Increasingly, our clients began to ask for “smaller” and “cheaper” options for circular sawmills; especially for this case, in 2013, the PD-2000 “Mini-450” circular sawmill was developed and put into mass production.

This is a new model of woodworking machines of the PD-2000 series. The mini-sawmill retained the main functions and capabilities of its “big sister” - the PD-2000 Katun-560 miter saw, but decreased in size and lost weight. The “appetites” have also decreased: if the PD-2000 Katun has a power consumption of the main electric drive of 11 kW, then the PD-2000 Mini has only 7.5 kW, plus by reducing the diameter of the saw blade to 450 mm, we increased the spindle rotation speed to 3000 rpm minute.

Thanks to the rotation of the saw by 90 degrees, you can obtain edged lumber of various parameters without turning the log. Thanks to the stability of the structure and circular sawing, you get high quality products. This version of a mini sawmill can be used not only in private households, for building a house or cottage, but also to set up your own small business for the production and sale of lumber.

In addition, the cost of the PD-2000 Mini is significantly lower than any other circular sawmill. The compact nature of the woodworking machine will allow it to be placed on the territory of a private farm or on a summer cottage.

Characteristics of the Mini 450 sawmill

| Spindle speed, rpm | 3000 |

| Cutting depth, mm | up to 150 |

| Max. log diameter, mm | 600 |

| Saw blade diameter, mm | 450 |

| Cut thickness, mm | 4,1 |

| Productivity, cube/shift | 6 |

| Main engine power, kW | 7,5 |

| Dimensions, mm: | 2100x1020x1550 |

| Weight, kg | 225 |

Self-production

You can make a mini sawmill of any type yourself. To do this, you need to decide what type of equipment is needed for the job. True, we should not forget that a homemade sawmill will have lower operating performance, but this will not interfere with work at home.

Before you start creating a mini-sawmill, it is important to decide on the indicators:

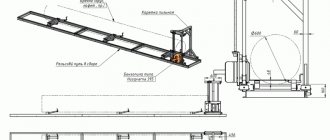

Mini sawmill drawing

- how many cubes of wood are planned to be processed on the machine;

- approximate dimensions of the log, its thickness and length;

- how the mini-sawmill will be installed, stay in one place all the time, or move around the work area;

- what type of energy will be used, electricity or gasoline.

The given characteristics depend on what materials and tools need to be prepared for production.

You can construct:

- disk installation;

- tape equipment;

- tire mini-sawmill (logosol);

- frame device.

All designs have their own manufacturing characteristics and require the use of certain materials.

Mini disc sawmill

A homemade mini-disc sawmill is very common. It has a simple design, and working with it is not difficult.

Scheme of a mini disc sawmill

In many cases, a circular saw is produced, which is a solid base; most often a table is used for this; a motor and a shaft with a circular saw are mounted on it. Parts made of wood or metal are used for the base; they are installed crosswise and secured with a board of the required length. Metal plates are installed on the board using bolts.

It is important to leave a slot in the plates for the engine and saw, as well as holes for their fastening, which must be countersunk. The saw is attached in the middle of the plate and connected to the base with screws. Attach the disk insert in the hole between the plates.

When producing a mini-disc-type sawmill, it is important to ensure that all connections are strong; the safety of work depends on their quality.

Mini band sawmill

It is quite difficult to make a mini band-type sawmill. To do this you need to have special skills and knowledge. To construct such equipment, it is necessary to prepare:

Band sawmill drawing

- pipes of different diameters and sizes;

- metal corners;

- channel;

- pulleys;

- profile pipes.

For manufacturing you will need an electric drill, a welding machine, a grinder and a set of fasteners.

Production begins with the construction of a U-shaped frame, this is done using corners or two channels. After this, make holes in the frame, the distance between which should be 1 m. Then tighten the channels with pipes with a diameter of 25 cm, secure everything with bolts and studs. Build racks on which the mini-sawmill will be mounted.

After installing the supporting part, it is necessary to construct a mobile element - a trolley on which the saw will be located. Its movement is carried out by an electric motor. To make a cart, you need to take a metal plate 40 mm thick. Attach a saw to the cart and make a steering wheel on the side to control the operation of the device. Make clamps from pipes with a diameter of 40 mm, place movable hoses inside. The final step is to install the saw blade and motor.

Tire mini sawmill

For production it is necessary to make a profile and a working trolley, which is moved by a motor.

For high-quality work, it is necessary to prepare a high-strength profile and attach supports to it. To ensure smooth cutting, 4 wheels and a manual drive are used. The optimal solution for the production of such an installation is to use a well driver with a drive wheel.

Frame mini sawmill

The frame sawmill is manufactured according to a specific pattern.

Base. It must be stable, the quality of the cut depends on this, metal or wooden structures can be used, guides must be made from profiles or pipes of different diameters.

Scheme of a frame mini-sawmill

Engine. It is recommended to use an electric type; a chain saw is not suitable for this type of work.

Element for fastening logs. It should be made not too thick and high, so that later there are no problems when sawing; metal supports or parts made of hardwood are perfect.

Tire or disk. They are a working part, the length of the disk and tire should be approximately the same, the chain with a sharpening angle of 10 degrees.

Since when working on a frame mini-sawmill a large amount of waste is generated, it is necessary to make a cinder block.

Self-production of a mini-sawmill is a rather complex process that requires special attention. It is important to follow safety regulations when designing.

Sawmill operation

The PD-2000 MINI-450 sawmill has a saw blade with a diameter of 450 mm. The cut on one side is 150 mm, which allows you to get a board with a maximum size of 300 mm. The design of the sawmill eliminates the possibility of the formation of a “step” when sawing logs into boards. Sawing is carried out in both directions of movement of the sawmill. The productivity of this equipment reaches 6 cubic meters per shift and depends on the type of product produced (boards, beams, slats, etc.) The maximum diameter of the processed log is 600 mm. The length of the workpiece is up to 6 meters (this parameter can be increased by installing an additional section of the rail track). The PD-2000 MINI sawmill is easy to use and easy to transport. The buyer is supplied with a configured sawmill, completely ready for work. The installation of the rail track is carried out by the customer on site independently (detailed instructions and options for installing the track are located in the technical data sheet for the sawmill).

Type of frame saws

There is a wide variety of equipment that is used for sawing wood. Basically, a frame is used on which the attachments are changed. Such equipment is a mini-sawmill. There are several types.

Tape

Band saw for wood

Refers to the most profitable technology. During the production of boards, a minimum amount of sawdust is generated and can be used in any weather conditions.

When working with such equipment, it is important to remember that it is suitable for logs with a diameter of less than 70 cm. It is a complex type to create with your own hands.

Disk

Circular Saw

Most often used in the household. Easy to use, does not require special care. It does not break and can be used when working with logs of different diameters.

But there is one drawback of such a device: the disks for installation are of high quality and are not cheap, however, all expenses pay off over time. In addition, when working on a disk installation, a large amount of waste is generated.

Tire

It is a professional device and is often used to create buildings and decorative elements. The basis of the device is a tire on which attachments are attached. It is characterized by high efficiency and power, capable of processing logs of any type.

General information

Principle of operation

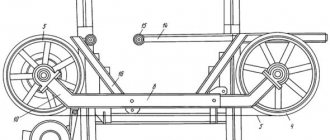

A band sawmill is a machine that performs longitudinal cutting of logs. It has the ability to precisely adjust the position of the cutting surface, thanks to which materials of different thicknesses are produced.

The design of the device includes the following elements:

- Band saw;

- Clamping mechanism;

- Frame movement mechanism;

- Device for adjusting the canvas height.

Note: The machine has an electric motor with a power of more than five kilowatts.

By means of a belt drive, torque is transmitted to the working pulleys on which the saw band is mounted. The saw mechanism must have a tensioning device for automatically adjusting the width of the retractable pulleys, spring or hydraulic type. This is necessary to compensate for the thermal expansion of the metal on the tape during operation.

When processing round logs, the frame with a saw and a power device moves along the fixed material on a concrete base with rails. By means of a screw mechanism, the height of the saw blade is adjusted relative to the lowest point of the device. It is made in such a way that any possibility of distortion during operation is eliminated.

In order for the workpiece to be securely held, it is placed between the guides and fixed using special hooks. Once the log is correctly laid and secured, the operator smoothly moves the moving part of the device, due to which the upper part of the workpiece is cut off. Afterwards, the cutting surface is raised and the frame moves to its original location.

Important: If you are using a homemade sawmill, you will have to move the carriage over the log by hand. Factory devices are almost completely automated.

Peculiarities

The industrial band sawmill has the following features:

- reliable design;

- good performance;

- energy saving;

- they have a high-quality cut, i.e. no waves occur when sawing and you can work with small materials;

- variety of types in size and weight, down to mini devices;

Varieties

Band sawmills can be divided into structural classes:

With an electric drive, there are up to five models, differing in carriage mobility, engine power, size of processed raw materials, additional components and auxiliary units;- with a gasoline engine, there are three types that have different power, different maximum diameter of the log used, as well as different saw sizes.

Also, as mentioned earlier, the sawmill can be with automatic or manual control.

Automatic band sawmills are designed to increase productivity and can process any type of wood. Various options for setting up the operation of the device are stored in the software memory - cut thickness, order of operations, etc.

A manual band sawmill can quickly solve a variety of tasks without automatic settings. The average yield of unedged board raw materials on such a device is about eighty-seven percent. The board is obtained with a clean surface, and the deviation from the cut length is no more than one millimeter.

A manual device with the movement of vertical tanks is found in gasoline band sawmills and in units with a low power of up to seven kilowatts of an electric motor.

Independence from electricity allows you to use the sawmill anywhere. At full load, fuel consumption is three liters per hour. Such a fuel tank is quite enough for continuous operation of the unit for several hours.

The diesel belt device is considered the most powerful analogue, which ensures uninterrupted sawing for a long time.

The band sawmill has an internal combustion engine and an easy start system. In gasoline engines, the shaft speed is higher, so the gear ratio is set based on the diameter of the drive pulley, the increase of which is regulated by the gearbox.