If it is necessary to weld seams with defects or weld metal structures made of steel, welders use coated electrodes and an inverter that produces direct current. Tungsten electrodes are also often used in welding stainless steel. Regardless of the chosen electrode or welder model, the problem of correct and quick ignition of the arc often arises. To solve this problem, just connect a welding oscillator to the equipment chain.

In this article we will tell you what an oscillator is in combination with other welding equipment, what the principle of operation is and how to use it in your work.

What is an “oscillator” and its purpose for welding

An oscillator is a generator of high frequency electric current. The current allows the cathode and anode to be connected without direct contact. The device is created in a modular design and is included in the electrical circuit between the tungsten electrode holder and the power source.

“Advanced” welding machines are supplied with oscillators already installed - for maximum convenience for the welder. In any version, the device is needed for the following purposes:

- creating a short-term impulse, as a result of which a welding arc appears between the anode and cathode - it looks almost like lightning jumping between the electrode and the metal surface;

- maintaining the required value of the rated voltage of the welding current - as a result, the arc becomes stable, which guarantees continuity of welding.

Active power reaches 200-250 W, while the pulse output duration does not exceed 30-40 microseconds. When shorted to a person, the current does not pose a danger - but only in a safe mode.

If a malfunction or error occurs in the connection, the electric welder is easily at risk of electrical injury.

Types of installations

Oscillators can be used for different purposes, taking into account the type and characteristics of the work performed. A characteristic common to all installations is the conversion of the current pulse to values up to a maximum of 500 kHz.

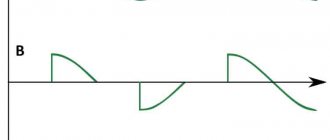

Oscillators differ in the time characteristics of high-frequency pulses.

Continuous cycle model supports arc burning. The connection must be made in series - this will protect the technician from the negative influence of high voltages present inside the electrical circuit. The units superimpose high frequency currents on top of the welding currents, ignition occurs quickly and without obstacles, and welding can be carried out at minimal currents. The installations are equipped with inverters and transformers.

The second type of oscillatory devices is used during non-contact arc ignitions. This principle is actively used in argon installations. The tungsten electrode element will quickly become dull during striking, which will reduce the quality of the weld, increase its thickness, and begin to dissipate the arc. Regular sharpening of the needle tip is possible, but it slows down the workflow. The introduction of an oscillator installation with a short-term pulse into the circuit will make it possible to excite an arc without contact with the working surface.

Main types

It is technically possible to create a homemade welding oscillator at home. “Factory” models are not cheap - but they are simply a set of electrical parts that a knowledgeable specialist will find in nearby devices.

On continuous current supply

A welding oscillator that produces a constant operating voltage is relatively safe for the welder.

It generates pulses with voltages up to 6 kV and frequencies up to 200-250 kHz. Its main advantage is that it ignites the arc regardless of the distance between the electrode and the metal being welded. Stability in operation is ensured precisely by the constant application of the high-frequency component to the welding current.

As a spark gap, this part is connected in parallel or in series. With the latter option, it needs means to protect the power source - high-frequency vibrations can damage it.

Impulse oscillator

This welding oscillator is optimal for machines using alternating current.

Its main advantage is that it holds the discharge when the polarity of the electric current changes (which happens up to 50 times per second). It generates a time-compressed impulse - it holds the existing arc.

When compared with a permanent product, this option has increased efficiency.

With additional capacitors

This oscillator for welding is less common due to its relative complexity: the main role in it is played by a couple of additional storage capacitors. They are charged by a separate power supply unit, which operates in stages (discharge – charge – discharge).

The essence of the device’s operation: first of all, the welding arc receives the accumulated energy, after which the capacitors are disconnected from the main circuit and charged, but when the arc breaks, the synchronizing device turns the capacitors back into the circuit, as a result of which the accumulated energy is released into the air gap.

Operating principle

All installations in this category are integrated inside the equipment circuit in the area between the rectifier element, transformer station and welding electrode holder. As a result, contact is created and the operation of the installations is stabilized. Most installations have a similar design of:

- rectifier;

- work blocks;

- power supply;

- main working node;

- valves;

- transformer devices;

- voltage sensor.

The main task of the device generating pulses is to modernize the incoming voltage, increase V, frequency, and reduce the duration of the pulse flash to a second interval.

Features of the scheme implementation:

- Start (press the corresponding button).

- The rectifying device stabilizes the strength of the input current and makes it unidirectional.

- Capacitor working parts accumulate discharge voltage.

- When the current is released, it flows into the oscillatory motion circuit (its main part is made up of transformer windings), and the force V increases.

- The pulse is released and the gas supply valve opens.

- The impulse force triggers the discharge.

- As the current charge passes through the circuit, the pulse stops. The seam connection will be created on the posts.

After the arc has died down, the oscillator purges the burners with argon gas for a few more seconds. After the seam has cooled, the work can be considered completed.

Design and principle of operation of the oscillator

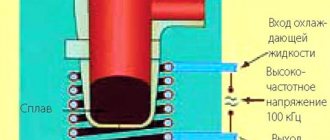

The welding oscillator consists of the following main components:

- transformer: mandatory characteristic - step-up (to generate the required voltage);

- standard oscillatory module: a device made of coils and a capacitor (one or more), needed to generate high-frequency oscillations;

- spark gap with tungsten electrodes: to produce a spark during breakdown;

- power stabilizer: to rectify the input voltage;

- control unit;

- current feedback line;

- fuse to break the electrical circuit when the current increases too sharply.

The design may also include a gas-type valve (to protect against an increase in the product’s own temperature), an output transformer and sensors for mechanizing operation.

For complete automation, a microprocessor and security system elements are installed - they can withstand correct operation.

This mechanism functions approximately as follows. The operating voltage is supplied to the step-up transformer - to the primary winding. As a result of the electrical process, an electromotive force of several kilovolts appears on its secondary winding. The current current frequency corresponds to the input frequency (50 Hz).

The secondary winding is connected to a special capacitor assembly - the so-called “oscillatory circuit capacitor”. Its gradual charging begins, which causes its own oscillations to appear in the circuit. Their frequency gradually increases and at some point exceeds the frequency of the input current.

In this case, the open circuit is closed by the forces of a spark gap - a special key. The accumulated vibrations flow through the energy circuit, the air gap is “broken” by voltage supplied at an extremely high frequency, and the welding machine begins active work.

For a complete picture of low complexity, we recommend taking a look at the diagram of a welding oscillator.

Safety

To understand what an oscillator is and what it is needed for, you need to have minimal welding skills. The main differences between the devices under consideration and the principle of their operation are given above. When working with such devices, certain safety precautions must be observed.

It is necessary to constantly monitor the correct connection to the welding circuit and check the contacts for serviceability. In addition, you should work using a protective cover, which must be removed and put on when the device is unplugged. It is also necessary to periodically check the condition of the surface of the spark gap (clean it from carbon deposits with sandpaper).

How to use

Regardless of whether the oscillator is made with your own hands or purchased as a finished product, it is important to remember a number of fundamental rules when using it for TIG welding with your own hands (however, for other methods too).

The welding oscillator may only be used by adults.

For inverter

The inverter oscillator needs additional safety measures:

- adjustment is carried out exclusively in a state of complete disconnection from the power supply network;

- general cleaning of the mechanism and stripping of contacts is carried out in the same mode;

- when working, it is important to check the serviceability of the interlock on an ongoing basis; the importance of this cannot be overestimated - failure can result in electrical injury to the welder or other specialist;

- The pulse frequency is also subject to control - it is not allowed to exceed 40 μs.

For plasma cutter

A welding oscillator, whether created by yourself or purchased, for a plasma cutter must be adjusted to the plasma cutter actually used. In order to obtain a stable process, thyristors are carefully selected for this purpose.

The main feature of the plasma cutter’s energy circuit is the constant presence of pulses, so when disconnected from the network, the contacts will be energized. Don't forget safety precautions.

Connection

The connection diagram of the oscillator to the main welding machine depends on the design of the device. First of all, the oscillator must be connected to a 220 Volt power supply.

Connection to the welding machine can be of two types: parallel and serial. The figure below shows options for connecting the oscillator, as well as an example of the layout of the device, made in the form of a separate block.

When connected in parallel, the oscillator leads are connected to the welding electrode and the workpiece. In the serial version, the oscillator is connected to a section of the cable supplying the welding electrode.

You can find a large number of diagrams and descriptions of this useful device, using which it is easy to make it yourself. The device does not contain expensive or scarce parts and is accessible for use by a person with basic knowledge of electrical engineering.

Circuits for the oscillator

The welding oscillator circuit is a technical solution based on the planned frequency of use and operating conditions.

Together with argon arc welding

A do-it-yourself oscillator for argon arc welding should be created according to the principle of constant action. The connection is made through a “standard” transformer. Assembly does not require expensive or unique parts; difficulties are possible only with thyristors. They are selected when checking the stability of the discharge.

Although it is possible to work without thyristors - the oscillator circuit of this design is simpler.

For inverter device

The oscillator circuit consists of the following elements:

- common power supply;

- power supply for capacitors;

- input current rectifier;

- block generating the target impulse;

- transformer for creating increased voltage;

- control block.

The finished product is mounted between the rectifier and the electrode holder.

You can learn more about what tig welding is by following the link.

Oscillator for aluminum welding

A homemade oscillator for processing aluminum is almost mandatory in the absence of a “factory” one. The point is in a special arc burning mode, which is characterized by poor stability.

The main task in this case is the constant transformation of low frequency alternating current into high frequency.

With plasma cutter

The oscillator for the inverter is created of a spark type - due to the required voltage of about 20 kW to generate plasma. When its power button is pressed, the charge begins to accumulate in the capacitor(s), being discharged into the air gap when ready or necessary.

These are sold ready-made, but it is also possible to make them yourself, the main thing is to know radio engineering.

When making your own oscillator for a plasma cutter, it is important not to forget the following elements:

- a button to start the power source of the entire plasma cutter, which also powers the capacitor;

- capacitor (pay attention to the required type and power) - this component directly affects the duration of the pulse;

- thyristors (also type and power) - when the thyristors are closed, the stability of the welding arc appears.

Useful article - How to weld stainless steel at home

Where are the devices used?

Oscillators are widely used in the processing of non-ferrous metals. If you need to make a strong, neat seam, the oscillator will solve the problem as quickly as possible - by exciting a lightning arc and starting the welding process. This is much simpler and more effective than striking the product with an electrode.

An oscillator is indispensable when you need to make a precise seam. The master attaches the end of an iron needle to the nearest edge of the joint, lowers the mask onto his face, then presses a button and an arc appears. This significantly reduces the complexity of processing products in order to remove traces of contact with electrode elements.

The welding oscillator is also used for processing thin sheets of various alloys. The inverter current in them is set to minimum levels; minor adjustments to the electrode ends from the weld pools are fraught with failures and gaps in the arc. The oscillator allows you to stabilize low-current electric welding processes.

Step-by-step production

It is best to assemble the oscillator yourself with the help of an experienced welder. At the same time, the economics here are simple: if you have to cook regularly, it is optimal to buy a certified product, and if literally once or twice a year, it is cheaper to do it yourself.

To do this, you will need a “regular” choke (ferrite ring with a copper cable), a ready-made transformer, and a switch. An indicator of a closed connection is desirable (for example, MTX-90).

Oscillator for inverter

Due to the versatility and wide range of capabilities of inverter and plasma technology, the features of the future use of the welding oscillator should be taken into account:

- intended purpose: type of alloys being welded and their thickness (believe me, this matters);

- required parameters of rated current and power - if they are exclusive (for example, quite high), electrical components will need to be expensive.

To assemble a device for an inverter with your own hands, do not forget the following:

- the transformer windings are adjusted to the required current - the number of turns is changed, the core is additionally wound;

- a spark gap is installed;

- the circuit is amplified by an oscillating circuit equipped with one or a pair of capacitors;

- After assembly, a check is performed: the start button activates the spark gap, which generates a welding arc.

If the device is assembled correctly, the arc will be easy to light and will be highly stable. You can learn more about what arc welding is by following the link.

Oscillator for plasma cutter

The do-it-yourself oscillator for a plasma cutter is assembled according to a well-known scheme, but it is important to pay attention to the capacitors. Components from fluorescent lamps are considered to have the greatest resource and operational flexibility.

Alternatively, you can connect not a transformer to the circuit, but a voltage multiplier - by removing it from the TV, LCD monitor or copy machine.

It is important to ensure the insulation is of the highest quality possible - otherwise the high-frequency current will “break through” its own winding. To prevent humming, it is recommended to treat finished windings with epoxy.

From the microwave

You can assemble an oscillator with your own hands using parts from a microwave oven. The main component is a transformer from a microwave oven, which will become a power unit. It is good for its ability to create as much as 2.2 kV - in a safe mode, a few tens of centimeters from users.

You can increase from 2 kV to 5-6 kV using added capacitors. The core for the high-frequency transformer will fit from an outdated monitor.

A copper cable with a thickness of 15 mm is suitable for the primary winding, and a copper cable with a cross-section of up to 50 mm2 is suitable for the secondary winding. The windings are covered with vinyl and special transformer paper.

The arresters are made with high quality from ordinary bolts and copper pipes.

The argon start valve is purchased ready-made. You can also add a start button along with its power source to your shopping list.

As an option for using scrap materials, you can take parts of not a microwave, but an unnecessary TV. Thus, the TDKS transformer is almost guaranteed to be in working condition - it is popular for creating homemade welding equipment, so it is easy to buy.

You can download the diagram that the author demonstrates in the video by clicking on the picture, and in the window that opens, right-click and select save as.

From the ignition coil

The prevalence of automobile ignition coils led technical thought to this design. However, due to the incomplete similarity of the output characteristics with the optimal level, it is still not recommended to use this option.

The coil is supplemented with a high-voltage diode and thyristor assemblies - for this you need to be proficient in electrical engineering. Otherwise, the arc will not burn, and electrical safety will be at risk.

Will you make the oscillator yourself?

Yes

33.33%

No

66.67%

Voted: 3

Operating rules

Using oscillators is not difficult, but requires following a number of rules. Then working with the device becomes safe, convenient and productive. The rules of use are as follows:

- The use of these devices is permitted both indoors and outdoors.

- In case of heavy snowfall or rain, it is better to refrain from turning on the device when working outside.

- The ambient temperature should be from -10 to +40 degrees Celsius.

- Air humidity should not be more than 98%.

- It is highly recommended not to work with the welding machine in rooms where there is a strong accumulation of dust or corrosive gases that can damage the metal or insulation.

- Be sure to make sure there is grounding before turning it on.

- The protective cover of the device can only be removed when it is switched off. The cover must be on during welding.

- There should be no traces of soot or dirt on the working surface of the spark gap. In case of contamination, you need to clean the tips of the spark gap with fine emery cloth.

When assembling an oscillator for an inverter with your own hands, you must also follow the rules of conduct with electrical devices. It is necessary to strictly follow the basic rules for assembling electrical circuits and use only those parts that have the required characteristics.

Basic mistakes

In order to avoid inconvenience and injury when operating this device, it is recommended to use it exclusively for its intended purpose - for a process in accordance with the design. It is better to demonstrate the theoretical circuit and the finished design to an experienced specialist before switching on.

To obtain the required stability in operation, sometimes it is not enough to use a standard power source. With constantly changing frequency and voltage, it is recommended to introduce a so-called autotransformer into the electrical circuit - it will smooth out unacceptable fluctuations.

The design of the unit should be planned with a margin for errors and external influences. Thus, the inductor will provide invaluable support in smoothing out oscillations at voltages up to 1 kV and will not allow the secondary winding of the transformer to burn out, and the blocking capacitor will protect the oscillatory circuit.

When laying windings, it is important to prevent short circuits - they can be easily prevented using insulating materials and impregnation of the finished cores with special varnishes (for example, bakelite).

Grounding is one of the key steps in terms of safety. Grounding helps prevent electric shock. Moreover, if the main damage from electricity is caused to internal organs and blood, then it is optimal to plan the nominal current frequency to 300 kHz - this will only cause burns to the skin and upper tissues.

Application

The main application of this device, as mentioned above, relates to welding of non-ferrous metals, although it is not limited to this area. The described device can be successfully used in combination with welding machines of any type.

Using an oscillator with a transformer for alternating current welding eliminates the disadvantages of this type of welding that cause unstable arc burning.

Moreover, in this option it becomes possible, in addition to standard electrodes, to use electrodes designed to work with direct current when welding.

This expands the technical capabilities of AC welding transformers and allows them to make welding joints that are not inferior in quality to those made by DC welding.

An oscillator designed for aluminum welding is often combined with. Aluminum is one of the most capricious non-ferrous metals that does not forgive the welder the slightest mistake.

It is prone to spattering and rapid burnout due to its low melting point. For this reason, it is for working with this metal that it is important to use technologies that allow working with low currents with high stability of the welding arc.