Use abrasive powder

As with steel wool, the more grip between the screw head and the screwdriver, the better. You can sprinkle the surface of the screw with a small amount of abrasive scouring powder or fine sand, then apply a screwdriver to the screw and try to remove it. In many cases, powder or sand is enough to keep the bit from slipping off the screw.

Why are the edges of the screw torn off?

There are several negative factors that explain why the head does not unscrew:

- corrosion of the metal, as a result the structure of the material is disrupted, it loses its properties, becomes less durable, crumbles, this leads to the fact that during the repair the technician will not be able to dismantle it by unscrewing the rusty fasteners;

- a screw tends to spin if it has been installed in a structure made of the wrong material.

The problem of how to unscrew a screw arises when the rules for using the tool are violated.

The problem occurs when the rules for using the tool are violated

crosshead screwdriver

Possible causes of fastener damage:

- poor quality of the tool: the metal is too soft, which causes the screwdriver to constantly slip out, the sharp edges have become dull due to wear, this also does not allow the screw to be firmly fixed in the slot, in addition, the tool may be incorrectly selected for such work (does not match the head size);

- weak efforts in the process of unscrewing the fastener, while the screwdriver is not held in the slot, constantly slips, as a result the head is deformed, for this reason it is called “slipped”;

- At the installation stage, the fasteners were installed in a structure made of a material that does not match the screws, because of this it rotates; using a screwdriver it will not be possible to pull out such hardware.

The tool may not be selected correctly for the job.

Screwdriver bit

A common problem with using power tools is the incorrect choice of operating speed. Use moderate force to drill out the fasteners. The operating time of the screwdriver should be short. If you drill a screw intensively, the slot will become deformed. As a result, you will have to additionally decide how to unscrew a screw with a damaged head, which will increase the time it takes to complete the work.

If you drill a screw intensively, the slot will become deformed.

Drill the screw

Select a drill bit that is slightly smaller in diameter than the screw head. Place it in the center of the screw head and drill slowly to create a hole 1 to 3mm deep. Remove the drill from the screwdriver and install the cue ball. Often the hole will help the screwdriver go deep enough into the screw, which will improve the grip between the cue ball and the screw.

Several techniques for removing a screw or self-tapping screw with a torn cross

When choosing a method, the degree of complexity of the task is taken into account. It is necessary to determine how deep the fastener is located in the layer of material. The condition of the surface is assessed: is there any rust, how badly damaged is the screw head. Use auxiliary means: rubber, chisel, hammer. If you plan to use the impact method on the fasteners, you need to prepare a gasket: made of brass, copper. This will avoid the final destruction of the hardware head.

Press down on the screwdriver

The main mistake when unscrewing fasteners is not using enough force. If you ensure a high degree of tight contact between the tool tip and the edges of the slot, you can contribute to the displacement of the screw. However, it is important to know in which direction the product is untwisted.

Hardware is produced with right-hand threads, but less common are screws that are screwed in the other direction - counterclockwise. If you put a lot of effort into unscrewing the fastener, you can screw it even more tightly into the layer of material in this way. When it becomes clear that the product cannot be touched by a screwdriver, you should immediately stop trying to remove it this way.

Press down on the screwdriver while rotating

Regular rubber band and screwdriver

The principle of action of such a tool is similar to how a screwdriver works in the previously discussed case. However, thanks to the rubber seal, the contact area increases. As a result, the chances of fastener removal increase. Instructions:

- It is recommended to use wide rubber, which increases the contact surface area;

- first you need to cover the sharp edge of the screwdriver with an elastic material, it is pulled tightly enough to ensure a tight fit, but there is a risk of deformation of the coating, so you should not be too zealous;

- the tool with the seal is installed in the slot, then they begin to slowly rotate the screwdriver.

The method is suitable for unscrewing a screw that is not too licked, how fasteners are removed - to answer this question, you need to understand the mechanism of action of a screwdriver: it begins to unscrew the fastener when it fits tightly to the edges of the slot, and the rubber partially fills the defects of the head. As a result, the friction between the tool and the hardware increases, which allows the latter to move from its place.

It is recommended to use wide tires

Drill the head

If the fastener protrudes slightly above the surface of the structure, it can be removed using a drill or screwdriver. You don’t have to put a lot of effort into this; the tool will do everything on its own. You only need to open the chuck. The tool is then placed on top of the screw.

When the head is fixed in the chuck, the drill and screwdriver turns on. After a few seconds, the fastening element is removed. The disadvantage of this method is its limited application. In most cases, the head of the hardware is deformed when it is flush with the surface of the structure. It will be impossible to capture her in this case.

Can be removed using a drill or screwdriver

Chisel and hammer

This method will not provide the required result if the fastener is completely recessed. The purpose of using impact tools is to move the screw slightly. This will make the unscrewing process easier. The chisel is installed at an angle relative to the fastener head. The hammer makes 1 blow. You should not repeat these steps many times, as in this case you can destroy the head. This option is suitable for situations where rust has formed on a metal product.

The purpose of using impact tools is to move the screw slightly

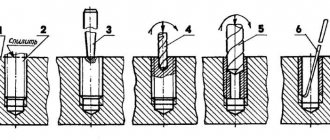

Extractor drilling method

This tool for removing threaded fasteners comes in different versions, differing in size. It resembles a drill, but has a conical shape and a thickened base. Before using it, you should prepare the fasteners. A small cross-section hole is made in it. The extractor is selected taking into account the diameter of the recesses of the threaded part of the screw - the tool should be smaller. To unscrew the product, a left-hand thread is cut into the hole. Please note that the screws have right-hand threads.

Drill a hole in the screw head

Screw extractor

Do not hit the extractor too hard

Turn the extractor

When the manipulations are completed, the fastening element is removed. The extractor is used for unscrewing various types of hardware. However, they are not used for self-tapping screws. This is due to the fact that such products are made from hardened steel. In this case, the fastener will move to the side when you try to drill it.

The extractor is used for unscrewing various types of hardware

Fastening element, can be easily removed

Sawing the edge

When the screw head becomes deformed, it is possible to remove such hardware by increasing the size of the slot. However, this increases the risk of fastener failure. As a result, it will be more difficult to remove. To avoid such consequences, it is recommended to make 1 cut - along the center line. Both cross-shaped grooves should not be expanded or increased in length.

Make a cut

To make the cut, it is recommended to use a hacksaw or grinder. The process produces metal shavings. It must be removed periodically to provide visibility for a quality cut. It should not be made more than 2 mm in depth. This will destroy the head. When the groove is ready, use a flathead screwdriver to remove the hardware.

Use a hacksaw for metal

With glue

Various adhesives are used. The purpose of this method is to ensure a high tight fit of the screwdriver. It is glued to the screw head. When the composition is completely dry (this may take 1-2 days), begin to unscrew the fastening element. Recommended types of mixtures: super glue, epoxy glue. The disadvantage of this method is the low degree of reliability. If you apply a little more force than necessary, the connection will break, and you will have to look for a new way to remove the hardware.

Various adhesives are used

Additional method

You can use a welding machine. In this case, the nut is welded to a metal product. The result is a strong connection. It is necessary to unscrew the nut, and the torn fastener will be removed along with it. This method also has limitations in use. Thus, it should not be used if it is necessary to remove a screw from flammable materials. In addition, the contact point is small, which will make the process difficult.

Weld the nut

A strong connection is created

Unscrew the nut

Use elastic bands to grip

Wide rubber bands work well to ensure that the screwdriver has enough grip on the stripped screw. Cut the rubber band with scissors and place it on the head of the screw. Place the screwdriver on the rubber band and press firmly while turning the screw counterclockwise.

Follow us on Pinterest for more interesting articles.

Useful short videos from Make-Self.net

Traditional methods

These methods are considered universal, but sometimes require much more time than using special tools.

Sets of wrenches: open-end, socket and socket

Working dimensions should not be “broken”, free wobble on a bolt or nut should not exceed 0.5 mm.

The tighter the key sits, the larger the stop area, the more force you can apply.

The size and type of the key are selected depending on the location of the hardware - it is necessary to ensure not only a tight fit, but also the ability to create a large twisting torque.

It is recommended to hit the bolt with a hammer while unscrewing it.

Drill

You can try to remove a screw that is not completely embedded in the material using an electric drill or screwdriver. The tool chuck is opened, put on the screw head and the clamping mechanism is tightened, securing the head in the chuck. Then set the reverse mode and carefully remove the screw from the material. This works on almost any type of threaded feature or stuck bolt, as long as there is part of the head that the chuck can catch on.

Extractor

If the previous methods did not produce an effect, you can use an extractor. It looks like a metal rod with a screw thread and is designed specifically for unscrewing stuck bolts and screws. Before using the tool, a vertical hole is drilled in the screw with a thin drill. The screw end of the extractor is inserted there and first turned slowly, achieving a strong fixation. Then unscrew the screw. The advantage of this method is that it does not damage the material from which the embedded fastener is removed. This method can be used to unscrew almost all types of fasteners, with the exception of self-tapping screws made of hardened steel. In such material it is almost impossible to drill a thin hole for the extractor; the drill will go to the side.

Preparing for extraction

Before unscrewing a bolt with torn edges, it is necessary to carry out preliminary preparation. The following methods can be used here:

- There are special liquids that easily penetrate cracks in metal and allow you to remove rust. An example of such a product is WD-40. It contains mineral oil, as well as white spirit and gasoline, which belongs to the light fractions. This treatment significantly reduces friction, allowing the bolt to be easily removed. Before unscrewing the stripped bolt, it is also possible to use kerosene. Brake fluid is used in the same way.

- Lightly tapping with a hammer can reduce the bolt's grip. In this case, you need to make sure that the blows are not too strong. Otherwise, the risk of damage to the object increases.

- Sometimes warming up helps. This can be done using any available means that provide heat. One of the popular tools in this situation is a gas torch. Heat treatment will help remove contaminants and remove rust, reducing the adhesion of the part.

It is convenient when there is sufficient space in the immediate vicinity of the problem screw so that the appropriate tools can be used.

Bolt with damaged edges Source sdelai-lestnicu.ru

A simple way to unscrew a licked screw

This was the easiest way to unscrew a licked screw without using a drill or other tricky devices. Also the fastest. So friends, take this advice into account. Watch the video If you don’t quite understand how to act, watch the video.

- 61 5 0

- vla917

- 27/04/2018, 21:45

- eboris_1

- 26/04/2018, 22:13

- gushan111

- 24/04/2018, 05:04

- blokroman

- 23/04/2018, 18:11

- alp001

- 27/04/2018, 09:28

- blokroman

- 27/04/2018, 20:46

There are only two simple and usually helpful methods. First: if the head of the screw protrudes even slightly above the surface of the wood, you can try to unscrew it with pliers, tightly squeezing the sides of the screw head with their jaws; Another option is to pick out the piece of wood around it, but it won’t look too neat. Second: if not, drill out the head of the self-tapping screw; Usually a drill with a diameter of 10 mm is sufficient. In this case, strictly speaking, the screw does not unscrew - but the parts connected by it are disconnected... If the slots on the head of the screw are at least relatively intact (the tip of the screwdriver reliably “clings” to them) - usually two or three times “carefully, but firmly” !” hit the end of the screwdriver handle with a hammer about three hundred grams. It twists like a sweetie... at least a couple of turns. Further, if it doesn’t work, use pliers again.

The simplest, but requiring patience, courage and some equipment, the third method is BURNING. It’s stupidly simple to do: the tip of a well-heated soldering iron with a power of 100 watts (or better yet more) is tightly “stuck” into the visible part of the screw and held for at least 5 minutes without lifting it off. The smell is not the most pleasant (especially if the screw is screwed into some kind of polishing) guaranteed - but after such an operation, even half-rotten screws, screws and other fasteners are guaranteed to be unscrewed...

«>

Unscrew the screw using a Phillips screwdriver

Such connections are not only found in cars; they are used during the assembly of many units. The choice of a specific method depends on the location of the hardware and the load on the connection.

- Rubber gasket. A small piece of thin rubber is inserted between the screwdriver and the bolt head; when unscrewing, the tool is pressed with maximum force. You need to work carefully and periodically make return movements.

- Use an impact screwdriver. This tool only allows you to loosen the connection; when struck, the end is pressed and at the same time rotated slightly. As soon as the screw goes easier, you can use ordinary tools.

- Use a special bit. At its end there are sharp edges that firmly cut into the body of the screw when unscrewing.

- Buy a set of extractors. They may be needed for various purposes and are always useful in every master’s kit. The extractors have left-handed conical serrations that cut into the metal and create excellent grip.

- Drill a hole in the cap with a left-handed drill. An important condition is that it is necessary to achieve not drilling a hole, but jamming the drill in the head. You must work carefully and constantly monitor the pressing force of the tool.

- A core or small chisel. The end of the tool is placed against the edge of the head with an inclination of 45°. With light blows, the hardware is unscrewed until the pressure is loosened. Then you can use ordinary pliers.

- Spline bits.

- Solder. The method can only be applied to vertically located bolts. A screwdriver is inserted into the slots and filled with molten tin. In this position, you need to wait until the metal hardens; it will fill all the cracks and ensure good adhesion of the surfaces.

A detailed description of the methods is presented in the article above.

Edge notch

In the case of a broken screw head or worn edges, you can make an incision on the head for better support of a flat-head screwdriver. The notch is applied using a Dremel, grinder or other tool cutting through metal. However, this method will damage the surface of the material if the screw sits deep.

Helpful advice: If the material allows, you can use the property of metal to expand when heated and contract when cooled. Stuck fasteners are heated using a lighter, soldering iron or hair dryer. The screw will expand slightly, pushing the material apart, and when it cools down, it will return to its previous state. As a result, a microscopic gap may appear between the rod and the material, which will slightly loosen the fastening and make it easier to unscrew.

Useful tips

Before deciding to use drastic measures to unscrew a stripped screw, inspect the back surface of the structure. Of course, if you have access to it. It is likely that the fastener has gone through and can be grabbed with pliers and forcibly unscrewed. Be sure to ensure that the threads are threaded in the correct direction, as the screw can have either left-handed or right-handed threads.

In the case when, after removing a broken screw, a larger hole remains in the body of the base, the assembly can be strengthened with larger hardware and sealant. An alternative solution is a fastener consisting of a bolt, washer and nut.

To facilitate the process of unscrewing a broken screw, it is necessary to reduce the friction force. You can use various lubricants, for example, WD-40. After removing the deformed hardware, the grease must be removed and the hole used to install a new screw.

And finally - remember about safety precautions! Deformed screws develop burrs and other damage that can lead to injury. You should work carefully, carefully, using personal protective equipment such as gloves and goggles.

Need some advice? Request a call! Send a request for fasteners

01.04.2020

Tool change

If the screwdriver constantly jumps off the slot, the reason may be that the tip is worn out. In this case, the tool is replaced. A new screwdriver is inserted into the screw head, making sure that the tip is pressed tightly against the slot, firmly inserted into the grooves, and try to unscrew the fastener.

Useful advice from Novate.ru: If the fastener cannot be unscrewed, the first thing to do is stop. Attempts to continue unscrewing can aggravate the situation, and a screwdriver that constantly jumps off can damage the material. Assess the condition of the screw and try other removal methods.

Video description

How to unscrew a bolt with torn edges of the door lock of an Audi A6 C5.

Some people in this situation weld a new head to the bolt. This method is convenient, but its use requires the ability to work with a welding machine, which is not suitable in all cases.

The spanners must match the size of the bolt Source sdelaysam-svoimirukami.ru

How to prevent edges from being torn off

A universal rule is that it is much easier to prevent a problem from occurring than to fix it later. A few basic rules will help you avoid trouble.

Do the following:

- Control the tightening force. As soon as you feel that the bolt is not moving, stop tightening it immediately. The same rule applies to unscrewing hardware.

- Use only serviceable tools. Old broken keys create point loads; the edges of bolts and nuts are not designed to withstand such forces.

- Before tightening, lubricate the thread, especially carefully follow the recommendation for steel hardware.

- Before unscrewing, clean the surfaces of the bolt heads and remove dirt from the screw slots.

- Fix critical components only with new bolts with completely intact head faces.

General advice is to always use a can of WD 40 or an equivalent, this will minimize the risk of edge breakage.

How to properly drill out a broken bolt: video, photo

During repairs, sometimes something bad happens - something breaks. Sometimes a broken part leads to trouble with a larger device. For example, a broken bolt in the cylinder block. A broken bolt can cause a lot of trouble. Especially when it breaks down in a place where access is limited.

Simple option

The first thing to do is not to panic. At all. A broken bolt can almost always be removed, the main thing is to do it correctly.

Removing a Broken Bolt

If it is broken at the part level, try unscrewing it with your finger. In fact, when a broken bolt is inside the hole along the thread, it is clean, and the screw simply broke due to metal fatigue or because it was pulled earlier - it can simply go from a finger

Or we pay attention to the chip - when a piece breaks off, a side always forms on the fracture plane - we substitute a chisel, a screwdriver - we try to unscrew it with light blows

Such cases often occur when a non-threaded part is attached with a pin or bolt - for example, a manifold to a cylinder block.

Complex option

If you can't unscrew it using these methods, we'll drill it. The main thing is that the broken bolt is not hardened. There are several methods to try before attempting to drill out a broken bolt. The most basic thing is to take a drill with reverse and a drill bit. Sometimes this trick can be done with a regular metal screw with a drill at the end. We press on the broken part, try to unscrew it with small turns, accuracy is needed here - you need to twist it “tightly”. If these methods fail, we move on to serious action. When the diameter of the pin is small, you need to determine how to remove the fragment - there is not enough space for two options.

Method one. Using a small diameter drill, we make two holes in the fragment. Against each other. We drill shallowly - about 5 - 10 mm, preferably away from the center. Then we take a lock ring remover, narrow-nose pliers, or simply insert two nails, clamp them with pliers and try to unscrew them.

Bolt Removal Technology

Method two. You need a special tool - an extractor. It is sold in tool stores. It is something like a cone drill, has a reverse thread, very hard hardened metal. First, we select a drill according to its diameter. Carefully mark the center of the stud with a core; we need it to drill the hole. It is not necessary to go deep - just drill a little deeper than the length of the extractor. Then we wrap the extractor and try to unscrew the broken piece.

https://youtube.com/watch?v=t3WmL6wh4iA

When none of the methods help, the most difficult option remains - drilling. To do this you need several sharp drills of different diameters and a strong hand. The most important thing is to catch the center of the fragment. We mark the center as accurately as possible with a core; the accuracy of drilling depends on this. Then, using the smallest drill, we drill through the broken one.

Tool for removing broken bolts Drilling a broken bolt Technology for removing a broken bolt

It is important to drill exactly along the rest, parallel to the wall, so that the alignment of the holes on both sides is maintained. Then we take the next diameter of the drill and so on until we reach the wall of the hole. If you slightly miss the center of the hole, it happens

The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out

If you slightly miss the center of the hole, it happens. The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out.

If you find an error, please select a piece of text and press Ctrl+Enter.

Best Ways to Remove Licked Bolts and Nuts

There are plenty of options. But none of them can be called universal. Each of them fits certain circumstances and requires a competent approach. Below you can learn about the most effective methods for unscrewing licked parts.

Using a tourniquet

The method involves the use of a tourniquet. To do this, you can take a small piece of dense rubber from a medical tourniquet or bicycle inner tube. It is important to choose a material that is as dense and rigid as possible. You need to select a screwdriver with a tip that fits the recess on the hardware head. The tourniquet is passed between the tip of the screwdriver and the head. They press hard and try to unscrew the hardware. Under certain conditions, the tight fastener unscrews.

Causes of the problem

Rust can destroy any surface, especially metal. It appears if the part is in contact with water for a long time, salt and various contaminants get on it. Even ordinary dust can cause friction between elements and aggravate the situation. Any metal product has a special protective coating. If it has been damaged, corrosion will form, causing the fastener to cease to perform its functions. Some metals react poorly to contact with oxygen or chemicals, resulting in rust.

Causes of licked bolts

Both masters and beginners face this situation. Slots or cuts are licked off due to the use of a worn-out tool, a low-quality fastening element, or incorrect use of a screwdriver or wrench. It happens that the edges are already damaged on the outside, or the hexagon is turned from the inside. Sometimes nothing is licked off, but it licks off when unscrewing. This happens because it was tightened tightly, and in order to unscrew the hardware, a lot of force is required. In addition to the tightening torque itself, the force must overcome the diffusion of materials, sticking and rusting of the bolt head. If the tool slips when trying to remove the fastener, the cause should be determined. It may be enough to change the key or screwdriver.