Non-ferrous metal does not contain iron or contains a small proportion of it. It is these raw materials that are used by the best blacksmiths to produce original decorative and functional elements. Working with compounds is a real art that requires special tools, knowledge and experience. For the production of forged interior decorations, scrap non-ferrous metals (alloys of brass and bronze, aluminum and copper, platinum, silver and gold) are used. Forging such metals is difficult because their compositions are highly conductive. The material is heated and processed using gas.

Features of bronze forging

Bronze is used to make highly artistic objects; experienced craftsmen with extraordinary taste can work with it. Metal with silicon impurities is used for work. The alloy of iron, aluminum and copper is also used for hot rolling and casting. When heated, the composition will change color from yellow to orange, so it is important not to overheat it. The blacksmith, knowing the characteristics of the alloy, will bring the mass to the desired temperature and only after that will begin processing it.

The finished metal is quite rigid and difficult to work with (it practically does not bend or straighten). But the edges of the forged product remain strong and strong, so you can use them to make thin spirals and curls that will be even and smooth.

Types of steel

All steels are called carbon steels because in their composition, in addition to iron and a small amount of other elements, carbon is always present. Depending on the content of the latter, metals for forging are divided into grades. In addition, steels can be structural and instrumental, as well as alloyed, soft, weather-resistant, and stainless steel.

Carbon

Carbon steel is characterized by a “C” content of no more than 2.14% and the absence of alloying elements. A small amount of impurities and an insignificant content of manganese, silicon and magnesium are allowed in the structure. This composition affects the properties and applications of the metal. It is characterized by hardness, strength, low ductility and viscosity. Widely used in the metallurgical industry.

Scheme 1. Composition of carbon steel

Depending on the areas of application, carbon steel is divided into structural and tool steel. The second is used to create high-strength tools that can perform almost all work, including cutting metal. The first is suitable for the construction of various buildings.

Scheme 2. Types of carbon steel

Some carbon steels are ductile and malleable. If the carbon content is up to 0.1%, then the iron, being soft, is well forged and welded using the forge method. An alloy with a “C” value of 0.1% to 0.3% is suitable for artistic forging. Tool steel with a carbon index of 0.6-1.35% requires skill when heating it.

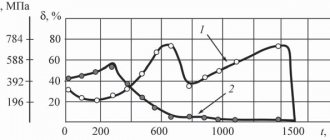

Table 2. Initial and final temperatures for forging carbon steels

Important: Among metals with an amount of “ C ” of 2.14% or more, only pearlitic, ferritic and ferritic-pearlitic, as well as puddling and charcoal cast irons are forged.

Alloyed

Alloyed steels are steels that, in addition to the main elements, contain additives in the form of molybdenum, chromium, tungsten, nickel, cobalt, aluminum, as well as manganese and silicon. The heating mode of such metals for forging depends on their thermal conductivity, which is lower than that of carbon analogues. Alloy steels are less ductile and more prone to cracking. In addition, they overheat and burn out faster.

When heating alloy steels before forging, the following thermal options must be considered:

- the metal is placed in a cold furnace and heated together with it;

- the ingot is first heated in a furnace at a low temperature, then transferred to another similar one, but with a high temperature;

- for thermal exposure, two-chamber furnaces are used, one of which serves only for heating;

- the ingot is processed in a methodical furnace, and the metal moves from the cold to the hot end and is gradually heated.

The heating mode must go through three stages. First, the steel is heated to 550-600 °C. The forging temperature is then reached. At the third stage, the metal for forging is kept at a stable temperature to equalize the heating throughout the entire thickness.

Table 3. Average temperatures for forging alloy steel

Soft

Mild steel, popular in blacksmithing, is an alloy of iron and carbon. The metal was obtained in 1856, when experiments were carried out on the mass production of malleable iron. To obtain the material, scrap steel was melted together with cast iron, removing slag and carbon. Mild steel has higher strength than ductile iron. The main disadvantage is the tendency to corrosion. Therefore, steel is coated with a layer of zinc on top to create the possibility of widespread use.

Weatherproof

Weather-resistant steel, also called Corten steel, is used in aggressive environments or for outdoor work without painting. Used for the construction of steel bridges, shipping containers, and as facade elements. The rusty brown patina that develops over time is considered an aesthetic finish. Since the material is susceptible to crevice corrosion, it has recently been in particular demand. This material is not popular in blacksmithing either.

Stainless

At foundries, stainless steel is forged using special technologies. Since stainless steel differs in characteristics from ordinary carbon steel, the individual thermal regime is monitored before loading the workpiece into the furnace. In order for the metal to be forged to heat up completely and evenly, the temperature rises gradually. This makes it possible to prevent defects in the structure of the material both during forging and during subsequent cooling. Until reaching 850 °C, stainless steel workpieces are heated slowly.

In order not to disrupt the technology, the temperature must be constantly monitored: at a later stage, the heating rate can be accelerated. In addition, stainless steel has low thermal conductivity, so the blanks must be kept longer compared to conventional steel grades. The enterprises use exclusively hot forging. When metal is cold deformed, it will not be possible to obtain a product of the desired shape and size.

Cast

During the steel casting process, alloys with different chemical compositions are formed. In ancient times, iron was mined from ore. Pudding technology was introduced in the 18th century. In the 19th century, the open-hearth method worked well.

Blades are often made from this material. Due to the lightness of casting, the entire workpiece or only part of it can be quickly heated for forging. A close look at the appearance of the finished product reveals an aesthetic swirling and fragmented structure on the surface.

The slower the forging is carried out, the higher the quality of the product. Careful exposure at not too high temperatures results in a beautiful contrast of patterns. When heated, the faces of large and small carbides dissolve, and upon subsequent cooling, the carbon again comes to the surface in the form of a strong fiber. As a result, the initially blurred pattern acquires distinct contrasting features.

Pure iron

Pure wrought iron has very little carbon (up to 0.08%). The metal for forging consists of a semi-molten mass of “Fe” and a small amount of fibrous slag (up to 2%), due to which it resembles wood when bent. Malleable iron is ductile, strong, corrosion-resistant, and easy to weld. In terms of functional load, this material resembles low-carbon steel.

The metal is 99.4% iron by weight. Thanks to the slag, it is easily forged to form a unique fibrous structure. In addition, silicate slag fibers protect cast iron from rusting and reduce the fatigue effect caused by vibrations after repeated impacts. Many items that are now created from mild steel were previously made from pure wrought iron.

Features of copper forging

Copper is very easy to work with because the metal has a wide operating temperature range. Using scrap and waste non-ferrous metals for work, the master can make large parts. Copper is a malleable metal, so it is suitable for stamping and bending. There is no need to pre-anneal it, since it has no hardening.

Copper should be heated until it turns red. Even if you use a large piece, no additional heating will be required. A mixture of gases is used to weld individual elements during forging.

Technical nuances of brass stamping

Factories also do not need to purchase any “special” furnaces for hot stamping of brass: ordinary forging furnaces are suitable for this purpose, providing uniform and gentle heating. Specific features of specifically stamping include:

- maintaining the required temperature range. Which, it should be noted, is very narrow: the minimum limit is +720-730 degrees, the maximum is +750. This is why die stamping of brass cannot be a lengthy operation: it is very important to carry it out in one blow or effort;

- if burrs form on the surface of the part, it is better to cut them off either at forging temperature (the same 720-730 degrees), or after cooling, when it has completely “accustomed” to room temperature.

However, in professional production it is possible to reduce the formation of burrs to a minimum. This is due to the design features of the stamps. When stamping brass products, the workpiece fills the mold without “climbing” beyond the established barriers in the form of internal forms and protrusions. In essence, it fills a closed cavity and immediately takes on the dimensions and shape of the finished product. As a result, finishing processing of the resulting part is not required.

Features of aluminum forging

Durable and strong, lightweight and reliable material is used in various industries. The alloy is popular in the aviation and space industries. Aluminum makes it possible to obtain light and strong elements for parts of aircraft and spacecraft, stations, and satellites. The composition is also used in the production of forged products.

Heating is carried out in special closed ovens powered by electricity. Aluminum takes longer to heat up than steel. Before working with heated aluminum, the blacksmith must also warm up his tools (up to 200–250 degrees). To simplify the work process, scrap metal, small ingots or rectangular blanks are used for work.

Aluminum sticks to the die, so you should thoroughly polish the surface before working with it.

Types of cast iron

The grade of cast iron is determined by the carbon content (more than 2.14%) and other components. Depending on the composition, the material is divided into several types.

- White. The carbon in the alloy is contained in cementite. The metal of this brand has good wear resistance and hardness. At the same time, the material is poorly processed on metal-cutting machines. Cast iron is divided into hypoeutectic, eutectic and hypereutectic. The latter has the most carbon - up to 6.67%.

- Grey. Castings from it are made using molds created by casting steel. This type of cast iron is used mainly in mechanical engineering. The alloy does not withstand impacts, so products are made from it that are not subject to mechanical stress. Among them are bearing cups and V-belt wheel drives.

- Malleable. The metal, in which carbon is in the form of flakes, is produced from white cast iron. To obtain blanks, raw materials are heated and maintained at a given temperature for the required time. This process is called languor.

- Highly durable. Carbon in the structure of this metal is in a spherical state. To obtain the desired shape, magnesium is introduced into the raw materials during production. Due to its high strength, cast iron has characteristics similar to carbon steel. The material is used to create crankshafts, pistons, and brake system elements.

Important: Inclusions in different cast irons can take the form of plates, balls and flakes. Malleable cast iron contains flakes.

Features of the production of malleable cast iron

To create malleable cast iron, white castings are needed. Carbon in their structure is associated with “Fe” - it is found in cementite, also called iron carbide. When the workpieces are annealed at a temperature of 950-970 °C, graphite is released from austenite and cementite. Austenite is iron with a face-centered lattice. As a result, graphite crystallizes to form flakes. The latter are finally formed in cast iron at temperatures from 720 to 760 °C.

Thermal annealing takes place in 2 stages. First, the workpieces are heated to a temperature of 950-1000 °C and maintained in this state until the decomposition of the austenite-cementite bond is completed. As a result, the first remains, and the second is replaced by graphite. Then the workpieces are gradually cooled to a temperature of 720 to 760 °C, after which the austenite releases secondary cementite, which is included in the pearlite structure. Subsequent cooling leads to the decomposition of pearlite into 2 components - graphite and ferrite.

Types of malleable cast iron

Cast iron is cast using different annealing technologies. Depending on them, they are divided into three categories.

- Pearlitic. Includes perlite and graphite flakes.

- Ferritic. The composition includes ferrite and graphite of the same type.

- Ferritic-pearlitic. Consists of ferrite, perlite and graphite flakes.

Pudding cast iron is soft when heated and very resistant to corrosion. Suitable for artistic hot forging. Charcoal cast iron also becomes very soft and pliable after firing. Even with cold forging, cracks do not form on it. Suitable for creating metal decorative items.

Properties of malleable cast irons

The properties and technical characteristics of malleable cast iron are influenced by the amount of carbon in the composition. The latter is usually found in the form of graphite and silicon. The amount of manganese and chromium is also important to the characteristics of perlite metal for forging. The structure is directly reflected in the properties, for example, pearlite casting has higher hardness and lower ductility than its ferrite counterpart. Graphite inclusions in the flake state give products good ductility with significant strength, which is why they are called “malleable”.

Malleable workpieces, characterized by stable properties throughout the entire thickness, have no internal stresses. Their mechanical and physical parameters are between the corresponding indicators of gray cast iron and steel.

Properties of malleable cast iron:

- good wear resistance and fluidity;

- high density and strength: a workpiece 0.8 cm thick can withstand pressure of 40 atm during hydrotesting;

- ability to absorb vibrations under cyclic loads;

- corrosion resistance.

Having these properties, castings are used to create various products for water and gas pipeline systems. However, under dynamic loads and minimum temperatures, the metal can become brittle.

Product marking

Explanation of marking using the example of cast iron grade KCH 30-6:

- KCh - malleable cast iron;

- 30 - tensile strength 294 N/mm2, divided by 10;

- 6 - relative elongation in percent.

Important: According to GOST 1215-79, there are 11 grades of malleable cast iron: 7 - pearlitic, 4 - ferritic.

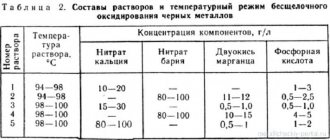

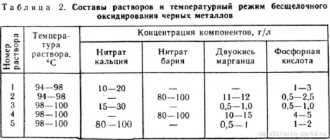

Table 1. Ductile iron: mechanical properties

Basic forging operations[ | ]

| * Felling | * Punching |

| * Disembarkation | * Piercing |

| * Bending (bending) | * Broaching (drawing) |

| * Branding | * Firmware |

| * Riveting | * Overclocking |

| * Basting | * Giveaway |

| * Crimping | * Cutting |

| * Run-in (billing) | * Rolling out |

| * Draft | * Forge welding (forging welding) |

| * Chop | * Twisting (torsion) |

| * Tackle | * Stamping |

| *Edit | * Coinage |

Stamped brass parts: wide choice

The versatility of our machines lies in the fact that they can produce completely different products.

We are ready to solve any of your production problems: stamping brass fittings, fasteners, gears, flanges and many other parts. Brass stamping offers no less possibilities in the production of original souvenir and commemorative products:

- icons and signs,

- medals,

- Schild,

- magnets,

- cufflinks,

- clamps,

- badges,

- keychains and much more.

As a rule, these are unique items that are developed according to an individual design. Often they are promotional in nature.

Services for manufacturing custom brass products

Our company will perform for you high-precision stamping of brass products according to standard and non-standard projects.

The workshop is equipped with equipment for various purposes. Thanks to this, we can offer you not only all stamping operations, but also metal post-processing - laser engraving on products, application of enamels, gilding, silvering, creating an antique effect, etc. To apply for stamping of brass products, fill out the online form and briefly describe the conditions of the project:

- what needs to be done

- number of details,

- urgency of work.

It will be great if you attach documents (photos, drawings, sketches) to your application. We are waiting for your orders!