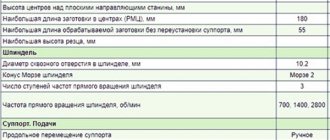

Equipment Specifications

The screw cutting machine has a wide range of technical features:

- The power of the electric motor ensures the functioning of the main drive and reaches 7.5 kW. And the drive itself, responsible for moving the caliper, has a power of 0.37 kW. The electric motor for the lubrication mechanism is 0.12 kW;

- the maximum length of the workpiece to be turned is 1.46 meters, and the maximum dimensions of the product fixed at the centers of the machine are 1.5 meters;

- Automatic transmission;

- thread cutting is carried out by the worker selecting a step, which he sets based on the type of workpiece;

- the maximum cross-section of the workpiece turned above the bed should not be more than 40 centimeters, and above the support - 21 centimeters;

- the number of revolutions of the spindle device in forward motion is from 25 to 2500 rpm, and in reverse motion – from 25 to 1250 rpm;

- in forward movement, the spindle device has 21 speed levels, and in reverse – 18;

- the machine is driven by a 2-speed electric motor together with a gearbox and a bulkhead that programs 12 speed levels of the spindle mechanism in any of the 2 ranges;

- transverse feeds vary from 0.025 to 1.4 mm, and longitudinal feeds - from 0.05 to 2.8 mm per rotation;

- The range of movement of the caliper along the screw is 75 centimeters (lengthwise) and 22 centimeters (crosswise). The maximum distance of its movement along the roller is 50 centimeters;

- Rolling bearings create rigid and high-precision support;

- the guides of the carriages and the rolling pairs of the screws have impulse lubrication;

- feed drive provides stepless feed adjustment;

- loading and unloading of parts is carried out manually.

These technical parameters enable the car to enjoy popularity even 50 years from the date of its release. The letters “K” and “P” in the name of the machine indicate that there is a copying mechanism and an increased degree of accuracy, respectively. The screw cutting machine is capable of operating from a mains voltage of 220, 380, 400, 415 and 440 V. It is characterized by a modern ergonomic structure and is easy to operate and control.

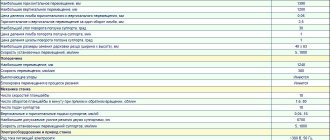

Dimensions and weight of the machine

The screw cutting machine is small in size and weight for a machine with similar functionality:

- width – 1110 millimeters;

- height – 1505 millimeters;

- length – 2270 millimeters;

- weight – 2 tons.

Purpose and scope

The 16b16kp machine is intended for performing various turning operations in centers, collets or in a 3 or 4-jaw chuck, for cutting various threads with a die or tap. Unlike most other brands, such a machine is intended for more thorough turning, and therefore is not recommended for roughing. It is usually installed in small repair shops. After processing on a lathe, the products are distinguished by excellent surface cleanliness.

Information about the manufacturer of the screw-cutting lathe 16B16kp

The manufacturer of the 16B16kp universal lathe is the Srednevolzhsky Machine Tool Plant SVSZ , founded in 1876.

The production of metal-cutting machines at the Srednevolzhsky Machine Tool Plant first began at the end of January 1926. The first machine produced at the enterprise was a screw-cutting lathe with a stepped pulley, model TV-155V.

In 1934, the plant created an original screw-cutting lathe, model SP-162 , with 8 speeds and spindle revolutions per minute from 24 to 482. For the first time, an individual electric motor with a power of 1.5 kW was installed on the machine.

In 1935, the plant was the first in the USSR to produce a thread milling machine model 561, and since the war in 1941 it began producing a whole range of semi-automatic thread milling machines: 5A63, 5A64, 5M63, 5M64.

During the war years, the plant mastered the production of a screw-cutting lathe 1615

and soon upgraded it, bringing the spindle speed to 1000 rpm.

In 1949, the machine was put into mass production 1616

, in the sixties the models were

1B616 and 1A616

, and from the beginning of the seventies the production of the

16B16 .

Since the 90s of the last century, the SVSZ company has been producing lathes under the SAMAT .

Machine tools manufactured by the Srednevolzhsky Machine Tool Plant, SVSZ, Samara

- 1A616

universal screw-cutting lathe, Ø 320 - 1A616k

screw-cutting lathe with automatic transmission, Ø 320 - 1A616P

high-precision screw-cutting lathe, Ø 320 - 1B811

turning and backing machine, Ø 250 - 1E811

turning and backing machine, Ø 250 - 1P611

universal screw-cutting lathe, Ø 250 - 16B16

universal screw-cutting lathe, 320 - 16B16A

especially high precision screw-cutting lathe, Ø 320 - 16B16KA

especially high precision screw-cutting lathe with automatic transmission, Ø 320 - 16B16P

high-precision screw-cutting lathe, Ø 320 - 16B16KP

high-precision screw-cutting lathe with automatic transmission, Ø 320 - 16B16F3

chuck center lathe with CNC, Ø 320 - 16B16T1

CNC lathe, Ø 320 - 16D16AF1

especially high precision screw-cutting lathe with digital display, Ø 320 - 561

thread milling machine, Ø 400 x 700 - 1615

universal screw-cutting lathe, Ø 320 - 1616

universal screw-cutting lathe, Ø 320 - 1716PF3

CNC lathe, Ø 320 - 5350A

semi-automatic slot milling machine, Ø 150 - Samat 400

high-precision screw-cutting lathe, Ø 400 - Craftsman

table lathe, Ø 175

Structural components and mechanisms of the machine

The machine has a number of main components:

- Caliper.

- Gearbox.

- Transmission.

- Rear grandma.

- Main bed.

- Apron.

Mechanisms:

- protective parts. There is a mechanism to protect the worker and aggregate components from chips generated during the execution of work. This significantly increases the degree of safety and service life of the machine;

- A mechanism responsible for changing gears has been introduced into the screw cutting machine. This significantly increased the functional reliability of the screw cutting machine;

- electrical equipment. The main parts of the electrical system are 4 asynchronous electric motors of the screw cutting machine with different powers. Almost all elements are located in a special cabinet;

- The turning machine has longitudinal shut-off stops, a protective device against excessive loads, and a mechanism for blocking feeds in all directions.

General view of the screw-cutting lathe 16B16KP

Photo of screw-cutting lathe 16B16kp

Photo of screw-cutting lathe 16B16kp

Photo of screw-cutting lathe 16B16kp

Photo of screw-cutting lathe 16B16kp

Photo of screw-cutting lathe 16B16kp

Location of the main components of the screw-cutting lathe 16B16kp

Designation of machine components

| Pos | Name | 16B16 16B16P | 16B16K 16B16KP | 16B16A | 16B16KA |

| 1 | Gearbox (guitar) | 16B16P.080 | 16B16P.080 | 16B16A.080 | 16B16A.080 |

| 2 | Electrical equipment | 16B16P.195 | 16B16KP.195 | ||

| 3 | Spindle head | 16B16P.020 | 16B16P.020 | 16B16A.020 | 16B16A.020 |

| 4 | Cooling | 16B16P.251 | 16B16P.251 | 16B16P.251 | 16B16P.251 |

| 5 | Tool holder | 16B16P.048 | 16B16P.048 | 16B16P.048 | 16B16P.048 |

| 6 | Caliper | 16B16P.045 | 16B16P.045 | 16B16P.045 | 16B16P.045 |

| 7 | Carriage | 16B16P.051 | 16B16P.051 | 16B16A.051 | 16B16A.051 |

| 8 | Tailstock | 16B16P.330 | 16B16P.330 | 16B16P.030 | 16B16P.030 |

| 9 | Rapid traverse drive | 16B16P.159 | 16B16P.159 | 16B16P.159 | 16B16P.159 |

| 10 | Right cabinet | 16B16P.017 | 16B16P.017 | 16B16P.017 | 16B16P.017.01 |

| 11 | Apron | 16B16P.062 | 16B16P.062 | 16B16A.061 | 16B16A.061 |

| 12 | bed | 16B16P.011 | 16B16P.011 | 16B16A.011 | 16B16A.011 |

| 13 | Gearbox | 16B16P.070 | 16B16P.070 | 16B16A.070 | 16B16A.070 |

| 14 | Gearbox | 16B16P.024 | AKP 109-6.3 | 16B16P.024 | AKP 109-6.3 |

| 15 | Main Drive Pulleys | 16B16.162 | 16B16.162 | 16B16.162 | 16B16.162 |

| — | Control cabinet | SCO 5906 | SCO 5906 | ||

| — | Lubrication system | 16B16P.240.000 | 16B16P.240.000-03 | 16B16P.240.000 | 16B16P.240.000 |

| — | Guide unloading device | 16B16A.062 | 16B16A.062 |

Gearbox

This 6-stage unit is installed in a separate housing and secured at the rear to the outer wall of the left transverse face. To tension the belt that goes from the box to the spindle device, it is capable of moving vertically using a screw. The device runs a 2-speed electric motor via a belt drive. Pulley 16, interconnected with hub 15, transmits rotational motion to shaft 14, which easily passes through sleeve shaft 20.

Shaft 14 is interconnected with coupling 25, when launched, the stroke from it passes to the shaft-sleeve 20 linked to it through half-coupling 24. This unit allows you to produce 6 speeds on pulley 13. The stroke is transferred to the headstock pulley by a belt drive. Connected to shaft 4 is coupling 3 with screw 12, which produces stable and efficient braking of the machine. All wheels 7-11, 18, 19, 22 are made from steels that have been subjected to heat treatment with further grinding, as well as alloying. The elements are lubricated by a pump using irrigation.

Headstock

The unit is started by a gearbox with a belt drive and an acceptance pulley 7 with a seal 4. The selection of axial play in the bearings is carried out by a spring 4. The unit acquires 12 rotational speeds from the acceptance pulley with a clutch 5; another 12 - through wheels 5, 8, 16, 15 with a bulkhead of 1:4, and 12 - through wheels 5, 8, 11, 10, 13, 14, 16, 15 with a bulkhead of 1:16. Starting the bulkhead groups, clutch 12 or turning off the spindle to divide into passes when cutting threads is done using a handle by translations through a lever mechanism, which is controlled by cams.

Strong fixation of the handle axis, which prevents rotation, is ensured by a spring-loaded ball located on the rear wall of the machine frame body in a glass. The rotation of the spindle device occurs with the help of 2 roller bearings 18 and 21. The clearance in the bearings is selected by springs 20. The transmissions are carried out by wheels 1, 2, 22, 23, 24 and the above wheels. The spindle, which has a flanged end and is made according to GOST, facilitates quick change and stable fastening of the faceplate. The device allows you to cut:

- thread with increased pitch of 4 and 16 times;

- right and left threads;

- multi-start threads when working with bulkheads 1:4 and 1:16 with a number of starts of 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, and when working directly - with a number of starts of 2, 3, 4, 6, 12.

Electrical equipment of screw-cutting lathe 16B16KP

Electrical circuit diagram of a screw-cutting lathe 16B16kp

Electrical circuit of lathe 16B16kp

The layout of electrical equipment on the machine is shown in Fig. 16.

The electric drive of the machine consists of four three-phase asynchronous electric motors M1, M2, MZ and M4.

The gearbox of the main drive of machines 16B16, 16B16P, 16L20, 16L20P and 16G16 has two electromagnetic clutches that start and brake the machine spindle.

The gearbox of machines 16B16K, 16B16KP, 1620K, 16G16K, 16L20KP has seven electromagnetic clutches, which are used to switch speeds, start and brake the machine spindle.

To control turning on and stopping the machine spindle, there are two handles: the right switch S 8 and the left switch S 9.

The machine spindle is reversed by reversing the M1 electric motor of the main drive.

The machine is equipped with an electrical cabinet.

The following voltages can be used at the rate: power circuit - three-phase, 50 or 60 Hz, 220, 380, 400, 415 or 440 V; AC control circuit - 110 V, DC - 24 V; local lighting circuit - 24 V; signaling circuit - 29 V.

Tailstock

It is connected to the frame with a handle. Its position is controlled by a mandrel located along the marks or in the centers. The gap between the rear quill and the rotating axis of the spindle must be more than 0.1 millimeters. The flat end of screw 4 slides in the groove of disk 3. To unscrew screw 4 to dismantle disk 3, you need to align the counterbore with it. Control of the correct position of the body is carried out by the areas suppressed during assembly and exactly by the mandrel, which is clamped in the central parts of the machine. Pin 8 is clamped by handle 7.

Important! The maximum travel of the quill is 120 millimeters. Screw 9 moves from flywheel 2.

Machine bed

Mounted on 1 cabinet. This unit is represented by a cast iron box with transverse ribs in the shape of the letter “P” - equipped with 2 flat and 2 prism-shaped guides, which have undergone heat treatment and grinding. In the niche of the right end of the unit there is an electric motor for the rapid movements of the sled. A gearbox is mounted on the rear wall at the left end of the unit, at the right end there is a lubrication station, as well as a coolant tank and a cooling device pump; The main drive electric motor is located inside.

Kinematic diagram of a lathe model 16B16KP

Kinematic diagram of a lathe model 16B16kp

- A - AKS - automatic gearbox AKP 109-6.3 for machines 16B16K, 16B16KP, 16E16KP

- a - spindle head

- b - tool holder

- in — caliper

- g - tailstock

- d - apron

- e - carriage

- g - gearbox for machines 16B16, 16B16P, 16G16

* for spindle speed 16..1600 rpm

** for spindle speed 25..2500 rpm

Apron

The apron has 4 pairs of couplings, making it possible to produce direct and reverse movement of the caliper and slide. The movement of the slide and the lower part of the caliper is controlled by a handle, the direction of launch of which corresponds to the direction of their movement. Starting rapid movements of the caliper in 4 directions allows you to additionally press the IB button, which is located in the handle. At the same time, the electric high-speed motor is started, which sends movement to the drive shaft through a belt drive.

Lubrication of the assembly parts is done by a piston pump embedded in the cover. The unit is equipped with a blocker that prevents the joint start of the feed of the uterine nut and the caliper. It also contains a special protective device that protects against overload and is designed for the highest switching force (6000 ± 500)H. When working on the stops, the value can be lowered to the desired level by using nut 6, as well as by loosening spring 7.

Location of controls for screw-cutting lathe 16B16KP

Location of controls for lathe 16B16kp

List of controls for screw-cutting lathe 16B16KP

- Plate with explanatory graphic symbols

- Handles for setting the feed rate and thread pitch

- Handles for setting the feed rate and thread pitch

- Emergency button

- Main drive motor activation button

- Normal or increased pitch activation handle

- Handle for changing cutting direction

- Plate with explanatory graphic symbols

- Switching handle

- Load indicator

- Signal lamp

- Handle for connecting the electrical equipment of the machine to the network

- Cooling pump activation handle

- Main drive motor speed shift handle

- Automatic transmission control handle

- Caliper cross feed handle

- Handle for turning and fastening the cutting head

- Screw securing the carriage to the frame

- Upper caliper feed handle

- Button for turning on the electric motor for rapid movements of the carriage and support

- Tailstock quill fastening handle

- Tailstock cross offset screw

- Handle for attaching the tailstock to the frame

- Tailstock quill movement flywheel

- Overdrive motor belt tension screw

- Handle for controlling the strokes of the carriage and caliper

- Lead screw nut engagement handle

- Nut for adjusting the apron release force against the stop

- Clutch activation handle for apron overload mechanism

- Plate with explanatory graphic symbols

- Handles for starting the machine and reversing the spindle

- Rack and pinion button

- Handwheel for manual carriage movement

- Plate with explanatory graphic symbols

- Handles for starting the machine and reversing the spindle

- Handles for setting the feed rate and thread pitch

- Gearbox control knob

- Headstock drive belt tension screw

- Main drive motor belt tension screw

Safety precautions

- Carry out work exclusively on screw-cutting machines for which you have access, and perform only the required work.

- Focus on work without being interrupted by unnecessary things and conversations; do not disturb other workers.

- Do not lean on a functioning lathe or allow others to do so.

- Do not give permission to your place to persons not related to the specific work. Do not trust the machine to another worker without the foreman’s approval.

- If you see another operator failing to comply with the rules, give him a warning about the obligation to comply with the provisions of the instructions.

- During repair work on the machine and starting mechanisms, it is necessary to hang a poster on it: “Do not start - repair.”

- It is prohibited to work on a lathe that is faulty and does not have the required guards, as well as to repair or remodel the machine yourself.

- Immediately inform the technician about any incident and go to the first aid station.

- To avoid accidents, contamination and chips getting into the devices of the screw-cutting machine, it is prohibited to blow air from a hose onto the surface being turned and the machine.

- It is forbidden to work on a lathe while wearing mittens and gloves, as well as with bandaged fingers without rubber fingertips.

- The dimensions and weight of the product being turned must meet the requirements of the lathe machine's technical passport.

- Firmly and rigidly fasten the workpiece being turned.

- If there is any interruption in the electrical power supply, immediately turn off the equipment.

- If there is voltage (feeling of current) on the metal parts of the screw-cutting machine, the electric motor operates in 2 phases (there is a hum), the ground wire is broken, stop the operation of the machine and immediately inform the foreman about the malfunction of the electrical equipment.

- Use a wooden grate and take proper care of it.

Preparatory work before overhaul of machine 16B16KP

Repair of a 16B16KP lathe begins with diagnosing its operation at idle and at all stages of spindle speed, as well as a thorough inspection of the components. To obtain more complete information about the degree of wear of the machine, in particular, about the condition of the spindle bearings, a control sample is processed. Based on the measurement results, deviations of the obtained values of the accuracy of the work performed from the machine’s passport data are determined.

Measuring the radial and axial runout of the spindle, as well as identifying extraneous noise and excessive vibrations, allows experienced engineers to accurately identify worn components and possible defects, which are sometimes difficult to detect after disassembling the machine. The information received is taken into account when compiling a list of defects and assessing the volume of planned repair and restoration work.