There is always a high temperature in the welding zone, which increases the rate of oxidation reactions with the formation of a large amount of oxides. Oxides degrade the quality of the weld so much that they make the welding process impossible. To prevent oxygen from entering the weld pool, several methods are used, one of which is submerged arc welding.

1 / 1

Why do you need flux when welding?

The use of fluxes provides the following advantages in welding.

- In both electric arc and gas welding, the welding flux provides more intense melting of the metal (at high currents or high oxygen concentrations, respectively). Thanks to this, there is no need to cut the edges of the future weld in advance.

- In the weld area and on the surfaces adjacent to it, it is possible to avoid metal waste - its losses due to oxidation and evaporation .

- Arc burning has higher stability , which is especially important for complex seam configurations

- Energy losses of the current source for heating the metal are reduced, and its efficiency increases accordingly.

- The consumption of filler material is optimized .

- More convenient work for the welder, because the flux shields some of the arc flame.

Conditions for using welding fluxes

The purpose of the flux is to stabilize metallurgical processes while maintaining the required productivity of the electrodes. To do this, certain conditions must be observed during the welding process.

- The flux should not react chemically with the metal of the rod and the base metal.

- The weld pool area must remain isolated throughout the welding process.

Residues of flux associated with the slag crust as a result of welding should be easily removed upon completion of work. Moreover, up to 80% of the material can be reused after cleaning.

Operating principle

First, to understand the principle of flux action, you need to understand what a typical welding zone consists of:

- An area of an arc column with an internal temperature of 4-5 thousand degrees Celsius.

- An area of a gas bubble that is formed due to intense atomic evaporation of components in an oxygen environment.

- An area with molten slag located in the upper part of the gas cavity.

- A layer of molten metal at the bottom of the cavity.

- A slag crust that forms a hard boundary to the welding zone.

In addition to the areas mentioned above, the welding wire is no less important, it also affects the chemical reactivity.

Now that we understand what the welding zone consists of, we move on to flux. During welding, the surface of the part is actively oxidized and a slag crust is formed. These processes can be avoided if an easily melting inert material enters the welding zone. This type of material is welding flux. It will protect the part from oxidation and contribute to the formation of a high-quality seam.

To effectively use fluxes in your work, you must meet the following conditions:

- The material should stabilize the speed of work, not slow it down.

- It must not react chemically with the surface of the parts being welded or the welding wire.

- The gas bubble must be isolated from the environment throughout the entire operation.

- If all recommendations are followed, flux residues should be easily removed after welding. In this case, most of the removed material can be reused (after cleaning).

In practice, it turns out that meeting these requirements is not so easy. The flux may vary in composition, as well as the technology for feeding it into the welding zone, so you need to consider what kind of metals you are welding and what type of welding you use.

How fluxes work

- Before welding, a thick (40-60 mm) layer of flux is applied to the joints.

- The electrode is inserted into the welding zone and the arc is ignited.

- Under the influence of high temperatures (up to 6000 °C), the flux with its low density quickly melts in a gas bubble, isolating the weld pool from above, blocking access to gas, water vapor and other chemicals.

- Having a high surface tension, in the same way the flux melt prevents intense splashing of the metal.

- This allows you to significantly increase the arc current (up to 1000-2000 Amperes) without serious loss of electrode material and while maintaining good weld quality.

- Under the influence of flux, thermal power is concentrated in the arc zone - as a result, the melting of the metal occurs faster.

- In this case, all joints are filled with metal, regardless of the condition of the edges.

- The material balance of the weld changes - 60-65% of it is the metal of the parts being welded, and only the rest is the metal of the welding electrode.

Principle of operation

What welding flux is can be understood by understanding how welding occurs with its participation.

- Before starting the welding process, a thick layer of flux is applied to the future joint.

- An electrode is inserted into the welding zone and the arc is ignited.

- Flux, which has a reduced density, begins to quickly melt, isolating the weld pool from air access.

- Due to the high surface tension of the flux, strong splashing of the metal is prevented, which allows the current to be increased.

- In the arc zone, under the influence of the flux, the heat value increases, as a result of which the welding process begins to proceed faster.

- All joints are filled with molten metal.

A significant part of the remaining flux after cleaning can be used again.

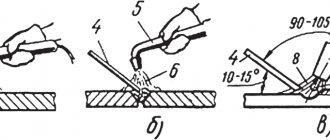

The flux welding process occurs differently depending on the type of welding. When manual welding, flux in powder form is poured onto the surface of the product in a layer of up to 60 millimeters. The width is in the range of 50-100 millimeters.

Insufficient thickness can lead to defects - lack of penetration, cracks and cavities. When moving the electrode during welding, the next layer of flux is added as it moves. Depending on the granulation, the required height of the flux powder layer is determined and the current strength is selected.

In automatic and semi-automatic welding, the flux is supplied through a special tube from the machine’s hopper. Then the supply of welding wire, which has the function of an electrode, is connected. The unused part of the flux, together with the slag embedded in it, enters a container intended for this purpose. The cooled crust is removed from the surface mechanically. To work with automatic equipment, fluxes from the AN category, as well as ceramic ones, are most often used.

Welding fluxes - classification

The classification of fluxes is extremely broad. They are distinguished by appearance and physical state, chemical composition, method of production, and purpose. So, for example, for surfacing or arc welding, as a rule, granular or powder fluxes with certain electrical conductivity indicators are used, and for gas welding, gases, powders, and pastes are used.

According to the method of obtaining composites

There are fused and unfused fluxes.

Fused welding flux is widely used not only in welding, but also in surfacing. It demonstrates high efficiency in cases where the surface of the weld metal, by adding additional chemical elements, must obtain higher technical characteristics - for example, increased resistance to corrosion or a very even and smooth weld.

Submerged Surfacing

Fused fluxes are obtained in the following way: the components are ground, mixed, then melted in flame or electric furnaces in the complete absence of oxygen. The heated particles are then passed through a continuous stream of water, hardening and thus turning into granulate. The particle size varies - the thinner the welding rod, the smaller the granules should be.

Unmelted fluxes (ceramic) for welding are made by mixing crushed particles of a mixture of ferroalloys, minerals, and slag-forming materials without subsequent melting. The particles are mixed with glass and then sintered.

Among their advantages:

- low consumption,

- possibility of repeated use,

- high quality of the resulting seam.

An example is UF grade ceramic welding flux (UF-01, UF-02, UF-03), which is used in energy and civil engineering for welding metal structures made of high-strength low-alloy steels.

Chemical composition of fluxes for welding

Chemical composition is an important component in the characteristics of fluxes. The material must be chemically inert at very high temperatures. In addition, it must ensure effective diffusion of individual elements (for example, alloying elements) into the weld metal.

The largest mass fraction (from 35...80% of the total volume) in welding flux is usually (but not all) silicon dioxide (silica) - an acidic oxide, a colorless transparent crystalline mineral. Silicon prevents the process of carbon formation , thereby reducing the risk of cracks and pores in the weld metal.

A significant part is manganese . As an active deoxidizer, this component of welding fluxes reduces the formation of oxides in the weld pool area, reacting first with oxygen in iron oxides, then with silicon oxide. The result of a complex reaction is manganese oxide, which is insoluble in steel and subsequently easily removed. In addition, manganese reacts with sulfur, which is harmful to the weld metal—it binds with it to form sulfide, which is then also removed from the surface of the weld.

Also among the chemical elements of fluxes are alloying additives - in addition to silicon and manganese, these are molybdenum, chromium, titanium, tungsten, vanadium and others . The task is to restore the primary chemical composition of the metal, and in some cases, by alloying, to replenish the burnt-out main impurities of the steel and provide the weld metal with additional special properties. Usually in flux they are represented by compounds with iron - ferroalloys (ferrochrome, etc.).

Functions of granular flux mixtures

Each type of flux must perform four functions:

Stabilization of the welding process

The right flux mixtures have the most beneficial effect on the electric arc: welding under a layer of flux creates the most comfortable environment for arc burning - an electrical discharge between the electrode and the edge of the product. Typically the distance between the poles of the arc is about 5 mm.

If there are special substances in the granular flux mixture, the discharge will be more stable. And this makes it possible to weld not only on direct current, but also on alternating current. In addition, such arc stabilization helps to use a larger number of different welding modes.

Gas Cloud Isolation

Ceramic flux options.

In any case, the gas cloud must be impenetrable; without it, metals will not be able to melt in the weld pool. In order for the powder flux mixture to cope with this task properly, it is necessary to calculate the dosage of the powder on the seam line as accurately as possible.

The smaller the flux granules and the denser they are, the better the insulation of the gas cloud. But the mixture should not be very fine either, otherwise the density of the filling on the surface of the seam will negatively affect its correct formation.

In addition to the size of the granules of the mixture, its insulating properties are affected by the mass of the filling. To determine it, there are special tables with the help of which you can very accurately determine the dose of flux supplied to the working welding zone.

Doping function

The weld is formed as a result of the action of high melting temperatures and the physical interaction of metals - base and filler.

The chemical composition of the seam is determined by the type of materials used. But under the influence of an arc, some necessary and useful elements can burn out or precipitate in slag masses. To fully replace them, special alloying additives are added to certain types of fluxes, which enrich the metals that form the weld. In addition, such additives inhibit an undesirable process - the transition of manganese and silicon to the slag. If alloying is used, a specialized filler wire is used in parallel.

Surface shaping

The appearance of the future weld begins to form as soon as the crystal lattice begins to appear in the molten metals. The seam is affected by everything that comes into contact with it. Flux for welding is included in this number: its viscosity and pronounced interfacial tension explain the excellent ability to correctly form the surface of the seam. And this directly affects the quality of the seam.

Copper submerged arc welding modes.

An excellent example is the submerged arc welding technology using so-called “long” powders. We are talking about welding thick edges of metals at high current levels. For such conditions, the best option would be to use flux mixtures with high viscosity, which makes the cooling process slow and gradual.

This gradualness makes it possible to form a crystal lattice with a smooth scaly structure.

In situations “on the contrary” - when flux welding with low currents, strong viscosity is not needed at all. In such cases, “short” flux mixtures are used, which upon cooling instantly turn into a solid substance. Submerged arc welding modes are subtle and important moments; both the quality of the seam and the shape of its surface depend on them.

Types of fluxes for welding by purpose

Their choice of chemical composition directly depends on the purpose of welding fluxes.

- For welding low-carbon steels, fluxes with a high content of silicon and manganese are used in combination with low-carbon steel wire without alloying additives. The second option is a small proportion of manganese (or no manganese at all) in the flux, but alloying additives are present in the steel of the welding rod.

- For welding low-alloy steels, fluxes with high chemical inertness are used - higher than for low-carbon steels. This results in a more ductile weld. An example is flux for welding steel AN-46.

- For welding high-alloy metals, fluxes with minimal chemical activity are used. Silicon, like manganese, is practically not used - it is replaced by fluorite (fluorspar), due to which easily separated fusible slags are formed. Also, such fluxes usually contain aluminum oxide and quicklime.

- To weld active metals (such as titanium), salt fluxes are used - as a rule, these are chloride and fluoride salts of alkali metals. The admixture of oxygen is completely absent in them, since it reduces the plasticity of the seam.

Electrode wire: brands, designation, supply

Steel welding wire manufactured in accordance with GOST 2246-70, which provides for 77 grades of wire.

The symbols for wire grades include the index St (welding) and the numbers and letters that follow it. The numbers after the C index indicate the average carbon content in hundredths of a percent.

Just as in steel grades, alloying elements in wire grades are designated by letters:

Read also: How to dress brightly in October

- A - nitrogen;

- Yu - aluminum;

- P - boron;

- F - vanadium;

- B - tungsten;

- K - cobalt;

- C—silicon;

- G - manganese;

- D - copper;

- M - molybdenum;

- N - nickel;

- B - niobium;

- E - selenium;

- T - titanium;

- X - chrome.

Purpose of welding flux - examples

| Fused fluxes | Unmelted fluxes | ||

| AN-348-A, AN-348-AM, AN-348-V, AN-348-VM, OSTS-45, OSTS-45M, AN-60, FC-9 | Mechanical welding and surfacing of low-alloy and carbon steels with low-alloy and carbon welding wire | ANK-35 | Welding low-carbon steels with low-carbon wire Sv-08 and Sv-08A |

| AN-8 | Electroslag welding of carbon and low-alloy steels; welding of low-alloy steels with carbon and low-alloy welding wire. | ANK-46 | Welding low-carbon and low-alloy steels |

| AN-15M, AN-18, AN-20S, AN-20P, AN-20SM | Automatic arc welding and surfacing of high- and medium-alloy steels | ANK-30, ANK-47 | Welding seams of high cold resistance |

| AN-22 | Electroslag welding and automatic arc surfacing and welding of low and medium alloy steels | ANK-45 | Welding of high alloy steels |

| AN-26S, AN-26P, AN-26SP | Automatic and semi-automatic welding of stainless, corrosion-resistant and heat-resistant steels | ANK-40, ANK-18, ANK-19 | Surfacing with low-carbon welding wire Sv-08 and Sv-08A; |

| AN-17M, AN-43 and AN-47 | Arc welding and surfacing of carbon, low and medium alloy steels of high and high strength | ANK-3 | As an additive to flux brands AN-348A, OSTS-45, AN-60 to increase the resistance of seams to pore formation |

Fluxes for gas welding

For welding aluminum and other non-ferrous metals, cast iron, tool steels, and certain grades of thin sheet steel, a protective gas atmosphere is used. It is provided by gaseous, paste, and powder fluxes. They can be applied:

- on the edges of the parts being connected;

- directly into the weld pool;

- to the filler rod.

Depending on the physical state of the material, fluxes for welding are supplied to the work area in different ways. Powdered composites cause some difficulty - they must be evenly and accurately introduced into the melt, without allowing the gas flow to blow up the powder. The compositions in the form of pastes are fed to the connection area. To supply gaseous fluxes, flow meters are used - with their help, gas is dosed into the working area.

Electromagnetic flow meter

An important point: for gas welding, the composition of the flux is selected depending on the oxides formed during welding. If they are acidic, the fluxes must be alkaline (basic); on the contrary, if they are alkaline oxides, acidic fluxes should be chosen.

The fluxes most widely used in gas welding are:

- copper, brass, bronze - for welding they use acidic fluxes containing boron-containing compounds (boric acid, etc.) - for example, brands such as MB-2 or BM-1;

- cast iron - for its welding, fluxes containing various compounds of alkali metals - sodium and potassium - are usually used;

- aluminum - compositions containing potassium, lithium and sodium fluorides, as well as chlorides, are used here. In this case, the most widely used welding flux is AF-4A.

Fluxes for gas welding are not used to join parts made of low-carbon steels, since low-melting iron oxides intensively accumulate on the surface of the molten metal.

Fluxes for automatic welding

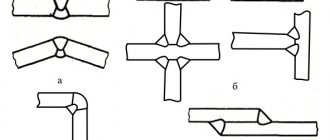

Automatic and semi-automatic welding is most widely used when working with large structures. Thanks to high currents and flux, it is possible to weld parts of considerable thickness, without preliminary cutting of the edge. Areas of use: pipe welding, tank manufacturing, shipbuilding.

This welding method is characterized by automatic maintenance of a stably burning electric arc, the required amount of flux (with suction of unmelted), as well as continuous renewal of the molten electrode. To maintain a protective gas cloud of the required composition in the welding zone, the thickness of the flux layer should be 40-80 mm, width 50-100 mm. The brand of flux for automatic welding, as for classical arc welding, also depends on the characteristics of the metal being welded. Welding is carried out in the lower spatial position.

You can buy flux for welding of various types and brands at a profit.

Products in this category

Ceramic flux UF-03 bags TU 5929-053-00186654-2013 Ceramic flux UF-N bags TU 5929-052-00186654-2013 Ceramic flux UF-K bags TU 5929-052-00186654-2013 Flux AN 348 A mesh ki GOST 9087- 81 Flux AN 47 bags GOST 9087-81 Ceramic flux UF-01 bags TU 5929-051-00186654-2013 Ceramic flux UF-02 bags TU 5929-052-00186654-2013 Ceramic flux UF-03 bags TU 5929-053 -00186654- 2013 Ceramic flux UF-N bags TU 5929-052-00186654-2013 Ceramic flux UF-K bags TU 5929-052-00186654-2013 Flux AN 348 A bags GOST 9087-81 Flux AN 47 bags GOST 9087-81 F luce ceramic UF- 01 bags TU 5929-051-00186654-2013