Band saws are used in wood and metal working. If you choose a band saw blade that is most suitable for the task at hand and set the optimal cutting mode, the cost of the technological process will decrease without sacrificing quality. In this article we will look at what points to pay attention to when purchasing.

Photo No. 1: blade for band saw 35x0.96 for wood

Classification of band saw blades

Carbon steel is used in the manufacture of band saws; it is highly wear-resistant. On sale there are blades made of bimetallic material, and band saws with a blade where carbide tips are used in the manufacture of teeth.

The dimensions of band saws in width (these saws are delivered to the customer mainly in the form of a coil or in the state of several bands connected to each other) vary from 13 to 80 mm. For machines where vertical cutting is used, band saws of smaller width (up to 6 mm) are manufactured.

Based on the variety of areas of use, the following classification of paintings has been compiled:

- M42. This bimetallic blade is used for cutting material made from carbon steel.

- M51. It is used for sawing material made from high-carbon steel, as well as its alloy.

- SP. This blade is preferred for cutting rare and heat-resistant alloys.

- TST. Manufacturing companies produce them for processing materials made of hard alloys or those that have a non-uniform structure.

When choosing products, pay attention to the TPI indicator, which reflects the number of teeth per 1 inch. It is worth finding out what material the workpiece is made of. This affects the thickness and accuracy of the cut.

The higher the TPI parameter, the lower the speed of work and the cut will be. Thanks to this, the cut is more accurate

If you are going to cut wood, it is better to choose a tape with a characteristic of 3 TPI or more. When working with metal, it is recommended to use tape with a TPI rating of 4 to 20.

The teeth in the belt differ not only in their distance from each other, but also in their shape. There are 2 types of teeth. One of them is called skip. It is most often found on belts with small pitches (from 3 to 6), which contributes to a larger area of sawdust ejection.

The second type is called regular. It has a triangular shape and, unlike skip teeth, does not have additional space for sawdust. For this reason, such products are used when sawing objects of large thickness or hard materials.

There are many types of canvases, the most popular are presented below:

- 3 TPI skip. This is a good choice if you need to cut thick materials quickly. The product is used for sawing wood lengthwise.

- 4 TPI skip. This type of tape is suitable for general sawing.

- 6 TPI skip. Blades are needed when the machine operates at medium speed; they can be used for longitudinal sawing of wood up to 50 mm thick and cross-cutting up to 150 mm.

- 10 TPI regular is required when you need to saw artificial materials - plywood, plastic, etc. When feeding at low speed, it is suitable for sawing wood 50 mm thick.

- 14 TPI regular. At a low feed rate, it can be used for sawing various materials up to 25 mm thick. Used when working with light metals.

The service life of the paintings depends on which company produced them.

Lapping in the strip by cutting

Just like a new car requires running-in, a new bandsaw blade requires grinding in by cutting. It is necessary if the standard mode of movement of the web is 30 meters per minute or higher. The blade must work about 1000 square centimeters at a lower load than with standard cutting conditions.

If grinding by cutting has not been carried out or has not been carried out sufficiently, then the cutting edges of the teeth are not yet aligned. In this case, problems such as vibration, tooth chipping, and uneven wear may occur. The resource of the canvas and its quality can be significantly deteriorated.

To perform proper grinding by cutting you must:

1. Set the blade speed on the band saw to 30 meters per minute and calculate the cutting time according to the graph below. For example, for a section width of 200 mm. cutting time will be 16 minutes. The cutting speed is set so that the required cutting time is achieved. Installation is carried out using the “+,-” buttons of the speed controller. Keep the cutting force at a fixed level, which is set in the standard cutting mode.

2. Increase blade speed and cutting speed step by step until standard cutting conditions are achieved. In this case, the number of cuts that will be required for grinding in by cutting is found as follows: the required running-in area must be divided by the cross-sectional area of the material being cut.

3. Cutting lapping is completed when the lapping area defined for the blade and material is reached.

The specified cutting grinding mode should be taken into account as a recommendation. It may be necessary to individually select a cutting mode that eliminates chatter or vibration during the initial cutting period.

How to choose a blade for metal, wood or meat

Before you start choosing a band saw for your machine, you need to read the operating instructions. In it, the manufacturer indicates the parameters of the product, its maximum and minimum width. The length is always set to a range that cannot be changed, while the width can be adjusted.

The product should be selected according to the area of use. For example, the maximum width is suitable if the workpiece is not expected to be cut to a radius.

When selecting parameters for a band saw, you need to decide on the following criteria:

- what will be the scope of work;

- consider frequency of use;

- what materials will you have to work with;

- the dimensions of the canvas itself.

You need to pay attention to the teeth. Their shape and size matter.

Each material requires different types of band saws. M-51 brand tools are suitable if you need to cut high-carbon steels. Saw grade M-42 is required for low-carbon steels and bimetallic blades. It is needed to work with medium carbon steel.

SP models are designed for long-term use with heat-resistant steel. TST type tools are required for processing titanium workpieces; they are also designed for working with nickel alloys.

If the choice of saw blade for a band saw is made correctly, the following will happen:

- the cut line will be straight;

- there will be no vibration when sawing materials;

- There will be no cracks or chips at the cut site.

Various band saws are used for cutting stone, metal, wood and synthetic fabric. Their cost depends on the purpose and type of canvas. For processing wood, use the “Bison 350” band saw blade.

Cutting plastic, glass and wood is carried out with 1425 mm blades; it is worth purchasing a 1650 mm blade for meat. For sawing wood, you can buy 2240 mm blades.

According to the type of tooth shape and sharpening angle.

Each manufacturer has many series of blades made from the same material, but intended for cutting different types of metal. The main difference between such blades is the shape of the tooth, the main varieties of which are discussed below:

- Shape S or Standard.

The rake angle of the tooth is 0 degrees. Ideal for short chipping materials, high carbon steels, cast iron, small workpieces, thin-walled profiles, brittle materials. - shape or Hook.

The front angle of the tooth is 10 degrees, positive. This is a form for universal use, i.e. If you don’t know which one, take this one. Typically used for non-ferrous metals and steels with a carbon content <0.8%, structural steels, tempered steels, large profiles, solid sections, non-ferrous metals and steels. - Shape L or Long.

The rake angle of the tooth is 0 degrees. Increased interdental space. Ideal for sawing soft materials (aluminum and wood). - Form M or Variable.

The front angle of the tooth is 10 degrees, positive. Tooth height is variable. Optimally suited for sawing stainless steels, high-performance cutting of viscous materials, and large-section workpieces. - Form P or Profile.

The front angle of the tooth is 5 degrees, positive. Ideal for hollow profiles and angles, steel beams, sawing packages of workpieces, because reduces the level of vibration when sawing. - R or shape .

The rake angle of the tooth is 16 degrees, positive. Optimally suited for stainless steels, high-performance cutting of viscous materials, and large-section workpieces. Has a long service life. - shape or Trapezoidal.

Provides high productivity and the best cutting quality. Let's list the main ones.

- TSN.

Negative rake angle combined with increased inter-tooth gullet for superior chip evacuation. Suitable for: hardened steel with a hardness up to 68 HRC, workpieces with a hardened surface (shafts), hard workpieces no more than 275 mm, chrome-plated surfaces, chrome. - TSN ENR.

Super-negative rake angle combined with increased inter-tooth gullet for superior chip evacuation. Suitable for: hardened steel with a hardness up to 68 HRC, workpieces with a hardened surface (shafts), hard workpieces no more than 275 mm, chrome-plated surfaces, chrome. - TNF- A.

Positive rake angle combined with an enlarged gullet for superior chip evacuation. Suitable for: non-ferrous metals and aluminum alloys. Optimally used on machines with low vibration levels and manual feed. - TNF- B.

Positive rake angle combined with a larger inter-tooth cavity for superior chip evacuation. Suitable for: non-ferrous metals and aluminum alloys. Ideal for use on machines with high feed speeds. - There are many more varieties of this type, because Each manufacturer has in its assortment a wide variety of blades with specific tooth shapes to solve highly specialized problems.

Basic parameters of teeth

The number of teeth is directly related to the quality of the cut. The more there are, the higher the result of the work. This occurs due to the fact that the load is evenly distributed over the entire area of the cutting surface.

If the band saw has large teeth, the cut will be deep. For this reason, such blades are used when cutting down trees. For small and thin sheet materials, blades with small teeth are suitable.

To work with large workpieces, it is better to opt for a band saw with large teeth. If it is necessary to reduce resonance phenomena, the teeth must have different heights. To cut large materials, you need to use saws with uniform and frequently set teeth.

To reduce clogging of the band saw during operation, variable teeth are needed that are suitable for cutting soft materials.

Saw pitch size for cutting solid steel

| Constant step | Variable pitch | ||

| Diameter, mm | Teeth per inch | Diameter, mm | Teeth per inch |

| to 10 | 14 | up to 25 | 10/14 |

| 10 -30 | 10 | 15 — 40 | 8/12 |

| 30 – 50 | 8 | 25 — 40 | 6/10 |

| 50 — 80 | 6 | 35 — 70 | 5/8 |

| 80 — 120 | 4 | 40 — 90 | 5/6 |

| 120 — 200 | 3 | 50 — 120 | 4/6 |

| 200 — 400 | 2 | 80 — 150 | 3/4 |

| 300 — 700 | 1,25 | 130 — 350 | 2/3 |

| > 600 | 0,75 | 150 — 450 | 1,5/2 |

| 200 — 600 | 1,1/1,6 | ||

| > 500 | 0,75/1,25 | ||

The best manufacturers

Among the companies producing band saws, experts recommend the following, which occupy the first lines of the rating:

- Arntz. A German company, in whose production facilities constant monitoring of the quality of products is carried out, and research is also being carried out in order to modernize technologies and improve the characteristics of band saws.

- Lenox. An American company, a special feature of this manufacturer is a specially developed coating, it is called Armor. Thanks to it, the products have increased strength and resistance to physical wear.

- Wikus. Another manufacturer from Germany, which has been at the top of the list of the best manufacturers of band saws for a long period of time. The advantages of the company include many years of experience in the production of tools and a large list of available models.

- Forezienne is a French company for the production and maintenance of cutting tools. Its main feature is the production of blades for band saws from steel, which is made from high-grade rocks and is processed by a hardening and tempering system.

- Lennartz is an equally large manufacturer of blades for tape machines, in demand in Europe. This company specializes in the manufacture of saws based on composite alloys.

- Doall is an American manufacturer, known in the market for its high quality band saws.

All products are reliable and have a long service life.

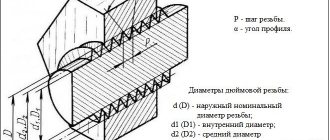

What you need to know about tooth sharpening angles

The geometry of band saw teeth can be modified based on the characteristics of the material being processed. This is expressed in the shape of the tooth and the distance between the individual elements of the cutting edge.

The profile of the band saw is determined by the markings applied by the manufacturer. It looks like this:

- WM is a universal option designed for sawing soft and hard wood;

- AV – used for longitudinal cutting and sawing of hard materials, such as frozen wood;

- NV – has a narrow blade width, so it is perfectly suitable for figure cutting;

- NU – cutting edge with a wide tooth pitch, which ensures highest performance when sawing soft wood;

- PV is almost a complete analogue of the previous blade, but has a flattened tooth shape;

- KV – profile is used for wide band saws intended for soft wood;

- PU – wide saw for sawing hardwood.

The tooth pitch is selected individually, depending on the material. For example, for sawing hardwood and metal, only fine-toothed blades are used to avoid damage to the cutting edge. Soft raw materials and thick-walled materials are processed with saws with a large distance between the teeth, which speeds up the production process.

Did you like the article? Subscribe to our Yandex.Zen channel

Profile, teeth and sharpening angle

International classification of tooth profiles.

Tape devices have different tooth geometries, which depend on the type and features of the materials being cut. A tool for wood can also be a carpenter's or a carpenter's tool. It is considered the 3rd type, intended for sawing timber and logs. Similar subspecies have their own properties and shape of teeth.

The sharpening angle of wood band saws is selected by the manufacturing company based on the judgment of several factors. Chief among them is that the harder the material, the smaller the rake angle should be. Below is a table with the main parameters of the saws.

Sharpening

This is the basic step of cutting edge dressing and can be done in 2 ways.

Full-profile sharpening of saws is done with a CBN wheel installed in a special sharpening machine.

This is a 100 percent automatic operation that requires the use of a professional. The operation of the machine for sharpening band saws for wood is controlled electronically, and the grinding wheel processes the entire band in one pass. The disadvantage of this method is that the CBN wheel is selected individually to the saw profile; to edit different tools, the sharpening element must be in stock.

Sharpening of teeth is done manually or, in other words, using special equipment.

First, it is natural to restore the sharpness of the teeth in the shortest possible time, as annoying as it may sound, the work requires certain opportunities. In the second - painstaking work: 4-5 movements along the edge of each tooth.

For automatic sharpening, diamond, CBN and corundum wheels are used. Remember that when performing this procedure, only sharpness is given to the teeth; the geometry made after setting the blade should remain unchanged.

Canvas repair

Cutting edge breakage is a rare occurrence in woodworking, but metal strip can be repaired and reused in the job. The recovery process includes the following steps:

- measuring the length of the tape web;

- identification of missing fragments;

- edge processing;

- electric contact welding;

- hardening and processing of the weld.

Restoring the blade for a band sawmill requires the qualifications of a craftsman. The cost of the service depends on how many seams need to be made and how wide the inserts should be.