Concrete drill bits for drills: what and how best to drill concrete

When making holes in materials that are characterized by increased strength, which include concrete, brick, etc., drills for metal work are useless: their cutting part quickly becomes dull. In such situations, it is better to use a concrete drill, which is characterized by a number of distinctive properties when compared with those used for drilling metal.

Concrete drills

Types and parameters of concrete drills

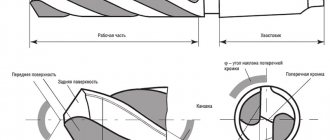

The peculiarity that distinguishes concrete drills is that their cutting part is equipped with tips made of a special alloy, the hardness of which is very close to the hardness of diamond. Due to its unique characteristics, this alloy is called “win.” Pobedit concrete drills are the most durable tool for processing this material.

Among concrete drills, there are two main categories:

- concrete drill bit for a drill, the design of which has a cylindrical or multifaceted configuration;

- a tool for working complete with a hammer drill, having a cylindrical shank, on which the designation SDS-plus or SDS-max is placed.

Drill shanks for concrete

Home craftsmen often have questions about how to choose equipment and tools for making holes in reinforced concrete structures. To solve this problem, a hammer drill with concrete drills for an impact drill is optimally suited. Drill bits of this type are often called drills and are divided into three main types:

- auger, with which you can drill holes of considerable depth;

- spiral-shaped (they can make holes of large diameter);

- flat, which allows you to obtain holes with small diameters and depths.

Drill bits for rotary hammers with different spiral shapes for dust removal

Thanks to such a design feature as a thickening on the shank, the drills are installed in the tool chuck by simply snapping into place. As a rule, they are chosen by professional builders and installation specialists to obtain holes with a diameter in the range of 4–30 mm.

In the event that the question arises about how to drill concrete, obtaining a hole of a larger diameter, choose a crown-type tool. It forms holes with a diameter of up to 12 cm. Core drills for concrete are also divided into several categories:

- diamond drills for concrete in the form of a tube or crown, which are fixed on a solid-section rod (diamond coating is applied to the working part of such a tool, which is why it is called a diamond drill);

- Pobedit drills, which have a similar design to diamond ones, but differ from them in the material used to make the teeth on the cutting part (these teeth are made of Pobedit).

Crowns for concrete

The need for a core drill for concrete arises if it is necessary to prepare seats for electrical sockets and switches, conduct communications and perform other work related to the need to obtain large holes and recesses.

The choice of drill for brick and concrete is also determined by the diameter and depth of the holes being formed. A diamond or pobedit drill can have the following diameter and length ratios:

Diameter to length ratio

In the table below you can see a simple pattern: the larger the diameter, the longer the length of the concrete drill. This is explained by the fact that a long and thin tool cannot withstand the perceived loads.

Drilling recommendations

There are several rules, following which will allow you to carry out drilling work on concrete as efficiently as possible.

- If you don’t know how to drill a concrete wall with a drill, stock up on different drills, including those designed for metal work. Each type of drill is designed to perform specific work: for brick - for drilling a brick wall, for concrete - for forming holes in concrete structures, for ceramics - for drilling surfaces finished with ceramic tiles. However, when deepening into the structure of the material being processed, the tool may rest against metal reinforcement, then it must be temporarily replaced with an appropriate drill. Some home craftsmen, when making holes in concrete structures, sharpen the drills they use so that they can also handle metal. However, in order to endow a drill bit with such versatility, it is necessary not only to have the appropriate knowledge, but also to have extensive experience.

- Under no circumstances should the concrete drill be allowed to overheat. It is necessary to take breaks every fifteen seconds and cool the instrument naturally, without using water or any other liquids.

- The structure of concrete necessarily contains hard stones, upon which the drill cannot move further. Such a stone must be crushed with a chipper and only then continue drilling.

- If you need to make a hole in a load-bearing concrete wall or ceiling, it is best to use a hammer drill, which will solve this problem as efficiently as possible.

- To drill a hole in a ceramic tile on a wall or floor, you must turn off the impact mode of the drill or hammer drill, otherwise the ceramic tile will simply collapse. When working with such surfaces, it is possible to use concrete drills.

- Inexpensive concrete drills made from a material that is not very hard should be sharpened periodically. To do this, you can use an angle grinder with a diamond blade installed on it.

The most popular brands of tools for drilling concrete

Drills that are used to perform concrete work are represented on the modern market by both foreign and domestic brands. Prices for such an instrument often depend on the reputation of the manufacturer who made it.

How to choose a drill for concrete? It should be understood that higher prices for these products are fully justified, given their guaranteed high quality and longer service life.

Concrete drills intended for professional use are distinguished primarily by their quality of workmanship

In the list of foreign companies that offer consumers high-quality concrete drills, the following manufacturers should be highlighted:

- Makita;

- Bosch;

- Metabo;

- stayer;

- FIT.

It should be borne in mind that the high-quality products offered by these companies are quite expensive.

General recommendations for drilling holes

It's a platitude, but many beginners hold the drill incorrectly. The tool must be positioned perpendicular to the surface and not move during operation. To make the task easier, use a special handle - it is sold separately or included with some drills.

How to drill correctly? The main point is that the material of the drill must be harder than the material of the surface being machined, otherwise it will not be possible to make a hole. We will discuss the choice of drill in detail below.

Not sure about your “eye”? Take care of accurate markings, and we advise both beginners and professionals to mark, because it is difficult to correct mistakes when drilling. To begin, cover the perforation areas with paper tape so that the tool does not slip, and mark the locations of future holes on top of it.

Drill misalignment is not allowed. The drill should lie comfortably in your hands and not slip out. Remember that this is not the lightest tool in terms of weight, and therefore, if you are not sure that you can hold it for the entire period of work, it is better to contact the experts.

At what speed should I drill?

RPM is the speed at which the drill rotates. You need to choose it based on the type of drill and surface material. Typically, the greater the hardness of the material and the thickness of the drill, the lower the speed should be, and vice versa.

If you have regular spiral-shaped drills, you can see some of the values in the table below; if you have non-standard drills, then read the manufacturer’s instructions or consult our specialists.

How to drill a hole straight?

The secret of how to drill correctly and evenly lies in the preparatory activities. We have already talked about markings and “backing” in the form of paper tape so that the drill does not move out, but there are a couple more features.

- Before work, check the sharpness of the drill. If it is uneven or the edges are dull, you will have to apply more force, it will be more difficult to make the hole, so it will end up uneven. Use only well-sharpened drills with smooth edges, then the perforation will be perfect.

- Sometimes the edges are unsightly because the drill bit is too thick. A little life hack: first take a thinner drill and make yourself a kind of mark - you will rest against it with a thick drill, and the work will become easier.

Drilling depth limiter

This is a small device that fits onto the working part of the drill and acts as a kind of “stopper”. If you need a hole of a specific depth, you are afraid that it will be larger than necessary, measure the distance with a ruler on the drill (the beginning is the cutting edge) and stick regular electrical tape on this place. Instead, professionals use cambric, but the essence of the device is the same: to make the drill thicker in a specific place so that the hole does not turn out to be too deep.

How to avoid getting caught in a wire?

How to drill a wall correctly so as not to get an electric shock and damage the wiring? First, inspect the place of work - are there any sockets, switches, or lamps nearby? If there is, the wire is definitely “hidden” inside the wall and goes to the nearest box. Ideally, it should be laid vertically, but in practice it can also be laid diagonally. How to bypass the wiring:

- In the place where you intend to drill, dig a hole 1-1.1 mm deep - usually the wires are located no deeper. A screwdriver or any other blunt object is suitable for this. If you don’t find anything, you can take up the drill, but don’t be too zealous at a depth of up to 2 cm - stop periodically and see if the wire is visible.

- The task can be simplified by special equipment that shows where the cables run in the walls. If you work with a drill often, it makes sense to look for it.

How to avoid dulling a drill?

The working element may become dull or even break if it is used incorrectly and not entirely for its intended purpose. For example, if you take a drill bit for soft wood to work on concrete, nothing good will come of it. Another risk factor is high rotation speed. In this case, the drill bit may become very hot and the tip will melt. To avoid this, reduce the speed, and if this is not possible, be sure to cool it with a special lubricant or machine oil - they reduce the friction force and, accordingly, the temperature of the drill.

Drill selection

There are different models of this tool, for example, there are industrial and household drills. Industrial ones cannot be used inside buildings - this is contrary to safety regulations. Plus, explore additional features and functionality. If you are going to drill cement, concrete or brick, you cannot do without a tool with an impact function. It turns the drill into a kind of hammer drill and makes it easier to make a hole. Why is that? These materials withstand pressure well, but crumble under shock loads. Therefore, drilling in normal mode occurs slowly, the drill heats up. When perforating with an impact, the tip of the nozzle seems to puncture part of the material, and indentations are formed with less force expended.

Choose the power depending on the intended use, but the minimum value is 600 W. The rotation speed is affected by the material being processed, but it is better if it is possible to smoothly regulate it. A useful function will also be reverse rotation - drilling in the direction and counterclockwise. Try to take a quick-release chuck - this simplifies and speeds up the process.

Drilling wood. Types of drills and features of their use

All photos from the article

When carrying out work on assembling various structures and repairing furniture and other products, it may be necessary to carry out such type of work as drilling wood. Despite the fact that this material is quite soft and pliable, it can not be processed with all devices; in this article we will look at the main equipment options and give recommendations for their correct use.

In the photo: drilling holes in wood is a simple process if you know all its features

Basic parameters to consider when choosing drills

If you have never carried out such work before and do not have experience in choosing devices, then just read a few simple recommendations to choose the best option. The most important factors are the following:

| Drill diameter | This is the main indicator on which a lot depends, for example, if you are laying a pipe, then a hole that is too small will not allow you to carry out this type of work, and if you are screwing in self-tapping screws, then a diameter that is too large will not ensure proper fastening reliability. It is necessary to use exactly the option that suits best, this is very important, and you should not guess by eye |

| Length of the product | This indicator is also important, since, unlike metal, you need to work with elements of large thickness; in some work you have to make holes about half a meter deep, which places special demands on the strength and durability of the tool. Therefore, you need to determine this parameter in advance so that when choosing a specific option, the seller could only offer solutions that would definitely suit |

| Hole type | When working, sometimes it is necessary to drill elements not through, but to a certain depth; in this case, options are often used that have a flat tip rather than a cone-shaped one. Most often, this need arises when drilling holes for furniture hinges, when the thickness of the material is small and it is important not to spoil it |

| Features of wood | The hardness of different types of wood varies significantly, so the load on the equipment when drilling oak will be much higher than when working with pine. In addition, one should take into account the fact that the chips that form during operation clog the drill, which can lead to overheating, so it is important to control this indicator |

Advice! You should not purchase the most budget options, there are many different products on the market, and the cost of many of them is simply negligible, but their reliability is so low, it makes sense to purchase them only if you need to make several holes; they are not suitable for serious work.

To drill holes for hinges, a special option is used - a Forstner drill, which has a special limiter, adjustable depending on the thickness of the material being processed.

Types of drills and features of their use

A wide variety of devices are used for work; we will look at the most common and popular ones and start with the simplest options that are suitable for small amounts of work; their price is low, so they are very popular among buyers.

Simple options

Here it is necessary to highlight the following types of drills:

- Very often you can hear the question whether it is possible to drill wood with a metal drill, everything is quite simple: metal is much harder than wood, so this type of device can be used for these purposes. But here you should remember several important nuances: the quality of work will be low, especially if the drill is poorly sharpened, it will tear the fibers on the side where it goes against the structure, also due to the fact that the turns become clogged with chips, the element may overheat and become deformed;

Don’t know the difference between drills for metal and wood? First of all, by the configuration of the tip, it is very easy to distinguish one option from another

For information: In the photo above on the left is a drill for wood, in the center is for metal and on the right is an option for concrete. As you can see, the tips of the products differ very much.

- Spiral options are in many ways similar to the above-described option in their design, but they have a different tip - it has a centering tip, which prevents the drill from moving from a given point and ensures high accuracy of work. They are suitable for simple work and have small diameters;

There are protrusions along the edges that cut the fibers, which allows you to avoid tearing the wood and ensures high quality work

- Feather versions got their name due to the fact that their working part is flat, the tip is similar to the one described above - it also has a protruding point and two protrusions along the edges for trimming fibers. The shank most often has a hexagonal shape for easy mounting in drills and other power tools. The diameter can vary from 8 to 60 mm, which allows you to make holes for a variety of purposes;

Is it possible to lay laminate flooring on old parquet?

Is it necessary to disassemble it in such a situation or can you put laminate on the old parquet? ... There are no contraindications to laying laminate flooring on parquet, but there are conditions that must be met in order for the new floor covering to look beautiful and last a long time.

Drills for wood, metal and concrete. How to distinguish

Sources:

https://armtru.ru/mozhno-li-sverlom-po-betonu-sverlit-derevo/

Is it possible to drill wood with a concrete drill?

» Articles » Is it possible to drill wood with a concrete drill?

All photos from the article

When carrying out work on assembling various structures and repairing furniture and other products, it may be necessary to carry out such type of work as drilling wood. Despite the fact that this material is quite soft and pliable, it can not be processed with all devices; in this article we will look at the main equipment options and give recommendations for their correct use.

In the photo: drilling holes in wood is a simple process if you know all its features

Learning to drill walls

- Log in to reply to this topic

#1 Weselova

- Participants

- 572 messages

- Top

#2 Anyuta

- Top

#3 Elena

You can go to a large hardware store and explain what you are going to drill. They will advise you on what kind of dowel and drill you need. It’s better to take a few dowels and a set of checked ones; it will still be useful on the farm. For hanging planters, I used a dowel with a hook. Drilling in a horizontal position is very difficult, so it’s better to ask your husband.

- Top

#4 Elena

- Top

#5 Kroky

- Top

#6 Elena

Weselova, glad to help.

- Top

#7 Kroky

- Top

#8 Elena

- Top

#9 Weselova

- Top

#10 Chapa

It's cool here. Weselova, drill a brick, you say? Have you purchased a PERFORATOR or at least an IMPACT DRILL? Creating a hole in wood, plastic, metal is done by CUTTING. The sharp edge of the drill precisely cuts off the layer of material. And a completely different principle when creating a hole in concrete or brick. A pobedite drill is not so much a drill as a chisel that crumbles the material, and then, due to rotation, these crumbs are removed from the hole along the auger. And you can twist a Pobedit drill bit into a brick - there will be no hole. It is necessary to hammer.

Kroky, usually a core is used to mark future holes in metal, this won’t really help a brick wall (the hammer will mark itself due to the first blows with light pressure, the main thing is a steady hand and a heavier hammer), but the core can get worse (if it’s under-heated, it will immediately become dull, if it’s overheated, it will become dull). will chip, the core is intended for plastic materials. Try putting a mark with a core on titanium or, even better, on a bearing ball.)

- Top

#11 Weselova

- Top

#12 Kroky

Chapa (25.6.2006, 11:54) wrote:

- Top

#13 Chapa

Kroky (26.6.2006, 14:47) wrote:

Yes, it seems, core punching is done so that the drill does not creep to the side when starting to drill hard material (metal), because the tip of the drill is not a needle, but when drilling chipboard, MDF and plastic, the slightest pressure - the drill penetrates into the material, and the process begins.

Somehow the thought never even occurred to me that I needed to core chipboard, MDF and plastic.

Weselova, well done! I respect you.

- Top

Is it possible to drill metal with a concrete drill?

» Articles » Is it possible to drill wood with a concrete drill?

All photos from the article

When carrying out work on assembling various structures and repairing furniture and other products, it may be necessary to carry out such type of work as drilling wood. Despite the fact that this material is quite soft and pliable, it can not be processed with all devices; in this article we will look at the main equipment options and give recommendations for their correct use.

In the photo: drilling holes in wood is a simple process if you know all its features

How to drill concrete, metal, tile and wood

Drilling a hole in the wall may seem like a piece of cake. However, if you choose the wrong tool for a particular surface material, the drill may become dull or even break, and scratches and cracks may appear on the surface. To prevent this from happening, you need to know certain nuances of doing the work. How to drill, how to properly prepare the surface and select a drill, we will consider further.

Source: https://ooo-asteko.ru/mozhno-li-sverlom-po-betonu-sverlit-metall/

Is it possible to drill wood with a hammer drill - All about timber and woodworking

A rotary hammer is a screwdriver, drill, jackhammer and construction mixer in one tool. How to use a hammer drill in different modes, what materials can it work with, and how to properly care for this tool?

A hammer drill is a versatile electric tool that can perform many tasks. With its help, you can drill holes in hard surfaces, tap walls, and also work in chipper mode. At the same time, the safety of the work carried out corresponds to a high level, and even a person far from the construction industry can learn how to use a hammer drill. From this article you will learn how to drill various materials with a hammer drill, prepare it for work, and also care for it.

What materials is the hammer used for?

Can a hammer drill drill into wood, metal or tile? Is this tool used as a concrete mixer? Many people have similar questions before buying a hammer drill. After all, you want to get the most out of an impact drill. Therefore, below are all the functions of the rotary hammer with brief explanations for each of them.

Rotary hammer functions

Drilling tiles. The drilling site is marked, and a hole is drilled at low speeds using a special drill for tiles without impact mode. Having reached the wall, the drill changes.

How to make a hole with a drill

First you need to prepare a drill, attachments and other related items. Then, while working, you won’t have to be distracted and waste time looking for the right things.

Drilling is often necessary in cases where:

- rough finishing;

- wiring;

- plumbing installation;

- concreting communications.

In this case, the concrete wall (if drilled ) should remain without severe damage or large chips.

When working with a drill with a pobedite bit, sometimes you need to use a metal punch. It is selected according to the size of the hole. This tool allows the drill not to jam when deepening the drill. To do this, the punch is driven into the concrete and driven with a hammer to split the solid obstacle into pieces. This process can take quite a long time, so it is better to use a diamond crown. In addition, a drill with such an attachment will never get stuck in concrete.

Sequence of actions when drilling:

- Carefully inspect the instruments. The drill must be in good condition, and the drill must be intact.

- Begin to carefully drill a hole in the concrete with a drill, stopping the continuous operation of the tool after 10 minutes from the start of action.

- The process can be continued only after the engine has cooled.

- Before drilling the next hole, it is necessary to moisten the nozzle with water. This will protect the metal from bending.

Using these simple methods you can drill a concrete wall without a hammer drill.

Sometimes there are cases when the drill gets stuck in the wall. It is not advisable to use force in this case, otherwise it will break off and the edge of the nozzle will remain in the concrete. To free the drill , you must first disconnect it from the drill, then put on a bit of a smaller diameter and remove the stuck part.

To perform drilling yourself and at the same time avoid various injuries and unpleasant incidents, you need to follow safety precautions and follow the recommendations of specialists.