The properties of the blade directly depend on several factors - thickness, angle and type of sharpening of the knife, that is, the shape of the cutting edge. In general, the thickness of hunting and tactical models is greater than that of kitchen models - such products make it possible to both cut, push, and rip apart material with a fairly high hardness index. The type of sharpening also determines the functionality, and therefore the scope of application of the tool.

Names of blade parts.

Knife sharpening

The process of forming the required angle between the cutting edges of the blade is called sharpening. Using an abrasive stone or other devices, the master shapes the cutting edge. This is sharper than the angle between the converging planes of the blade.

The sharpness of the blade will be determined by the angle of convergence of the edges. But not everything is so simple, depending on the purpose of the tool, different sharpening angles may be needed.

Do you sharpen your knives yourself or in a workshop?

SamIn the workshop

How to do it manually?

Regardless of whether you decide to master manual sharpening or use small-scale mechanization means, the right thing to do is start with a block of the coarsest grain size and move on to finer ones. It is advisable to hold the knife perpendicular to the block. The most important thing is to maintain the same angle of inclination of the blade to the surface at all times. Movements when sharpening should be uniform and monotonous. The sharpening stone and the surface on which it rests should not move. To do this, you can put a piece of sheet rubber on the table, or, failing that, a moistened sheet of paper.

Grinding the first third of the knife edge "G. SakaiFoldingHunter" on a 600 grit water stone (before starting work, a block of natural stone is soaked in water for 15 minutes, and then its surface is lubricated with soapy water)

Don’t forget to periodically check how much metal is being removed from the handle, and don’t press the knife too hard - the pressing force against the block should be small but constant. Moving the knife away from you or towards you is a matter of taste; to save time, I do it in both directions. To begin with, you should practice using a regular board instead of a sharpening stone, and, say, a short ruler instead of a knife. Hands will remember.

Many consider the sharpening process to be a kind of movement meditation; in principle, that’s how it is. The need for constant control and concentration on the task at hand forces you to disconnect from external factors. It turns out to be a kind of zen.

Features of knife sharpening - angles

The purpose of a knife can be different. There are products for cutting carcasses, for hunting and even for war, and there are blades that are used to plan wood and prepare branches for a fire. There are universal and multifunctional samples that can perform several tasks.

The ability of the product to cope with certain materials will depend on the sharpening angle of the blade.

The smaller the angle, the sharper the blade. But it should be borne in mind that in this case the cutting edge will be thinner and its strength will decrease.

Determining the correct ratio of the angle between the cutting edges of an edge and its thickness is quite a difficult task. But over the centuries-old history of the knife, certain standards for sharpening angles have emerged depending on the purpose of the blade:

- Shaving blades and similar tools are sharpened to 8-12°.

- Products for skinning and cutting meat have an angle of 10-15°.

- Kitchen and household appliances have 15-20°.

- Hunting and general purpose knives are sharpened at 20-25°.

- Products for cutting branches, wire, opening cans and splitting wood are sharpened at an angle of 25-40°.

The legendary Japanese katana has a sharpening similar to that of a kitchen utensil. The strength of steel with good sharpening gave the weapon incredible properties. By the way, long edged weapons often had different sharpening angles in different parts of the blade.

What is a sharpening angle?

Not just knives...

The original Apex sharpener is not very suitable for sharpening carpentry tools - chisels, planer bits. The sharpening angle of the Apex floats for the same reasons as that of the Lansky-Metabo. Meanwhile, if the sharpening angle of the chisel along the width of the blade “walks” by more than 1-1.5 degrees, then the tool strives to move to the side, crawl out, or go deep into the solid wood along its fibers. It is very difficult to evenly and accurately select a groove for a tenon/ridge using such a chisel.

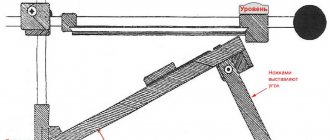

Roller sharpener trolley for knives and carpentry tools

There are special devices for sharpening carpentry tools, which require a special discussion. Homemade products like a roller sharpener-trolley, see fig. on the right, they are more of a curiosity: not to mention the complexity, they require a stone or steel table, and, most importantly, they do not guarantee against distortion of the blade on the whetstone, which leads to the same undesirable result.

Meanwhile, 2-3 years ago, in one of the Chinese magazines on technical creativity, a modification of Apex for sharpening was flashed, not inferior to that of a factory electric semi-automatic sharpening machine. The alteration is not difficult, see figure: the rod is set horizontally according to the level and the rod level is held along the same level while sharpening. Within the angle of rotation of the rod in the horizontal plane of 10-12 degrees to the right and left, the sharpening angle error is less than 1 degree. If the offset of the contact point is from 250 mm, it is possible to sharpen chisels and planer pieces up to 120 mm wide.

Improvement of the Apex knife sharpener for increased sharpening accuracy

In this operating mode, a zero (theoretically) sharpening angle error can be achieved by keeping the bar stationary and moving the knife held by the magnetic holder, see above. In this way, it is also possible to sharpen the pieces of shaped planes if a round, semicircular, elliptical or segmented whetstone is placed in the clamps. The main thing is that the touch spot is always point-like.

Modification of the Apex knife sharpener for sharpening scissors

...but also scissors

Another modification of the Apex sharpener for sharpening scissors (also a necessary thing in the household) is shown in Fig. on right. The total work required is a couple of pieces of angle or galvanized scraps and 4 additional holes in the sharpener table. How to make your own attachment for sharpening scissors for the Skomorokh sharpener, see next. video.

Video: sharpening scissors, attachment to the sharpener Skomorokh

Finally, about scissors

Before you grab your poorly-cut scissors and stick them in the sharpener, check to see if the hinge is loose. Open the scissors and look at them from the side. Do you see how the tip is turned with a screw towards each other? That’s why scissors cut: the point of contact of the blades when cutting moves from the roots to the ends. And therefore it is difficult to cut with scissors with your left hand: turning the ends is designed for the kinematics of your right hand. And if the hinge of the scissors is loose, the blades will move away from each other and will not even be able to cope with paper. In this case, you just need to tighten the riveted joint with a hammer and the screw joint with a screwdriver.

Types of knife sharpening

All options that are possible when sharpening a knife are divided into two types:

- double-sided - the blade is sharpened on both sides;

- single-sided - the blade is sharpened on one side.

Double-sided

This is a universal option and, one might say, optimal for most knives. Such a blade will be able to cut, chop, rip and perform many other operations. Let's take a closer look at blade profiles that can be sharpened with double-sided sharpening:

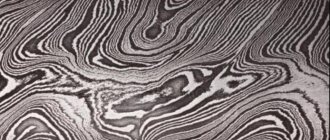

- Blade with lens-shaped slopes (Fig. 1). Very popular on professional models. Products of considerable thickness can be cut with uniform force. This cutting edge is very durable during cutting and chopping blows. This sharpening is rarely used and is done only by hand, so it is very expensive.

- Blade with concave slopes (Fig. 2,3). This sharpening is used for straight razors. Due to the lack of initial resistance, the product cuts very thinly. But due to its configuration, it has relatively low strength and reduced resistance to impact loads. This blade makes it easy to cut and cut. But cutting the product will be very difficult, due to serious resistance when penetrating the material.

- Wedge-shaped profile (Fig. 4). In shape it resembles an isosceles triangle. It penetrates the product very well, but due to its own geometry it has a very fragile cutting edge. The wedge is quite rarely used on modern knives.

- Pentagonal profile (Fig. 5). Often found in Scandinavian knives. It is much stronger than the previous version. But due to the additional ribs, the material fits a little tighter. Sharpening such a product is not difficult.

- Pentagonal profile (Fig. 6). Considered the most popular in the world. The set of characteristics of this sharpening is perfectly balanced. Very good combination of strength and cut quality. This sharpening is considered universal and is used by most craftsmen.

- Pentagonal wedge with inlet (Fig. 7,8). Optimal and high-tech sharpening for a knife, which provides a good cut to the blade. This type is often called European. The strength of this blade is slightly less than that of the previous one, and the cutting properties are slightly better.

- Double-sided asymmetric sharpening (Fig. 9). This blade combines the advantages of double-sided and single-sided sharpening. But the width of the left side is different from the right. Some Japanese knives and some craft products are sharpened this way.

Various knife profiles.

One-sided

This method of sharpening is called chisel. The blade is sharpened on one side. This sharpening method stiffens the cutting edge so that the knife remains sharp. The product is not intended for chopping, but it can perfectly cut material into thin slices. When choosing a sharpening side, it is taken into account which hand a person has as a worker.

Chisel sharpening.

L.M.

The use of a manual knife sharpener such as Lansky-Metabo, pos. 1 in Fig. The diagram of its device is given in pos. 2, and the procedure for use is in pos. 3. The disadvantage of the Lansky-Metabo sharpener is the instability of the sharpening angle along the length of the blade: a rod with a touchstone is driven along it. The offset of the touch point is constantly changing, because it describes an arc of a circle, and the blade has a different configuration. Resp. The angle also “floats”. Therefore, the Lansky-Metabo sharpener is used primarily for sharpening camping and hunting knives with a relatively short blade.

Knife sharpener type Lansky-Metabo

However, this disadvantage can be turned into an advantage if the blade is clamped in the terminals with the root part A (at the handle) and the tip slightly turned away from you, pos. 4. Then the sharpening angle at the root of the blade will be greatest, which is optimal for processing hard materials or using the knife as a cleaver. This is how they work in such cases, so that the outer arm of the arm-blade lever is shorter.

Towards the middle of blade B, the sharpening angle will gradually decrease and reach a minimum at the bend of its generatrix B1, which is convenient for fine work. Then towards the tip the B angle will increase again, making the tip more resistant to drilling, chiselling/impacting and punching (piercing).

Note: Another disadvantage of the Lansky-Metabo sharpener is the difficulty of using it in a desktop version. But this drawback, as they say, is fake, see pos. 5.

Drawings of parts of the original Lansky-Metabo sharpener are given in Fig. The numbers at the windows under the rod (guide) correspond to FULL sharpening angles.

Drawings of Lansky-Metabo knife sharpener parts

On the trail. rice. An assembly drawing of the clamp is given, and then there are drawings and dimensions of Lansky-Metabo terminals made from angle 90x90x6 mm. The author of the development hides under the pseudonym Serjant. This is certainly a matter of his modesty. But, by the way, in production, technological innovations that make it possible to use standard profiles for the manufacture of shaped parts are sometimes valued more than serious inventions.

Assembly drawing of a Lansky-Metabo knife sharpener clamp

Drawings of homemade terminals for a Lansky-Metabo sharpener from a 90x90x6 corner

Note: next rice. An assembly drawing of the Serjant sharpener is given. Regarding the inconvenience of fastening in a vice, see above.

General assembly drawing of the Lansky-Metabo knife sharpener

Serreytornaya

The previous sharpening options refer to smooth varieties. But there is a serrated edge, it has teeth like a saw, only the teeth are not spread in different directions. From the outside, this sharpening looks like a wave with sharp protrusions.

This product is convenient for cutting hard material with a minimum amount of crumbs or sawdust. This is mainly how knives for kitchen work are sharpened. But it can be found on the blades of hunters, tourists, or on survival products.

It is very difficult to do such sharpening yourself; you will need a special tool. For some knives, a semi-serrator is made, this is when the blade is sharpened in this way only halfway. And also the teeth can be located on the butt of the blade.

Serrated knife sharpening.

Why is one-sided sharpening necessary?

The chisel blade profile is most popular in the manufacture of various types of woodworking tools. In particular, knives for planes, cutters, chisels and chisels. With this profile, you can achieve a clean cut, and all the material being removed ends up on one side of the blade.

This is very popular when processing wood. The descent is left flat without leads. Some traditional blades are sometimes made with one-sided sharpening. An example is Yakut knives.

This profile is also used for Japanese kitchen knives. The specific cuisine of Japan sometimes requires no less unique knives.