantage of direct current in the process of joining metals is the possibility of a magnetic blowing effect. It occurs when connecting large structures, when an extraneous magnetic field (from magnetized products) affects the magnetic field of the arc. In this case, the arc begins to “run out” beyond the area where the seam is located and combustion stability decreases sharply. This disadvantage can be combated by

- fencing the work area with special screens that protect from “extra” magnetic fields

- grounding of welded surfaces

- identify possible options for using alternating current

The advantage of working on direct current is a stable arc and the ability to select polarity. Direct polarity is also called electrode-negative, reverse polarity is also called electrode-positive. Reverse polarity occurs when the electrode is connected to the positive and the metal to the negative. With direct polarity, the opposite is true. The difference between the polarities is as follows. The laws of physics say that where the plus is connected, that element heats up more. Thus, with straight polarity, the metal product heats up more. This polarity should be used to join thick parts, since this process requires more melting of the metal to obtain a good weld. If direct polarity is used on a thin product, it will “burn” and the seam will turn out to be of poor quality. For thin metals, reverse polarity is carried out.

The amount of current is determined by the characteristics of a particular welding machine. In modern models, these indicators are indicated in the instructions. If for some reason you do not have instructions, then the current strength can be selected depending on the diameter of the electrode used. It is not allowed to use a current strength that is more suitable for a particular electrode. In this case, the electrode coating used to make the connection will be damaged and the arc will operate unstably. Using an electrode that is too large also has a bad effect on the process of joining metals: the current density decreases, the arc “runs away,” its length changes, and the weld does not turn out smooth and of high quality.

Influence on the choice of electrodes

The type of current also affects the choice of electrodes for welding. Thus, a unit operating on alternating current will be able to weld products only with electrodes specially designed for this purpose.

When working with such equipment, it is also possible to use universal consumables.

But this device cannot work with electrodes intended for use in direct current mode (UONII, for example). Note also that the inverter can cook with almost any consumables, but preference is usually given to universal rods.

Thus, the type of current, as a factor influencing welding procedures, determines the choice of a suitable apparatus and electrodes used in welding.

Electrode diameter

Welding modes depend on the type of electrode. The choice of its diameter depends on the thickness of the metal and the position of the seam. For any thickness, seams in a vertical position, horizontal and ceiling seams are welded only with a diameter of 4 mm. If the seam is multilayer, then a 3 or 4 mm electrode is used to weld the first seam, and subsequent seams are corrected using a larger electrode.

The table below shows the parameters of manual arc welding with the ratio of current, metal thickness and electrode diameter.

| Workpiece thickness, mm | 0,5 | 1-2 | 3 | 4-5 | 6-8 | 9-12 | 13-15 | 16 |

| Electrode thickness, mm | 1 | 1,5-2 | 3 | 3-4 | 4 | 4-5 | 5 | 6-8 |

| Current strength, A | 10-20 | 30-45 | 65-100 | 100-160 | 120-200 | 150-200 | 160-250 | 200-350 |

Content

- Current strength

- Arc Length (Arc Voltage)

- Welding speed

- Current polarity

- Ignition of the welding arc

When starting to work with manual arc welding, you need to choose the right welding mode. The quality of the weld is influenced by many parameters that are selected immediately before starting work:

- current strength;

- arc length;

- welding speed;

- current polarity;

- location of the seam in space;

- electrode diameter.

Mode depending on arc voltage

Arc voltage is related to its length. Typically the voltage is set in the range of 20-36 V. It increases as the arc length increases. The length of the arc can be short, medium and long.

Arc length is the distance from the tip of the electrode to the metal being welded. To make a quality connection, you need to ensure a stable arc size. It is believed that for beginners it is easier to maintain an average arc size. It is possible to make a high-quality seam with a short arc, but this requires experience and professionalism.

Features of forward and reverse welding

The direct polar method is designed for:

- rolling installation from special steels using fusion method;

- non-consumable tungsten welding using surfacing wire;

- working with fluid materials;

- cutting workpieces using welding fixtures.

The thermal balance of the arc determines the nature of the distribution of thermal power.

If you accidentally change the pole, the working process with direct current will be delayed, the seam will become wide, and the rate of burning of consumables will increase. Reverse polarity is appropriate for carefully welding the workpiece, without allowing burns. This method is used for processing non-ferrous metals during flux welding.

Welding speed for manual arc welding

Manual electric arc welding is characterized by the speed of its implementation. It affects the width of the seam. The faster the speed, the narrower the seam. When working slowly, the seam is wide. Transverse movements of the electrode during the joining process also affect the width and also the depth of the seam. Do not cook too quickly or too slowly. When working very quickly, spaces unfilled with metal will form, which can cause cracks. Working the electrode very slowly allows the molten metal to spread, which will make the product of poor quality. The movements of the electrode end can also be different (zigzags, herringbones).

Options for electrode direction when welding

Thus, choosing a manual arc welding mode is a set of actions aimed at finding the necessary parameters for connecting a specific product. If you are not a professional or even a complete beginner in this matter, then choosing the welding mode required for a particular product may not work the first time. But this is why there is practice, reference information, and instructions for reference, which indicate the parameters of manual arc welding depending on various indicators. It is worth noting that in each case all parameters are selected individually. You can select manual arc welding modes with coated electrodes yourself.

Features of each connection

Changing the polarity of the unit connection primarily affects the quality of the weld and the condition of the electrode. The use of reverse polarity when welding is characterized by the following positive features:

- increased amount of thermal energy consumed from the electrode;

- high-quality and deep penetration of the workpiece being processed;

- minimal splashing from the side of the fused product.

In turn, the direct current limits the flow of heat to the workpiece from the electrode side and reduces its melting compared to reverse polarity. However, the electrode rod still melts quickly and requires frequent replacement.

When evaluating each of these modes, it cannot be guaranteed that one is preferable to the other.

At first glance, reverse current welding has a clear advantage, but other factors of the welding process must also be taken into account.

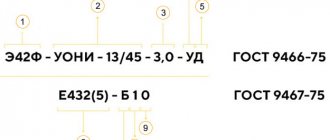

For this purpose, for most electrodes used in welding, the recommended polarity is indicated on their packaging (on a special label).

Basic welding mode parameters

Welding mode refers to the main characteristics of the welding process, due to which welded joints of specified parameters, shapes and sizes are obtained. In this case, these characteristics can be: current density in the electrode, strength of the cooking current, speed of the cooking process, grade and granulation of flux, arc voltage, shielding gas consumption.

VT-metall offers services:

In order to determine which welding mode is required, it is necessary to determine the thickness and type of structure, as well as the composition of the metals. Based on the data received, the desired mode is set. There are two groups of factors on which the quality of welding depends: primary and secondary.

What criteria should you use to choose polarity?

When choosing the type of connection for a welding machine, you need to pay attention to a number of important criteria. This will prevent defects or excessive consumption of materials and ensure the required strength of the connection.

Sheet metal thickness

Parts whose thickness does not exceed 3 mm are often burned through. To weld such workpieces, a reverse-polar scheme is used, providing an anode thermal spot at the edge of the electrode. This approach is appropriate when processing non-ferrous, alloyed materials.

We recommend reading: How to adjust the welding current

Types of metals

The positive terminal is responsible for the final heating of the products and the holder. The cathode generates less heat than the anode. When machining refractory steels, it is better to use direct connection when the temperature reaches 4000 °C. For metals that change characteristics when overheated, connect the negative terminal. With direct-polar processing, the seam deepens; with “reverse” processing, it concentrates on the surface.

Types of electrodes

When choosing the brand of electrodes, take into account the type of current. Any variety is suitable for alternating voltage, since polarity does not play any role in this case. For varieties OK, OZS, MR, reverse connection is recommended. UONII and similar modifications are designed for a direct circuit. Manufacturers' recommendations are indicated on the packaging. Many welders prefer universal analogs to other options.

Arc Length Options

In welding, arc voltage is the most important parameter that determines its length. To put it simply, this is the distance from the end of the electrode to the object. This indicator directly depends on the electrode and is presented in tables. A piece of work is considered to be of high quality if there is not a single imperfection throughout the entire seam. In this profession, experience is important; only a professional is able to follow such a subtle nuance.

We recommend articles:

- Butt welded joint: types, execution technology

- Welding arc: its properties, types, principle of operation

- Lap joint: welding for a wide range of applications

Combustion becomes stable if the arc voltage is increased. With such welding, the likelihood of air entering the seam zone increases, and the elements contained in the wire burn out, resulting in the formation of pores. The arc ignition process includes three stages: a short circuit of the electrode to the workpiece, after which the electrode is withdrawn by 3–6 mm and a stable arc discharge occurs.