A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt. The main thing is not to panic, but to carefully read this information material to the end.

How to properly drill out a broken bolt: video, photo

During repairs, sometimes something bad happens - something breaks. Sometimes a broken part leads to trouble with a larger device. For example, a broken bolt in the cylinder block. A broken bolt can cause a lot of trouble. Especially when it breaks down in a place where access is limited.

Simple option

The first thing to do is not to panic. At all. A broken bolt can almost always be removed, the main thing is to do it correctly.

Removing a Broken Bolt

If it is broken at the part level, try unscrewing it with your finger. In fact, when a broken bolt is inside the hole along the thread, it is clean, and the screw simply broke due to metal fatigue or because it was pulled earlier - it can simply go from a finger

Or we pay attention to the chip - when a piece breaks off, a side always forms on the fracture plane - we substitute a chisel, a screwdriver - we try to unscrew it with light blows

Such cases often occur when a non-threaded part is attached with a pin or bolt - for example, a manifold to a cylinder block.

Complex option

If you can't unscrew it using these methods, we'll drill it. The main thing is that the broken bolt is not hardened. There are several methods to try before attempting to drill out a broken bolt. The most basic thing is to take a drill with reverse and a drill bit. Sometimes this trick can be done with a regular metal screw with a drill at the end. We press on the broken part, try to unscrew it with small turns, accuracy is needed here - you need to twist it “tightly”. If these methods fail, we move on to serious action. When the diameter of the pin is small, you need to determine how to remove the fragment - there is not enough space for two options.

Method one. Using a small diameter drill, we make two holes in the fragment. Against each other. We drill shallowly - about 5 - 10 mm, preferably away from the center. Then we take a lock ring remover, narrow-nose pliers, or simply insert two nails, clamp them with pliers and try to unscrew them.

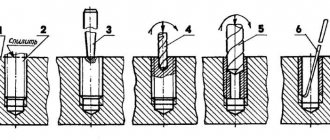

Bolt Removal Technology

Method two. You need a special tool - an extractor. It is sold in tool stores. It is something like a cone drill, has a reverse thread, very hard hardened metal. First, we select a drill according to its diameter. Carefully mark the center of the stud with a core; we need it to drill the hole. It is not necessary to go deep - just drill a little deeper than the length of the extractor. Then we wrap the extractor and try to unscrew the broken piece.

https://youtube.com/watch?v=t3WmL6wh4iA

When none of the methods help, the most difficult option remains - drilling. To do this you need several sharp drills of different diameters and a strong hand. The most important thing is to catch the center of the fragment. We mark the center as accurately as possible with a core; the accuracy of drilling depends on this. Then, using the smallest drill, we drill through the broken one.

Tool for removing broken bolts Drilling a broken bolt Technology for removing a broken bolt

It is important to drill exactly along the rest, parallel to the wall, so that the alignment of the holes on both sides is maintained. Then we take the next diameter of the drill and so on until we reach the wall of the hole. If you slightly miss the center of the hole, it happens

The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out

If you slightly miss the center of the hole, it happens. The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out.

If you find an error, please select a piece of text and press Ctrl+Enter.

Combined

It combines a drill and the extractor itself. However, for its application it definitely requires a reversible drill with a variable speed (from 350 to 800 rpm).

This model consists of two parts: a bushing and a drill screwed into it. Drill - left rotation. On its middle part there is a thread cut into which the bushing is screwed. The bushing has a tapered left-hand thread, like the tapered model previously described. In its upper part there is a hexagonal profile for using an open-end wrench or a spanner wrench.

How to drill out a broken bolt using a combination model? Drilling out broken bolts and removing studs using this model involves four steps.

- Drilling. Left rotation of the drill is used. Before drilling begins, the threaded sleeve is “driven” back, where it rotates freely together with the drill;

- By rotating the drill in the forward (right) direction, the sleeve is “driven” down along the drill. In this case, the sleeve is held by the hexagonal profile;

- Using a hexagonal profile, the bushing is initially screwed into the hole in the broken pin;

- The drill switches to left rotation, and the sleeve is screwed into the hole until it jams. Continuing rotation causes the pin to turn out.

Effective ways to unscrew a broken bolt

There are several ways to unscrew a broken bolt, but before you begin, you should do some preparatory work. Such work means:

Cleaning the work area from dirt, oil, etc.

Treat the threaded connection with WD-40 or at least machine oil. Alternatively, you can hit the fragment a couple of times with a hammer or heat the bolt with a soldering iron or lamp, provided that this is possible and other important parts (rubber, plastic, fabric, etc.) will not be damaged by the heating.

How to unscrew a bolt if it breaks above the threaded surface

1. If you have already managed to “break” the threads of the bolt even a little, that is, if it has already begun to unscrew, you can try to unscrew the broken bolt using pliers or a good adjustable wrench.

2. The second option will require you to use a hacksaw or a grinder (depending on the size of the bolt); sometimes a chisel also helps, the main thing is not to overdo it. The principle is as follows: make a transverse hole for a screwdriver and try to unscrew the bolt with a screwdriver.

3. Option three - welding. As you understand, this method requires a welding machine, everything is done as follows - take a bolt with a head of approximately the same diameter and weld it to the fragment, then using a wrench, carefully without using excessive force, try to unscrew the broken bolt. Rumor has it that there are so-called “aggressive adhesives” that can supposedly perform the role of welding. However, this method has not been personally tested, so we will not claim its effectiveness.

How to unscrew a broken bolt if it breaks off flush with or below the surface

- In this situation, you will have to act more radically; you will need a drill with a thin drill and good skills in using this tool. You need to drill 2-3 or more thin holes in the body of the bolt in order to then combine them into one. You will need to install a screwdriver in this hole and unscrew the broken bolts.

- The second method is more complicated. If you cannot unscrew the broken bolt using any of the above methods, you will have to use more drastic measures. You will need a drill, a tap, a lot of skill and patience. Your task is to drill a hole in the center of the bolt, then carefully cut a left-hand thread in it (either yourself or ask someone who knows how to use a tap). When you screw a new bolt with a left-hand thread into a freshly made thread, then having reached the end, that is, having screwed it in completely, the old broken bolt should begin to unscrew.

- The third way to remove a piece of a bolt that has broken flush with the surface is by drilling. This method is the most difficult and most dangerous, since when doing this work you risk damaging the thread.

The principle is as follows - you need to drill a hole exactly in the center using a thin drill, after which a thicker drill is installed, and the procedure is repeated. The most important thing is to drill the first hole exactly along the broken bolt there will be practically no left, and the walls will become thin enough to break them, try to very carefully break the remnants of the thread using thin sharpened wire or tweezers. If you do everything correctly, you won't have to cut a new thread or "drive" the old one

If you have an “extractor” with a left-hand thread, you can use it to unscrew the remaining debris, see more details in the view at the end of the article.

And lastly, if after several attempts you notice that something is not working out for you, there is no need to act rashly, as you will only complicate everything, it is better to entrust this work to someone who has already encountered this problem many times. We wish you good luck in your hard work, we hope the article was useful to you and helped resolve your issue. See you again on the website of automotive advice - Question Auto.

What to do in the event of an emergency: a few tips

Of course, it is very unpleasant when a bolt breaks off during operation. This significantly slows down repairs. But in this case there is no need to be nervous. It is best to sit down and calm down a little, and then solve the problem with hardware with a cool head. You won’t be able to change anything anyway, but it’s easy to ruin a part by trying to rashly remove a broken piece. And yet, if the part itself was damaged during drilling, it’s never too late to fix it.

Most often, the thread in a part becomes unusable due to uneven drilling. In this case, you will have to remove the fragment completely, simultaneously leveling the thread in the channel. After this, you can proceed in two ways.

- Cut a larger diameter thread and select a bolt for it. This is easy to do, but not always possible. After all, the walls of the part may be too thin, which will not allow threading.

- Another option is sleeving. The most problematic method of resolving the issue. It is necessary to select the sleeve according to size, and then press it into the hole. If there is no experience in performing such work and the necessary equipment, it is better to completely forget that such a repair method exists.

How to unscrew a broken aluminum bolt

The time has come to change the levers, but bad luck I couldn’t unscrew the bolts. The bolts securing the silent block holder to the subframe were welded to death with the subframe itself. This phenomenon is known and predictable. Iron alloys and aluminum alloys become welded over time, especially in a humid environment.

Normal manufacturers understand this and use thread sealant, which, in addition to its ability to fix fasteners, also insulates, thereby preventing welding of parts. But the previous owner had already changed the levers and tightened the bolts dry. As a result, two of the four bolts were unscrewed, the remaining two broke off.

I started with simple but unsuccessful attempts. VD-ashka, heating, welding of iron. Everything is in vain, boiled to death.

The VD-ashka did not help simply because there was no gap left in the thread where it could leak. Welding the piece of iron to unscrew it also did not lead to success. A piece broke off, not due to welding, but the bolt itself, just like the first time.

All that remains is to remove the debris. You can drill it, but you need to understand that we have a hardened bolt in soft aluminum, and the length of the fragment is more than four diameters. There is a risk that the drill will go to the side, and drilling a hardened bolt is not much fun. Then it’s not a fact that all the carvings will be saved. Although, if you make a jig and have straight hands, you can drill it, I’ve done this more than once, but now I decided to use a different method, corresponding to my nickname, chemical.

First of all, we clean the surface from dirt and degrease.

Let's take nitric acid. I came across a chemically pure one with a concentration of 64%. This concentration is not particularly poisonous, and even passivates the surface of the iron. But for etching, the optimal concentration is about 30%. So we use water for dilution.

They stuck a plasticine bucket over the object to be etched. We poured the solution and observed the process.

We have two bolts in total, one bucket is red, the other is black.

The next day I changed the solution and looked at how the process was going. Everything is in order, half of the bolt is gone, the thread is intact.

When a third of the bolt remained, I decided to try to unscrew it. I didn’t have any welding tools at hand, so I used a small nut-pick and grabbed the tip of the piece of wood.

And he twisted it!

As a result, the thread is intact, nerves are saved.

How to unscrew a hex or sprocket head bolt

In the automotive industry and other equipment, hex tool bolts are often used. How to turn out a torn cap that has broken edges:

- Make a horizontal notch on the head with a grinder or file. In this case, a strong screwdriver is used to unscrew the broken screw.

- Using a special TORX sprocket, which is driven into the head. The nozzle is selected in size, slightly larger than the torn cap, for a strong connection between the walls.

- A set of extractors that can be purchased at a hardware store. Before using the extractor, a hole is drilled with a drill in the base of the bolt, then the extractor is inserted, and the screw is removed with pliers or a special clamp.

- Using a left-handed drill with a slightly smaller hole diameter. Work with the tool is carried out in reverse mode, with this method it is possible to damage the thread.

Broken nuts are more difficult to unscrew, since during work there is a possibility of damage to the threads. The simplest way is to use chemicals; the surfaces are cleaned and treated with the product for 15 minutes. If the edges are torn off, it is impossible to use a wrench or socket. In such cases, a chisel is used to destroy the main part of the nut, then removed and replaced with a new nut.

How to properly drill out a broken bolt body in a hard-to-reach place

This is one of the most labor-intensive ways to remove a broken bolt from a thread, and it is worth using it in practice only when there are no other options. And not only because it takes time, it is important to maintain the accuracy of the work. The slightest mistake and the internal coils of the case will be damaged. In addition, to implement the method you will need a whole set of tools:

- Metal drill with a set of attachments.

- Screwdrivers with different blades.

- Triangular file

- Reliable pliers or, better yet, a wrench.

- Tap.

- Several needle files of various shapes and sizes.

WD-40 will also be useful: we remind you that it is worth pouring it into the work area 15 minutes before performing operations, it will dissolve some of the rust.

So, the bolt has broken off, how to unscrew the broken part from the thread using drilling:

- Put on the thinnest attachment, turn on the drill and make a recess exactly in the center of the hardware; try not to go aside, this is fraught with subsequent difficulties.

- Change drills, gradually increasing their cross-section, until the hole occupies 1/3 of the diameter of the body.

- Drive the file in, carefully but firmly, because if it does not hold well, you will not be able to remove the damaged element.

- Take pliers or a gas wrench, clamp the trihedron with them and begin to make circular movements, trying to pull out the fasteners.

It should work, but how to unscrew and remove the broken part, how to unscrew a broken bolt if it does not give in even after all these steps? It is necessary to widen the hole so that another hardware fits into it, but smaller and with the opposite thread (usually the left one). In this case, the second one will act as a cap after it is screwed into the first one.

If this doesn’t work, just continue to increase the diameter and length of the recess until the pressure on the remaining fastening element weakens, then they will begin to wobble and it will not be difficult to remove them using a suitable tap.

What to do if the bolt breaks off flush with the surface of the part

According to experts, such a breakdown is the most difficult. The problem is that it is not always possible to determine the circumference of a broken piece of hardware. Therefore, before you start unscrewing the bolt, you need to clean the place where it is located. This is the only way to determine where the edge of the hardware is and not damage the thread of the part when unscrewing it.

When the boundaries are determined, you need to mark the center of the broken bolt and, using a special tool (punch), knock out the recess. This is necessary in order to start drilling. Otherwise, the drill will “float” and it will not be possible to drill exactly in the center. The same actions are performed if the bolt breaks off deeper than the upper level of the part.

In theory, the drill should go along the bolt exactly in the center of the PHOTO. yandex.ua

Next, you need to drill a hole exactly in the center, with a diameter smaller than that of the hardware. It should go as smoothly as possible along the axis of the bolt. When this work is completed, you can proceed directly to twisting. To do this, use a tap with a reverse thread, which is screwed into the drilled hole counterclockwise until it stops, after which rotation continues in the same direction. The remaining bolt should come out.

What to do if the cap comes off and the hardware protrudes above the surface

This problem is the easiest to solve. There are several options for this. To begin with, we again generously treat the bolt and its connection points with the part with diesel fuel or a special compound. Next, we try to pick up the bolt with wire cutters or a gas wrench (it has greater clamping force).

Of course, the situation is unpleasant, but not fatal, everything can be solved PHOTO: drive2.ru

Another good method will require a hacksaw or hand engraver. Using the tool, you need to make a notch across the circumference of the piece of hardware, and then try to unscrew it using a powerful slotted screwdriver.

A percussion instrument is well suited for such purposes. But in this case, you should not make a deep cut. If you hit the back of the screwdriver, the bolt may simply break.

If you cannot unscrew the hardware, you need to move on to more radical measures.

Many experts recommend a method using a welding machine. To perform it, you will need a piece of steel bar (you can use reinforcement, but the strip is more reliable). In it, in the middle, a hole is drilled, with a diameter slightly larger than the bolt.

The tire is placed on the part so that the hardware fits into the hole, after which the elements are welded together. This method allows you not only to weld the lever to the broken bolt, but also to heat up the hardware, as a result of which various dirt burns out, and the corrosive coating ceases to “hold” the thread so tightly.

After complete cooling, all that remains is to turn the welded lever counterclockwise and remove the broken hardware, replacing it with a new one.

What to do if the extractor, drill or hexagon is broken

You can etch them with nitric acid. One condition is that the body into which the broken part is screwed must be made of aluminum alloy. Nitric acid is one of the strongest acids. It dissolves metals well, but does not touch aluminum.

The chemical reaction will take several hours, approximately 10-24, it all depends on the properties of the steel, the diameter of the fragment and the ambient temperature. Nitric acid must be diluted with water before use. For example, 57% acid is diluted with water in a 1:1 ratio. That is, the acid must be diluted to 30-35%. During the chemical reaction, nitric acid will itself be reduced and at the same time destroy the metal.

Nitric acid is poisonous, so be careful when using it and try not to inhale its fumes.

Methods for unscrewing bolts, screws, screws with licked edges

If the usual method fails to unscrew the fasteners whose edges have licked off, you can use one of several proven options.

Gas key

This method is used when unscrewing bolts, since they have a protruding head that you can grab onto. For this:

- Clean the bolt head.

- Lubricate the joint with kerosene or diesel fuel, a liquid like WD-40 works well, and leave for 15–20 minutes.

- Unscrew the bolt. They do this with a gas wrench. With its help, a lot of force is created and it is possible to grip even a round head well.

The disadvantage of this method is that it is not always possible to get a gas wrench to the desired bolt.

Cutting new edges

If the bolt is large, then using a grinder you can cut new edges on it. It is enough to make only 4 of them and use a smaller key to unscrew the bolt. You can cut new edges on a bolt with a file, but this is more difficult and takes longer. You can make a cut on the head of a screw or screw using a hacksaw or grinder.

You can make a deeper cut on the head of a screw or screw for a screwdriver.

Hammer and chisel or impact screwdriver

This option is more suitable for licked nuts or fairly large screws. The chisel is pressed against the head of the fastening element and, hitting it with a hammer, the screw or nut is gradually turned. Small screws or screws can be removed using an impact driver and a hammer. After loosening the fastening, the work is done with a regular screwdriver.

An impact screwdriver can be used to unscrew small screws or screws with licked slots.

Band or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of thick rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is placed between the screwdriver and the head of the screw or screw.

Extractor

An extractor is a special tool that is used to unscrew screws, bolts or screws with licked or broken heads.

Extractor - a tool for unscrewing screws, bolts or screws with licked or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the licked screw slot.

- Select an extractor of the required diameter. Drive or screw it into the prepared hole. This depends on whether a regular or screw tool is used.

- Unscrew the bolt.

Video: unscrewing a licked screw using an extractor

Regular or left hand drill

Left-handed drills with counterclockwise rotation are available for sale. They improve tool centering and reduce the load on the drill, which gives higher productivity and drilling accuracy. By inserting such a tool into a drill, you can unscrew a screw or screw with a licked head. If you don’t have a left-handed drill, you can try to drill out the stuck fasteners using a regular one. In this case, you need to take a drill whose diameter is smaller than the diameter of the bolt or screw

You must act carefully so that you do not have to cut threads for new fasteners later.

The drill bit should have a diameter smaller than that of the problem bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called “cold welding”. After the glue secures it securely, use a wrench to turn the nut and unscrew the screw or screw together with it.

Using glue, fix the nut to the licked head, and then unscrew the screw together with it.

Welding

If you have a welding machine nearby, you can fix a new nut on the head of a bolt or screw by welding it. After this you can immediately unscrew it.

A new nut can be welded to a problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or cog, use a soldering iron and solder:

- Heated solder is dripped onto the head of the fastener with licked edges.

- While the tin has not hardened, insert a screwdriver into it and wait a few minutes.

- Unscrew the problematic screw and clean the solder tip of the screwdriver.

Flat head screwdriver and hammer

An accessible method, effective if the fracture occurs above the thread and the surface has an uneven edge. Then for extraction you will need a simple set of tools, which can be found in any garage.

We carefully examine the cleaned surface and find the largest protrusion on the fracture area. We place a flat-head screwdriver at an angle, pressing into the selected location. For more reliable support, you can use a core, with which the unevenness deepens. After this, using gentle blows, we carefully try to turn the thread. If you can’t do this right away, you need to gradually increase the strength.

However, you should be extremely careful with this method, since, firstly, the surface must be accessible enough for the hammer to work. And secondly, you need to carefully calculate the force of the impact in order to prevent damage to adjacent parts.

How to unscrew a broken bolt?

Basic methods:

- Clean the surface with a metal brush and treat it with diesel fuel or kerosene. They try to unscrew the nut with a spanner. Although there is no absolute guarantee that it will unscrew.

- Using a chisel and hammer, strike in the direction of unscrewing. This method is not suitable for a small nut.

- A gas wrench with a powerful clamp is a good tool in this situation. It is easy for them to grab even round objects, but it is harder in hard-to-reach places. The longer the handle, the easier it is to unscrew.

- When the fastening material is large and difficult to unscrew, you can use welding equipment to apply a metal coating and prepare the desired turnkey shape with a file.

- Use a drill to cut out a hole inside the body of the fastening element, thread an L-shaped rod through it, which will serve as a handle, and remove it.

When there is enough space to use an adjustable wrench or pliers, this is good, but what to do in other situations?

Read also: When cooling a steel part

How to unscrew a hex or sprocket head bolt

To remove the element, use a gas wrench to compress the part, make a cut on the head with a grinder and unscrew it with a screwdriver, an extractor of the appropriate size, or special tools (wrench, pin driver), which are beneficial to purchase only if you have to deal with such problems quite often.

Select the TORX sprocket according to size (it should not be large and the slots should fit into the hole for the hexagon). It is inserted tightly into the head and the bolt is jerkily unscrewed to avoid the sprocket spline from breaking off. When driving sprockets with holes in the center, they break off, so their use is not recommended.

Any hardware or auto store sells sets of extractors. Externally, this device looks like a metal rod with a conical thread on the left side and a faceted base on the right. They are used to unscrew nuts with torn edges. To do this, drill a hole strictly in the center of the bolt, drive an extractor of the required size into it and unscrew it with pliers. This is done simply and quickly, because the extractor has the opposite cutting.

A drill with reverse is an irreplaceable thing. Use a thin drill to make a hole near the bolt. Take a left-hand rotation drill with a smaller diameter and drill out the damaged bolt in inverse rotation mode.

Where to begin

Assess the degree of complexity of the problem: if the stripped screw is recessed into the structure of the material, complex methods are considered; To remove the fastener at the screwing stage, use pliers - they grab the head and unscrew it.

Before starting the product removal procedure, check that the screwdriver is selected correctly. To do this, check all types of tools. If the screwdriver is initially selected incorrectly, then you will not need to perform complex procedures for removing the fasteners. The problem will be solved by replacing the tool.

Precautionary measures

When choosing a way to unscrew a screw with torn edges, you must follow the recommendations:

- when using an auxiliary tool, you should control the intensity of the applied forces: sometimes, in order to remove the fastener faster, you have to press harder on it, but the situation will worsen in this case and, conversely, too careful actions with weak pressure will lead to even faster erasure of the edges of the slot;

- when the fastener is unscrewed too intensively or an auxiliary tool is used, during work with which metal shavings are formed (a hacksaw, etc.), it is necessary to periodically remove them, since the presence of foreign particles causes the tool to not fit tightly enough to the edges of the slot, what will slow down the work;

- It is recommended to wear safety glasses when removing a screw without a head, since during the procedure, metal shavings may form when using a power tool;

- you need to know which way to unscrew the screw, so, in most cases, hardware is made with a right-hand thread, which makes it possible to install the fastener by screwing it clockwise, and it is removed, on the contrary, when the screwdriver moves in the opposite direction.

When using an auxiliary tool, the intensity of the applied effort should be controlled

Rusty screw

Before tackling the question of how to unscrew a self-tapping screw that is susceptible to corrosion, you should consider all available methods:

- a blow to the fastener, in this case the integrity of the rust shell is violated, thanks to the vibration created by this, it will be easier to unscrew the rusted screw;

- use of an impact tool: the resulting effect is the same as in the first case; a manual or mechanical impact screwdriver is suitable;

- If the question is how to unscrew a broken screw, which, when trying to remove it, scrolls, and is also covered with rust, you should use the heating method, in which case the metal expands; after cooling, the product will shrink to its original size, as a result, the integrity of the rust shell is damaged, which allows you to quickly remove fasteners;

- an alternative method is the use of the chemical WD-40, a rust converter is used, which destroys the formed shell, however, a positive result can only be obtained if the entire surface of the screw is treated, this condition is often difficult to fulfill.

If corrosion occurs, all available methods should be considered.

Why do the bolts break?

Despite a lot of advantages, threaded connections have one significant drawback: bolts break quite often

In an industry such as the automotive industry, threaded connections are used very widely. Almost all car parts are assembled using threads. Despite the even greater simplicity and cheapness of welding, it cannot completely replace threads, since the latter has the ability to quickly disassemble the structure.

When a bolt breaks, situations arise when part of it remains in the hole and removing it from there is quite problematic

The article discusses the question of how to remove the remainder of a torn bolt from a threaded hole using the example of working with a car cylinder block.

The upper part of a broken bolt with a head can often be unscrewed from a threaded hole, since in 90% of cases bolts break in the direction of twisting

There are few reasons why bolts fail. The main one is excessive force when twisting. Using long-handled wrenches, you can apply enormous forces to the bolts, which will ultimately lead to the force exceeding the yield strength, and the bolt will simply break at its weakest point. Most often this is the first third of the thread length, starting from the bolt head.

When assembling some devices, it is important not only to select the correct bolts by thread and strength class, but also to tighten them with the correct force. Moreover, it should be no more and no less than what is indicated in the assembly instructions

Usually, the bolt is tightened until it stops, and then tightened.

The tightening force is measured in newtons per meter or kilogram-force per meter (outdated method). As often happens, craftsmen may not have the necessary key, and they use what is at hand.

A situation may well arise when a hypothetical bolt, for example, with an M8 thread, which should be tightened with a wrench with a nominal force of 3.8 kgf m, will be tightened with a wrench with a force of 4 kgf m. This may cause the bolt to break. Even a 5% difference in torque often leads to bolt failure.

If you attach the bolt to the engine, you can see that it broke right next to the cylinder block, that is, there are thread remnants in both the block and the head

The lower part of the bolt remains in the structure. Moreover, since the thread is already in its normal place, and the bolt is simply tightened, it can be located in both parts being twisted at once.

That is, even disassembling the entire structure could not remove the remains of the bolt. The only possible solution in this situation is to extract the broken thread in some other way.

At the same time, you need to understand that when removing the bolt, under no circumstances should you damage the internal thread of the structure, otherwise you will no longer be able to screw anything into this hole.

We build a house for a cat with our own hands. Interesting ideas and step-by-step instructions: from plywood, cardboard boxes, fabric. Drawings with dimensions (120+ Photos & Videos)

Preparation before turning out the fragment

The first step in a situation where a bolt has broken is to clean the surface of dirt and lubricants so that every little detail and unevenness of the surface is visible. Thanks to this, you can often see a crease in a hard-to-reach place, thanks to which it becomes possible to unscrew the damaged bolt with virtually no additional effort. In this case, you can remove it using a screwdriver and a hammer. This method will be described below.

The second stage evaluates the nature of the fracture and determines how to remove the broken bolt. The choice will depend on the condition of the mount and how convenient it will be to unscrew the mount.

How to unscrew the cylinder head stud

Threaded connections are the most widely used among detachable connections. They come in a variety of sizes; screws, bolts and nuts are found in both a smartphone and a nuclear reactor. Each connection must be tightened with proper torque. Sometimes the threads become clogged with dirt or become a victim of corrosion. When you try to unscrew the connection, the maximum force is exceeded and the thread breaks. It even reaches the point of destruction of the fastener body. In order to remove a damaged pin from the body, various techniques are used.

Features and advantages of cylinder head studs

In any engine, the cylinder head (cylinder head) is attached to the block itself with studs. They are screwed into the block in such a way as to ensure the best and uniform pressing of the cylinder head to the block. A high-quality compressed gasket prevents the leakage of oil and antifreeze and the penetration of gases from the cylinder into the engine crankcase. Fasteners are made from high quality steel. However, over time, the threads on them may corrode and become clogged with various contaminants. Due to exposure to high temperatures, these contaminants are sintered, and the nut “sticks.” When you try to unscrew such a stuck nut and exceed the maximum force, either the thread breaks off or the fastener breaks off. In both cases, it is necessary to replace the broken part.

Replacing the stud

Experienced craftsmen recommend unscrewing and changing all the studs at the same time. Parts from the same batch have similar physical and mechanical characteristics, will bear loads evenly and will last much longer.

Before unscrewing, thoroughly moisten the thread with WD 40 or kerosene. In extreme cases, brake fluid will do. If you don’t have a special puller at hand, you can unscrew it with a gas wrench. You need to pull smoothly, without jerking. If you can’t unscrew it right away, you should apply WD 40 again and wait 5-10 minutes.

After all connections have been unscrewed, they should be replaced with a new set. The threads can be lubricated with graphite lubricant - this will help you easily unscrew the parts if necessary. Next, you should install the cylinder head in place and begin tightening the nuts according to the diagram from the user manual.

- First, all nuts are tightened to light resistance.

- Using a wrench and a dynamometer, achieve the specified tightening force value.

- In the sequence described in the manual, all nuts are finally tightened.

The nuts can also be lubricated with graphite grease.

How to unscrew the remaining fragment

If the pin does break off, don’t despair. To unscrew the broken part, several techniques are used. Some require the use of industrial equipment, while for others, simple equipment available to a home craftsman is sufficient.

How to unscrew a broken hairpin

If a fragment remains sticking out, then use one of the following techniques:

- Put on a nut with a slightly larger diameter and weld it. Next, you can use a key to unscrew the broken pin.

- Weld a transverse rod (reinforcement) 30-40 cm long. Using it as a wrench, you can unscrew the fragment.

- Use a file to sharpen the top to a square. Now the fragment can be unscrewed with a tap wrench.

Unscrewing a broken pin

If the breakdown occurs flush with the surface of the cylinder head (or other unit), the fragment will have to be drilled out.

Drilling out the threads of a broken stud

Before drilling, cover the cylinder head with a thick cloth to prevent sparks and waste from entering the cylinders.

Next, you need to use an angle grinder with an abrasive disc to level the surface of the fragment. It should become strictly horizontal. A point is marked in the middle.

Next, take a drill with a diameter slightly smaller than the internal diameter of the thread. It is best to place the cylinder head on the workbench of a stationary drilling machine - this way there is less risk of the drill deviating from the vertical.

Drilling out the threads of a broken stud

After passing the hole to its full depth, you should unscrew the remains of the drilled fragment from it using pliers or needle-nose pliers. Next, you must go through the hole with a set of standard taps.

Replacing a stud with a repair part and cutting a larger thread

If all of the above measures fail, there is another replacement method. To do this, take a so-called repair pin of a larger diameter. In place of the old hole, a new, larger one is drilled. The thread is cut into it using appropriate taps, and the repair pin is screwed in. Of course, you will have to take the corresponding nut for it.

When installing the head, you need to be especially careful not to damage the threads on the new stud - it will fit into the hole on the cylinder head with less clearance than the standard ones.

Drilling out the fragment

The most time-consuming method is to drill out broken bolts. It should be used only in extreme cases when other methods will not work. This is due to several reasons. Firstly, high precision of the work carried out is necessary, since the likelihood of damage to the thread is very high. Secondly, breaking the bolt will not be so easy; it will require time and several sizes of drills.

If you don’t have the skill to do such work, the most acceptable option would be to use a thin drill first, and then a larger diameter one. The point of the method is to choose a size that will be as close as possible to the size of the hairpin. After the work has been completed, the bolt fragment must be removed using a magnet.

Reasons for tearing off edges

The desire to quickly replace failed parts secured with a threaded connection is not always feasible. Sometimes, when trying to unscrew a bolt from the unit body, the key begins to spin. This is due to the tearing of the edges on the head of the hardware when exposed to increased load. And the reason for this may be the following factors:

- sticking, which is caused by the diffusion of atoms during a long connection;

- displacement of the parts being connected relative to the axis of the holes, which leads to jamming of the screw;

- tugging during installation (increased load);

- using the wrong tool during assembly (for example, to tighten a bolt whose head size is 14 mm, a 17 mm wrench is used, and a screwdriver is inserted to eliminate the gap);

- corrosion that has eaten away the surface of the head.

Core and hammer

If the fracture occurs below the head or directly at the very beginning of the thread, then there is no possibility of influencing it with a hammer or chisel. Then the question arises: how to unscrew a bolt with a torn head?

A core can do the job perfectly. Due to the good shape of the tip, you need to gradually work on the fracture using a hammer. As a result, the top is deformed, unevenness appears and it becomes clear how to remove the broken bolt. By hooking this part with pliers, you can easily unscrew the fastener without deforming the thread.

Surface cliff

This type of failure includes the option when part of the hardware protrudes above the surface. We can assume that such a problem is easiest to solve without using radical measures. However, before any unscrewing of the broken bolt, it is worth treating the area with kerosene to remove carbon deposits and loosen the contact of the surfaces.

- If the protrusion is quite large, then the easiest way is to use tools such as pliers, pliers or a clamp, with which you can grab the part and unscrew it along the threads.

- Some experts, answering the question of what to do if a bolt that fits very tightly in the hole breaks, recommend using a welding machine. With its help, you can weld a lever to the hardware, which will result in a large arm for rotational movement.

- You can also use a drill with a diameter slightly smaller than the bolt itself. Using a drill, make a hole along the central axis of the bolt to the full depth. After this, the remaining fasteners are removed using a hook, trying to unscrew the thread from the very bottom.

Let's sum it up

As you can see, there are several ways to unscrew a broken bolt or stud. Moreover, in each case, it is necessary to separately take into account in advance the nature of the broken body, the location of the fragment itself, the possibility of access to the problem area, the possible consequences of heating the remains of the bolt, etc.

Finally, we note that before unscrewing the bolts, it is advisable to carry out treatment to remove dirt and soften rust before starting the procedure. Moreover, if various standard methods of unscrewing do not give the desired result (the bolt does not fit), then it is optimal not to make much effort so as not to break the stud.

The same can be said about tightening studs or bolts. The fact is that fasteners must be tightened with a strictly defined force and in the specified order (for example, covering the cylinder head). Ignoring this rule often leads to studs or bolts breaking, stretching, deforming, etc.

If such problems arise, it is better to contact experienced specialists who, in many cases, will unscrew the problematic broken or soured bolt. If it is not possible to avoid breaking the bolt, then qualified craftsmen will remove the residue from the hole with minimal risk, and, if necessary, restore the damaged thread.

Drilling

One of the methods that allows you to remove rusty and welded bolts, destroying them completely. It is used in cases where a bolt is turned. This method is especially convenient if during operation of the mechanism the edges of the head were damaged (licked off).

After selecting a drill, it is necessary to eliminate the effect of the drill moving to the side during the drilling process. To solve this problem, devices called conductors are used. Structurally, this is a plate with holes into which sleeves equal to the diameter of the drill are inserted. They do not allow the drill to go to the side during operation.

If fasteners of large diameter are drilled, two holes are drilled on the side of the center to a depth of ten millimeters. Insert metal pins (nails, studs of suitable diameter) and try to turn the old bolt.

If the thread gives in, the problem is solved. If not, you should drill the hole completely to the full depth or all the way through. Then remove any remaining metal.

What tools will you need?

To remove the problematic bolt without damaging the thread of the product, we will definitely need a metal drill and drill, several screwdrivers with different sizes of tips, a triangular file, high-quality pliers or a gas wrench (as a last resort), a tap to create the opposite one (relative to the one in which it is screwed). bolt) threads and of course needle files.

Note

: A number of tools can actually be replaced. The most important among the listed equipment is a drill with drills and pliers. It is also recommended to acquire WD-40, which should be used to treat the work area 15 minutes before starting extraction. This is necessary to facilitate the unscrewing process.

Using the extractor

However, the surest option to help unscrew a broken bolt is to use a special tool for this operation. It is called an extractor, it is sold in a set of tools of different diameters

. Outwardly, it is similar to a tap, but it does not have longitudinal slots and has a conical notch for cutting.

You can use the extractor after drilling a hole in the center with a diameter that will allow the tool to go several turns. Turn it until it stops, and then until it is completely unscrewed.

So here are some ways

unscrewing broken bolted elements. Each of them should be used depending on the complexity of the breakdown and the availability of appropriate tools. But the most practical and optimal option is to purchase a set of extractors. They are quite practical and allow you to work with bolted parts of various sizes and with any types of threads.

It is imperative to treat the surfaces, this will eliminate unnecessary contact and contamination. Good job on unscrewing the broken bolted joints.

, because the full operation of the entire mechanism depends on this, especially for cars! You can learn more about how to unscrew broken bolt elements using videos on specialized websites or forums!

Sooner or later, one of the bolts may break off inside its hole. There are several ways to unscrew it. Before purchasing an expensive extractor kit, try some of the following cheaper methods first.

First, no matter which of the following methods is used, use a special fluid such as WD-40

. This is a special fluid liquid with excellent penetrating properties for freeing dirty and rusty fasteners. But it also works well on tight, broken fasteners. If enough of the bolt or stud is protruding from its hole and it is not too tight, it can often be removed with a pliers or a small pipe wrench. If this does not help, or the fastening parts do not protrude enough to be securely grasped by pliers or a wrench, try sawing it down to fit a regular wrench or cutting a slot in it for a screwdriver.

If you still can't get it off, but you know how to use welding, try welding a flat piece of steel or nut onto the top of the broken fastener.

If a fastener is broken flush or below the top of its hole, use a small, sharp punch to knock it out.

If this does not help, try drilling out the broken fastener with a drill bit whose diameter is only slightly smaller than the inside diameter of the hole. For example, if the hole diameter is 12 mm, then use an 11 mm drill bit. This will leave a shell that can be knocked out with a sharp chisel. If this does not help, you need to resort to some kind of extractor. Extractors are sold in sets; they can be used to unscrew bolts and studs measuring 6-25 mm.

Most extractors are conical, grooved and made of high quality steel. To use an extractor, drill a hole slightly smaller than the outer diameter of the extractor being used (extractor kits include the manufacturer's recommendations for what size drill to use with each size of extractor); then screw the extractor into the hole and remove it along with the broken screw or pin.

The threads of the extractors are reverse (left-handed), so they will not unscrew when pulled out.

A LITTLE TIP:

Extractors usually save effort and money, but if you are inattentive or in a hurry, it will even cause pain and damage. Drilling the extractor hole off-center or using a drill bit that is too small or too large for the bolt or stud you are extracting will only make things worse. Therefore, be careful!

A rusty bolt, if too much force is applied, may break when unscrewed. This situation becomes a problem for any beginner, because it seems that now the bolt cannot be unscrewed with any tricks. But in fact, you can always choose an approach to solving a problem.

Flush break

This type of failure is considered the most difficult to repair, since it is very difficult to determine the diameter of the hole, especially when cutting fasteners. Therefore, in order to drill out a broken bolt of a certain type, it is necessary to clean the surface. This will allow us to determine the gaps we need.

The following unpleasant situation often occurs:

the break point has curved shapes that are very difficult to process and straighten. And it is categorically not recommended to drill a product in such a state, because there is a risk of completely ruining the structure. Therefore, you first need to use a core, which is used to prepare a place in the center of the drill.

The further procedure for drilling

a bolt broken in one way or another is similar to the option for a surface break. After creating the hole, the remaining threads are removed using a hook.