Cast iron is the most common iron-carbon non-malleable casting material, containing over 2% carbon, up to 4.5% silicon, up to 1.5% manganese, up to 1.8% phosphorus and up to 0.08% sulfur. In practice, cast irons containing 3÷3.5% carbon are used.

Cast iron has high casting properties, therefore it is widely used in foundries as a structural material. It is easy to cut. Sliding bearings are made from cast iron, which has a low coefficient of friction. Specially treated cast iron (high-strength) successfully competes with cast steel and forged steel in terms of quality.

The insufficient strength and high fragility of cast iron are explained by the presence of large carbon inclusions in it in the form of graphite.

The introduction of a small amount of magnesium and cerium into liquid cast iron changed the shape of graphite, it became spherical. Cast iron gained strength and lost brittleness. Such cast iron (called high-strength) is not inferior in quality to structural carbon steels. The durability of parts made from this cast iron has increased almost threefold.

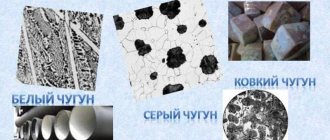

Carbon in cast iron can be in the form of a chemical compound - cementite (such cast iron is called white) or partially or completely in a free state in the form of graphite - (such cast iron is called gray).

Cast irons consist of a metal base (perlite, ferrite) and non-metallic graphite inclusions. They differ mainly in the shape of graphite inclusions. White cast iron has limited use. Some castings that require increased surface hardness are made from bleached cast iron. Its surface layer consists of white cast iron, and the core is gray. The size and hardness of the bleached layer is controlled by changing the chemical composition of the cast iron and the rate of solidification of the casting.

Gray cast iron

Gray cast iron is widely used in mechanical engineering. It received this name from the gray color of the fracture, due to the presence of free carbon in the form of graphite in the cast iron structure. Based on the type of metal base, gray cast irons are pearlitic, pearlitic-ferritic and ferritic.

Table 1. Gray cast irons, their main properties and applications

| Brand | σin MPa | NV | Properties and Application |

| Sch10 | 275 | 139-274 | Low-critical castings with wall thicknesses up to 15 mm (cases, covers, casings, etc.), parts for which strength characteristics are not mandatory - flasks, fittings, frames, frying pans, decorative parts, massive building columns, foundation slabs |

| SCH15 | 314 | 160-224 | Low-critical castings with a wall thickness of 10 - 30 mm (pipes, valve bodies, valves at pressures up to 20 MPa, etc.), low-load housing parts, sub-motor plates, levers, pulleys, flywheels, containers for oil and coolant, filter housings, flanges, covers, chain sprockets |

| SCH18 | 354 | 167-224 | Critical castings with a wall thickness of 10 - 20 mm (pulleys, gears, frames, calipers, etc.) |

| SCH20 | 397 | 167-236 | Critical castings with wall thicknesses up to 30 mm (cylinder blocks, pistons, brake drums, carriages, etc.), for the manufacture of basic body parts of increased strength and wear resistance, parts that are subject to tightness requirements at pressures up to 8 MPa (80 kgf/cm2 ), housings, gearboxes, spindle heads, balancers, faceplates, sleeves, carriages, cylinders, pumps, spools, fittings, compressors |

| SCH25 | 450 | 176-245 | Critical castings with wall thicknesses up to 40 mm (chill molds, piston rings, etc.), for the manufacture of basic body parts with increased strength and wear resistance, parts that are subject to increased requirements for tightness |

| SCH3O | 490 | 177-250 | Critical castings with wall thicknesses up to 60 mm (pistons, diesel liners, frames, dies, etc.), for the manufacture of brackets, table slides and calipers, surface-hardened parts, cylinders, pump housings, diesel engines and internal combustion engines, piston rings, crankshafts and camshafts |

| SCh35 SCh45 | 540 | 193-264 | Critical, highly loaded castings with wall thicknesses up to 100 mm (small crankshafts, parts of steam engines, etc.) of parts for which production requirements are required for tightness at pressures above 8 MPa |

Graphite has low mechanical properties. It violates the integrity of the metal base. Located between the grains of the metal base, graphite weakens the bond between them. Therefore, gray cast iron has poor tensile strength and has very low ductility and toughness. The larger and straighter the graphite inclusions, the worse the mechanical properties of cast iron. The hardness of gray cast iron, as well as its resistance to compression, is close to that of steel, which has the same structure as the metal base of cast iron.

Graphite also has some positive effects on the properties of cast iron, in particular, it increases its wear resistance, acting similarly to a lubricant, increases machinability by making chips brittle, helps dampen vibrations of products, and reduces shrinkage during the manufacture of castings.

The mechanical properties of gray cast iron can be improved by uniformly distributing fine-lamellar graphite in the casting. This is achieved through special processing - modification, when additives are introduced into liquid cast iron before casting, which form additional graphitization centers, resulting in fine-plate graphite. Cast iron with such graphite is called modified. It differs from ordinary gray cast iron in its higher tensile strength, but its ductility and toughness do not improve when modified.

According to GOST 1412-85, the letters SCH in the designation of the cast iron grade mean gray cast iron. A two-digit figure corresponds to the tensile strength σin MPa. The standard normalizes the tensile strength of gray cast iron σв = 274÷637 MPa, hardness - 143÷637 HB and chemical composition.

The main properties of gray cast iron and its application are given in Table 1.

Features of receiving

When producing white cast iron, it is important to exclude the graphitization process during crystallization of the melt, which is done:

The degree of wear resistance of castings is largely determined by the nature and composition of carbides. Alloying the metal with nickel, manganese and chromium gives a martensitic carbide structure. When their total concentration is equal to the carbon content, the hardest structure is formed.

Most often, chromium is used as the main alloying additive. It gives the alloy high corrosion resistance, which is maintained even in aggressive environments. After normalization, these blanks are resistant to acids at temperatures up to 1000 degrees. Additional alloying with nickel (0.1%), titanium (0.5%) and copper (0.5-2.0%) gives the parts the ability to maintain their geometric shape and original dimensions under prolonged heating conditions.

Products made of high-chromium white cast iron, called sormite, are capable of operating at temperatures of 800-900 degrees. It contains:

The blanks are first fired to relieve internal stress. During the annealing process, the temperature slowly rises to 850 degrees, followed by gradual cooling. The resulting parts are characterized by:

Mechanical properties

Due to the fact that white cast iron contains carbon in the form of carbides, it exhibits good strength characteristics:

Alloys with reduced carbon content are more resistant to intense thermal effects. This feature is used to reduce the number of cracks in the metal. When alloyed with nickel, chromium, and vanadium, a heat-resistant alloy is formed that has high wear resistance.

The compositional features determine the negative properties of white cast iron:

The material is very difficult to weld even when heated - microcracks form at the seam, which increase even more when cooled.

Explanation of markings

The alloy is marked with an alphanumeric code, which indicates its main properties and alloying additives:

Decoding the grade of white cast iron ChN20D2KhSh gives the following information - this is a high-alloy heat-resistant material, along with iron and carbon containing:

Grades X28, X34 are stainless cast iron with high electrical resistivity.

Application area

The high strength characteristics of the alloy and the ability to maintain a given shape under thermal influence have found application:

High hardness combined with brittleness makes machining difficult by cutting or milling methods and requires the use of tools made of special steel grades. Therefore, the use of white cast iron as a structural material is limited. Special conversion types with low silicon content are used for steel smelting and foundry production.

Half-and-half or bleached varieties contain carbon in the form of carbides and in a free state. They have high wear resistance and are used for the manufacture of friction mechanisms subject to dry friction:

Some products require high surface hardness of the cementite structure. It is created artificially by rapidly cooling the workpiece to a depth of 5 mm. This operation is called bleaching. It is required:

Preparation of malleable cast iron

White cast iron serves as a raw material for the production of other types of metallurgical products. It is used for the production of malleable cast iron using heat treatment, during which the process of graphitization and decarbonization of the workpieces occurs. The ratio of the starting elements in the raw materials is:

It contains the structure of ledeburite, which is a mechanical mixture of cementite and perlite. Workpieces on special pallets are slowly passed through chambers with a given temperature regime. The speed of movement is calculated in such a way that the metal is exposed to heat for a certain time.

Annealing takes place in several stages with different temperature conditions:

The annealing time can be reduced by pre-hardening the castings and subsequently using a higher temperature regime. But at the same time, stresses and cracks form in the metal structure. Therefore, the method is used to a limited extent - only for small parts of simple shape.

Source

High-strength cast iron with nodular graphite

Ductile iron is produced by introducing magnesium (up to 0.9%) and cerium (up to 0.05%) into liquid gray iron before pouring it into molds. The main part of these modifiers evaporates, oxidizes and turns into slag, so that no more than 0.01% of these elements are found in the solid metal. Magnesium and cerium actively remove sulfur from cast iron. But their main role is to change the flake-plate shape of graphite to spherical. After modifying the cast iron with magnesium or cerium, 75% ferrosilicon (an alloy of iron and silicon) is added to the ladle. Unlike modified gray cast iron, ductile iron has a higher carbon and silicon content and a lower manganese content.

The metal base of ductile iron consists of ferrite and perlite or only perlite. This cast iron combines the valuable properties of steel and cast iron. It has relatively high strength with sufficient ductility and toughness. High-strength cast iron successfully replaces steel casting and even steel forgings, which gives a great economic effect. Products made of high-strength cast iron, due to its increased wear resistance, can work under friction conditions. High-strength cast iron retains its strength better than gray cast iron when heated, so it can be used for work at temperatures up to 400°C (gray cast iron can withstand temperatures up to 250°C).

GOST 7293-85 normalizes the tensile strength σв, yield strength σт, relative elongation δ and hardness НВ of high-strength cast irons. Requirements for castings made from these cast irons are established by regulatory and technical documentation. The principle of marking high-strength cast iron (DC) differs from the marking of gray cast iron. The designation of their brand includes two numbers - the first indicates the tensile strength, the second - the relative elongation. For example, the grade of cast iron HF 42-12 means that this cast iron has a tensile strength σв = 412 N/mm2 (42 kgf/mm2) and elongation δ = 12%.

The standard provides for 10 grades of high-strength cast iron: VCh 38-17, VCh 42-12, VCh 45-5, VCh 50-7, VCh 50-2, VCh 602, VCh 70-2, VCh 80-2, VCh 100-2, HF 120-2. The standard or reference book provides additional information about this cast iron: yield strength σt = 274 N/mm2 (28 kgf/mm2), hardness 140÷200 HB.

Many parts (including shaped ones) are made from high-strength cast iron, which were previously made from steel, base and body parts of increased strength (cases and frames of machine tools, large faceplates, sleeves, carriages, cylinders, brackets, gears, overhead guides of machine tools and parts with surface hardening). They replace Steel 20L, 25L, ZOL and 35L steels.

Application area

This alloy is used in the following industries: mechanical engineering, machine tool building, shipbuilding. Some elements of household products are produced from it. In mechanical engineering, it is used to make parts for trucks and cars, tractors, combines and other agricultural machinery. The use of alloying additives makes it possible to obtain specially specified properties. For example, they are used in the manufacture of slabs with different surface shapes.

White iron casting

Bleached cast iron has a fairly limited scope. It is used to produce parts of simple configurations. For example: balls for mills, wheels for various purposes, parts for rolling mills.

It is widely used in the production of parts for such large units as hydraulic and molding machines, and other industrial mechanisms in this area. A specific feature of their work is that they are constantly exposed to abrasive material.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source: stankiexpert.ru

Malleable cast iron

In the structure of malleable cast iron, graphite has a flaky shape. This type of graphite is called annealed carbon. Compared to gray cast iron, ductile cast iron has higher strength, ductility and toughness. It got its name because it has increased plasticity. Cast iron is not subject to forging in the truest sense of the word.

The process of producing castings from malleable iron includes two stages: the production of shaped castings from white cast iron and annealing of the resulting castings for the purpose of graphitization of cementite. During annealing, white cast iron cementite decomposes to form flake-shaped graphite. As a result, brittle and hard castings become ductile and softer. Depending on the conditions and annealing mode, the structure of cast iron can have a ferritic (F), pearlitic (P) and ferrite-pearlite metal base. The most widely used is ductile ferritic ductile iron. Annealing of malleable cast iron is a very lengthy process, taking 70-80 hours. However, it can be accelerated by hardening white cast iron castings before graphitization, as well as modifying cast iron with aluminum, boron, bismuth or titanium. There are other ways to speed up the annealing process. The use of these methods allows you to reduce the annealing time to 35-40 hours.

Table 2. Malleable cast irons, their main properties and applications

| Brand | NV | Properties and Application |

| CC 35-10 CC37-12 | 160 | Ferritic cast irons are used for the production of parts, operated under high dynamic and static loads (cases, gearboxes, hubs, hooks, brackets, rear axles, brackets) |

| CC 30-6 CC 33-8 | 160 | For the manufacture of less critical parts (clamps, nuts, valves, parts of agricultural machines, mufflers, flanges, couplings, brake parts, pedals, wrenches, pads, brackets) |

| CC 45-7 | 203 | Malleable cast irons of pearlitic class grades have high strength, moderate ductility and good anti-friction properties. They are used to produce cardan shaft forks, gears, worm wheels, pistons, bearings, links and rollers of conveyor chains, bushings, clutches, brake pads, crankshafts |

| CC 50-5 | 226 | |

| CC 55-4 | 236 | |

| CC 60-3 | 264 | |

| CC 65-3 | 264 | |

| CC 70-2 | 280 | |

| CC 80-1.5 | 314 |

According to GOST 1215-79, malleable cast iron is marked according to the same principle as high-strength cast iron. For example, the grade of cast iron KCH 33-8 means that this cast iron has a tensile strength σв = 32.4 N/mm2 (33 kgf/mm2) and elongation δ = 8%.

Ductile iron castings can be obtained with a cross-section of up to 55 mm. With a larger cross-section, lamellar graphite is formed in the core of the castings and the cast iron becomes unsuitable for annealing. In mechanical engineering, high-strength cast iron is more often used, which is obtained using less complex and cheaper technological processes than the production processes of malleable cast iron.

The main properties of malleable cast iron and its application are given in Table 2.

Composition and types of white cast iron

White cast iron consists of the so-called cementite eutectic. In this regard, it is divided into three categories:

- Hypoeutectic. These are alloys in which carbon does not exceed 4.3% of the total composition. It is obtained after complete cooling. As a result, it acquires the characteristic structure of such elements as pearlite, secondary cementite and ledeburite.

- Eutectic. Their carbon content is 4.3%.

- Hypereutectic white cast iron. The content exceeds 4.35% and can reach 6.67%.

In addition to the above classification, it is divided into ordinary, bleached and alloyed.

The internal structure of white cast iron is an alloy of two elements: iron and carbon. Despite high-temperature production, it retains a fine-grained structure. Therefore, if you break a part made of such metal, a characteristic white color will be observed. In addition, in the structure of a hypoeutectic alloy, for example, hard grades, in addition to pearlite and secondary cementite, cementite is always present. Its percentage can approach 100%. This is typical for a eutectic metal. For the third type, the structure is a composition of eutectic (Ep) and primary cementite.

One of the varieties of such alloys is the so-called bleached cast iron. Its basis, that is, the core, is gray or high-strength cast iron. The surface layer contains a high percentage of elements such as ledeburite and perlite. The whitening effect up to 30 mm deep is achieved using the rapid cooling method. As a result, the surface layer is white, and then the casting consists of an ordinary gray alloy.

White cast iron structure

Depending on the percentage of alloyed additives, the following types of metal are distinguished:

- low-alloyed (they contain no more than 2.5% alloying elements);

- moderately alloyed (the percentage of such elements reaches 10%);

- highly alloyed (in them the amount of alloying additives exceeds 10%).

Quite common elements are used as alloying additives. The alloyed white cast iron obtained in this way acquires new, predetermined properties.

Advantages and disadvantages

Like all cast iron alloys, white ones are distinguished by great strength combined with brittleness under strong mechanical shocks. Among the main positive qualities of white cast iron are:

- high hardness;

- high resistivity;

- wear resistance;

- increased corrosion resistance.

An important quality of white cast iron is considered to be very good resistance to high temperatures, which is used to reduce the number of cracks in initial castings.

The main disadvantages include such qualities as:

- fragility and the possibility of destruction under mechanical stress;

- low casting qualities and poor mold filling;

- the likelihood of internal cracks forming during casting;

- complex and low-quality mechanical processing.

Formation of defects during welding due to the rapid burnout of carbon and the formation of pores.

Marking

In industry, types of cast iron are labeled as follows:

- pig iron

- P1, P2; - pig iron for castings

- PL1, PL2, - pig iron

- PF1, PF2, PF3, - conversion high-quality cast iron

- PVK1, PVK2, PVK3; - cast iron with lamellar graphite (gray cast iron

- SCh (the numbers after the letters “SCh” indicate the value of tensile strength in kgf/mm2, 1 kgf/mm2 = 10 MPa); - malleable cast iron

- KCh (the numbers after the letters “KCh” indicate the value of tensile strength in kgf/mm2 and relative elongation in%); - cast iron with nodular graphite for castings (high-strength cast iron)

- HF (the numbers after the letters “HF” indicate the value of tensile strength in kgf/mm2 and relative elongation in %); - anti-friction cast iron

(gray - AChS, high-strength - AChV, malleable - AChK); - alloyed cast iron with special properties

- Ch (the letters after the letter "C" indicate alloying elements: X - chromium, C - silicon, G - manganese, N - nickel, D - copper, M - molybdenum, T - titanium, P - phosphorus, Yu - aluminum).

Stainless alloys

To increase the resistance of white cast iron to corrosion, large amounts of chromium are added to it. This leads to the formation of an oxide film on the surface and further cessation of oxygen access. In addition, high-chromium white cast iron becomes resistant to alkaline solutions, sulfuric and nitric acid.

Additionally, the process of alloying with chromium prevents the possibility of coagulation of carbides when the alloy is heated strongly. This allows you to obtain high-quality welded joints of parts made of white cast iron. If nickel and molybdenum are added along with chromium during the alloying process, the resulting stainless alloy can be compared in strength to the best heat-resistant steels, which are much more expensive.

Chromium-containing white cast iron is used in cases of severe operating conditions, the presence of alkalis and oxidizing agents, and the need for high electrical resistance.

Physical and mechanical properties

White iron castings are wear-resistant, relatively heat-resistant and corrosion-resistant. The presence in part of their cross-section of a structure different from the structure of white cast iron reduces these properties. The strength of white cast iron decreases with increasing carbon content in it, and therefore carbides. The hardness of white cast iron increases with increasing proportion of carbides in its structure, and consequently with increasing carbon content.

White cast iron with a martensitic structure of the main metal mass has the highest hardness. Coagulation of carbides sharply reduces the hardness of cast iron.

When impurities dissolve in iron carbide and form complex carbides, the hardness of them and white cast iron increases. According to the intensity of their influence on the hardness of white cast iron, the main and alloying elements are arranged in the following sequence, starting with carbon, which determines the amount of carbides and increases the hardness of cast iron more intensely than other elements.

The effect of nickel and manganese, and partly chromium and molybdenum, is determined by their influence on the formation of the martensitic-carbide structure and their content in quantities corresponding to the carbon content in cast iron ensures maximum hardness of white cast iron.

Cast iron containing 0.7-1.8% boron has a particularly high hardness HB 800-850. White cast iron is a very valuable material for parts operating under wear conditions at very high specific pressures and mainly without lubrication.

There is no direct relationship between wear resistance and hardness; Hardness does not determine wear resistance, but must be taken into account in conjunction with the structure of cast iron. The best wear resistance has white cast iron with a thin structure of the main metal mass, in which carbides, phosphides, etc. are located in the form of separate small and evenly distributed inclusions or in the form of a fine mesh.

The structure of the main metal mass also determines the special properties of alloy cast iron - its corrosion resistance, heat resistance, and electrical resistance.

Depending on the composition and concentration of alloying elements, the main metallic mass of alloyed white cast iron can be carbide-austenitic, carbide-pearlitic and, in addition, contain alloyed ferrite.

The main alloying element in this case is chromium, which binds carbon into chromium carbides and complex chromium and iron carbides.

Solid solutions of these carbides have a high electrode potential, close to the potential of the second structural component of the main metal mass of cast iron - chromium ferrite, and the resulting protective oxide films determine the increased corrosion resistance of high-chromium white cast iron.

In the presence of chromium as an additional component, the temperature resistance of carbides increases significantly due to a significant slowdown in diffusion processes during complex alloying.

These characteristic features of alloyed white cast iron have determined its areas of use, depending on the structure, as stainless steel, magnetic cast iron and high electrical resistivity cast iron.

Source