To process small items, you can use an engraver. Using a microdrill, grinding and milling of various materials is carried out. The use of various attachments allows you to expand the list of jobs that can be performed with a power tool. Often, beginning craftsmen are interested in the question: nozzles for engravers, which ones are used for what. Below you can learn more about the types of equipment and their scope of application.

To prevent the microdrill from vibrating during operation, it is necessary to first center the nozzle

What are engraver attachments?

Today, construction stores offer a wide range of attachments for working with engravers. The design of the equipment consists of:

- a shank with which the tool can be fixed in the equipment chuck;

- the working part interacting with the materials being processed.

When choosing attachments for an engraver, you should pay attention to the characteristics of the materials being processed and the list of tasks that you plan to perform. If the mini-drill will be used on an ongoing basis, it is best to immediately purchase a full set of consumables.

Important! Professional kits contain equipment that allows you to process metal, wood and other surfaces.

Arsenal of wood carver tools

The main tool for cutting wood, as mentioned above, is a burr. The implementation of such a procedure, during which a layer of the processed material of various depths is removed, is ensured by the rotation of the cutter, as well as its translational movement along the required trajectory. Accordingly, equipment is also required with which the tool used will be driven into rotation. Such equipment, indispensable for an engraver and any woodcarver, is a drill, often called a Dremel.

Dremel produces electric engravers for household and professional grades

The word “Dremel” comes from the name of the German company Dremel, which produces a large range of electrical equipment, in which drills and specialized engravers occupy a significant place. Drill kits from Dremel and other manufacturers already include everything you need to install the tool and get started.

You can also cut wood using cutters using a conventional electric drill or screwdriver, if you equip them with a flexible shaft and a special attachment on it, into which a burr is installed. This simple device is also suitable for an engraver who works with products made of metal and other materials.

Flexible shaft for drill

The quality and attractiveness of the work performed when cutting wood directly depends on the characteristics of the equipment used. Even the experience and knowledge of the person performing such work cannot positively affect the characteristics of the finished product in the absence of appropriate equipment and wood burrs.

Engraving pen

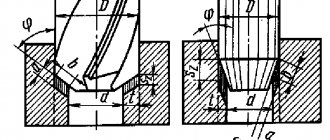

The design of the graver consists of a handle, a ring and a blade. The handle, the outline of which resembles a mushroom, is turned on a lathe. A sleeve mounted on its tip protects the handle from cracks. It is convenient for novice craftsmen to engrave copper and brass products with a pen. Experienced engravers can work with any non-ferrous metals.

Note! When mastering engraving technology, the first step is to achieve clear application of straight and curved strokes.

With a sharp sharpie you can easily cut metal to a depth of 0.1-0.2 mm

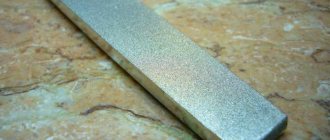

Diamond burs for engraving work

The most popular types of working attachments used to complete engraving installations include diamond burs for engravers. The base of such a tool is made of tool steel, and diamond powder is applied only to their working part. The mechanical characteristics of diamond powder make it possible to successfully use the attachment for processing hard materials such as steel, ceramics, glass, artificial and natural stones.

Expensive dental diamond burs have a long service life

Diamond burs (or cutters) are used primarily for finishing shaped holes. As a rule, diamond consumables for engravers are sold in whole sets of 10–20 tools of various shapes and sizes. When working with them, you should strictly follow the rules of their operation so as not to damage the diamond coating. The standard shank diameter of diamond-type engraving bits is 3 mm.

Abrasive tools

Nozzles, the working part of which is made of rubber or abrasive, belong to the category of budget tools. Abrasive equipment is available for sale, painted in various colors. This allows the technician to quickly determine the category of attachments.

For example, green tools are made from silicon carbide. They can be used to process stone, glass and ceramic surfaces. Abrasive equipment is often used for boring holes, grinding surfaces, etc.

Friday, February 4, 2011

Dremel: attachments, purpose and methods of use

It is advisable that the tool be equipped with a speed control system. A digital display that allows you to visually control the speed will not hurt at all. The ability to directly switch on the maximum rotation speed increases the convenience of using the machine and eliminates the need for unnecessary operations. The flexible drive shaft guarantees comfortable and precise work in hard-to-reach places. The machine comes complete with attachments selected to perform basic operations - grinding, polishing, milling, cutting, drilling.

I’ll briefly try to tell you about these attachments (which are included in the kit and made from available materials) in this review.

Let's start from afar - with basic safety rules

when working with a Dremel