- Types of fences

- Making a concrete fence

- Manufacturing of forged fences

- Making a metal fence

- Installing a fence on a grave

Unfortunately, for every person there comes a sad moment in his life when he is forced to say goodbye to loved ones forever. The memory of them remains in his heart, it needs to be perpetuated. To do this, they install monuments, memorial plaques, and plant flower beds in cemeteries. Fences are an integral part of the burial site. The Orthodox faith allows graves to be fenced; in addition, fences give burials a well-groomed appearance, mark the boundaries of the site, and protect from animals.

Sooner or later the question of choosing a fence, material for it, and design arises. The market offers a variety of options, mostly ready-made designs, or based on customer sketches, which are paid for and installed in a short time.

However, there is another option - to make a fence with your own hands, which will undoubtedly be cheaper and will give freedom for creativity even at this tragic moment. In addition, it is important that a person puts his soul into the selection and manufacturing process, wanting to perpetuate the memory of the deceased.

Why do you need a fence for a grave?

Previously, it was not customary to delimit space in a cemetery. Today, fences perform several functions simultaneously:

- prevent the possibility of stray animals entering the site, and also block the passage of antisocial individuals who may appear in the cemetery after sunset;

- declaration of rights to the site: after 20 years, the cemetery administration reuses lands that are not maintained, so the presence of a fence will act as a conditional guarantee that the grave is being looked after.

Often the fence is put up on the day of the funeral - along with a wooden cross, citing the fact that the supports will be located on virgin soil, and not next to the grave. Believers recommend waiting forty days until the soul rests. Experts insist that installation must be done after 1 year, together with the monument, when the soil has compacted.

Metal fence

What size can a grave fence be?

The dimensions of the fence are determined by the parameters of the grave mound and the permissible deviations from it. But some plots in the cemetery are larger than others, accommodating just one grave, while others are 2 meters wide and 3 meters long. This is exactly the size of a standard fence.

Most likely, a large area is legally allocated for another burial expected in the future (the daughter wants to bury her father next to her mother, the children plan to be buried next to their parents).

You cannot decide on your own what size the fence will be. Even if there is a lot of space around the grave, you should notify the cemetery administration and obtain permission to carry out installation work.

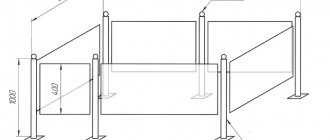

Fence drawing example

Types of fences: description, pros and cons

Having decided to make a fence with your own hands, consider the following options:

- metal (welded, forged): the simplest design, made by welding, it is also quite durable, but inferior in external characteristics to forged analogues, the latter variety often consists of artistic elements that decorate the fence, and the metal lasts a long time, but for this it is necessary to provide care for it (remove rust, paint);

- concrete: they are distinguished by their simplicity of appearance, as well as simple manufacturing and installation technology, but you will need to make a foundation, the color of the structures is always the same, in addition, the material is porous, hygroscopic to some extent, and therefore it is necessary to use impregnation to increase service life;

- wooden: they are distinguished by their low weight, low price, attractiveness and ease of processing; such structures last a long time, but subject to constant care (they must be treated with impregnation with various properties: they use water repellents, antifungal agents, etc.), but sooner or later they will still have to be replaced wood to a more reliable analogue;

- stone (granite, marble): an expensive option, especially if natural stone is used, and the weight of the fence is significant, which means it is necessary to carefully prepare the base - make it from concrete, the main advantage is attractiveness, in addition, stone products last a very long time and do not require special care;

- plastic: the main advantage is the low price, the fence is sold ready-made - prefabricated sections are installed, but it is characterized by low strength, low weight, is easily exposed to wind loads, and can break upon impact, which is why its service life is usually short.

Polycarbonate is not used on graves because it is not strong enough.

Granite plinth as the base of a fence

Fence made of profile pipe: features and advantages

Even at the selection stage, the advantages and disadvantages of all varieties are studied. Products made from corrugated pipes deserve special attention; they are most often used for fencing graves due to the following advantages:

- durability even with constant contact with moisture;

- there is not always a need to build a foundation;

- affordable price;

- easy installation.

A fence for graves from a profile pipe is made using sections that are welded in a workshop. Final assembly is carried out on site. Such designs often contain forged elements. They can be welded to the frame, resulting in an ornament or design/pattern of varying complexity.

Grave fence made of profile pipe

Types of fencing made from profile pipes

Main differences:

- type of supports: round, square, rectangular section, the latter option is most often used, such pillars are easier to weld with your own hands;

- types of sections: primitive - from rectilinear elements (diamonds, rectangles, lines), complex - from figured parts (patterns, curved rods, etc.);

- with forged parts: in this case, the corrugated pipe is used only as supports, the remaining parts of the structure are made from round or square rods.

Forged fencing comes in different designs:

- stamped;

- with artistic inserts.

The difference lies in the different levels of attractiveness and price. Sizes are usually different. The dimensions of the pipes are determined taking into account the weight of the entire structure - the larger the value of this parameter, the more powerful the supports should be.

Forged fence on the grave

Installation steps

Metal structures are made from aluminum, copper, and steel. Models of the first type are more accessible. But they are most often prefabricated. Copper products are rarely used due to their high price, but individual decorative elements made from this material are often used. The most common are steel structures. They are welded or manufactured using standard fasteners. If you have no experience in this area, it is better to order the manufacture and installation of the fence from specialists. Main stages:

- Call a technician and take measurements. On his first visit to the cemetery, the specialist examines the area. By this time, relatives should already discuss the issue of installing a fence with the administration of the cemetery. Then the preferred dimensions of the future structure are determined. Such a decision is not made arbitrarily.

- Selection of material and calculation of estimates. The type of material is discussed with the customer, and suitable pipe parameters are determined. The dimensions are always different, but the thickness of the metal profile in the production of such products is often the same - 1.5 mm. Based on the drawing, the amount of material is determined, all items are included in the estimate, and the costs for it are calculated.

- Manufacturing in the workshop. The main work is carried out remotely - specialists work on site. Only assembly is carried out at the cemetery, since it is difficult to connect to a power source. If necessary, the contractor takes equipment with him.

- Installation on the foundation. The choice of base is made taking into account the weight and dimensions of the structure. Depending on this, the appropriate type is determined: strip, columnar foundation or another type.

- Treatment with primer and paint. Metal, especially in places where it has been cut or welded, is exposed to water, and corrosion develops. Soon the structure loses strength as the properties of the base material change. To avoid such consequences, the product is coated with special compounds - a primer and then paint.

Metal fence section with forged elements

How to make drawings for a fence and its sketch

Projects for fences for graves are made in the form of separate sections and fences as a whole. In the drawing of the product for the cemetery, do not forget to plan the gate, wicket. The accuracy of the work performed will be required:

- When installing the structure, sections cannot be shortened;

- purchase a ready-made fence for a cemetery after carefully lengthening the fence;

- the calculation is the basis for the symmetrical arrangement of sections, which consist of profiles and reinforcement with a certain thickness;

- take into account the profile fastening scheme. The strength and reliability of the entire structure depends on the parameter;

- the correct scheme is the key to high-quality installation of a brick support. The products have certain parameters, which creates the need for accurate calculation of the masonry.

The slope of the cemetery requires special attention; the drawing of the fence in this case is an important stage in construction. Taking into account the height of the hill, adjustments are made to the design features.

A well-designed scheme for constructing a metal fence helps save time and money.

A simple material for making fences in a cemetery is corrugated sheeting. Making a fence for a grave with your own hands is not difficult. The finished product has the following properties:

- High strength. The fence will last in the cemetery for a long time, regardless of high wind loads. The larger the corrugation, the larger the load it will withstand.

- Ease of installation. The design implies the absence of a foundation or brick pillars.

- Sketches are simple sketches on paper. For clarity, supports, fasteners, and quantity material are displayed.

A stone fence in a cemetery stands out for its reliability and durability. To build a small fence you will need to study every detail. The diagram takes into account the levels of all sides of the site. The construction process has the following steps:

- precise marking of the territory + determination of the parameters of the future fence;

- pouring a small foundation. The drawing will save time and money;

- erection of formwork, pillars, plinth;

- production of caps, pillars + stone laying.

Making a grave fence with your own hands is not difficult. Having high-quality drawings, you can start working.

You will need to own a welding machine and a grinder.

Dimensions for making structures in a cemetery:

- Supporting post made of square pipe 25*25, 30*30 and 40*40 mm. It is easier to make from such material.

- Frame section made of high-quality rolled pipes 20*20 / 25*25 mm.

- Gate (chains with slack).

- Patterned element.

To produce a pole in a cemetery, the pipe is carefully cut into 1-meter pieces. The ends are welded with a 100*100 mm metal plate, the posts are dug in to a depth of 0.4 m, and the joints are filled with concrete.

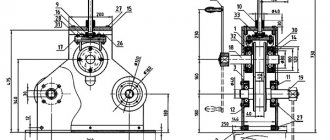

Do-it-yourself fence made of corrugated pipe for a grave. Drawing with dimensions, diagram, plan

If you have experience and knowledge, you can take on making a fence with your own hands. To make a beautiful fence, you need to proceed in stages.

Drawing of a fence made of corrugated pipe

Fence sizes

If it is not yet clear how to make a fence in a cemetery with your own hands, first a sketch is drawn up - this is a simple sketch that determines the configuration of the fence, the pattern and the main parameters. It is best done at the grave in order to take into account all the nuances of the location (the presence of bushes, trees, benches, tombstones, etc.). Based on the sketch, a drawing of the fence is drawn up. In this case, the exact dimensions of the profile and fence are indicated. Thus, the average height of structures is no more than 1 m. The perimeter fence is usually standard - 2 by 3 m.

Fence made of profile pipe, drawing

Profiled pipe parameters

There are different product options, they differ in cross-section:

- side length no more than 2 cm - for small decorative inserts that are used to fill sections;

- with a side length of 2.5 to 3.2 cm - common options; supports and longitudinal elements are made from such pipes to increase rigidity.

Medium-section pipes are more often used for the manufacture of sections; they are immediately cut into lengths of 2 m. The larger ones serve as supports. For this purpose, blanks up to 1 m long are suitable; they will be installed in the ground or become part of the foundation (columnar, strip-column).

Stainless steel profile pipe

When drawing up a sketch of a fence in a cemetery from a profile pipe, they immediately determine what the inserts that fill the section will be like. Then the dimensions of all parts are transferred to the drawing and the distance between them is indicated. This will allow you to weld the structure without errors and with high quality.

Manufacturing a fence according to specified parameters

The main nuances that you should know about at the installation stage:

- It is recommended to fasten parts by welding rather than bolting, since the first option provides higher reliability and protection from vandals;

- first, sections are made, they are installed and fastened together in the cemetery;

- determine the area where the gate will be located, here the hinges are attached to the fence;

- the height can be different within the given dimensions (0.5-1 m length of the stand), if the pillars are not deeply buried in the ground, there will be a gap between the lower belt of the metal section and the soil, its size can be adjusted by changing the installation depth of the pillars;

- determine the types of decorative elements at the stage of installing the fence: you can buy a chain, fittings of any shape (curved, arched, etc.);

- the base of the pipe differs from the top part - a plate measuring 100 by 100 mm is welded here.

The plate at the base of the support will provide increased fixation strength. When the post is buried, the lower part will be supported by a significant layer of soil.

When using a cement mixture and stone chips (concrete filler), the strength increases further.

Fence installation

The choice of method is made taking into account the weight of the product, but the characteristics of the soil are also taken into account. The denser the soil in the cemetery plot, the lower the costs. But sometimes even in this case, a concrete base is still prepared, since this is a good way to protect against vandals.

Concrete plinth for the grave

In the basement

This method is suitable for bulky products of significant height, made from powerful pipes. In addition, fencing is sometimes made for family burials. Then the weight of the fence will increase even more. In this case, prepare a shallow strip foundation up to half a meter deep. The choice is influenced by the properties of the soil - the depth of soil freezing is taken into account.

To increase the strength of the foundation, a frame made of reinforcement is used.

In dug holes without additional reinforcement

The strength level of structures of this type is the lowest. The installation of pillars is carried out in pits, but concrete is not poured. But it is permissible to fill holes in the soil with broken stones and bricks. This option is more suitable for installing wooden fences. The disadvantage is the high risk of damage, since during cold periods the supports are often pushed out by the ground.

Fence for a grave in dug holes without reinforcement

In pits with concreting

To install a fence with your own hands, you should follow the instructions:

- Wells of the required depth are prepared. Their diameter should be larger than the pillars.

- Install supports pre-treated with liquid bitumen. This will help slow down the rate of corrosion.

- Spacers are installed - wooden stakes, they are used to prevent the supports from falling.

- Fill the holes with broken bricks or stone chips. Such additives increase the hardness and strength of the cement mixture.

- Fill holes in the ground with prepared concrete.

This option is considered the most suitable. It provides high strength. In this case, you can install individual pillars and then fix the finished inserts on them. The result will be a collapsible fence.

But in this case, the reliability of fastening the inserts will be lower than the rest of the structure, so it is better to weld them to the pillars.

Fence with concreting

Beginning of work. Manufacturing and installation

Pillars and foundation

First make fence posts. Mark the pipe 80*80 and 100*100 using a tape measure and a square in accordance with the project. Cutting to size using a grinder must be done very carefully, without trying to cut immediately to the entire height of the cutting disc. Cut in a circle, being careful not to drive the disc too deep. The slightest misalignment will cause the disc to rupture. Serious injury may result. Weld the upper end of the workpiece with a plug and paint it with a primer for metal.

Take a drill and drill holes for installation with a diameter twice the size of the pipe, strictly according to the markings made earlier for the pillars. Make the depth 10-20 cm more than you plan to bury the pillars. Cover the resulting “extra” 20 cm with sand or crushed stone. You need to install the corner ones first. The pillars must stand strictly vertically along the front and boundary lines. This is where two magnetic levels come in handy. You can fix the vertical position using stretch marks. Then you can fill it with concrete.

Tip: before pouring concrete, place roofing felt in the drilled hole around the entire circumference. You will get a sleeve like this. This will preserve the cement laitance and increase the strength of the concrete. Particularly important for areas with high groundwater levels.

When the concrete at the base of the pillars “sets”, pull the string from corner to corner. Install the remaining supports along the cord.

Advice: it is better to connect the supports on which the gates will be hung together with a foundation with a three-dimensional reinforcement frame. This will prevent the pillars from moving when the ground freezes deeply and the gate will always close freely. The size of the concrete foundation must be at least 200 mm wide, 400 mm deep. Reinforcement frame 150*350.

Frame welding

While the concrete gains strength and dries, we make a table for work. Its size should be equal to the size of the links and gate leaves. It should be positioned so that you can walk around the table.

On the table you mark and cut the pipe. Lay out the resulting blanks by size near the table. We place all the necessary equipment, tools, and a welding machine at the table so as not to waste time looking for something necessary. Start making the frame. Lay the logs on the table so that the horizontal width is greater than the height. If the log is 60*40, then the height is 40 mm.

Then you align the outermost vertical elements using a square and weld them to the joists. Then you begin to fill out the resulting frame, as it is drawn in the project. Secure all elements with tacks for now. When you finish the preliminary assembly and you like the result, boil all the potholders. Clean all welds. Make each link according to the dimensions of the installation site. Because the distance between the pillars cannot be adjusted with great accuracy.

Make the gate and wicket in the same way. The installation of wicket and gate locks and welding of hinges will have to be done not on the table, but in place.

It will not be easy to install fence links and gates with a wicket alone. We need one more person's help.

After installing the fence, it needs to be primed and painted. There are a lot of options for this, and you probably included one in the project.

Installation of decorative grilles on brick pillars

The same links can be mounted in a fence combined from brick and metal. The posts of such fences are made of brick, and if during construction no embedded elements for welding were provided, decorative grilles can be installed in the following way. Using a hammer drill, holes are made in the pillars at the installation sites. An anchor made of reinforcement is hammered into them and a decorative lattice is welded to this anchor.

Table: making a forged fence in your city

The price of a fence made from a profile pipe differs, which is determined not only by the properties and dimensions of the structure, but also by the area where it is made and sold.

| City | Price, rub./linear m |

| Moscow | 3000 |

| EKB | 5500 |

| St. Petersburg | 2300 |

| Krasnodar | 3000 |

| Novosibirsk | 2500 |

The average cost of the finished product is several tens of thousands of rubles.

Front garden near the fence

Fencing for the front garden and flower beds can be made of the same materials: concrete, wood, metal. But the height is often less than that of a fence for a grave made of corrugated pipe. These fences are made by hand. For this, improvised materials are often used: brick, wood, plastic - this way you can delimit the space. It is not practical to use reinforced structures, since the front garden in the cemetery area is located inside the perimeter of the fence.

You should not prepare a reliable foundation for the front garden, since this is a lightweight structure. It is enough to install the sections as deep as possible so that they are not carried away in bad weather.

Installation

The fence installation process comes down to the following steps:

- Assembly (purchase) of modular sections.

- Arrangement of the foundation and installation of load-bearing pillars.

- Installation of block sections in spans.

- Painting of metal segments.

Frame welding

To assemble the frame yourself:

- Cut the required blanks according to the calculations and trim them.

- Using the grinding method, remove unevenness or other defects from the surface of the workpieces formed during the production and cutting of the profile.

- First, weld the section frame around the perimeter, and then the internal filling (vertical and horizontal joists), carefully measuring the joints and corners.

- Weld decorative elements (some decorative parts can be welded or screwed after the block section is installed in place).

- The seams formed during welding should be leveled and cleaned of plaque and scale.

“Question-answer” section

How do Muslims arrange their graves?

Expert opinion

Klochkov Andrey

Employee of the improvement department of the municipal unitary enterprise "Clean City"

The main requirement for the design of Muslim plots is modesty. Excesses are not welcome when creating a tombstone; the shape and appearance - everything should be simple. Often a simple rectangular slab is installed. Initially, it was forbidden to even go to cemeteries, until the Prophet Mohammed himself lifted the ban. But later the rules were somewhat abolished. Gradually, strict restrictions regarding the arrangement of graves were relaxed. If previously it was customary to leave the simplest identification marks, over time new traditions were formed. This is due to the fact that Islam became more popular; other peoples who previously adhered to pagan beliefs also accepted this religion. As a result, a mixture of cultures occurred, and some customs became part of Islam.

Are there ready-made fences for sale? Collapsible?

Expert opinion

Klochkov Andrey

Employee of the improvement department of the municipal unitary enterprise "Clean City"

We offer ready-made parts of the structure, as well as small inserts for creating a fence on your own. If you have never had to do such work before, purchase a collapsible version. Individual sections are connected by welding or special fasteners, which depends on the type of material. Moreover, the first method mentioned has many advantages. If possible, you should choose this one. The only drawback is the lack of skills in working with a welding machine.

Expert commentary

Sergey Sivokonev

Head of the improvement department at the Northern Cemetery, Rostov-on-Don

When manufacturing metal structures, you need to remember the properties of iron. Large-sized products (and 2- and 3-meter ones are just such ones) can lead to trouble. To prevent the metal from warping, you must first weld the elements that will be located on the inside of the pipe (when viewed relative to the entire structure). Before painting, the product must be degreased. Another nuance is cleaning the welds. This will make it possible to better prepare such areas for finishing work. A wire brush is used for cleaning, but it must be used carefully to avoid deep scratches. Such defects can negatively affect the decorative qualities of the entire product.

Tools and equipment

When building metal fences, you will need the following tools:

- 3 meter tape measure, with magnet;

- Measuring tape (fabric or metal tape measure) 30 - 50 meters;

- Square

- Construction lace (rope);

- Sledgehammer 3-5 kg.

- Hammer.

- Welding machine, gaiter mask, 3 mm electrodes;

- Pendulum cutting machine or miter saw, or angle grinder (grinder), cutting and cleaning discs;

- A device, like a miter box, for cutting pipes at an angle if you plan to work with a grinder

- Building level. Preferably for metal work, with a magnet on the sole; if possible, level 2 is better.

- A hand drill with an auger with a diameter twice as large as the cross-sectional size of the post.

- For marking, chalk or marker.