The duration of high-quality cutting of the knife tip is directly dependent on the methods of operation and methods of sharpening the blade. Yes, there are self-sharpening options, but in 90% of cases such a name is more of a marketing ploy than reality.

In today's article we will tell you how to make a sharpener with your own hands. Drawings with instructions will be included, and therefore, even beginners in handling garage equipment should not have any difficulties in assembling the device.

A simple device for sharpening knives

The simplest device for sharpening knives is based on the use of an angular frame and a whetstone. The price of such a primitive factory-made device is quite high, as is the price of replaceable whetstones, but making such a device for sharpening knives at home will not be difficult for a craftsman. You will need the following equipment:

- Wooden blocks of the same size - 4 pcs.

- Drill (or any other drilling tool).

- Bolts and nuts (about 4 pieces each).

- Touchstone.

- Protractor.

First you need to make a pair of wooden corners, placing the bars to each other strictly at an angle of 90º (Fig. 1). Close the resulting wooden corners together parallel to each other as a single whole and drill holes through the diameter of the bolts. Insert bolts into the holes and tighten the corners slightly with nuts.

The simplest device for sharpening knives

The point of this invention is that it is possible to sharpen simply by holding the knife vertically in relation to the sharpening surface located at a given angle.

The most important thing is to properly secure the whetstone between the wooden corners of the device. To do this, using a protractor, you need to set the desired angle of inclination of the touchstone and tighten the bolts tightly to clearly fix the position of the touchstone.

With some modification of the device, you can also fix the position of the knife relative to the sharpening stone. A significant disadvantage of such a machine for manual sharpening is the inability to smoothly adjust the angle of inclination of the sharpening stone.

Main types of homemade devices

The main condition for homemade knife blades is not to distort the angle between the edges of the blades specified in production. It is not easy to hold it by hand without a trained hand and skill.

The device fixes the sharpening angle, so sharpening a knife with a special tool is much easier than with a whetstone.

The simplest and most popular sharpeners are listed below, each of which you can make yourself:

- Selecting a quality stone. If you have a sharpening stone in the shape of a roof with two slopes, you can easily restore the sharpness of a dull instrument. This “house” is easy to work with: the blade is attached to one roof slope, and its other side is sharpened with an abrasive stone, making horizontal movements. Then the knife is turned over and the second surface of the blade is processed. The convenience and effectiveness of the method is that you do not need to maintain the angle between the blades with your hands; it is fixed by the shape and angle of the bar.

- A simple home sharpening device can be made from two wooden triangles. They are placed parallel to each other and connected with wing screws. The sharpening stone is fixed between wooden supports at an angle, which can be changed if desired. The required inclination of the abrasive can be easily set using a protractor or a program on a tablet.

Knife sharpener diagram.

When processing blades on triangles, the knife must be held 100% vertically. If such a design is used for a long time, the ties may weaken and the set degree of the beam will change, and with it the sharpening angle. - Instead of vertical triangles, you can make a reliable horizontal base from wood, plastic or metal. It must have movable mechanisms for fixing the sharpening stones. The idea is that it should be possible to set different angles of inclination of the bars. Abrasive stones are inserted into holes in the base and fastened. The knife “walks” vertically. Such a device must be held by hand so that it does not move on the table or secured with clamps.

- You can make a sharpener from a stable block that is attached to a rolling cart with wheels. The knife is sharpened by moving the hand back and forth. The sharpening angle is determined by the height of the block in relation to the working surface. This device is used for working with kitchen knives and only on a flat plane. It happens that the sharpening angle during movement deviates slightly from the specified one. For greater accuracy, the structure should stand still in place.

- A more complex device, the manufacture of which will require time and effort, involves not only fixing the beam, but also the ability to adjust its position. The peculiarity of the system is as follows: the knife blade is securely fixed on a horizontal support, the sharpening stone is attached to the guide, and a slotted bar is made on the vertical stand. Thanks to the hole in the vertical support, the guide with a fixed abrasive surface can be moved and the angle of the blade can be adjusted. With this method, maximum accuracy is achieved.

A sharpening (abrasive) bar or stone is a necessary element of any factory or homemade device for sharpening a knife. It is convenient when it has the shape of a rectangle (it should be longer than the blade), it makes it easier to sharpen the tool.

Stones come in different grain sizes: coarse, medium and fine.

It is determined by the number of grains per unit area and is expressed as a number; the smaller it is, the rougher the stone.

To sharpen knives, you will need stones with medium and fine grain.

To sharpen knives, abrasives with a grain size of 200-350 are not used. Such grains can deform the blade. Knives are sharpened on medium-grain whetstones - from 600. After the main processing, the blade is ground and brought to a shine with 1000-1200 grain sandpaper.

A double-sided whetstone, with a rough abrasive surface on one side and a more refined one on the other, is doubly convenient, since it can be used for basic knife sharpening and finishing work.

Stones also differ in the material from which they are made. Natural - from shale and corundum rocks. These stones have a large grain and are quickly ground down because they are moistened with water or oil during operation.

There are diamond and ceramic bars, which are more wear-resistant and will last longer than natural ones.

Device for sharpening from mounting angles

The diagram and drawings of a homemade knife sharpener made from mounting angles, based on a Lansky device, are clearly shown below.

Diagram of a homemade sharpener made from mounting corners

To assemble this device you will need:

- Metal corners 90*90 mm with a wall thickness of 6 mm.

- Stud with M6 thread and length 160 mm.

- Thin rod (electrode, knitting needle, etc.).

- Touchstone.

- 2 rectangular pieces of metal (sponges for clamping the whetstone).

- Pliers.

- Hacksaw for metal.

- File (or any other tool for processing sharp corners).

- Set of hardware (nuts and bolts).

Drawing of clamping jaws of a Lansky type device

Drawing of clamping jaws of a Lansky type device

Holes should be made in the metal corners and threads cut into them according to the drawings. Then grind off the bevels on the jaws that secure the knife blade in order to prevent interference with the movement of the whetstone. All sharp corners and edges of the future sharpening device must be processed with a file.

Diagram of a finished sharpening device made from mounting angles

In both metal jaws intended for fixing the keystone, you need to drill holes and cut a thread for the connecting bolt. Fix the touchstone. A thin smooth knitting needle, previously bent at an angle of 90º, must be inserted and secured in the hole of one of the jaws. In the future, using this knitting needle-shaped clamp, a certain angle of inclination of the touchstone will be set. Such a device for sharpening knives is characterized by a wide range of sharpening angles, which will undoubtedly be of interest to most craftsmen.

Alternative sharpening methods

If your kitchen knife is a simple and inexpensive “hard worker” and/or you just don’t want to delve into the “knife culture”, then we recommend using an electric sharpener, a roller knife or a sharpening system for sharpening at home. What are their pros and cons?

- An electric sharpener sharpens knives perfectly and quickly, but even the highest quality models remove too much material from the blades, thereby shortening their service life. Another disadvantage of an electric sharpener is that a good device costs more than $200.

- A roller knife is an inexpensive and easy-to-use option. With its help, you can quickly sharpen a kitchen knife, but, unfortunately, the sharpness of the blade will not last long and the knife will deteriorate over time. The most trusted tool among roller scissors is the one from Fiskaris (pictured). Do not confuse a roller blade with a V-shaped blade. The latter is an option for the most frugal.

Sharpening systems are good because they allow you to more accurately set and maintain an angle. There are different types of such sharpeners - with blade fixation (manufacturers DMT and Lanski) and with fixation of the stones themselves at a certain angle (Spyderco Triangle Sharpmaker). Separately, we can highlight a sharpening system in which you can select the desired angle and control the position of the knife - this is the Edge Pro Apex Knife Sharpening System. Each system has its own pros and cons. For example, on sharpeners with a fixed blade it is inconvenient to sharpen wide chef knives, but on a triangle from Spyderco the knives are straightened rather than sharpened, and you can only choose an angle of 30 or 40 degrees. However, for kitchen knives these are the angles that are needed, and using a triangle is very simple. A detailed review and operating instructions for the Spyderco sharpener can be seen in the following video.

What are the disadvantages of Apex Edge Pro? Perhaps this is just a high price - $245. However, to sharpen kitchen knives, you can buy a Chinese copy of this sharpener (for example, on Aliexpress).

There is another clever way to sharpen a knife at home - using a rough mark on the bottom of a ceramic mug or plate. The principle of operation is still the same - maintaining the angle, smooth movements, maintaining the cutting edge (cutting edge) perpendicular to the direction.

- Guide to choosing a utility knife and “kitchen three”

- A guide to choosing a good all-purpose frying pan

- Choosing cookware for glass-ceramic hobs (standard and induction)

- Choosing a pan for universal use: comparison of 7 types, 6 tips and 1 video

- How to clean a pan outside and inside - 8 simple ways for difficult cases

- Guide to choosing a dish drainer

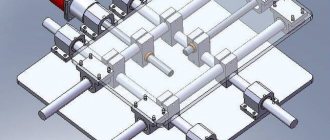

Locking blade machines

Knife sharpening machines with locking blades will attract the attention of those people who want to sharpen a knife not only efficiently, but also quickly. The design, which rigidly fixes the knife blade relative to the sharpening stone moving at a set angle, allows you to accurately set the angle of inclination.

To create such a homemade machine with your own hands you will need:

- The base is a rectangular wooden plate with dimensions 440*92 mm and a thickness of 18 mm.

- Wooden die 92*45*45 mm (for fixing the vertical threaded rod).

- A wooden block 245*92 mm and 18 mm thick (the plate to which the knife will be attached).

- Iron plate 200*65 mm and metal thickness 4 mm.

- Piano hinge, 92 mm long.

- M8 hairpin 325 mm long.

- Nuts and bolts with M8 thread.

- Drill 6.5 mm.

- M8 tap.

- Self-tapping screws 50 mm, 4 pcs.

The die intended for fixing the vertical threaded rod must be drilled through with a 6.5 mm drill. The hole should be located at a distance of 15 mm from the edge of the die, approximately in the center.

Layout of the hole in a wooden die

Next, in the resulting hole you need to cut a thread for an M8 stud. The wooden block prepared in this way must be screwed to the base at a distance of 265 mm from the edge using ordinary self-tapping screws 50 mm long, screwed into the back of the base.

Determining the location of the bar attachment

Screw location diagram

After the block and the base are securely fastened, you need to insert an M8 pin into the hole in the block. The pin should run across the entire cross-section of the beam and the base; thus the risk of changing its position is minimized. The pin at the base of the block must be firmly fixed with an M8 nut, slightly recessed when twisting it into the wood of the block.

The second part of the work involves assembling a clamping device to fix the position of the knife. To do this, a piano loop is attached to a block of wood 245*92 mm with three self-tapping screws from the end of the wooden plate, with the help of which it will be attached to the base of the device.

Attaching the fixing bar to the base using a piano loop

After securing the wooden part of the holding device, you can begin to attach the iron plate. In the center of the 200*65 mm plate, you need to drill an oblong groove, 90 mm long and about 1 cm wide. The groove should be located from the edge of the clamping plate at a distance of 60 mm. Additionally, you need to drill a hole at a distance of 20 mm from the opposite edge and cut a thread in it for an M8 bolt. Then you need to attach the clamping plate to the previously prepared wooden base using this bolt. Using another bolt and a suitable washer, you need to fix the clamping plate in the center of the cut groove. The fixation should be clear, but at the same time neat, so as not to damage the surface of the blade.

Attaching the Iron Clamp Plate

The most difficult part of assembling this device is preparing the control device that will set the sharpening angle of the knife. For this you will need:

- metal square profile 40×40 mm;

- furniture bracket, 40 mm wide;

- a pair of rivets;

- a piece of plywood 42×25 and 18 mm thick;

- bolt and nut M5;

- a pair of M8 wing nuts;

- whetstone;

- steel bar with a diameter of 0.8 cm and a length of 40 cm.

It is necessary to drill a couple of holes on a piece of plywood: a through hole with a diameter of 8 mm along a cross-section of 42×18 mm (the distance from the edge on the 42 mm side should be set at 15 mm) and a through hole with a diameter of 5 mm along the side with a cross-section of 42×25 mm (the distance from edges 10 mm). The square pipe should be cut in half so that you get a “U”-shaped bracket with a width of 40 * 15 mm and ears of 20 mm. You need to drill 8 mm holes in the ears, into which an M8 pin will later be inserted. Connect the resulting bracket to a furniture hinge using rivets. Using the second part of the furniture bracket, attach a block of plywood to the resulting structure with an M5 bolt.

Location on the spoke of the guide mechanism

Connect the touchstone to a guide rod, which is a steel rod with a cross-section of 8 mm. When connecting the keystone and the guide rod, you should strictly ensure that their center lines coincide. If desired, for ease of use of the sharpener, a handle-holder can be attached to the whetstone on the reverse side. All that remains is to secure the whetstone in the guide mechanism, secure it with a thumb and the homemade device for sharpening knives is ready.

Sharpener assembly

Why do kitchen knives become dull quickly? The sharpening angle depends on their purpose.

Do-it-yourself grinder: drawings with dimensions of components and assembly algorithm

A sharp kitchen knife is the key to fast and efficient work in the kitchen, but the use of various cutting boards does not have a positive effect on the sharpness of the blade, because they round off the cutting base of the device. You should also know that cutting on a wooden board has less effect on the deformation of the knife blade than working on a plastic board. Other reasons why kitchen knives become dull:

- Cutting up an animal carcass. The bones and tendons of any animal are hard and can dull a knife even after one use. The seeds of most fruits are also similar in strength.

- Slicing unpeeled fish with bones. The scales and bones of the fish are very hard in structure and quickly dull the edge.

- Improper storage and care. If you store the knife not in a special holder, but together with other cutlery, the blade will quickly become unusable. You should also keep in mind that most knives are not recommended to be washed in the dishwasher.

When cutting animal carcasses, knives can become dull very quickly due to the presence of tendons and bones

When working with a kitchen knife, you need to know that even poorly peeled soft vegetables and fruits that have sand or lumps of dirt on them can worsen its sharpness. Therefore, before slicing, you should thoroughly wash all products.

There are no special rules for sharpening kitchen knives, but experts still recommend observing different angles of inclination for devices with different purposes, as shown in the table:

| Knife type | Features of application | Sharpening angle, degrees |

| Dining room | For chopping food on a plate, it becomes dull mainly due to the constant contact of the cutting part with the utensils | 55-60 |

| Regular kitchen | Cutting and slicing food on a board | 25-35 |

| Professional chef | For cutting meat and fish | 20-25 |

| Povarskaya | For vegetables and fruits | 35 |

| Deboning (cutting) | Separating meat from bones and tendons | 20-30 |

| Tourist | For mixed use | 30-45 |

Machines with fixed sharpening surfaces

Machines with fixed sharpened surfaces are a simple modification of the device for processing household knives. In such a device there is no possibility of adjusting the sharpening angle, but you can pre-set several different angles for sharpening different types of knives. The work of sharpening blades using such machines is not difficult; you just need to move the blade along the abrasive surfaces in the recess.

The device consists of a pair of planes inclined to each other at a certain angle, one of which is a grindstone.

What to sharpen with?

Before you start restoring the sharpness of an edge, you need to familiarize yourself with all types of tools for work and their features. Not every device can sharpen a blade to working condition.

Sharpening stone

Sharpening stones, made from abrasive materials, are the most popular tools used for restoring cutting edges. Foreign companies indicate on the surface of the bars the number of abrasive grains per 1 square millimeter. There are stones with small, medium, and large grains on sale. With their help, you can perform both rough and finishing metal processing. Sharpening knives on sandpaper must be done carefully, making movements only in one direction.

Mechanical sharpener

Popular sharpeners that are purchased for sharpening kitchen knives. It is a structure that has two abrasive plates that are fixed at equal angles. It is enough to run the blade over them several times to restore sharpness. Cannot be used for sharpening special blades (hunting, sporting).

Electric sharpener

Expensive devices that are used for sharpening various blades. Allows you to achieve better results compared to mechanical sharpeners. This is due to the fact that this mechanism automatically selects the optimal sharpening angle.

Musat

A cylindrical file, sold separately, included with kitchen tools. Used to bring the cutting edge back to working condition after a short period of use with the blade. If there is serious damage to it, musat will not help.

Lansky sharpener

A special device that is used to restore sharpness to small blades. The main advantage of this sharpener is the ability to set any angles and maintain them throughout the working process. The sharpener is equipped with several bars for rough and finishing processing. The work is carried out manually.

Sharpening and grinding machines

In production, blades are often sharpened on machines. Using industrial equipment, you can accurately sharpen any tool. However, a master must operate the machines. This is due to the fact that the abrasive disc at high speeds can damage the cutting edge if moved incorrectly. We must not forget about cooling the metal during work.

Sharpening a knife on a machine

Electric knife sharpeners

The procedure for creating an electric sharpening machine is simple: it is enough to equip almost any device for sharpening knives and scissors with an electric drive. Such a sharpening machine allows you to quickly and efficiently sharpen the product and at the same time provides a better concave shelf at the edge of the blade.

The mechanism of an electric sharpener for sharpening knives contains a guide, which is located along the axis of rotation of the sharpening stone, and with the help of which the blade is adjusted at a given angle. The sharpening angle is set and set by the guide, and the clamping force is determined by the master.

Particular attention must be paid to the speed of sharpening, because... The electric drive allows you to sharpen the product at high speed, as a result of which the surface of the knife heats up. Such surface heating leads to tempering of the hardened steel, as a result of which the knife can quickly lose its hardness and its service life will be noticeably reduced. To prevent tempering of the steel, sharpening should be done on a high-speed electric sharpener in short periods of time and with sufficient breaks to allow the knife to cool.

Making a simple model yourself

All homemade devices for sharpening knives help to accurately maintain a given angle of inclination of the block to the blade, which is important for maintaining the functionality of the tool and obtaining a good cutting edge of the blade.

A machine designed by Lansky is easy to assemble yourself. To do it, you do not need special training or special technical knowledge. You will need a minimum of simple materials that are always at hand. In a store, such a machine costs from 2000 rubles.

The operating principle of the Lansky machine is that the knife is securely fixed and processed at a given angle using replaceable sharpening attachments made of stone of different grain sizes. The result is a sharp blade edge.

Materials

Required consumables:

- A metal rod with a diameter of 6 mm, which must be cut into rods of different lengths.

- Welding electrode for the manufacture of corner guides. It is completely cleaned of flux and sanded with medium-grain sandpaper.

- Carbon stainless steel 3-5mm thick for clamps. Through holes are made in them. Tip: machine oil will make it easier to drill slots in the plates. You can wash off the oil with a concentrated solution of soap residue.

- Metal corners measuring 9x9x0.6 cm.

- Fasteners: nuts, screws.

Step-by-step manufacturing instructions

Sequencing:

- Using a grinding machine with a diamond disc (grinder), the corners are cut, the edges of which are then smoothed with a file and sanded with sandpaper.

- Holes are drilled in horizontal and vertical planes.

- The bevels of the guide rail are processed.

- A stand is made from a bolt and nut. Then they secure it in a clamp or vice so that the entire structure is securely fixed.

- Assemble the entire device.

- Attach the abrasive and knife.

- Testing the device.

Making sharpening stones

It will not be difficult for a modern craftsman to make sharpening stones with his own hands. For this you will need:

- a wooden die to the size of the future sharpener;

- epoxy resin;

- cardboard boxes according to the size of the block;

- abrasive;

- protective rubber gloves.

You can use ready-made powder as an abrasive, or you can prepare your own abrasive, for example, from an old Soviet-made green block. Such a block can be ground into powder and used in the future as an abrasive.

Knife sharpening device

The wooden die needs to be treated on one side with sandpaper and frequent cuts must be made with a saw. Mix epoxy resin with abrasive chips. Having previously placed the block in a cardboard box glued to the size of the block, cover the prepared surface of the wooden block with a mixture of epoxy resin and abrasive. Once the resin has completely cured, the block is ready for use.

Another option for making your own sharpening stones is to create a sharpening stone from small rectangular glass plates about 5 mm thick. Using double-sided adhesive tape, sandpaper is glued to the surface of the glass plate. The sharpening stone is ready for use.

L.M.

How to make a knife with your own hands at home

The use of a manual knife sharpener such as Lansky-Metabo, pos. 1 in Fig. The diagram of its device is given in pos. 2, and the procedure for use is in pos. 3. The disadvantage of the Lansky-Metabo sharpener is the instability of the sharpening angle along the length of the blade: a rod with a touchstone is driven along it. The offset of the touch point is constantly changing, because it describes an arc of a circle, and the blade has a different configuration. Resp. The angle also “floats”. Therefore, the Lansky-Metabo sharpener is used primarily for sharpening camping and hunting knives with a relatively short blade.

Knife sharpener type Lansky-Metabo

However, this disadvantage can be turned into an advantage if the blade is clamped in the terminals with the root part A (at the handle) and the tip slightly turned away from you, pos. 4. Then the sharpening angle at the root of the blade will be greatest, which is optimal for processing hard materials or using the knife as a cleaver. This is how they work in such cases, so that the outer arm of the arm-blade lever is shorter.

Towards the middle of blade B, the sharpening angle will gradually decrease and reach a minimum at the bend of its generatrix B1, which is convenient for fine work. Then towards the tip the B angle will increase again, making the tip more resistant to drilling, chiselling/impacting and punching (piercing).

Drawings of parts of the original Lansky-Metabo sharpener are given in Fig. The numbers at the windows under the rod (guide) correspond to FULL sharpening angles.

Drawings of Lansky-Metabo knife sharpener parts

On the trail. rice. An assembly drawing of the clamp is given, and then there are drawings and dimensions of Lansky-Metabo terminals made from angle 90x90x6 mm. The author of the development hides under the pseudonym Serjant. This is certainly a matter of his modesty. But, by the way, in production, technological innovations that make it possible to use standard profiles for the manufacture of shaped parts are sometimes valued more than serious inventions.

Assembly drawing of a Lansky-Metabo knife sharpener clamp

Drawings of homemade terminals for a Lansky-Metabo sharpener from a 90x90x6 corner

General assembly drawing of the Lansky-Metabo knife sharpener

Device for sharpening from wooden blocks

A simple device for sharpening knives is a tool consisting of a pair of wooden slats and a pair of abrasive bars with the same geometric dimensions.

Wooden slats should be thoroughly sanded with abrasive sandpaper. Then, after applying auxiliary markings, depending on the sharpening angle of the knife, make cuts to a depth of 15 mm. Insert sanding blocks into the resulting holes so that each groove matches, then secure them with bolts. To give the sharpening device greater stability, the lower part of the surface can be padded with a piece of rubber.

The types of devices for sharpening cutting tools are different and each master will be able to choose the manual machine that will fully satisfy his needs.

About sharpening angles and methods of fixing the blade

But no matter what stone you choose, the sharpening technology is the same. And this is the main thing you should learn.

To begin with, train on the simplest ceramic bar, and when you see what you can do, buy something more expensive.

The most important thing in the sharpening process is to return the original angle of the edge. For kitchen and home knives it is usually standard: from 25 to 45 degrees.

Moreover, the lower the degree, the thinner the cutting edge becomes. Yes, the knife will be sharp, but it will also dull much faster, and also lose its edge shape as soon as it touches something hard.

So, if you want to resort to sharpening as little as possible, you should not make an angle of 25 degrees.

A knife that is too sharp is a rather traumatic thing in everyday life.

It will cut well not only vegetables and meat, but also kitchen towels along with your hands at the moment you wipe it.

Here is a table of recommended angles:

And here, pay attention to the fact that the angle in the table is indicated as full, that is, it is the sum of the two sides of the edge. And if you want to sharpen a knife by 30 degrees, then you need to remove 15 from each side of the blade

Accordingly, if you need an angle of 45 degrees, then remove 22.5 degrees from each side.

You need to maintain this angle during the entire sharpening process, trying not to deviate from the specified value, since the final result depends on it.

Now the question is different: how to fix and calculate this angle by eye?

This can be done as shown in the picture:

After you place the paper, you will approximately know at what angle you need to hold the knife.

Well, now let's move on to the sharpening process itself.

What will we make it from?

The next question to consider is.

The materials from which you will make it.

To create such a device you will need the following materials:

- A sheet of thick plywood (can be replaced with a sheet of chipboard) 16 mm thick;

- Self-tapping screws 50-70 mm long; (it is better to use furniture format);

- A drill corresponding in diameter and length to your self-tapping screws or conformation;

- M8 hairpin of appropriate length (approximately 70 cm);

- Aluminum plate (at least 5 mm thick);

- M8 bolts with nuts (it is advisable to use wing nuts, although you can also use regular nuts, but keep in mind that then, with each sharpening, you will have to use a wrench, and this, you will agree, is not very convenient);

- You will also need a small block of textolite or ebonite to create a movable connection between the stud and the frame, which can be adjusted in height (if necessary, it can be replaced with a block made of hard wood, for example, it could be oak, beech or hornbeam);

- Of course, you will also need abrasive stones of various grain sizes;

- You will also need a powerful neodymium magnet (“you can get” such a magnet from an old computer hard drive that has become unnecessary).

How to sharpen a drill without special tools

Many experienced specialists, who often deal with drills, sharpen them without special tools, using for these purposes only a sharpening machine equipped with a tool rest. It should be said right away that for those craftsmen who do not have such experience, it is better not to try to sharpen the tool in this way: otherwise the drill, which can be expensive, will have to be replaced with a new one. You should especially not experiment with this sharpening method in cases where you need to restore a drill whose diameter exceeds 3 mm.

When manually sharpening a drill, you have to rely only on your eye and experience, if you have it.

Those who are faced with the need to frequently drill various materials and do not yet have sufficient experience to sharpen drills without the use of special devices can purchase a similar device: the modern market offers a wide variety of models in different price categories. Moreover, many of these devices, ranging from a full-fledged drill sharpening machine to the simplest sharpening device, can be made with your own hands on a minimal budget.

Do-it-yourself blade sharpening

Sharpening a knife with a whetstone

Sharpening a blade made with a sharpening stone is considered to be of the highest quality, provided, of course, that it was carried out by an experienced craftsman. To sharpen a knife on a whetstone, do the following:

- Place a low abrasive grit sandstone on a stationary surface. If the block is small, it can be clamped in a vice.

- Holding the knife at an angle of 20-25 degrees relative to the surface of the block, begin moving the knife along the whetstone with the cutting edge forward.

- Move the blade along the block so that during movement it touches the surface of the whetstone along its entire length.

- As you move, try to maintain the same blade angle.

- After making 2-3 movements, turn the knife over and repeat the sharpening process on the other side of the blade.

- Thus, alternating sides, sharpen the knife until an edge (burr) appears along the edge of the blade.

- Swap the coarse whetstone for a grinding stone.

- Sand the knife blade until the edge disappears.

- Test the sharpness of the knife by cutting a hemp rope folded several times, or try cutting a sheet of paper.

Sharpening a hunting knife on a Lansky sharpener

Hunting knives are made of hard steel, so their initial sharpening requires sharpening stones with a low content of abrasive grains.

- Clamp the knife in a sharpener vice.

- Place a sharpening stone with a low content of abrasive grains on the rod.

- Select the angle of the block (for hunting knives it is usually from 20 to 30 degrees).

- Insert the rod into the desired hole.

- Lubricate the whetstone with the special oil included in the sharpener kit.

- Start moving the block along the knife blade, from the base to the tip.

- Flip the sharpener over and repeat the process on the other side of the knife.

- Once the edge is formed, change the stone and do the final sanding.

- Since hunting knives are mostly made with a double-sided blade, after finishing sharpening on one side, change the position of the knife in the vice and begin the sharpening process on the other side.

- Once you've finished sharpening, polish the knife blade with felt.

How to sharpen knives in a Lansky sharpener, watch the video:

Sharpening scissors

Sharpening of scissors must be done on a special sharpening machine. Sharpening blades using improvised materials (sandpaper, the edge of a glass, etc.) can temporarily improve the sharpness of scissors, but not for long. If you do not have the opportunity to have your scissors sharpened by a professional, you can try to sharpen them yourself on an abrasive stone. When sharpening you need to follow a few simple rules:

- The sharpening stone should be fine-grained.

- The blade is sharpened over the entire surface of the edge at the same time.

- The angle of the blade should match the factory edge.

- The movement of the blade along the stone should be from the screw to the tip.

- Scissors need to be sharpened disassembled.

When sharpening scissors, do not rush; patience will be your ally in this matter.

You can also watch the video on how to quickly sharpen scissors:

Sharpening plane and chisel blades

Sharpening the blade of a plane and a chisel are practically no different from each other. Therefore, the sharpening process described below applies to both tools:

- Place the chisel on the whetstone at an angle of 30-40 degrees.

- Holding the chisel with your hand, use the fingers of your free hand to press the bevel onto the whetstone.

- Start running the chisel over the whetstone until a burr forms on the smooth side of the chisel.

- Change the whetstone to a fine-grained one and do the final grinding of the chisel.

- Check the sharpness of the chisel blade by removing shavings from the corner of the block.

In addition to manual sharpening, the chisel can be sharpened on a machine with a rotating abrasive disk:

- Turn on the machine and let the disc reach full speed.

- Holding the chisel with both hands, place its bevel against the sharpening wheel.

- Be sure to maintain the angle of the chisel, otherwise you will damage the blade of the tool.

- Do not press the chisel with great force and do not hold it on the blade for too long, this will lead to overheating of the metal and destruction of the blade.

- While sharpening, wet the blade with water.

- The final grinding of the chisel blade is best done by hand, using a fine-grained stone or sandpaper.

Do not forget that when sharpening products on a machine, a lot of sparks and small particles are generated that can get into your eyes, so be sure to wear safety glasses. To avoid damaging your hands on the rotating disk, wear gloves.

You can also learn how to sharpen tools from the video:

Necessary conditions for a sharpening machine

In order to make a knife sharpening machine with your own hands, you need to carefully plan the stages of work and draw up drawings. If the master has experience, then he can develop them himself or use ready-made drawings that are offered in specialized literature.

For ideal processing of the cutting surface, the machine must meet the following requirements:

- reliable and at the same time not too rigid fixation of the knife in a vice;

- compliance with the angle, during the sharpening process the angle must be constant;

- The design of the machine must provide for the possibility of changing the sharpening angle.

You can read below about how to make your own blade straightening devices that are in no way inferior to purchased mechanisms.

DIY knife sharpener

Homemade sharpening machine for autonomous type drills

If desired, you can make a sharpening machine for straightening drills, the design of which will have its own electric drive motor. Such equipment will be completely autonomous and will not have to be attached to an existing grinding machine.

The frame of such a compact machine can be made of plexiglass or textolite 10 mm thick, and an electric motor from an old fan can be used as a drive motor. The guide element of such a machine, on which the stop for the drill shank is fixed, works on the principle of a conventional caliper. The angle at which the drill, which has the ability to move in the horizontal direction, is sharpened is set by using a rotary platform.

DIY sharpening machine

Despite the fact that today stores provide a wide selection of tools and equipment for high-quality and quick sharpening, users sometimes tend to use their hands to create, for example, a machine that is useful for performing this process.

To manufacture the machine you need:

- plywood sheets;

- metal pin. Its diameter is 10-12 mm;

- steel in the form of a sheet, the thickness of which is 1 mm;

- block of wood;

- a pipe made of metal;

- abrasive block;

- a hacksaw, which will be used to cut metal;

- drill;

- plane.

The machine assembly process looks like this:

- Plywood is taken, and the future frame of the machine is made from it, or rather, the base on which the remaining components will subsequently be attached.

- After this, holes are drilled in the base using a drill. Needed to secure the adjusting pin.

- Sheet steel is used to make tool rests.

- The pin is inserted into the drilled holes, and the steel is attached above.

- Next, special devices are manufactured that will fix the angle of inclination.

- Upon completion of the previous step, they begin to manufacture the carriage and another base, but for replaceable bars. The carriage is made of another metal pin and pre-prepared wooden blocks.

- The base for placing the abrasive bars is made of a pipe and attached to the carriage.

https://youtube.com/watch?v=nliTUKgdbL8

The drawing of the machine that will be obtained after completing the steps is presented below.

The assembly of the machine is completed by installing additional parts. After which the unit is considered assembled and ready for use.

There are many photos and videos on the Internet that present lessons on how to properly sharpen knives and other cutting surfaces: select an angle, adjust equipment, fix the initially specified position. With their help, you can carry out the process yourself and at the same time avoid common mistakes. After several attempts at sharpening knives, blades and other tools, you can call yourself a professional and help others. If you cannot sharpen a knife yourself, it is recommended to seek the help of professionals or ask someone who has experience in this matter.

Thus, the knife sharpening device allows you to use the devices for several years.

What are the differences between abrasive stones?

Sharpening stones come in a variety of shapes, bar sizes, and grain sizes. The optimal size of the bar is considered to be one in which its length exceeds the length of the blade of the knife being sharpened by at least one and a half times. This allows you to work with such a bar much more comfortably than with a bar that does not meet this simple requirement.

As mentioned earlier, sharpening stones can have not only different sizes, but also very different grain sizes. There are five main levels of grain size for such bars:

- Grain size 200-300 Extra coarse. In English called Extra coarse. Such bars are not used for sharpening tool blades and knives in particular;

- Grain size 300-350 Coarse grain. In English called Coarse. With the help of such bars, damaged or very dull blades are sharpened;

- Grain size 400-500 Medium grain. In English called Medium. You can do without such a block in the household;

- Grain size 600-700 Fine grain. Called Fine in English, these whetstones are the most popular for sharpening tool blades in the home workshop.

- Grain size 1000-1200 Very fine. In English called Ultra fine. These bars are used for final processing of blades that need to be brought to a shine. Such bars can be used as a tool for a homemade knife sharpener.

Methods for checking the blade tip

After carrying out the work, you need to check how sharp the blade is. Several methods are used for this.

On paper

Try to cut a sheet of paper while holding it with one hand. If you can do it without problems, the sharpening is good. A sharp blade will cut the sheet under its own weight.

On a tomato

Often the sharpness of kitchen blades is tested on tomatoes. If it is blunt, the vegetable will be crushed. You need to put it on the table in front of you, try to cut the tomato with the blade horizontally without holding it with your hand. A sharp blade will easily cut a vegetable.

Checking knife sharpening on tomatoes

Possibility of adjusting the position of the knife

An alternative to a machine with a moving sharpening stone is a device where it is possible to adjust the position of the knife relative to the whetstone. Basically, its design is similar to the machine with an adjustable bar, a little easier to manufacture.

A movable block is mounted on the base plane to secure the rod with the bar. Clamps are also installed on it, one is adjustable, the other is persistent. Using an adjustable clamp, you can adjust the sharpening angle.

The only drawback of this model is the appearance of wear on the bar in one specific place. This drawback can be eliminated by installing a long pin to adjust the edge relative to the surface being processed.

Each option described above has its own advantages and disadvantages. When making your choice in favor of one model or another, you need to focus on the level of skills and the magnitude of the needs for operating the machine.

Why do you need a sharpener?

A living relic of our days is the Finnish hunting knife. Not a gangster Finnish knife, sometimes of a bizarre shape, but a Finnish-type hunting knife, on the left in the figure. Traditional hunting knives (center and left) are similar in shape, but the difference between them is very large.

Finnish knife and classic hunting knives

The blade of a Finnish knife is forged from cast iron, which can be smelted right in your yard from swamp ore in a furnace-furnace, without resorting to the blast furnace process, puddling, and other methods of converting cast iron into iron and steel. The viscosity of crinkly iron is excellent; it is very difficult to break a blade made from it. But the hardness is also low, somewhere around HRS55, the knife becomes dull quite quickly. Finnish hunters did not care about this: a blade of such hardness can be sharpened (sharpened) by beating on many natural stones, and there were always enough smoothed moraine boulders in Fennoscandia.

They sharpen a knife by beating it in much the same way as beating a scythe, only the whetstone is motionless and the blade is moved. First, they pull it along the whetstone with the butt away from you, then they turn it over and pull it with the butt towards you. The position of the cutting edge (CR) on the whetstone is always dragging; quick movements: shirk-shirk! During each movement, you need to keep the contact patch of the blade with the touchstone (see below), but the requirements for maintaining the angle of inclination are not so strict. Learning to sharpen a knife by beating is not very difficult, and with some skill you can create a smoothly running profile on the blade, see below. However, the Finnish knife is, in general, a dead end in the evolution of a cutting tool, surviving in special natural conditions.

A good knife has never been cheap, and in extreme situations, the durability of the blade, combined with the toughness of the blade, became vital factors. Therefore, even in ancient times, they learned to harden knife blades from the surface and cement them: the core remained viscous, not brittle, and a hard, red-hot crust formed on the outside, see next. rice.:

Structure of a knife blade with surface hardening and carburization

It is still possible to sharpen a knife with a cemented blade, but you need a skill that is not given to everyone. And the abrasive is already needed from a special type of stone - lithographic grunstein slate. There is little of it in nature; Grünstein is still considered a strategic raw material. There is no artificial grenstein and it is not expected. It’s as easy as shelling pears to ruin a cemented knife with inept beating - a little somewhere the cementation bark will be stripped down to raw metal (this is not visible to the eye), the knife will only have to be thrown away, the blade will immediately become dull and begin to crumble.

Service knives do not require the same durability and toughness as hunting and hiking knives, and they should cost much less. As a result, special steels and powder metallurgy are widely used in the production of utility knives. The blade of an “eternal” kitchen knife is structured like a rodent’s incisor: in longitudinal layers, the hardness of which decreases from the core outward. In any case, you have to sharpen the knife less often, but chipping is definitely ruled out - the blade immediately becomes discolored.