People use bolts very often because they are a convenient fastening method. However, when they have not been loosened for a long time, it seems almost impossible to unscrew the nuts with torn edges. In these cases, it is still possible to solve the problem by using special techniques for this purpose. To be fully equipped in such situations, you need to know the existing methods that could help in such a case.

Using heat to unscrew Source moy-instrument.ru

How to unscrew the bolts

First you will have to remove the entire assembly, including the steering column. Most likely you will see two bolts with torn off splines in the form of rounded heads. Next, you can proceed in two ways:

- Unscrew the shear bolts using a hammer and chisel. To do this, you need to fix the steering unit in a vice. Then place the chisel at an angle of 45º to the fastener head. Tap the chisel so that it imparts counterclockwise torque to the bolt. In this way, you need to move around in a circle until the bolt breaks off. Then you can unscrew it using regular pliers.

- Take a drill or grinder with a thin disk for metal. Make a neat slot in the bolt head exactly in the center. A couple of millimeters is enough. Then slowly try to remove the fasteners using a large flat-head screwdriver.

These methods are sufficient for most cases. If the bolt is “tight”, you can try treating it with WD-40 spray.

Please note that this fastener is not suitable for reuse. To reassemble the steering column you will need to find new bolts.

With damaged edges

When deciding how to unscrew a bolt with stripped edges, you need to consider whether there is access to it, its location, and what tool you can use. Based on these factors, you can use one of the following methods:

- Using a chisel. The method is suitable for large bolts that have easy access. All you need is a hammer and chisel. The chisel is applied tangentially to the head and sharp blows are applied to it. The method is simple, but it rarely achieves the desired result. It should only be used when there is no other tool at hand.

- If there is free access to the location of the fastener, you can use a universal adjustable wrench. This tool allows you to securely clamp even a round head. If you use small adjustable cobra-type wrenches, which have sharp notches on the working surfaces, you can unscrew the smallest bolts. Such a tool can help out in many cases, but it must be new. In a worn tool, the notches can no longer provide reliable adhesion to the metal, and the key will slip.

If the edges are not severely damaged, then socket wrench heads can help out. For these purposes, the ring wrench profile must have 12 edges (there is an asterisk inside the head, not a hexagon). Unscrewing is done as follows. Select a head one size smaller than the size of the bolt, and use a hammer to press it onto the torn edges, then unscrew it in the usual way.

- This method involves using a hacksaw for metal, with which a cut is made on the head of the bolt for a flat screwdriver. The depth of the cut should not be more than 75% of the height of the bolt head; with a greater depth, one of the halves may break off.

- If you have a file or grinder at your disposal, you can restore smaller turnkey edges. If you have an open-end wrench, it is not necessary to cut out a hexagon; it is enough to make two parallel edges.

- If you can use welding at the location of the fastening, this will greatly facilitate the task. In this case, you can put a nut of a suitable diameter on the head and weld them together, and then use regular wrenches.

In difficult cases, in order to achieve the desired result, you need to combine several methods. Therefore, first assess the situation, decide how you can unscrew the bolt, and only then get to work.

With damaged thread

There are cases when the thread of the fastener is damaged. In this case, the hardware rotates freely, but it is not possible to remove it from the threaded connection. To solve this problem, you need to lift the bolt. This can be done using a screwdriver or other similar tool, which is inserted under the head and lifts it with force.

When the bolt rests, it begins to rotate in the direction of unscrewing. This is done until the hardware is completely removed. If the hole in the threaded connection is through, then you can push from the reverse side using any suitable tool.

If you have a similar problem with the nut, then proceed in the same way. Hardware with damaged threads must be replaced, so if there is access, the nut can be cut off with a grinder or knocked down with a chisel.

With the head torn off

Very often, when disassembling old threaded connections, you can not only damage the edges of the bolt, but also tear off the head. Then the question arises: how to unscrew the broken bolt. If you have separated parts and the broken bolt protrudes from the body of the part, then you can use all of the above methods.

How to unscrew a bolt with a torn head if the body of the bolt does not protrude from the part? There are several options for solving this problem.

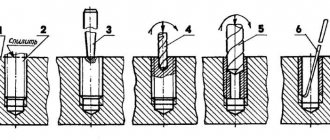

- It is best to use a special tool - an extractor. The extractor is made of a cylindrical metal rod, at one end of which there is a conical thread of opposite cutting, and at the other - a square shank. In order for it to be used, a hole must be drilled in the center of the bolt. The hole diameter is 2-3 mm less than the thread diameter. After this, you need to take an extractor of a suitable size and hammer it into the hole with a light blow. Rotating the extractor by the shank, unscrew the remaining bolt.

- If you have a left-hand thread tap, you can successfully use it as an extractor. The only difference is that the diameter of the hole must be the same as for threading. The exact value can be found in the corresponding tables.

- If you still can’t unscrew the fragment, you can try to remove it this way. Drill a hole in the bolt with the largest possible diameter, being careful not to damage the threaded connection. Then take the appropriate tap and cut a thread in the hole. During this process, the threads are cleaned and any remaining bolt residue is removed.

Drilling a hole accurately is quite difficult. And if you damage a threaded connection, the situation can only be corrected by drilling a hole and cutting a thread of a larger diameter.

A cut stud is no different from a bolt with a torn head, and therefore the methods for unscrewing it are the same.

Detailed consideration of various techniques

Here we will talk about the most effective and common ways to unscrew a bolt if it is spinning or a stuck nut. Among them, you can choose the appropriate ones for each specific situation.

Application of various wrenches

The use of open-end wrenches can be called very popular. However, when using them they encounter the following disadvantages:

- The gap between the key and the nut is not always tight. It often exceeds half a millimeter, affecting the grip density.

- This tool only covers three of the six faces.

Therefore, when using it, it is easy to tear off the nut instead of unscrewing it. Other types of keys may not have such disadvantages. For example, a socket or socket wrench covers all six edges, allowing for a tight grip and increasing the chances of successfully unscrewing a frozen part.

Using a long-handled tool may help. In this situation, having good leverage will allow you to exert more force. The length of the handle can be increased artificially, for example, by using a long pipe. However, in the case considered, it will be less convenient to perform the necessary movements.

Using a gas nag is an effective means of loosening nuts Source moy-instrument.ru

How to unscrew a bolt with broken hexagon edges

As a rule, fasteners can be made in various versions, so the methods for removing them are somewhat different.

Hex head bolts (asterisk)

The following bolts are removed:

- Flat screwdrivers. To do this, you need to make a notch cut on the cap in advance. The walls of the cut must be vertical so that the tool does not jump off.

- TORX sprocket with suitable size. It must be selected based on the principle that the splines do not fit into the hexagon hole, but also that it is not excessively large. With such an asterisk, a slot is cut through the head of the bolt when it fits tightly into the head. After this, the bolt is jerkily unscrewed to avoid breaking the spline on the sprocket. For such work, you should not use TORX sprocket models with center holes, since they may break off during the driving process.

- Drill, drill and special extractors. To extract, you need to drill a hole in the center and hammer the appropriate extractor into it. Then, using pliers, you need to unscrew it along with the fasteners. This is not difficult to do, since the extractor has threads cut opposite to the bolt threads.

- A drill with reverse and drills with left rotation, the diameter of which is less than the diameter of the damaged bolt. First of all, using a regular thin drill, a small hole is made, after which the drill is installed, and the drill is turned on in inversion rotation mode.

Hex Bolts

The following bolts are removed:

- using a needle file, by enlarging the connector to the next hexagon size (this method makes it possible to reuse the bolt);

- TORX sprockets of the appropriate size;

- flat screwdrivers, if a notch has been prepared in advance on the head of the fastener;

- through extractors that are screwed into a hexagonal hole.

Step-by-step instructions for unscrewing the hexagon

There are several options for step-by-step instructions for unscrewing a hexagon.

- On a bolt with a protruding hex head, the head is cut using a grinder or a hacksaw. It can then be unscrewed using a regular screwdriver. The cut must be made with the utmost care so that the screwdriver does not jump off it during operation.

- A suitable Torx sprocket is driven into the place where the hexagon is inserted. When driven in, it cuts through the head with splines and inserts into it. The bolt is pulled out with a strong jerk. If unscrewing is carried out slowly, the splines will break and the operation will have to be done all over again. Torx with a central hole cannot be hammered, since when hammered it is destroyed.

- Unscrewing the hexagon can be done using a drill and a regular drill, and various extractors that are purchased in the store. Using a core, a future drilling point is marked strictly in the central part of the bolt being processed, at which a hole is then drilled. With a little force, an extractor is inserted into the resulting hole with a hammer. Then, using a handy tool, it is unscrewed. The extractor can be reused after this procedure.

- Can be unscrewed with a drill with left rotation and a construction drill with reverse. A drill with a thin diameter drills a hole in the head of the element. Then a drill of a smaller size is taken compared to the diameter of the damaged bolt. The drill is inserted into the drill and set to inverse rotation. The speed of the drill should be low and the pressure strong. When the element is pressed firmly, the drill will screw into it and pull it out.

A bolt or hex screw can become damaged at any time. Various available tools can help in its repair, but the use of special tools may be required, without which it is impossible to unscrew the hex head of the damaged element.

Therefore, it is important to know all currently available methods for repairing this element. The hexagon is found in various types of indoor water faucets, in car spare parts

At the moment, these bolts are considered quite convenient fasteners, so they are widespread and found in many mechanisms.

Their use is advisable where a reliable power connection is required. This type of fastener is perfectly adapted to high loads and significant physical pressure. These bolts are especially often used in industries such as construction and mechanical engineering.

If we turn to the process of creating a hexagon, it becomes clear that the process of their manufacture is long and quite labor-intensive. These bolts are made from steel wire rod, which then softens after being in a hot oven for a long time. Then the wire rod is placed in a sulfuric acid solution for some time to completely remove rust particles. After being washed with water and treated with phosphates, the steel becomes resistant to rust and is then sent to be formed into a hex head element.

In the process of creating these products, many people are involved, providing the Russian market with modern, high-quality fasteners.

This problem often arises when the hex bolt is torn off and it is not possible to unscrew it with a wrench. The causes of this problem may be the sticking effect, displacement of the parts being fastened, over-tightening when installing hex hardware, as well as the use of inappropriately sized keys.

Unscrewing a broken bolt using another

This method is suitable if the diameter of the residues is relatively large.

Because you will have to drill a smaller threaded hole in the body, into which you will then install a fastener with a left notch and begin to tighten it, going deeper and deeper - it will push out the previously destroyed part. The only downside is that a drill is required to complete the task, but it is not always at hand, and you will have to spend one new hardware. Therefore, it makes sense to consider solutions that are easier to implement and universal in everyday life, and put this aside in reserve for the case when there is no other option.

Alternative methods for unscrewing bolts with torn edges

If the threads are completely stripped, pipe wrenches may be useless if there is not enough space to manipulate the tool. In this situation, the most successful solution is to create new edges on the bolts using files.

The edges of the old base are ground down to the specified new size, so that spanners with heads of the required diameters can be used. Some experts give advice on welding a new nut to the head of an old bolt.

If the fastening materials are excessively large, then the right solution would be to use welding to apply a metal coating to the surface of the damaged edges. And only after this is it possible to cut out the required shape to install the key.

A simpler, and in some cases more effective, method is to use a hammer and chisel to split an intermediate piece (a plastic gasket or a rusty washer) between the surface of the bolt and the body.

In such cases, blows are applied directly both to the nut and near it, maintaining a certain angle and slope in the direction of unscrewing the bolt.

Some craftsmen prefer to drill out a bolt with a broken edge using a drill. In such cases, a hole is drilled in the middle of the fastening element structure into which a special L-shaped rod is installed. This device acts as a handle that allows for extraction.

Any of the methods described above can be done even by a person who has no previous experience in plumbing work. If you use the right tools and related equipment, no one will have any difficulties. By following the recommendations presented, you can easily unscrew a bolt with torn edges with the slightest time and physical effort.

How to replace an LED lamp?

Replacing them is quite simple using the following instructions.

- Turn off the network power;

- Before replacing, check the power of the lamp being replaced. ...

- remove the retaining ring, which is located along the diameter of the body. ...

- remove the light bulb from the socket, holding the base with your other hand, install a new one;

- return the retaining ring to the groove.

17 Sep.

2022 Interesting materials:

How to calculate the amount of tax deduction? How to calculate the amount of transport tax for the year? How to calculate the amount of transport tax? How to calculate transport tax 2022? How to calculate transport tax 2022? How to calculate transport tax for an LLC? How to calculate transport tax for an individual? How to calculate transport tax on a car? How to calculate transport tax for an excavator? How to calculate transport tax on a boat?

Rusted nut

Another problem that is familiar to car enthusiasts (and not only) is a rusted nut and/or thread. In this case, you should not make heroic efforts to unscrew the fasteners. Your edges will simply “stick together” and another problem will be added to the boiling thread. If after a couple of attempts you can’t unscrew it, try the following methods one by one:

- Tap the bolt with a wrench. There is a chance that the rust will crack and the nut will be unscrewed.

- Fill the connection with kerosene and wait. It will eat away the rust, after which it will be easier to unscrew the rusted nut. But during this operation you cannot smoke, turn on welding, or be near an open flame.

- Warm up the nut. The metal will expand, making it possible to unscrew it. The trick is to get the nut to heat up while the bolt shank stays cold, so heating up must be fast. To do this, use a hair dryer or an open fire (be careful with this). If the screw is small, you can take a powerful soldering iron, heat it to maximum temperature, then quickly heat the joint.

This method will (almost) destroy the nut, so it should only be used in hopeless situations. Grooves are made on the edges (using a metal saw, grinder, or file). A flat screwdriver is pressed into this groove, giving it a direction in the direction of unscrewing. The handle is hit with a hammer. If there is at least a couple of movements, it may be possible to unscrew it.

- Use a special puller (pictured above). Using a bolt, the pin rests on one of the faces, after which you can try to move it from its place. Due to the fact that the lever can be attached, it can work even in very difficult situations.

You can also fight rust with lubricant. Try filling the joint with fluid universal lubricant (available in WD40 cans). After waiting a couple of hours, we try to work with the key. If it doesn’t work, we try other methods one by one.

Reasons why you cannot unscrew the nut

It is often easy to unwind if you use the right tools. However, sometimes this creates problems. The reasons why it is difficult to remove the nut in most cases are the following:

- Over a long period of time, the connection rusts, seizing the nut and bolt.

- Sometimes the person doing the twisting makes too much effort. This can happen, for example, in cases where the wrench has a large lever.

- Sometimes, due to mechanical influences, parts become deformed.

To cope with the problem, it is enough to use one of the suitable methods.

Drilling a screw Source moy-instrument.ru

How to unscrew a stuck bolt

“Stuck” (seized by dirt and/or rusted) threads can be absolutely serviceable (not torn off). But due to the presence of dirt or rust in its depressions, the bolt is “clamped in a vice.” And excessive force to unscrew it can just lead to thread failure! Which is undesirable, since eliminating “sticking” and still removing a serviceable bolt is much easier than eliminating a broken thread.

However, before “turning” the wrench, you should, firstly, thoroughly clean the bolt from adhering dirt. And secondly, treat it with a special liquid. The best choice is one that contains molybdenum disulfate.

Penetrating all-purpose lubricant WD-40 will also work. As a last resort, you can use kerosene, brake fluid or diesel fuel (with great caution for safety reasons!). It is true that it is much more difficult to deliver fluid to the threads under the head of the bolt than in the case of unscrewing the nut (especially when the threads of the bolt shaft or stud protrude beyond the dimensions of the nut), but this step will still not hurt.

After waiting for some time (until the liquid works), you can start unscrewing. If a regular socket wrench does not help, it is better to use special socket heads with an impact mechanism.

“Sticking” of threads occurs not only on units exposed to dirt (for example, in a car suspension). But also on those threads that fasten components operating under conditions of significant temperature changes. For example, the engine exhaust manifold or muffler intake part is often difficult to dismantle due to “stuck” nuts. Although this fastener is not subject to severe contamination, its “sticking” is due precisely to operation under conditions of cyclic heating to high temperatures and repeated cooling.

Which way does the hub nut unscrew?

Yes, you may very well be one of the lucky ones who won't need any extra effort as the problem with unscrewing the hub nut may simply be a matter of going in the wrong direction.

So, we take the wrench and, when your car is far from new, try, if the nut does not lock, on the left wheel, unscrew the nut counterclockwise, and on the right wheel, unscrew it clockwise. In modern brands, it is usually necessary to unscrew the hub counterclockwise .

Before you start unscrewing the hub nut, do not forget that it comes off when the car is standing on the wheels and the stops are placed under them. On the side from which the nut will be unscrewed, a stop is securely installed.

Although if the nut is located deep and the brake disc is ventilated, then you can try to unscrew it (fixing it with a powerful screwdriver) and only after making sure that the car is securely secured. Remember about personal safety precautions: protect your eyes, do not overdo it, because in the spirit of enthusiasm you can accidentally get hurt or damage the car body.

Unfortunately, in most cases, it is not enough to use a wrench with a large lever; you have to use additional tools and special mixtures. Let's consider the other options.

If the cylinder head bolt is broken

The method is suitable for cases where the bolt has burst and part of it in the form of a pin remains inside the cylinder block. We use welding, a tube, a nut.

Advantages of the method:

- there is no need to disassemble the engine;

- saves time.

Take a tube with the following diameters:

- The outer one is slightly smaller than the diameter of the cylinder head bolt.

- Internal – such that an electrode of 2–3 mm fits freely into the tube.

Weld a 17 - 19 nut onto one side of the tube.

- Insert the tube into the hole so that it touches the broken pin.

- Insert the electrode into the hole of the tube at a slight angle, so that its end is located where the edge of the tube touches the pin.

- Weld the tube to the stud.

- Use a wrench to unscrew the pin.

Another way if the cylinder head bolt breaks.

Suitable for cases where the broken pin is not deep, no more than 5 cm.

To unscrew the stud from the block, first use a drill and a long 10 mm drill bit. This will help you level and center its surface. Next, using a 4 mm drill, drill a hole in the stud with a depth of at least 1 cm.

Carefully drive a 25mm Torex key into the stud and use a lever tube to unscrew it. You need to unscrew without jerking, gradually increasing the force on the lever.

Unscrewing the hub nut on a VAZ: “burn, hit and twist!”

Now let’s look at the methods that may be the only effective ones in your case, but that doesn’t make them any less radical, even barbaric.

Strong hammer blows

If you hit the hub, you hit the bearing! If you are going to make a replacement, then go ahead! If you value the bearing, avoid this method.

Warming up the hub nut with a burner. Not recommended!

Using the burner

The law of physics is guaranteed to work, and the body (read: hub nut) will expand. And this will make it much easier to remove the stubborn part. There is one “but”: not only this one part heats up, but also everything else in the area of the burner. For example, a bearing. And it’s better not to allow this. As a more gentle option, we can suggest using a soldering iron and... patience. You'll need it.

Jumping on a lever

A chisel will help you remove the hub nut.

The “method” is fraught with the danger of unexpectedly breaking off the edges of the nut, breaking the key, and so on. Just don't do it.

Take a chisel and make notches on the edges

An increase in diameter, of course, makes the hub nut unsuitable for further use, but it will be easy to unscrew it.

How to unscrew self-tapping screws with broken slots

If overheated screws are unscrewed/twisted a couple of times, their edges lose their sharpness, the screwdriver turns, but the screw itself remains in place. If it “sits” in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band (for example, for hair) under the screwdriver. Due to the elastic force, a tighter fit is achieved to the remaining edges, which helps to move the self-tapping screw from its place. Other methods are more “traumatic”:

- Cut grooves inside the “licked” funnel using a flat-head screwdriver and unscrew. This method is quite dangerous: if the walls of the “funnel” are too thin, there is a chance that the screw head will simply crumble from the effort. All that remains is a screw that cannot be unscrewed.

- Drill and unscrew using a small diameter extractor.

- Take a chisel and grind it to the size of the cap. Place it on the cap, hitting it well with a hammer a couple of times. A new cap is formed and, at the same time, existing rust may crumble (if the screw is stuck in the iron). Using the same chisel, try to move the stubborn screw from its place. To make the process easier, you can drop oil on wood or WD40 on metal.

- Drill out the material around the cap, take a tube with an internal diameter slightly larger than the diameter of the cap, and put it on the cap. Pour glue inside. When the glue hardens, unscrew the tube.

- The remains of a bolt or stud without a head can be unscrewed as follows: cut a left-hand thread in the remaining body, drip “moment” glue, screw in the left-hand tap, and leave for an hour. Apply some oil to the main thread and leave for an hour. When the glue sets, unscrew it. If the remains of a self-tapping screw are stuck in the wood, it is easier to seal this hole and install another fastener nearby.

Unscrew the broken bolts and nuts

“Licked” edges on bolt heads or nuts are not that uncommon. Excessive forces that we apply when tightening and then when unscrewing often lead to the fact that the boundary between the edges of the bolt is erased. If the bolt does not unscrew, ordinary wrenches are powerless in this case - they simply turn, and the fasteners remain in place.

Torn or licked edges on a nut or bolt prevent it from being unscrewed

There are several ways to unscrew shear bolts and nuts:

- Using a gas adjustable wrench. Due to the ribbed jaws, adjustable degree of “tightening” and a fairly large lever, an adjustable wrench helps in most cases. This tool is not uncommon, so the first thing to do if you need to unscrew fasteners with licked threads is to try this method.

A gas (pipe) wrench is the best tool for loosening nuts - Make new edges. Smaller, but clearer. This will allow you to better grip the nut with the same adjustable gas wrench. The edges are made using a grinder. You must work carefully so as not to damage the surface under the nut/bolt head. This is a risky undertaking and should be used as a last resort.

- With a file. This method takes more time, but is safer. If there is no urgency, it is better to straighten the edges with a file.

How to use the extractor

If there is a plastic or rubber gasket under the bolt, remove it and try one of the suggested methods again. If you can’t unscrew a bolt with torn edges using all these methods, there is only one thing left: cut off/saw off the head and drill out the pin.