The bluing of weapons is considered by hunters in two ways: for some it is style, beautiful execution, for others it is practicality. Blued metal is much more resistant to corrosion; the blued shade is an additional camouflage. Blueing will restore the appearance of a battered weapon, completely protect it from rust, and protect it from mechanical damage and abrasions. It is not always possible for a shooter to purchase a gun that is already blued. Many hunters blue their weapons themselves using a variety of methods.

What can be achieved by bluing

As a result of chemical or thermal treatment, a layer of iron oxide with a thickness of 1 to 10 microns appears on the surface of a steel part. The thickness of the layer is determined by the selected processing technology.

Blueing of metal allows you to achieve two main goals:

- Increasing the corrosion resistance of the product. Treated parts do not rust.

- Improved appearance. It is especially important for those parts that, due to operating conditions, cannot be painted.

Temperature conditions for bluing

The treatment does not affect other properties of the steel.

Blueing of steel is possible not only in production conditions, but also at home. There are many methods and compositions, almost all of them involve the use of chemically active substances that can cause serious harm to health. To successfully and safely use these substances at home, you must follow the following safety rules:

- Use a protective mask and gloves.

- Ensure ventilation of the room in which work is carried out.

- Use stainless steel utensils.

- Do not exceed the recommended processing temperature.

Basic processing rules

Blueing is essentially a chemical treatment of metal surfaces, in which not only the blackening is removed, but also a protective layer is applied.

These works are classified as hazardous, and therefore must be performed in compliance with certain rules and under special conditions.

Since the solution used for bluing contains chemically active substances with acid, special containers must be used for it.

Video:

In addition, such processing of metal surfaces also involves mechanical work, which means it is necessary to have on hand appropriate means to protect the eyes and skin.

You should also perform metal processing in a room that is equipped with a ventilation system or has a powerful exhaust hood.

In the video posted above, you can see how such processing of metal surfaces should be carried out.

When working with acid and other chemical reagents, you should use only those containers that are made of earthenware, porcelain or glass.

It is not recommended to use containers made of metal for these purposes.

Immediately before starting bluing, you should carry out a uniform and high-quality cleaning of the surface, and also completely remove traces of dirt and grease from it.

In this case, sandpaper, powdered pumice, and fine-grained sand can be used as processing material.

Before starting all work, it is recommended to thoroughly study the properties of the reagents used, as well as the procedure.

It should be remembered that the liquid contains a variety of chemical elements that, if used incorrectly, can harm the product.

You must also ensure that the solution used does not come into contact with the skin or eyes, as this can cause serious injury or burns.

Methods for bluing metals at home and requirements for their implementation

Popular methods of bluing metal at home are:

- Boiling in self-prepared or purchased chemical compositions.

- Coating the steel with special oil and subsequent heat treatment.

- Coating the surface with the prepared composition at room temperature.

Burnishing steel at home

Chemical bluing of iron also involves preparatory operations of etching and cleaning, as well as grinding and polishing.

When carrying out blueing of steel, it is important to select a container for the solution so that it completely covers the object being treated.

Safety precautions and preparation for bluing

If you look at the root, then bluing is a common chemical reaction. And for the same reason, certain rules should be followed and the action should be carried out in a designated and equipped safe place.

Ventilation must be excellent, since caustic fumes from chemicals can easily harm the respiratory tract. All containers are allowed only from glass, porcelain or earthenware. It is mandatory to unload the weapon and dismantle the wooden parts.

Whatever bluing method is chosen, the following auxiliary materials will be needed:

- Latex gloves;

- Steel wool;

- Sandpaper of various grain sizes;

- Cleaner;

- Protective glasses;

- Powdered pumice;

- Fine sand;

- Gun oil for cleaning and lubrication;

- Cotton pads and swabs, rags, a pair of toothpicks, a shoe brush (new) and a toothbrush.

Popular bluing methods

The most common methods of bluing at home are:

- alkaline;

- thermal;

- acidic.

The alkaline method is well suited for self-use at home. It will require

- water;

- precision scales;

- sodium nitrate and hydroxide.

For the coating to become durable, the process must last at least an hour and a half.

Alkaline

The technology for bluing steel using the alkaline method at home is divided into the following operations

- Degrease the surface with a solvent or special degreaser.

- Pour 100 g of water into a stainless steel container with a capacity of at least a liter.

- Add 120 g of caustic soda and 30 g of sodium nitrate, stir thoroughly until completely dissolved.

- Heat the solution to 130-145 °C.

- Place the product in the dish, avoiding touching the walls.

- After 20 minutes, after the part has turned black, rinse it in distilled water.

- After drying, generously lubricate the product with machine oil and wipe thoroughly.

Steel bluing with alkali

Careful adherence to proportions and parameters will allow you to obtain a smooth and abrasion-resistant coating that does not require polishing.

Important! The product must be completely covered with the solution throughout the treatment. Otherwise, coating inhomogeneities, color transitions, etc. are possible.

Acid

This method involves the use of acidic solutions.

Before starting processing, you should carefully remove all rust from the surface of the object. To do this, use ordinary sandpaper, and in hard-to-reach places and with severe rust, use a grinder or a screwdriver with a wire brush.

Means for degreasing steel before processing

Next, chemical cleaning is carried out. It is used for

- sodium triphosphate;

- ethanol mixed with kerosene;

- or pure kerosene.

The product is placed in a container with the solution so that it completely covers it and kept for at least a quarter of an hour. After cleaning, the product is washed with plenty of water and dried.

The composition for acid bluing consists of:

- water: 1 l;

- tannic acid: 2g;

- tartaric acid: 2g.

After thorough mixing and complete dissolution, the composition is heated to 150 ° C and the workpiece is completely immersed in it. Leave for 15 minutes, then rinse with running water and briefly dip in boiling water for complete and high-quality rinsing.

Components of the solution for bluing

The last stage of the process is soaking in machine oil for an hour. After drying, the product is ready for use.

Thermal

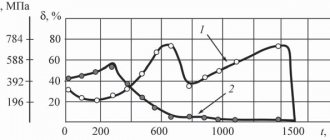

Thermal bluing is the oldest and simplest method for home use. The whole process boils down to heating the steel in the open air. It lasts until the upper layers of steel react with oxygen in the air and result in an oxide film. The more a part is heated, the darker it becomes.

Thermal bluing

It should be remembered that heat treatment also changes the physical properties of the steel of the entire product.

Burnishing with citric acid

This method is good for high carbon steel. Oxidation reliably protects against rust, oxide films, and corrosion.

The bluing does not have long-term durability, so it is suitable for weapons that the shooter uses extremely rarely.

For hunters living in big cities, who rarely go out to shoot, this method of bluing is more than suitable: it is budget-friendly, and the procedure can be carried out in apartment conditions. All you need is machine oil, water and a pack of citric acid.

The acid is poured into a container, poured with boiling water and stirred. The product is immersed for 1 hour, periodically moving it to knock down bubbles. Having removed the part, it is rinsed and lubricated with oil.

Features of chemical bluing and recipes for some compositions

Before applying a new coating at home, you must remove the old one. This is done by combining mechanical and chemical cleaning methods.

To obtain a durable and beautiful coating, the part must be boiled for 30 to 90 minutes, during which time part of the solution boils away. The workpiece must be completely covered with the composition at all times, so the composition must be prepared with a reserve and periodically topped up during boiling.

At the end of the chemical bluing procedure, the product should be washed in a soapy solution, dried and generously lubricated with oil.

There are many options for chemical bluing. In some, the composition is made by the master himself, while others involve the use of ready-made factory-made products, such as Parisian oxide, Voron3M, Clover and others.

I want to share the result of my experiments with clover.They were subjected to bluing: completely “revolver - bluff” (except for the mainspring, of course), PMoid 654 - frame, bolt and bracket. The bluing turned out to be wear-resistant, with a bluish, beautiful tint, like a crow’s feather. Five layers of bluing.

What we need: - Rubber gloves, the solution corrodes your fingers if you work with it for a long time (tested by bitter experience: your fingers will then wash off and peel off - Cotton swabs, BUT it’s better to get a dummy pack of cigarettes (ask at the kiosk) it contains cigarettes made of solid a cotton filter, you get a kind of pencil for rubbing in the composition. - Acetone for degreasing. - A metal sponge (we take it from a soft, small, flat wire for dishes, there is also a round steel wire - it will not work) or steel wool.

Process. We wash the part with laundry soap to wash off the gun oil and put it in boiling water, take it out and wipe it. We clean the part from the old coating, sand it, polish it where necessary. Degrease with acetone and a piece of cotton wool. From this moment on, do not touch these areas with your fingers; if you need to intercept the part, then only using cotton wool moistened with acetone. Pour the required amount of Clover into a separate clean container. We take a cotton pencil (remember the pack?) and begin to rub it evenly into the surface of the part; the solution on the pencil will turn from blue-green to black.

Rub until the surface becomes homogeneous, set the part aside to dry for five to ten minutes. While it dries, wipe the container from clover residues. After it has dried, we clean off with a metal sponge or cotton wool everything that has been erased (the surface will turn gray)

degrease with acetone, take a new clean pencil, pour in a new portion of clover and repeat the cycle. With each cleaning, the surface will become darker and darker. A blue tint will appear on the fifth - sixth layer. After applying the last layer and drying, wipe the part with acetone and place it on an electric stove (the wife should not be at home, otherwise the same part can be used in one place)

heat it up to 100 - 150 degrees, after warming up, lower the part into gun oil until it cools completely (if it is a frame, bolt, apply oil to clean cotton wool and rub until cool). Once it has cooled down, wipe off excess oil with a clean cloth, assemble the device and enjoy.

Photo of the revolver parts after the entire cycle. I couldn’t photograph the frame itself, etc., I didn’t have a camera at that time.

PS I wanted to throw it into <Methods of chemical coloring of metals>, but I think it will be off topic. If the moderator decides to move it there, then no matter what.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Chemical oxidation treatment

Most often, metal surface treatment is carried out using chemical oxidation.

This method is quite effective and, if the technology is followed, allows you to achieve a high quality final result.

This method of bluing metal is based on the ability of the metal to oxidize.

Video:

At the preliminary stage, it is necessary to mechanically treat the surface of the workpiece, as well as completely degrease it.

After this, the appropriate solution should be properly prepared.

For these purposes, you should take a container of a certain size, which must be made of porcelain.

Next, one hundred milliliters of ordinary tap water is poured into it, after which a small amount of sodium nitrate and about one hundred grams of technical soda are added.

After this, the solution should be thoroughly mixed and ensure that all components are dissolved in it.

The resulting mixture should be heated to a temperature of about one hundred and forty degrees Celsius, and the workpiece should be immersed in it for about thirty minutes.

After the specified time has elapsed, the part is removed from the solution and thoroughly washed with distilled water.

Next, you should dry it thoroughly and generously lubricate it with machine oil using a soft brush, achieving a uniform layer.

IMPORTANT TO KNOW: How to choose a primer for metal and rust?

The metal surface treated in this way will acquire a pronounced black tint with a blue tint.

If the bluing was done correctly and in accordance with the technology, the metal will become smooth and does not require subsequent polishing.

In the video posted in the section, you can see how a metal surface is treated at home using a chemical solution.

Cold bluing at home

“Clover” does not require heat treatment of the part, so this method is considered cold bluing. Cold bluing can be carried out by other means.

- "Voron-3M". The drug forms a dense film of deep black color on the surface.

- "Paris Oxide" An imported selenium-based preparation is supplied in three containers: 1- for surface preparation, 2- the main composition and 3- a fixative that gives the coating additional protection.

Liquid for cold bluing is applied to the parts with a brush, and after painting it is washed off with warm soapy water. The method is popular for processing barrels and other parts of firearms that do not require boiling.

Burnishing steel at home

If you are bluing steel at home, you need to wisely choose the components of the boiling solution. Heating hardened parts can lead to them losing their strength properties.

Alkaline solutions have a less harmful effect on steel, and experienced craftsmen advise choosing them. Treatment with acidic solutions is preferably carried out at low temperatures

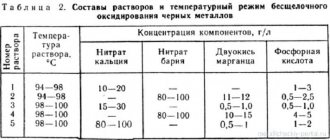

So, for example, when using an acid composition for bluing steel from:

- calcium nitrate – 94%;

- orthophosphoric acid – 3%;

- manganese dioxide – 3%.

processing is carried out from half an hour to 45 minutes at 100 ° C

Metal blackening

Depending on the acidity of the environment in which the workpiece is processed, the color of the resulting coating changes, from yellow to black. Therefore, bluing and blackening of metal are not the same thing. The required shade is selected by varying the intensity and duration of heat treatment and the percentage of solution components.

Metal blackening

If you take a mixture of 7 parts copper nitrate and 3 parts alcohol denatured alcohol, apply it to the product and heat it over a fire, then as it heats up the coating begins to change its color. When the desired shade is achieved, stop heating.

It is also possible to blacken steel by coating it with oil and calcining it in an open flame. The result is a durable film of deep black color. There are other compositions for blackening.

Application of rust varnish

The method using the so-called “rusty varnish” is distinguished by its cost-effectiveness against the backdrop of quite acceptable quality of the coating.

The product is immersed in a chemically active corrosive liquid based on hydrochloric acid, which forms red and black oxides on its surface.

To remove rusty deposits, you will have to use a stiff wire brush. A black oxide film will remain on the product.

Ready rusty varnish

The method is long and labor intensive, but provides excellent results at home.

Before starting processing, as with all other methods, you should thoroughly clean the object with sandpaper and degrease it with a solvent.

The active liquid is prepared in special porcelain vessels; the use of protective gloves, an apron, acid-resistant shoes and thick work clothes is mandatory. A respirator and clear face shield should also be used.

A small amount of hydrochloric acid is poured into the vessel, adding rust scraped off the iron, sawdust and nitric acid. The mixture should be stirred carefully with a porcelain stirrer until bubbles stop appearing.

Next, carefully add water and vodka in equal parts. The solution is allowed to settle and drained from the sediment.

The result of using rusty varnish

The part is placed in the solution for a time sufficient to acquire a deep black color. At the end of the process, the part should be rinsed with plenty of water.

Attention! The solution used in this method is one of the strongest solvents. Beware of even the smallest splashes - they can cause very serious injury and property damage.

If splashes get on clothes, they should be removed immediately. If, despite all precautions, drops get on the skin, the affected area should be washed generously with a soda solution and immediately seek medical help.