General information

Steel, the percentage of carbon in which is more than 0.7%, is called tool steel. The phase structure is based on martensite and only in some cases ladyburite.

It is used mainly in mechanical engineering as a material for the production of tools for processing ferrous and non-ferrous alloys.

Tool steel has a number of features compared to structural steel. Among them, the most important are:

- Increased hardness, which is 60-65 units on the Rockwell scale.

- Extra strength. The tensile strength should not be lower than 900 MPa.

- Ability to resist abrasive wear.

- High hardenability is the property of steels to be thermally hardened.

- Red resistance, which characterizes a metal in terms of its ability to maintain its strength characteristics with increasing temperature exposure to it.

According to state standards, the following types of tool grades are provided, based on their technological purpose:

- Tool carbon steels GOST 1435-99. Marked with the letter “U” at the beginning of the marking. The number that follows in the designation shows the carbon component: U12, U10, etc. The dimension is taken in hundredths of a percent. The letter “A” may be placed at the end (for example, U10A), which indicates that this tool steel has a reduced number of negative inclusions. In particular, this applies to sulfur and phosphorus, elements responsible for the deterioration of the mechanical properties of the steel alloy.

- Alloyed tool steels GOST 5950-2000. The number at the beginning shows one hundredth of a percent of carbides in steel. If it is absent, the value of this parameter is assumed to be 1%. This is followed by the letter designation of alloying elements with numbers indicating their content in whole fractions of a percent: X, 5ХВГ, 9ХС and so on.

- High-speed tool steels GOST 19265-73. In technical documentation they are marked with the letter “P”. The number behind it indicates the approximate content of tungsten, the basic chemical component for this steel. In addition to it, high-speed cutters can contain cobalt and vanadium. They are also indicated in the marking with the corresponding letters: K and F. The chromium content in all high-speed steels ranges from 3-4%. For this reason, it is not indicated in the labeling.

- Stamped tool steels GOST 1265-74. This type of steel is marked similarly to alloyed steel. Depending on the nature of their application, they can be cold- and hot-formed stamped steels.

Tool steels and alloys

Carbon cutting steel. The first material used for the production of cutting tools was carbon cutting steel; this material has been known for a long time, is well studied and represents the following steel grades: U9A, U10A, U12A and U13A, the number in which indicates tenths of a percent of carbon in its composition. The material is hardened to a hardness of 61 - 63 HRC. The mechanical strength of cutting tools made of this material is quite high, but this material has the shortest service life of all known tool steels and alloys due to its low heat resistance and wear resistance.

Low-alloy tool steels are carbon tool steels with a low content (up to 1%) of alloying additives, such as vanadium, silicon, tungsten, manganese, chromium. This cutting material is marked accordingly, for example: Х6ВФ, 95ХГСВФ, 9ХС, ХВГ. These grades are also the most widely used of this group and are hardened to a hardness of 65 HRC. Increased wear resistance, compared to conventional carbon steels, and equally low heat resistance of 250-350 ° C - does not allow processing hard materials and alloys. These characteristics allow us to produce standard hand and machine tools for non-responsible and low-precision work, for processing materials at low speeds and low loads. The advantage is the low cost of manufacturing cutting material from carbon and low-alloy carbon steels.

High-alloy tool steel - made on the basis of high-carbon high-speed steel with a carbon content (C) of 0.7-1.4% with a significant content of carbides (chromium carbide, molybdenum carbide, vanadium carbide, tungsten carbide) - this significantly increases the heat resistance of the material (up to 670 °C), increases tool strength and wear resistance. These characteristics make it possible to increase the processing speed by 2-4 times compared to previous materials in this group (US and NLIS). Below we provide a grouped list of high-alloy tool steels in chronological order that appeared in the tool industry with a description of their characteristics:

- P9 and P18 are grades of high-speed tool steel that first appeared in production. The chemical composition of high-speed steel P9 is 0.8% carbon, 4% chromium, 9% tungsten, 2% vanadium. The chemical composition of high-speed steel P18 is 0.8% carbon, 4% chromium, 18% tungsten, 1% vanadium. They have equally high heat resistance. Increased wear resistance of high-speed steel P18 by 2 times compared to P9 due to the higher content of free carbides (about 3 times). P18 sands much better than P9 and burns less*. In view of all these advantages and positive qualities, it has long been accepted to consider P18 high-speed steel as a standard, in comparison with which other grades of cutting material in this group are evaluated.

- In an attempt to reduce the consumption of expensive tungsten and increase the cutting properties of cutting tools, scientists and engineers at domestic research institutes have developed many grades of molybdenum cutting steels: R9M4, R6M5, R6M3; cobalt cutting steels: R9K10, R9K5; vanadium cutting steels: R18F2, R14F4, R12F3, R9F5; and high-speed steels with a combination of alloying additives: R18F2K5, R12F2M3K8, R12F4K5, R6M5K5. These grades of high-speed steels, there are more than 40 types in total, are divided according to performance and heat resistance into groups: normal, increased and high: Cutting steel with normal heat resistance is tool steel containing tungsten P9, P12 and P18, as well as their modern analogues - P6M5 (imported analogue - HSS), Р6М3.

- Cutting steel with increased heat resistance is a tool steel containing 2% molybdenum, 2% to 4% tungsten with 6% - 8% vanadium, or 9% - 10% tungsten with 4% - 5% vanadium. This group also includes steels with alloying additives in the form of 5% cobalt, 3.5% - 4% vanadium and ≤ 12% tungsten. And also steels with 6% - 8% cobalt, 1.5% - 2% vanadium and ≤ 10% tungsten. Examples - R6M5K5 (HSS Co), R6M5K8, R9K5.

- High heat resistant cutting steel is a high alloy carbon steel containing ≥ 12% cobalt, ≤ 18% tungsten and ≤ 3.5% vanadium. In some brands, the share of tungsten is reduced to ≤ 14% by introducing an additional amount of molybdenum.

This is interesting: Description of steel 40X

All tools for working on machine tools are mainly made of high-speed steels. Technologists and managers of metalworking organizations are required to understand the grades of high-speed steel, their characteristics and the properties of alloying additives, since this data will allow them to reasonably approach the choice of a grade of high-speed steel that will be optimal for specific operating conditions and the material being processed. This choice can be made only on the basis of the technological and operational properties determined by the alloying additives included in the composition of high-speed steels.

The influence of alloying additives of cobalt, vanadium, molybdenum and tungsten on the properties of high-speed steel

- Tungsten is an alloying additive that gives high-speed steel heat resistance, increases wear resistance and significantly increases hardness. High-speed steel P18, which contains 18% tungsten in free form and is taken as the standard, is perfectly hardened and ground. High heat resistance (≤620°C) in relation to carbon and low-alloy carbon steels is due to the high tungsten content. Tungsten slightly reduces strength and thermal conductivity. Steel P18 is less ductile than P9 and P12. High carbide heterogeneity (it has slightly larger carbide segregations), therefore it is less plastic than the same P9 and P12 and is more difficult to process under pressure in a heated state.

- Molybdenum is an alloying additive for high-speed steel with more pronounced characteristics than tungsten. The molybdenum content in steel is reduced by 1.5 times compared to tungsten, while maintaining the same level of heat resistance. Steel containing molybdenum in the hot state is more ductile than steel containing tungsten, and it is easier to process using pressing and forging equipment. In addition, molybdenum significantly increases thermal conductivity (heat removal from the working area). Increased strength in steels with molybdenum content ≤5%. Carbide heterogeneity in steels with molybdenum is less, and the quenching temperature range increases. The downside is decarburization when heated before hardening.

- Vanadium is an alloying additive for high-speed steel, which gives it increased hardness (≤ 67 HRC) and increases heat resistance (≤ 635 ° C). Somewhat negatively affects such indicators as fragility, strength and thermal conductivity. Vanadium in steel worsens the grindability due to the tendency of these steels to burn*, which depends on the concentration of vanadium carbides, since they have low thermal conductivity and are harder than the base composition of the steel; the more vanadium, the worse in this sense.

- Cobalt - as an alloying additive in high-speed steel, forms finely dispersed intermetallic compounds in its composition, and not carbides as with chromium, molybdenum, vanadium and tungsten, which increases heat resistance to 670 ° C and hardness to 65 HRC. Cobalt significantly increases thermal conductivity, surpassing molybdenum in this indicator. High-speed steel with cobalt, for example R6M5K5 (imported analogue - HSS-Co), grinds better than vanadium steels. Despite these positive characteristics, cobalt reduces strength and increases fragility, high carbide-intermetallic heterogeneity. In addition, cobalt drills are almost 100% more expensive than P18 drills.

The use of cutting tools made from steels with increased and high heat resistance is rational only when working at high speeds and processing difficult-to-cut materials, since only in this case can one gain an advantage due to a faster processing speed (3-4 times faster) than with tools made from high-speed steels. steels of normal heat resistance. Steels of normal heat resistance have a number of advantages - low price, higher strength, easier to process. It is very important to take into account the professionalism and equipment of the production site with all the necessary tools to perform the work and sharpen. If the recommendations for hardening, tempering, sharpening and grinding are violated, the advantages of such steels will not be realized, in addition, the tool will be damaged (the characteristics of the tool will become worse than those of a tool made of cutting steel with normal thermal conductivity) and costs will increase.

Additionally, the cutting properties of steel can be increased by adding nitrogen to their composition in an amount of 0.06% - 0.09%. It is marked very simply, with the letter A, for example: P6M5 - P6AM5 (AP6M5), AP18, AP12. The introduction of nitrogen into the composition of high-speed steel increases the hardness by 1-2 HRC and increases the cutting properties by 20% - 30%.

The use of powder metallurgy technology in the production of cutting tools significantly increases the properties of high-speed steels. The process consists of pressing from powder, rolling and at the end of the process - forging the workpiece (hardening and shaping). This technology makes it possible to obtain cutting steel that is more homogeneous in its structure, reduce deformation during heat treatment and improve the wear resistance of the tool by up to 2 times.

Since tungsten has limited reserves on Earth and the process of obtaining tungsten is quite expensive, the world, as well as our country, began to develop tungsten-free grades of cutting steel, such as: EK-42, EK-41, 11M5F, etc. These grades of cutting steel are similar in their characteristics to grade R6M5.

Relatively recently, carbon-free highly alloyed alloys (dispersion-hardening DTS) with a carbon content of up to 0.06% have appeared, for example: V16M4K16Kh4N2, ZV20K20Kh4, R10M5K25, R18M7K25, R18MZK25. Dispersion hardening of these alloys during quenching and tempering leads to an increase in hardness to 69 HRC and heat resistance ≤ 720 °C. Having high strength ≤2000 N/mm2, cutting tools made from this material are used to work with difficult-to-cut materials, and the cutting speed increases by 1.5-2 times in comparison with P18 high-speed steel. It is economically inexpedient to process carbon and moderately alloyed structural materials with tools made from DTS, since they have a high cost and when processing ordinary materials, their properties appear at the level of R18F2 and R9K5, no more.

High speed tool steel

High-speed tool steels are distinguished from all the types of tool steel alloys presented above by their higher red resistance. These alloys do not change their mechanical characteristics at temperatures up to 650 ºС. As a result, cutting speed increases by 5 times, and tool life increases by 32 times.

This became possible due to the inclusion of tungsten or its analogue of molybdenum in their chemical composition. Also, the addition of metals such as cobalt, vanadium and chromium to steel has a positive effect on heat resistance. The most popular brands in the mechanical and machine tool industry are R18, R12, R6M4 and R10K5F5. Of this group of tool steels, it is worth noting P12, because it has better manufacturability: it is more amenable to pressure treatment.

Thermal treatment of these steel alloys includes hardening at 1250 ºС and repeated low tempering at 350 ºС. Exceeding the specified temperatures is extremely undesirable, because this leads to a sharp decrease in mechanical characteristics, in particular the formation of brittleness. Sometimes, to improve the corrosion-resistant properties, high-speed cutters are additionally treated with steam.

Stamped steel

Stamped tool steel is used in the production of dies and punches. As mentioned earlier, it is divided into cold and hot deformed steel.

Cold-formed tool steel operates at a temperature of 250-300 ºС. These include X12M and X12F1, which are based on the ladyburite phase structure. Their difference is the high value of hardenability, red-hardness and hardness (64 HRC). They are used to make massive dies of complex shapes, rollers for thread rolling, etc.

This is interesting: How to harden metal at home: on fire, in oil or in a furnace

Hot stamped steels work with hotter metal, the temperature of which can reach up to 550 ºC. Therefore, among other things, they must have heat resistance - the ability to withstand repeated overheating without cracking. The most popular brands here are 5ХНМ and ХГМ.

Tool steels at one time made a technological breakthrough in the field of metal processing. Their use made it possible to increase the cutting speed by almost 5 times. But progress does not stand still. Now they are becoming less and less relevant. Especially against the backdrop of news about the improvement of ceramic alloys.

Classification of alloy steels

Based on the carbon content of steel, it is divided into:

- low-carbon steels (up to 0.25% carbon);

- medium carbon steels (up to 0.25% to 0.65% carbon);

- high-carbon steels (more than 0.65% carbon).

Depending on the total amount of alloying elements that alloy steel contains, it can belong to one of three categories:

- low alloy (no more than 2.5%);

- medium alloyed (no more than 10%);

- highly alloyed (from 10% to 50%).

The properties of alloy steels are determined by their internal structure. Therefore, the classification of alloy steels implies division into the following classes:

- hypoeutectoid - the composition contains excess ferrite;

- eutectoid - steel has a pearlite structure;

- hypereutectoid - their structure contains secondary carbides;

- ledeburite - the structure contains primary carbides.

According to their practical application, alloyed structural steels can be: structural (divided into machine-building or construction), tool, and also steels with special properties.

Purpose of structural alloy steels:

- Mechanical engineering - used for the production of parts for various mechanisms, body structures, and the like. They differ in that in the vast majority of cases they undergo heat treatment.

- Construction - most often used in the manufacture of welded metal structures and are subjected to heat treatment in rare cases.

The classification of engineering alloy steels is as follows.

- Heat-resistant steels are actively used for the production of parts intended for work in the energy sector (for example, components for steam turbines), and they are also used to make especially important fasteners. Chromium, molybdenum, and vanadium are used as alloying additives. Heat-resistant steels refer to medium-carbon, medium-alloy, pearlitic steels.

- Improved steels (from the categories of medium-carbon, low- and medium-alloyed) steels, in the production of which hardening is used, are used for the manufacture of heavily loaded parts that experience variable loads. They differ in sensitivity to stress concentration in the workpiece.

- Case-hardened steels (from the categories of low-carbon, low- and medium-alloyed) steels, as the name suggests, are subject to carburization followed by hardening. They are used for the manufacture of all kinds of gears, shafts and other parts similar in purpose.

Dependence of the thickness of the cemented layer on temperature and processing time

The classification of construction alloy steels implies their division into the following types:

- Bulk - low-alloy steel in the form of pipes, shaped and sheet products.

- Bridge construction - for road and railway bridges.

- Shipbuilding cold-resistant, normal and high-strength - well resistant to brittle fracture.

- Shipbuilding cold-resistant high strength - for welded structures that will operate in low temperature conditions.

- For hot water and steam - operating temperatures up to 600 degrees are allowed.

- Low-cut, high-strength - used in aviation, sensitive to stress concentration.

- Increased strength using carbonitrite hardening, creating a fine-grained steel structure.

- High strength using carbonitrite hardening.

- Strengthened by rolling at a temperature of 700-850 degrees.

Application of tool alloy steels

Tool alloy steel is widely used in the production of various tools. But in addition to its obvious superiority over carbon steel in terms of hardness and strength, alloy steel also has a weak side - higher fragility. Therefore, such steels are not always suitable for tools that are actively exposed to shock loads. Nevertheless, in the production of a huge range of cutting, impact-stamping, measuring and other tools, alloy tool steels remain indispensable.

Separately, we can note high-speed steel, the distinctive features of which are extremely high hardness and red resistance up to a temperature of 600 degrees. Such steel is able to withstand heat at high cutting speeds, which allows you to increase the speed of metalworking equipment and extend its service life.

A separate category includes alloyed structural steels, endowed with special properties: stainless, with improved electrical and magnetic characteristics. Depending on what elements, as well as in what quantities, are predominantly contained in them, they can be chromium, nickel, chromium-nickel-molybdenum. They are also divided into three-, four- and more-component ones according to the number of alloying additives they contain.

Advantages and range

Tool steel is one of the most popular materials on the market. The alloy has high hardness and low cost. However, the material also has a drawback - its low wear resistance, so it is not used for the production of machine parts and equipment that are subject to constant loads.

The range of this material is as follows:

- hot rolled squares and circles;

- forged strips, circles and squares.

Marking of alloy steels

The category of alloyed steels includes a wide variety of steels, which necessitated the need to systematize their alphanumeric designations. The requirements for their marking are specified by GOST 4543-71, according to which alloys endowed with special properties are indicated by markings with a letter in the first position. By this letter it is possible to determine that the steel, by its properties, belongs to a certain group.

An example of deciphering alloy steel markings

So, if the marking of alloy steels begins with the letters “F”, “X” or “E” - we have an alloy of the stainless, chromium or magnetic group. Steel, which belongs to the stainless chromium-nickel group, is designated by the letter “I” in its marking. Alloys belonging to the category of ball bearing and high-speed tool alloys are designated by the letters “Ш” and “Р”.

Steels classified as alloyed may belong to the category of high-quality, as well as especially high-quality. In such cases, the letter “A” or “W” is placed at the end of their mark, respectively. Steels of ordinary quality do not have such designations in their markings. Alloys that are produced by the rolling method also have a special designation. In this case, the marking contains the letter “N” (hard-worked rolled steel) or “TO” (heat-treated rolled steel).

The exact chemical composition of any alloy steel can be found in regulatory documents and reference literature, but the ability to understand its markings also allows one to obtain such information. The first figure allows you to understand how much carbon (in hundredths of a percent) alloy steel contains. After this number, the brand lists the letter designations of alloying elements that are additionally contained.

Designation of alloying elements in steel markings

After each such letter the quantitative content of the specified element is indicated. This content is expressed in whole fractions. There may not be any number after the letter indicating the element. This means that its content in steel does not exceed 1.5%. State standard 4543-71 regulates the designation of alloying additives included in alloy steel: A - Nitrogen, B - Niobium, C - Tungsten, G - Manganese, D - Copper, K - Cobalt, M - Molybdenum, N - Nickel, P - Phosphorus, P - Boron, S - Silicon, T - Titanium, C - Zirconium, F - Vanadium, X - Chrome, Yu - Aluminum.

This is interesting: At what angle to sharpen drills for metal. Sharpening options that can be done by hand

Areas of use

This material has a fairly wide range of applications in industry. They are used in the manufacture of:

- cutting tools;

- measuring devices;

- casting molds operating under pressure;

- working parts of dies that operate on the principle of hot and cold deformation;

- high-precision products.

Main types

This type of material is divided into the following three main categories:

- tool carbon steels;

- alloyed tool steels;

- high-speed.

All of them are produced in accordance with established GOST.

Carbon types of material lose their strength when heated; accordingly, they are used for the production of tools that operate at low speeds or under simple cutting conditions, when the heating temperature is no more than 200 degrees.

They are mainly used for the production of:

- files;

- drill;

- scans;

- taps and more.

Since carbon tool steel has low weldability, it is not used in the manufacture of welded structures.

Depending on the percentage of carbon, manganese, silicon, sulfur and other elements in the material, it is divided into the following grades:

- U7;

- U8;

- U8G;

- U10 and others.

Alloyed materials and their markings

Alloyed materials additionally contain the following elements:

- nickel;

- copper;

- manganese, etc.

All of them improve the characteristics of the material. Alloying elements must be indicated when marking using special symbols and letters. All this allows you to see in advance what a given tool steel consists of. Material brands can also include not only letters, but also numbers. The numbers indicate how much of a particular element is contained in steel as a percentage. If a number is not given when marking, then the amount of the element is about 1 percent.

When marking alloy steel, the first place is taken by the amount of carbon, which is equal to tenths of a percent. For example, grade 6ХС contains carbon in the amount of 0.6%, as well as one percent each of silicon and chromium.

Tool alloy steels are mainly used for the production of stamping or cutting tools, these include:

- dies;

- taps;

- sweeps;

- drill;

- cutters and more.

Like carbon steels, alloy materials are also unsuitable for the production of welded structures.

High speed steels

The marking of high-speed materials consists of the letter “P”, a number indicating the mass fraction of tungsten and the letters of the elements present in the material. This can be cobalt, molybdenum and others. Next come the digital values of their mass fractions. If the marking includes the letters “Ш”, then this means “electroslag remelting”.

The proportion of chromium in high-speed steel is not indicated when marking, and there is also no indication of the mass fraction of molybdenum if it does not exceed one percent.

These types of materials are optimally suited for the production of cutting tools, which, due to friction, are heated to temperatures from 600 to 6500 degrees. At the same time, they will not deform and lose their hardness. This type of product lends itself well to welding using electric butt welding with steel grades such as 45 and 40X.

Options for using tool steels (using carbon as an example)

Name Steel grade Application

| Carbon instrumental | U7 U7A | Hammers, cores, screwdrivers, chisels, blacksmith tools, scythes |

| Carbon instrumental | U8 U8A | Scissors, chipper knives, hand carpentry tools, frame saws |

| Carbon tool, high hardness | U10 U10A | Drills, small diameter cutters, band saws, reamers |

| Carbon tool, increased hardness | U12 U13 | Wood turning tools, metal hacksaw blades, needle files, files, engraving tools |

Brands of alloys intended for use in cold deformation conditions must, in addition, have a smooth working part, the ability to retain size and shape, and also have different yield and elasticity strengths. And tool steel, suitable for work under conditions of hot deformation, must have high thermal conductivity, resist tempering and be resistant to temperature fluctuations. The grades of steel used for the production of cutting tools must also meet special requirements.

Material requirements

Requirements for these materials depend on how exactly they will be used. But there are general requirements for them, regardless of brand:

- high level of hardness;

- high level of strength;

- wear resistance;

- good viscosity, which is especially important in the manufacture of parts that will be subject to shock during use;

- low level of sensitivity to overheating, adhesion and welding processes to parts that are subject to processing;

- good level of processing through metal cutting;

- resistance to cracks;

- susceptibility to calcination;

- hot plasticity;

- possibility of grinding;

- the ability to resist decarbonization.

Naturally, these are not all the requirements. Thus, grades that are intended for use in cold deformation conditions must additionally have a smooth working surface, retain their shape and size, and have a yield and elasticity limit. And those materials that must be used under conditions of hot deformation must have high thermal conductivity, prevent tempering and be resistant to temperature fluctuations.

Application

The use of carbon tool steels largely depends on the chemical composition. Most often used to obtain:

- Cutting tool. For many years, tools were made using ordinary steel, which could become hot during use and wear out quickly. At that time, lathe and drilling machines were installed, which could carry out processing only at low speed and low feed. The emergence of modern equipment, in particular CNC machines, has led to increased requirements for tools. Only the advent of tool steel and hard alloys made it possible to fully unlock the potential of modern equipment. Also, do not forget that in order to obtain high-quality surfaces, the feed rate must increase significantly; productivity can be increased by increasing the feed. Modern cutting tools can withstand repeated heating and cooling cycles, and their service life increases by several tens of times.

- High quality parts. An example is the design of an internal combustion engine, which has surfaces with precise dimensions and roughness. To ensure that the moving elements do not change their shape during operation due to heating, they are made of tool steel.

- Instruments used to make precise measurements. To obtain small parts with linear dimensional accuracy of several hundred millimeters, the workpiece should not be heated or deformed due to the pressure exerted by the cutting tool.

- A casting mold that must withstand significant pressure.

Application of carbon tool steels depending on grade

For the manufacture of parts, the most suitable brand is U7 or U7A, for the manufacture of cutting and other tools, U10 or U12. This pattern is due to the fact that harder metals must be used to produce cutting tools.

The marking of carbon tool steels in this case indicates the percentage of carbon and the presence of other impurities.

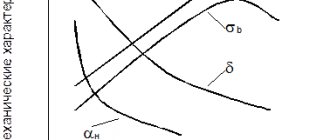

The properties of carbon tool steel are largely determined by the carbon concentration - the higher it is, the harder the surface, but the brittleness also increases.

For cold pressing, grades U10 – U12 can be used. The tests carried out indicate that their hardness is 57-59 HRC. Among the features we note:

- Sufficiently high viscosity.

- High level of resistance to plastic type deformation.

- Increased wear resistance.

If the dimensions of the tool are large, then alloys that contain useful impurities can be used.

Quenching and tempering of carbon tool steels

GOST 1435 specifies both the composition of carbon steels and their main characteristics. The carbon content in such alloys (which can be determined by their grade) ranges from 0.65 to 1.35%. In order to obtain the optimal structure and required hardness, these alloys are annealed before tool production begins. In this case, for tool steels with a hypereffectoid structure, spherodizing type annealing is performed. Heat treatment carried out using this technology leads to the appearance of granular cementite. And the cooling rate, which can be easily adjusted, allows you to obtain grains of the required size.

Steel hardening production process

After the tool is manufactured, the tool steel is subjected to hardening and subsequent tempering. This makes it possible to obtain a material of the required hardness. It is also quite easy to regulate the hardness of the finished tool; this is achieved by selecting a certain temperature for the tempering operation.

Thus, for tools that are subjected to systematic shock loads during operation, the optimal hardness is from 56 to 58 HRC, which is obtained by tempering at a temperature of 290 degrees Celsius. The most stringent requirements are imposed on the hardness of dies, engraving devices, and files (62-64 units on the HRC scale). It is achieved by tempering at a temperature of 150 to 200 degrees Celsius.

Hardening increases the hardness of carbon steels for the reason that it is with its help that it is possible to obtain the optimal structure of the alloy of iron and carbon. Variants of this structure:

- carbides with martensite;

- only martensite.