A wood sawing machine (saw bench) is a rather complex special production equipment that requires strict adherence to safety measures during operation. In the conditions of the Russian Federation, your own sawmill can greatly reduce the cost of wooden construction and/or become a source of stable income. The purpose of this publication is to help the reader understand how to make a sawmill with your own hands, choose a suitable design for yourself and avoid insurmountable difficulties in its manufacture.

The principle of operation of the sawmill

It is necessary to secure the log on the sawmill so that it remains motionless. At this time, the mobile cart is activated and cuts the log. The saw must be in a horizontal position.

To obtain boards of a given size, immediately before cutting, the operator must set the required parameters. The saw blade must be well tensioned so that it acts as a saw.

The most common types of sawmills:

- Chain.

- Disk.

- Tape.

- Angular.

Main types of sawmills

There are the following types of sawmills:

- Frame. It is a structure with flat saw blades mounted on a frame. Frame sawmills are most often installed in large woodworking shops. This device is distinguished by its high power and robust design. The frame sawmill does not require additional maintenance. Its disadvantage is the large thickness of the cut, which increases the amount of chips produced.

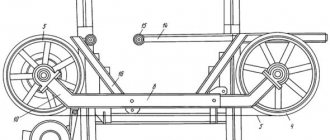

- Tape. Processing of workpieces is carried out using a saw band, regulated by stabilizing rollers. The cutting element makes only translational movements obtained from the rollers. Band sawmills are used in small woodworking shops.

- Disk. It is one of the most common types of manual sawmills. It is equipped with a disc with teeth. Each tooth cuts a small part of the log. To improve productivity, these machines are equipped with several cutting discs.

- Chain. Sawing of logs is carried out using a chain saw mounted on a frame with a metal profile. The chain sawmill is lightweight and small in size. Therefore, this mini-machine is most often used in domestic conditions.

When choosing a sawmill, it is necessary to determine the volume of workpieces processed and the operating conditions of the equipment. You also need to take into account the technical characteristics and materials from which the cutting elements are made. One of the main selection criteria is the strength of the structure. The woodworking machine must be able to support the weight of the logs being processed.

Disc type of sawmill

Considered the best view. This sawmill is easy to use and does not require much effort when making it yourself. The basis of this design will be a circular saw. It should be installed on an electric motor or on the machine spindle.

Today it is not difficult to find ready-made drawings of such a sawmill on the Internet or in books in order to make it yourself. The simplest type is considered to be “circular”. To do this, you will need a shaft with a circular saw, a table and a motor that will drive the saw.

General characteristics

It's no secret that wood is one of the most popular materials in private construction. Despite the rapid expansion of the range of such products and the emergence of cheap alternatives, wood is still in demand and has no analogues. And although purchasing good material in a hypermarket is not considered difficult, because solutions in the form of boards, timber or slats are available in every building materials shopping center, the opportunity to make similar products at home looks much more attractive.

This is not strange, because in this case you deprive yourself of many costs, and the only thing you need to buy is commercial timber. But cut lumber is very expensive. Naturally, it is unwise to buy your own sawmill to touch up a renovation or repair a roof. If you intend to build some kind of structure on a clean site, then a sawmill can be a very useful solution. And if you also try to make it yourself, this will reduce the costs to a minimum.

Today, several key modifications of such equipment are used. However, if you intend to make a homemade sawmill, then most likely you will need to choose between two main types:

- option with fixed saw placement,

- option with a trolley where the workpiece is fixed.

It is she who moves along the rails during operation. Any other varieties are modernized versions that significantly simplify the task and ensure maximum quality of work. For example, you can take a mobile saw.

The dimensions of the structure depend on the location. It is no secret that all areas (adjoining houses, country houses, etc.) have their own characteristic layout, so the selection of the optimal dimensions of the machine must be approached with special care. Any drawings available on the network (relevant literature, Internet resources and other sources of information) serve as “guidelines” - in terms of individual components, parameters and other properties. A homemade sawmill is made in such a way that it is convenient to work in a specific place under specific conditions. In most cases, such solutions are used for dissolving logs and cutting boards .

Band sawmill

Has more advantages than disk. This sawmill can work with wood of any species. It doesn’t matter to her whether the wood is highly resinous or deciduous.

- The range of wood produced is also wide - from edged and unedged boards to gun carriages, veneer and more. The sawmill is a high-risk facility and when working on it, you must remember to use protective covers. This will prevent the operator from getting caught under the cutting belt.

- In order to make a band sawmill with your own hands, you need to at least briefly familiarize yourself with the drawings. A simple option involves a basic band sawmill, which has a manual feed of the workpiece. The complex option already implies the presence of sensors and automation. Considered to be a high performance product.

The basis will be a frame that has guides. It is assembled with welded soles in which movable rollers will be placed. The U-shaped frame can be assembled by welding two channels.

On one side of the frame it will be necessary to secure the drive pulley, and on the other end (movable) - another one will be secured. The guides should be mounted in the middle of the frame - this will be a collapsible structure. If the structure needs to be subsequently transported, this will be relevant.

Corner or disc sawmill

Since the corner sawmill is multifunctional, it is most often used for large volumes of work. The design is quite easy to make with your own hands. It is much cheaper than purchasing a ready-made structure.

- To assemble this type of sawmill, you must first prepare drawings, and immediately before starting work, make sure that you have all the necessary components and components on hand.

- The first step is to assemble the frame. To do this, you will need metal pipes and guides (rails may be ideal). The joints must be secured by welding.

- The next stage is assembling the carriage. Be especially careful at this stage - the dimensions of the parts indicated in the drawings are important down to the smallest detail.

The engine can be used with high power. The engine is mounted directly on the structure frame. Through special holes, the working elements are attached to the engine. Do not install a chain drive on such a sawmill if you do not want the drive itself to overheat.

Important: Do not neglect safety precautions. Compliance with safety rules when working with a sawmill will eliminate all possible risks during operation.

Which sawmill is better

It's up to you to decide. Only you can determine what kind of design of the future installation you will need. To do this, you need to determine the available area where the sawmill will be located, and also understand the specifics of the work that you plan to carry out on this structure.

If you plan to work with small-sized boards that are used for containers and pallets, pay attention to a sawmill with a simplified design.

- If you need to get boards with clear geometric parameters, put in a little effort and make a stationary installation, with a frame on a concrete foundation.

- In order to make a portable homemade sawmill, you can use a gasoline saw made in the USSR. Models of that time are famous for the special strength of the body, which is made of aluminum alloys.

- The most popular series “Friendship” or “Ural” are equipped with engines with a power of up to 5 hp. This is enough to cut a log up to 6 meters long.

To cut logs into pieces, you can use a gasoline sawmill, which is equipped with a disk or belt mechanism. The disadvantages of such a sawmill include a large amount of sawdust that scatters around. The internal combustion engine has forced ignition.

Recommendation: Install an emergency switch in the operator's area. This will allow you to stop the motor in the event of a dangerous situation with just the press of a button.

Selection of materials and components

If you are seriously thinking about making a homemade band sawmill, be prepared to pay due attention to the selection of all parts and materials.

- The first step is to select an engine . In most cases, gasoline or electric units with appropriate power ratings are used. If you look at the situation from a practical point of view, then asynchronous (electric) models are the most optimal. This is due to the fact that they have no problems connecting to the home electrical network, and besides, their service life is quite long. And the stability of the speed ensures maximum quality of cutting logs at the sawmill.

- Materials . It is no secret that when processing huge wood, you should use high-quality products made of durable metal. For example, it is customary to install a workpiece made of a profiled (thick-walled) pipe of square or rectangular cross-section on the moving part of the “trolley”. But the supporting frame is made of channel bars, which is associated with cumulative loads. Based on this, the rails are mounted from a dimensional angle (at least 45), although a channel is also effective here, but with less linear characteristics.