The Resanta inverter, like a number of similar equipment, produces high current, which is a decisive factor in comparison with the classic AC transformer used for welding before the advent of more advanced equipment. In order to be able to take advantage of the benefits of welding connections of elements in a domestic environment, it is necessary to have a device such as a Resanta inverter or another analogue, since the standard parameters of the electrical network (voltage 220 V and frequency 50 Hz) are not enough to implement such tasks.

- Scope of application

- Manufacturing company

- Product range

- Let's look at the features of the Resanta brand

- Consumer Opinions

Operating principle of the inverter

Until recently, huge transformers were used to operate a welding machine using electricity. The bulkiness forced the use of vehicles to transport it, as well as the use of more than one person. With the introduction of inverter-type devices, this need has disappeared. The Resanta welding machine uses this technology.

When alternating current is supplied to the Resanta welding inverter, the process of converting it into direct current occurs, followed by distribution to transistors, which produce a reversible process of converting direct current into alternating current, the required frequency for welding.

This principle made it possible to significantly reduce the transformer, which is implemented in the device, and thanks to this, the Resanta Sai 140 welding inverter receives positive feedback from users.

Design features and model range

Inverters are presented in a wide range. Each model differs from the other primarily in the value of the maximum operating current. There are separate lines of such equipment: SAI, SAI COMPACT, SAI PROF, SAI PN. A lightweight inverter of the Resanta brand can be selected from the Compact series. At the same time, the main parameters practically do not differ from those in analogues of standard AIS devices; the only difference is more compact dimensions and less weight.

Watch the video and product review:

The SAI series inverter from Resant is equipped with a number of additional and extremely important functions for operation. The design provides protection against overheating, the so-called “anti-sticking”, “hot start” and “arc force”. The inverter of the PROF line from Resant differs from other devices in the ability to set the required value of the welding current using a digital panel. Another difference is a wider operating voltage range (up to 260 V).

The Resanta welding inverter can be used with different values of electrical parameters. The designation of each model indicates the maximum permissible operating current. Also, in the technical characteristics of such a device as a Resanta brand welder, there is a limitation on the level of current consumption. Additionally, the degree of protection of the device, the diameter of the electrode, the welding arc voltage and no-load voltage are indicated.

The welding inverter from the manufacturer Resanta is also characterized by such a parameter as the duration of the load, which allows you to estimate the duration of operation of the device at maximum load values.

The operation of this equipment is based on the principle of converting alternating mains voltage of a standard frequency value into a direct voltage of 400 V, after which the Resanta inverter welding machine converts this value into high-frequency alternating voltage.

Pros and cons of the device

If we compare Resanta brand equipment with analogues that were used before the advent of a fundamentally new type of equipment, we can highlight a number of positive qualities:

- Compact dimensions, and even the most productive Resanta inverter electric welding machine will have several times less weight and overall body dimensions;

- Easy control - due to the fact that the design provides a digital panel, thanks to which the inverter electric welding machine from the manufacturer Resanta can be controlled as simply as possible;

- Overheat protection prevents equipment failure;

- The high level of performance that distinguishes the Resanta brand inverter electric welding machine determines the rapid performance of the work, while the efficiency of the equipment can reach 95%;

- Lightness allows the unit to be transported to the required distances, thanks to which the SAI welder becomes a mobile device.

Among the positive qualities that are determined by the design features of such equipment, one can highlight the security of the units. This means that the Resanta SAI welding inverter and analogs from other lines of this manufacturer are made in a completely closed housing, which significantly reduces the likelihood of a large amount of contaminants getting inside the mechanism. Some models of equipment such as the Resanta SAI welding inverter are equipped with a special case where the device is placed. This simplifies the task of transporting it to the welding site.

Let's watch the video, the advantages and disadvantages of welders:

However, the Resanta SAI welding inverter also has its drawbacks, for example, the relatively high price of the units themselves, as well as their maintenance. Thus, these models of maximum performance (with an operating current above 300 A) will cost approximately 35,000 rubles.

Customer ratings

As for the working side of the issue, the electric welding inverter from the manufacturer Resanta of the SAI line is in good standing with users. Electrical equipment of this brand has been offered on the Russian market for more than three years. And during this time, there have been practically no complaints about the quality of operation of such equipment as the electric welding inverter of the Resanta company, model SAI; on the contrary, with unstable voltage and surges in electrical networks, it is quite possible to use electrodes with a diameter of 3 mm.

However, there are some nuances that become clear during operation. The point is that the welding electric inverter of the Resanta brand of the SAI series is almost never serviced under warranty, since it is extremely difficult to find a service center. And at the end of the allotted service life, the cost of repairs, if necessary, is quite high.

Thus, the welding electric inverter of the Resanta company of the SAI line has all the qualities to carry out the relevant work. The wide range of products of this brand allows you to select the most suitable device in terms of compliance of the electrical parameters with the assigned tasks.

If the goal is to purchase a welding inverter of the Resanta brand of the SAI line of low productivity with minimal values of electrical parameters, then you will not have to spend large sums. However, the cost of maintenance is still a big problem for most.

Advantages of the device

The mobility of the device is achieved by its relatively low weight, equal to 4.3 kg, as well as a special shoulder strap, which makes it very easy to carry and allows you to perform work at heights.

The main advantages of the inverter welding machine Sai 140 are:

- mobility;

- ease of operation;

- safety;

- affordable price.

To quickly form an electric arc, a special Hot start function has been implemented, which makes it easier to perform the work thanks to the automated conversion of an increased current pulse.

When welding, the master often encounters the problem of electrode sticking, but in Resant this problem is eliminated, since the device includes an anti-stick function. By using it during operation, you can automatically reduce the current value. After using the option, the system quickly restores the parameters to continue operation. Those who use the Resanta Sai 140 welding inverter in reviews describe it as convenient and reliable. The advantage of this device is its low energy consumption, in comparison with more powerful ones in its line.

Application area

In fact, the Resanta inverter is one of the modern versions of welding machines. Until the user became acquainted with such units, transformers and rectifiers for welding were in use. In comparison with them, an inverter for a home is much lighter, and therefore easier to operate. Under these conditions, equipment productivity increases significantly.

All these factors make it possible to use units such as the Resanta inverter for both domestic and industrial purposes. At home, it is necessary to convert the standard network parameters to provide a sharp jump for electric welding. Having an inverter available, you can do this without difficulty, taking into account the convenience of the design and the availability of elements for transportation.

Features of Resanta devices

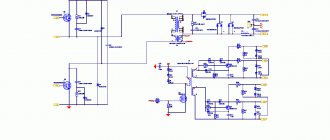

The technical process of improving the performance of the device is implemented through the introduction of a special transistor current conversion board - IGBT.

The Resanta welding inverter has a design feature - the vertical arrangement of the transistor board. This design feature made it possible to avoid the accumulation of dust, and as a result, the wear resistance characteristics were increased.

The device also implements a continuous operation system, the average of which is equal to a ten-minute interval, when using less than 70% power. If during operation this indicator of the use of power resources is increased, the average time of continuous operation will be no more than 7 minutes, after which an automatic transition to idle occurs. At the same time, the idle power consumption, equal to 75 V, allows for rapid ignition of the arc, starting the immediate process of work. The company that produces the Resanta device has provided everything for its easy use.

During operation of devices of such a system, there is a high probability of overheating of the device, which can lead to its breakdown. However, Resant devices are equipped with a special indicator that informs the welder about the presence of this problem; in such cases, it is necessary to interrupt the work process for about 5 minutes, while there is no need to disconnect the device itself from the power supply. Thanks to this feature, operation of the device becomes safer for the user. To cool the device, the system uses a set of two coolers.

An intuitive control panel is located on the front of the case, and the rear contains the power switch and cable. The electric current regulator is a relay with a rotary mechanism, which allows you to control the power of use. The front panel is equipped with:

- power indicator;

- device heating indicator;

- terminals;

- current regulator.

The device has conveniently located terminals to which the cable is connected, with its help a closed circuit is created. A strap is attached to the top of the case for easy carrying of the device.

Inside the case there is a transformer, which converts the frequency of a current equal to 50 Hz into frequency indicators of 20 kHz, using a voltage not exceeding 75 V, it is possible to obtain a current of 140 A.

Other devices in the line, such as the Resanta sai 160 pn, implement a larger input voltage range, which allows for increased current. This improves the quality of welds.

If you look at how many kilowatts the Resanta 220 welding machine consumes at maximum power, then this value can reach 6.6 kW per hour, 4.9 kW is consumed by the Resanta sai 160. Reviews from the owners of the device note only one drawback - it is a short power cable . Read about malfunctions and repairs of the Resanta SAI 190 device in this article.

Semiautomatic welding machine Resanta Saipa 220

The semi-automatic welding machine Resanta Saipa 220 has found wide application in various fields of human activity. It is used in the construction of houses and landscaping, in auto repair shops, service centers, at large production facilities and small enterprises.

Semi-automatic inverter welding machine SAIPA - 220 Resanta

41845 rub. Night discount:

-5% on all products. RUB 39,753

Features and benefits of Resanta Saipa 220

The semi-automatic Resanta 220 is a practical and easy-to-use equipment that is popular among Russian buyers. Technological and design solutions incorporated into the model by its creators make it possible to perform welding work of any complexity.

The semi-automatic Resanta Saipa 220, the price of which is quite affordable for the average Russian, has the following competitive advantages:

- Resanta semi-automatic Saipa 220 operates from a conventional electrical network. The device implements special technologies that allow pulse-width modulation of the welding current and ensure its smooth adjustment;

- the inverter circuit made it possible to make the semi-automatic welding machine Resanta Saipa 220 compact and lightweight, thereby increasing the ease of use and transportation;

- Resanta semi-automatic Saipa 220 inverter is capable of ensuring an even seam even for novice welders;

- Resanta semi-automatic welding machine 220 is equipped with built-in protection against overloads and voltage surges in the supply network;

- Saipa 220 Resanta inverter semi-automatic welding machine does not cause any problems in maintenance and operation.

In addition to the standard functionality, the semi-automatic welding machine Resanta 220, whose price cannot but please with its affordable price, includes several additional options:

- “Hot start” - this option is designed to ensure rapid ignition of the welding arc by increasing the current;

- “Anti-sticking” - the option provides for automatic shutdown of the current as soon as the wire begins to weld to the surface of the part;

- “Arc force” is an option that provides for an increase in current strength at the moment the arc length is reduced.

Excellent technical characteristics, efficiency and functionality allow us to talk about the Resanta Saipa 220 welding inverter as an effective equipment that occupies an intermediate position between household and professional tools.

You can buy the semi-automatic Resanta 220 right now in our electronic catalog. Here you will find a wide selection of components and related products to make welding work comfortable and safe.

Owner reviews

Cheap, very easy to use. I bought it not for work, but for farming. I shared it with my friends, and everyone praised it, you can easily weld 4 mm metal. Indispensable at the dacha. The body is metal and the weight is light.

Kirill G.

I bought a Resanta inverter for my garage and am very pleased. As an amateur, it is easy to work with him. Pleased with the non-stick electrode. Compact and affordable.

Sergey P.

The device is not heavy, and it is easy to carry it to the desired point, the work itself is just a fairy tale, but the cable is a bit short.

Peter K.

Main technical characteristics

| Network - voltage | 220 V |

| Highest current consumption | 25 Am |

| Idling - Voltage | 80 V |

| Arc voltage | 27 V |

| Current adjustment - range (depending on model). | From 10 to 315 Am |

| Cooling | Air |

| Largest electrode size (diameter). | 6 mm |

| Power consumption | 5 kVA |

| Weight | Up to 5 kg |

We recommend: Buying a cordless screwdriver: which one is better to choose?

The Resanta welding machine has a warning against overheating - a light on the panel. When it is triggered, it is necessary to stop the operation of the device and allow it to cool.

Options HOT START (instant start) and ANTISTICK, no sticking of the electrode, facilitate the welding process, save energy and improve the quality of work.

The device operates stably at voltages from 160 to 240 V.

The current regulator allows you to achieve an accurate result and an even seam.

The welding machine https://poluavtomat.by/ operates in the temperature range from minus 10° to +40° C. Forced tunnel cooling and a durable steel case ensure high reliability of the device.

For convenient transportation, the device is equipped with a belt.

Pros and cons of Resanta welding inverters

The Resanta inverter has competitive advantages compared to other devices:

- works on IGBT transistors (bipolar current receiver with insulation gate);

- light weight;

- compact size - easy to move around the entire construction site;

- forced tunnel cooling - reliable protection of the device;

- high productivity;

- welding of various metals;

- no heating of the cable during operation;

- economical electrode consumption;

- smooth adjustment of operating mode;

- energy saving.

We recommend: Kress rotary hammers: advantages and disadvantages

The inverter does not require highly qualified welders.

Disadvantages include:

- Welding cable length is short. Sometimes the welding process takes place with the device on the shoulder, which is not always convenient;

- at low ambient temperatures (minus 25°) - the fan freezes;

- quite high cost in contrast to other types of devices;

- The inverter requires storage in a dry, warm place. The device requires periodic cleaning as it becomes dirty.