In some cases, it is impossible to solve an economic or production problem without unscrewing the bolts in certain places. At first glance, this may seem very difficult, but if you know how to do it correctly, in most cases you can easily achieve success. Next, we will consider practice-tested, effective ways to unscrew a bolt with torn edges.

Using a grinder, they make a slot for a screwdriver Source pro-instrymenti.ru

Causes of damaged bolts

Problems with bolts are usually due to the following reasons:

- The considered method of attaching parts is considered reliable, but in some cases it does not prevent their displacement under mechanical influences. The result is misalignment or damage to the fasteners.

- The mechanic who tightens the bolts sometimes does it too hard. If they are not untwisted for a long time, it may require considerable effort later.

- A common cause of boiling bolts is rust. It can fasten parts so that it will be impossible to unscrew.

- When working inaccurately, sometimes a larger wrench or other ill-suited tool is used. This can lead to the edges of the bolt licking off.

- When connecting for a long time, diffusion phenomenon may occur. In this case, metal atoms gradually penetrate into adjacent parts of the fastener. This attachment develops slowly, but within a few years it becomes strong.

For these and other similar reasons, connections arise that cannot be processed immediately. In such situations, you need to know how to unscrew a bolt with a broken head.

Drilling a bolt using a drill Source sdelai-lestnicu.ru

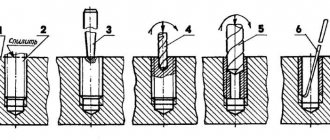

Application of the extractor

Specially designed tools that allow you to unscrew a spinning bolt, remove the remains of a broken fastener or part remaining inside the hole. They are used to remove any fastening elements (screws, studs). The principle of operation of the extractor is to drill a hole in the center and then jam the hole with the tip of the extractor. The depth of its placement depends on the nature of the wear of the head and rod, the degree of corrosion on the threads.

Extractors can be internal or external. In design, it resembles a tap for threading. It has a square shank. This allows you to use a standard crank to rotate it.

Modern manufacturers of metalwork tools offer the following types of extractors:

- wedge-shaped;

- made in the form of a rod;

- spiral shape;

- have the shape of a screw.

The method of using these devices does not cause difficulties even for non-specialists. This technology can be found in the instructions that come with each set of extractors. Before you begin, you should prepare the following metalworking tools: hammer, core, pliers, clamp, tap driver, drill, set of drills and the required extractor. First you need to drill a hole in the center in the shaft of the bolt to be removed. To get an accurate hole you need to use a jig. If this is not possible, you should manually mark the point of the future hole using a core and a hammer. Next, a guide hole is drilled in this place. It is recommended to drill to a depth that is three times the diameter of the selected drill. During drilling, the centering and vertical position of the drill relative to the plane of the bolt must be strictly observed.

An extractor is inserted into the finished hole. For reliable fixation, it is allowed to make several blows with a hammer on the tool. Using a wrench, which is used for cutting threads, begin to slowly screw the extractor into the drilled hole. It is necessary to screw in until it stops. Further force should cause the bolt to rotate. The force must be applied carefully without displacement. Otherwise, you may break the extractor itself. Instead of one broken bolt, you get two broken parts, firmly attached to each other.

Experience from similar work shows that when part of the bolt is unscrewed, it is advisable to use pliers or a clamp. With their help, the broken product is completely removed.

Therefore, experts advise that before embarking on radical methods of removing faulty bolts, screws and studs, you should try an extractor. Its use will preserve the thread and eliminate the need to machine the hole for new fasteners.

Preparing for extraction

Before unscrewing a bolt with torn edges, it is necessary to carry out preliminary preparation. The following methods can be used here:

- There are special liquids that easily penetrate cracks in metal and allow you to remove rust. An example of such a product is WD-40. It contains mineral oil, as well as white spirit and gasoline, which belongs to the light fractions. This treatment significantly reduces friction, allowing the bolt to be easily removed. Before unscrewing the stripped bolt, it is also possible to use kerosene. Brake fluid is used in the same way.

- Lightly tapping with a hammer can reduce the bolt's grip. In this case, you need to make sure that the blows are not too strong. Otherwise, the risk of damage to the object increases.

- Sometimes warming up helps. This can be done using any available means that provide heat. One of the popular tools in this situation is a gas torch. Heat treatment will help remove contaminants and remove rust, reducing the adhesion of the part.

It is convenient when there is sufficient space in the immediate vicinity of the problem screw so that the appropriate tools can be used.

Bolt with damaged edges Source sdelai-lestnicu.ru

How to remove a bolt if it is broken and nothing helps or the thread is already badly damaged

In such a difficult situation, you should drill a hole so that its width is sufficient for cutting new turns. Although the hardware may be hardened and difficult to give in. Then it must be subjected to heat - heated red-hot - and then left to cool. It is strictly forbidden to forcibly cool it with water - too sharp a temperature rise will only lead to the appearance of cracks.

The operation of slowly changing the temperature regime must be carried out several times. Due to this, the metal will be tempered and slightly softened, and the damaged element will become easier to drill out. But if the body of the part (unit, functional unit) is made of aluminum, special care should be taken to ensure that the surface in the heating zone does not warp.

Extraction procedure

When a master sees a rusted screw with damaged edges, he must begin work with pre-treatment. With its help, it will remove dirt, rust, and reduce the durability of the bolt. Next, you need to directly proceed to the procedure of how to unscrew a bolt with a broken thread.

If the edges of the bolt head are smooth, removing it will require a strong grip on the tool being used. This is ensured by using a gas key. It can even unscrew fasteners with no edges, almost completely. It is important to consider that the handle is of sufficient length so that the procedure requires moderate effort.

Damaged bolt Source intehstroy-spb.ru

Good grip can be achieved by using spanner wrenches. It should be borne in mind that its strength depends on the exact selection of the size of the tool. If the fastener uses a washer, then in some cases you can make it easier to unscrew by breaking it with a hammer and chisel.

Using these tools helps most of the time, but not always. If it was not successful, then other methods will need to be applied.

A set of tools that may be useful for unscrewing bolts Source sdelaysam-svoimirukami.ru

How to unscrew self-tapping screws with broken slots

If overheated screws are unscrewed/twisted a couple of times, their edges lose their sharpness, the screwdriver turns, but the screw itself remains in place. If it “sits” in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band (for example, for hair) under the screwdriver. Due to the elastic force, a tighter fit is achieved to the remaining edges, which helps to move the self-tapping screw from its place. Other methods are more “traumatic”:

- Cut grooves inside the “licked” funnel using a flat-head screwdriver and unscrew. This method is quite dangerous: if the walls of the “funnel” are too thin, there is a chance that the screw head will simply crumble from the effort. All that remains is a screw that cannot be unscrewed.

- Drill and unscrew using a small diameter extractor.

- Take a chisel and grind it to the size of the cap. Place it on the cap, hitting it well with a hammer a couple of times. A new cap is formed and, at the same time, existing rust may crumble (if the screw is stuck in the iron). Using the same chisel, try to move the stubborn screw from its place. To make the process easier, you can drop oil on wood or WD40 on metal.

- Drill out the material around the cap, take a tube with an internal diameter slightly larger than the diameter of the cap, and put it on the cap. Pour glue inside. When the glue hardens, unscrew the tube.

- The remains of a bolt or stud without a head can be unscrewed as follows: cut a left-hand thread in the remaining body, drip “moment” glue, screw in the left-hand tap, and leave for an hour. Apply some oil to the main thread and leave for an hour. When the glue sets, unscrew it. If the remains of a self-tapping screw are stuck in the wood, it is easier to seal this hole and install another fastener nearby.

Using destructive methods

The methods outlined below are united by the fact that when they are used, the bolt is destroyed. However, if other options do not lead to success, then you need to use them.

If you saw off the bolt head with a grinder or remove it with a hammer and chisel, you will be left with a threaded part embedded in the part being fastened. It is necessary to make a longitudinal notch on it, using which you can use a screwdriver.

Sometimes the remaining part of the bolt does not respond to such attempts. In this case, you can unscrew a bolt with torn edges by trying to turn a screwdriver, while helping yourself with blows of a hammer.

If the edges are torn off so much that it is completely impossible to use them, then the following methods can be used:

- A deep cut with vertical walls is made on the bolt head. Then you can use a screwdriver to unscrew it.

- Sometimes a hammer and chisel are used to turn a bolt; in this case, you need to use the following method on how to unscrew a torn hex bolt. The blows are applied slightly obliquely and are done in such a way that the bolt gradually twists around its axis.

- A TORX sprocket can be used. A slot is driven into the head until a hole that exactly fits the shape is obtained. After this, twisting is done.

- You can use a special part - an extractor. To do this, use a drill to drill the bolt along the longitudinal direction. Insert it into the resulting hole and remove the fasteners.

- A drill with reverse may help. Its peculiarity is rotation in the direction corresponding to the unscrewing of the screw. To do the job, drill a thin hole, then use a tool to turn it so as to remove the screw.

One of the effective ways to remove a bolt is to additionally sharpen the head. It is again made hexagonal, but now its size will be smaller than the previous one. Next, select the desired wrench and disconnect. The edges are processed using a file.

By watching the video you can learn more about how to unscrew a broken bolt:

Rusted nut

Another problem that is familiar to car enthusiasts (and not only) is a rusted nut and/or thread. In this case, you should not make heroic efforts to unscrew the fasteners. Your edges will simply “stick together” and another problem will be added to the boiling thread. If after a couple of attempts you can’t unscrew it, try the following methods one by one:

- Tap the bolt with a wrench. There is a chance that the rust will crack and the nut will be unscrewed.

- Fill the connection with kerosene and wait. It will eat away the rust, after which it will be easier to unscrew the rusted nut. But during this operation you cannot smoke, turn on welding, or be near an open flame.

- Warm up the nut. The metal will expand, making it possible to unscrew it. The trick is to get the nut to heat up while the bolt shank stays cold, so heating up must be fast. To do this, use a hair dryer or an open fire (be careful with this). If the screw is small, you can take a powerful soldering iron, heat it to maximum temperature, then quickly heat the joint.

This method will (almost) destroy the nut, so it should only be used in hopeless situations. Grooves are made on the edges (using a metal saw, grinder, or file). A flat screwdriver is pressed into this groove, giving it a direction in the direction of unscrewing. The handle is hit with a hammer. If there is at least a couple of movements, it may be possible to unscrew it.

- Use a special puller (pictured above). Using a bolt, the pin rests on one of the faces, after which you can try to move it from its place. Due to the fact that the lever can be attached, it can work even in very difficult situations.

You can also fight rust with lubricant. Try filling the joint with fluid universal lubricant (available in WD40 cans). After waiting a couple of hours, we try to work with the key. If it doesn’t work, we try other methods one by one.

Video description

How to unscrew a bolt with torn edges of the door lock of an Audi A6 C5.

Some people in this situation weld a new head to the bolt. This method is convenient, but its use requires the ability to work with a welding machine, which is not suitable in all cases.

The spanners must match the size of the bolt Source sdelaysam-svoimirukami.ru

Adviсe

Sometimes difficulties when unscrewing arise only at the beginning. If you manage to turn the fastener, you can often use a regular screwdriver.

Sometimes, in order to successfully unscrew a hex with broken edges, you need to increase the friction between the wrench and the part. Having rubber can help in this situation. They wrap it around the head of the bolt and use a gas wrench. As a result, when scrolling, the use of this material increases friction, helping to solve the problem.

Choosing the right tool will ensure the connection is working properly Source sdelaysam-svoimirukami.ru

Sometimes it is advantageous to use “cold welding” to attach a nut with high-quality edges to a bolt. We are talking about a special glue that provides reliable adhesion. After this, use a wrench to unscrew it. This option can be effectively applied to almost any bolts, even those that cannot be removed by other means.

It makes sense to pay attention to the use of an extractor. It is a drill with a small head at the tip. It is used to drill damaged hardware lengthwise. Its feature is the use of threads in the opposite direction than the screw. When creating a hole, wedging occurs, and at some point this process begins to slow down. After this, the extractor rotates along with the bolt, which makes it possible to unscrew it.

A key spanning six edges ensures a strong grip. Source sdelaysam-svoimirukami.ru

Preventive measures

If the bolt's edges are damaged, then to unscrew it, you can use the methods outlined in the text. However, it is important to prevent fastener damage or at least reduce its likelihood. To do this, you need to pay attention to the following:

- You need to buy high-quality and reliable hardware. It is advisable to first verify its suitability.

- When tightening, you must use a tool that is exactly the right size. It should not slip and damage the edges of the head.

- You should only use the right tool. If the edges of the wrench are damaged, it will cause the formation of poor-quality fasteners.

Tightening the bolts carefully will help reduce the likelihood of it sticking.

Sometimes warming up the fasteners helps Source sdelaysam-svoimirukami.ru

Table of types and sizes of internal hex bolts and their characteristics

Hardware of this type is made of carbon and stainless steel. They have thermal diffusion or galvanic coating with oiling; sometimes they produce samples with oiling, but without coating.

The color of the coating is light gray, dark gray and golden yellow. Black bolts do not have a protective coating, so they cannot be used in areas with high humidity or structures in contact with water.

An internal hex screw ensures reliable fastening of parts and is universal, but, first of all, it is necessary to select hardware of the appropriate type and size.

Types of hexagon socket bolts according to DIN

In terms of size, hardware corresponds to three accuracy classes: A, B and C. The marking on the head of the hardware corresponds to its class. The accuracy class determines how accurately the rod will correspond to the diameter of the hole prepared for it, taking into account the size of the bolt.

Due to the high degree of deflection, a Class C screw can become deformed under dynamic loads, however, it is easier to install because it fits easily into the prepared hole.

The parameters of bolts (screws) manufactured according to GOST 11738 / DIN 912 / ISO 4762 are presented in the table:

Hexagon socket bolt measurement diagram

DIN912 parameter table

Experts advise buying domestically produced products, since imported hardware may be labeled in an unusual way and vary in size.