Some say that after using the converter everything is bad for them. And others say that everything is fine with them.

The trick is that everyone is right. :))

Let's figure out what these people did.

Some applied the converter and waited for it to work. We cleaned off the accumulated deposits with a hard scourer or simply wiped them with a rag, then degreased the part (what matters here!) and primed it.

Others applied the converter and waited for it to work. We washed it off with water (with or without baking soda, it doesn’t matter), degreased it (what matters!) and primed it.

For both the former and the latter, the result can be either positive or negative. :)))

Magic?! NO! Magic doesn't exist.

Phosphoric acid (namely, it is the main element in the rust converter) dissolves in water, ethanol and other solvents. For those who don’t know, ethanol is banal alcohol.

From here the following follows. Any rust converter based on this acid can be neutralized either with water or any other solvent. Alcohol is also a solvent if so :))

Further, following common logic, everyone knows that if bare metal is poured with water, it will accelerate the formation of rust almost instantly (and it will not necessarily be visible to the naked eye)

This leads to the following: Wash off the rust breaker from bare body metal with water, idiotic!

And this is where we start to get to the magic.

Why is it that some people washed off the part with water and primed it and everything is fine for them, while others who seem to have done the same thing are doing poorly?

And at the same time, for some who did not wash it off, everything can either be good or bad.

And the magic lies in the pre-priming stage. Namely, degreasing the surface.

———- thinner solvent degreaser——

Before painting, as everyone knows, the surface must be degreased.

And here the dancing with the tambourine begins. Which then can become one of the reasons that will lead to misunderstandings with the rust converter.

The fact is that there are DEGREASERS and there are SOLVENTS. Both are designed to clean the surface.

BUT! SOLVENT AND DEGREASER ARE DIFFERENT PRODUCTS. When painting a car, it is a degreaser and not a solvent that is used to clean the surface before painting.

DEGREASER (SO CALLED ANTISILICONE) ACTS DIFFERENTLY THAN SOLVENT.

The difference between them is the same as between a solvent and a thinner. Car paint cannot be diluted with a solvent; for this purpose, a thinner must be used.

———- thinner solvent degreaser

——

*Thinner and degreaser*

THINNER AND DEGREASER

much

less aggressive

than

solvents

and in addition to this, both THINNER AND DEGREASER, unlike

solvents

, DO NOT LEAVE AN OILY RESTRAINT on the surface after they evaporate. There are nuances in the composition itself, but that doesn’t matter anymore.

How to remove rust from clothes using citric acid?

Dissolve 15 grams of citric acid in a glass of water and heat until dissolved. Soak a piece of fabric with a stain for 10-15 minutes, remove the stain and wash the item as usual.

Interesting materials:

How to disable automatic file sorting in Windows 10? How to disable automatic driver installation on Windows 10? How to disable autorun in Windows 10? How to disable Autosleep Windows 10? How to disable auto-installation of Windows 10 drivers? How to disable Secure Boot in Windows 10? How to disable Windows security? How to disable Secure Boot for Windows 10? How to disable Safe Mode on a Windows 10 computer? How to disable Safe Mode in Windows 7?

Rust converter

Industrial rust converters are made based on orthophosphoric acid. They can be purchased at automotive stores. In addition to the acid base, the converter contains additional additives. These additives provide a reliable protective layer that protects the metal from secondary corrosion and prepares the surface for priming and painting. Converters must be used in accordance with the manufacturer's instructions. In most cases, the preparation should not be applied to the surface, but rubbed into it, and there is no need to remove etching products by washing.

Protective measures during operation

This solution is classified as a substance hazardous to health, so it should be handled with extreme caution. Before using phosphorus liquid, prepare a respirator, as well as protective rubber gloves. They will protect the body from burns, and the respiratory tract from exposure to dangerous vapors. In addition, this composition is explosive and fire hazardous. The work area must be well ventilated.

If a chemical composition comes into contact with the skin, the following steps must be taken:

- get rid of clothes with solution on them;

- rinse the affected area of the skin with running water for 15 minutes;

- Do not rub the product into the skin or remove it with napkins;

- if the burning continues, continue the water treatment for another 15 minutes;

- Apply a gauze bandage to the affected area;

- take a painkiller.

Be sure to seek help from a medical facility to avoid worsening the injury.

The procedure for treating rust using phosphoric acid solution requires special care and attention.

Methods for removing rust

Instructions for removing rust with phosphoric acid for various cases are given below. The general rules will be:

- clean the surface of the corrosion source from foreign dirt mechanically;

- remove the loose layer of rust in the same way;

- degrease the product - it is not advisable to use gasoline; acetone, alcohol or solvent is better;

- dilute the acid in a percentage ratio of 1 to 10 in a chemically inert container (plastic or glass);

- prepare an alkaline solution to remove residues - you can dilute soda (1%), ammonia (2%), chemical pipe cleaners (1-2%), in extreme cases, soapy water or stir up washing powder.

The further procedure will depend on the size of the part being cleaned and other conditions.

Etching of products

Immersion in a vessel

Small components and products can be etched using the immersion method. It is necessary to prepare a plastic or glass vessel so that the product can be completely placed in it for cleaning, and completely filled with etching solution. The entire process will take approximately an hour, but the etching speed will depend on various criteria:

- temperature of the solution and the processed unit;

- thickness of the rust layer;

- drug concentrations;

- other factors.

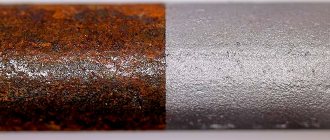

The end of the process is monitored visually by the disappearance of the “red” coating and the formation of a characteristic dark gray film instead. Upon completion of etching, the part must be rinsed with clean water, then with a washing solution, and finally dried thoroughly.

Important! Drying the assembly should be done with great care to avoid the appearance of secondary rust.

After this, you can prepare the surface for painting - putty, apply primer.

Applying acid to the surface

Removing rust by applying it to the surface is used when repairing car bodies, car rims or other large objects. Anti-rust acid is applied to large surfaces using a brush, roller or sprayer (strictly observing labor safety requirements!). Care should be taken to ensure that the solution does not get on decorative surfaces - this can damage them. If after the end of the reaction the deposits are not completely removed, the treatment is repeated again until the result is achieved. Next, the surface is washed and dried in the usual way.

Removing rust from plumbing fixtures

Cleaning the bathtub from plaque

Due to the increased content of dissolved iron in tap water, a rusty film can form on the surface of earthenware appliances (toilets, sinks) or metal surfaces (taps, pipes, siphons), which is difficult to remove mechanically, and rubbing movements lead to to mechanical damage. Phosphoric acid can also be used to remove plaque. The features of the technology in this case are as follows:

- Pre-contaminants should be removed with a soft brush;

- the cleaning period can last up to 12 hours;

- Residues of the drug must be removed more carefully; the etching products must be washed off several times.

Recommendations to help

For more successful work in removing rust from metal, it is recommended to use the following tips:

If the rust layer is more than 0.1 mm, simply cleaning the surface may not help - you need to use a converter.- The use of any chemicals should be carried out only after reading the instructions for the specific product.

- The more thoroughly you rub in and distribute the converter better, the higher the effect will be.

- Oily areas must be degreased before treatment begins.

- Applying the paint coating should be done only after the remover has completely dried.

Everything you need to know about rust converters can be found in this section.

How to properly treat metal before painting?

For these purposes the following is used:

- oxidation (creating a protective film on metal using oxides);

- phosphating (phosphate films under the influence of orthophosphoric acid);

- nitriding (saturation of the steel surface with nitrogen);

- cementation (combination of metal with carbon using a chemical reaction);

Aug 31

2022 Interesting materials:

Which city in Russia should I move to for permanent residence? Which porridge has the most fiber? In which room should I put the money tree? Which cereal has the most fiber? What foods contain magnesium? How long are maternity benefits required to be paid? How long does it take to pay for electronic sick leave? When are annual financial statements submitted? When is the initial training carried out? Which Sheremetyevo terminal do domestic flights arrive at?

Why orthophosphoric?

One of the most important advantages of using this method is the formation of a thin protective film on the metal surface after thorough cleaning of the loose mass of oxides. Thanks to this, the treated body element will be reliably protected for some time from further development of corrosion.

The principle of action of the acid is that it corrodes and absorbs iron oxide, while phosphating the surface. Therefore, after the procedure and the product has completely dried, a grayish oily film forms in place of the “saffron milk caps”.

The acid composition removes rust very quickly - in just 1-2 hours. In addition, the use of this method does not involve subsequent painting, since it does not affect the factory paint layer, and does not require the use of specialized tools: a drill, an angle grinder, a sandblasting unit, or even sandpaper.

Storage and transportation

Phosphoric acid is one of the rather serious substances, and therefore requires proper storage and compliance with transportation standards. So, the powder should be packaged strictly in airtight containers, vacuum bags, glass jars. All containers must be dry and clean to prevent foreign impurities from entering the acid, which will spoil the quality of the resulting solution.

The use of a spoiled solution can lead to the most unexpected consequences: from vapor poisoning to the absence of any result after work (the product simply will not dissolve rust). The storage area must be dry and warm to prevent condensation. Experts recommend leaving the powder in its original packaging.

Acid is transported only in special tanks with identification signs indicated on them, indicating that the cargo belongs to the category of increased danger. For transportation over long distances, you will have to obtain the necessary accompanying documents, as well as take care of the escort. In some localities or cities, the passage of such vehicles will require permission from local authorities.