Steel rope

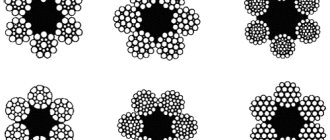

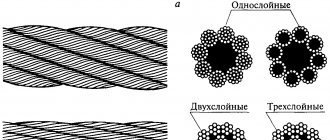

Based on the combination of directions of laying of wires in strands and strands in ropes, one-way and cross-laying ropes are distinguished. In one-way lay ropes, the winding directions of the wires in the outer layer of the strands and the strands in the rope are the same. In cross lay ropes these directions are opposite. One-way laid ropes have a smoother surface, their cross-sectional area is better filled, they are more flexible and durable due to the increased contact surface of the wires with the surface of the block or drum. Their service life is 25-50% longer than the service life of cross lay ropes. In cross lay ropes, the outer wires of adjacent strands come into contact at separate points, which increases contact stresses, increases wear and reduces the durability of the rope.

Single lay and cross lay ropes

Due to the tendency to untwist under the influence of a tensile load, single-layer ropes are unsuitable for use in cases where the load is freely suspended on one branch. In these cases, cross lay ropes are used, and one-way lay ropes are used when the load moves in the guides or when using movable blocks that prevent the rope from unwinding. Due to greater structural strength, that is, better retention of shape under the influence of external radial load from the upper layers, cross lay ropes are used not only for single-layer, but also for multi-layer winding on a drum.

The lay direction is of great importance when winding the rope onto a drum. For each revolution of the drum, the rope shifts by the size of its diameter and the bending deformation of the rope is supplemented by torsional deformation. Depending on the adopted direction of rotation of the drum, as well as depending on the direction of lay of the rope strands, torsional deformation can reduce or increase its twist. To increase the density of the rope and extend its service life, you should select the winding direction so that the rope is additionally twisted during operation. The direction of lay of the rope, depending on the direction of laying its turns on the drum, must be chosen, as shown in Figure 1. When securing both ends of the rope to the drum, the direction of lay of the rope can be taken in any direction.

Selecting a rope according to lay direction

Rice. 1

Operating practice recommends the following rope designs for their use in cranes as lifting and traction elements: ropes with an organic core LK-R 6x19 (GOST 2688–80), LK-RO 6x36 (GOST 7668–80); ropes with a metal core TLK-RO 6x36 + 7x7 (GOST 7669–80) and LK-Z 6x25 + 7x7 (GOST 7667–80).

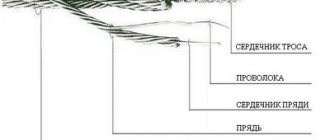

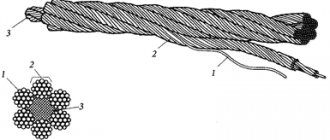

In order to improve the quality of steel ropes, factories began producing radially crimped strands of ropes for lifting machines (Fig. 2). When making ropes, a strand twisted from wires of round cross-section is passed through a die, as a result of which the wires of the strand, being plastically deformed, lose their round shape and the linear contact between them becomes contact along the surface, the supporting surface of the strand and the degree of filling of its cross section increase.

Steel rope made from radially crimped strands

Rice. 2

Compared to traditional construction, these ropes are characterized by high density and uniformity, increased wear resistance of wires, increased tensile strength by 12-15% and increased durability by 30-50%.

Advantages of steel ropes

The advantages of steel ropes, which ensure their predominant use in lifting machines, are smooth and silent operation at any speed, flexibility in all directions and reliability in operation (since the degree of wear of the rope can be determined by the number of broken wires), and relatively low weight. The significant elasticity of steel ropes significantly reduces dynamic loads during starting and braking due to the damping of shocks perceived by the metal structure of the lifting machine and the lifting mechanism.

Disadvantages of steel ropes

The disadvantage of steel ropes is their relatively short service life, increasing the length of the ropes during operation. The need to use large-diameter drums leads to an increase in the gear ratio and the total weight of the machine.

Parameter No. 4 - Type of rope core

This parameter is not mandatory, but it is also recommended to observe it, since the core gives the rope a certain torsional rigidity and increases the breaking load of the rope as a whole.

- FC

- fiber core (some manufacturers do not distinguish between organic and synthetic cores); - NFC

- organic fiber core; - SFC

- synthetic fiber core; - FC(R)

- fiber reinforced core (the base of the core is metal with fibers woven into it, usually synthetic); - ( I )WRC

(another name for

WSC

) is a steel wire core of a separate lay; - EIPWRC

- based on a metal core, but at the same time it is in a plastic shell, which protects against excessive friction and corrosion.

Operation of steel ropes

To increase the durability and reliability of ropes, the possibility of them falling off blocks and drums, moving beyond the established dimensions and chafing due to contact with structural elements or with other ropes must be excluded.

The ropes of lifting machines transporting molten metal must be protected from direct exposure to heat and metal splashes by installing reflective covers. Premature wear of ropes and their damage can occur as a result of incorrect choice of rope design, type and direction of lay (see types of lay), incorrect winding on the drum, incorrect choice of the ratio of the diameters of the rope and the drum or block, the profile and size of the block thread and drum grooves, overloads, excessive dynamic effects on the rope, abrasive wear and corrosion.

When choosing a rope, you must keep in mind that if it is made of thick wires, it has increased rigidity, but has good resistance to abrasive wear. With a decrease in the diameter of the wires, the flexibility of the rope increases, but at the same time the wear of the wires increases, its structural strength decreases (especially with multi-layer winding), and the service life is reduced.

Parameter No. 6 - Minimum breaking force of the rope as a whole

In certificates from various imported steel rope manufacturers or in passports for load-lifting cranes, this characteristic is usually indicated in two ways:

- MBL

(Minimum Breaking Load) - minimum breaking force of the rope as a whole - or MBF

(Minimum Breaking Force) - minimum breaking force.

These concepts are absolutely identical.

This characteristic is indicated in kiloNewtons and depends on the marking group of rope wires. When selecting an imported rope, it must be no less than what is indicated in the passport for your crane.

Also, if the rope is subject to severe wear, or is intended to work in an aggressive environment, we advise you to consider a rope with a PVC sheath.

Wire rope wear

To reduce wear on the rope and protect it from damage, during storage and operation the ropes are coated with a protective lubricant. Typically, rope lubricants 39u and Torsiol 35 are used as lubricants, and for ropes of especially critical mechanisms - Torsiol 55. These types of lubricants have good adhesion, are not removed during operation, penetrate to the center of the rope and strands, have the ability to cover the surface of the rope with a thin film and harden quickly, do not evaporate or harden over time, do not contain alkalis, acids and other elements that cause corrosion.

The rate of rope wear is determined by the number of broken wires in the outer layers of the strands over the length of one lay step and is established according to the rules of Gosgortekhnadzor. If the standards are exceeded, the rope must be rejected and replaced. The number of broken wires is determined either by visual inspection or by using an electromagnetic flaw detector, the operating principle of which is based on local magnetization of the rope through the creation of a longitudinal magnetic field by a special device. When the cross-section of the rope changes (for example, due to broken wires), a dissipation flow is formed, which excites an electromotive force in the measuring coil, which is recorded by the device. The measuring coil is designed in such a way that it perceives only the radial component of the magnetic field intensity. Most devices use several measuring reels or half-reels, which makes it possible to determine the depth of the defect inside the rope. The electromagnetic testing method also makes it possible to detect hidden defects: breaks and breaks of individual wires, corrosion, and so on.

Parameter No. 1 - Direction of lay.

This is one of the most important parameters. If the laying direction is not observed, there is a high probability of rope failure (for example, “Cage”, which we wrote about in our previous article https://strop-arsenal.ru/blog/prichiny-vybrakovki-gruzovyh-i-strelovyh-stalnyh-kanatov- gruzopodemnyh-kranov)

- sZ = cross right lay;

- zS = cross left lay;

- zZ = one-sided right lay;

- sS = single-sided left lay.

The small letter shows the direction of the lay in the inner layer of the strand, and the large letter shows the direction of the lay in the outer layer. The lay direction is determined from top to bottom.

How to choose the right rope?

The choice of rope primarily depends on the conditions in which it will be used. Therefore, the buyer first needs to decide what type of rope he wants to buy. In this case, the choice must be made taking into account the technical and mechanical characteristics of the cable.

Next, you will need to decide on the thickness and length of the cable, especially since today many companies can offer such products in the required sizes.

In addition, the choice of rope for loading or other mechanisms is determined by technical documentation, which precisely indicates the length, thickness, type of lay and other qualities of the product used in this unit. The client just needs to indicate the rope code (according to GOST) in the application, and the manager will send the required product to the specified address.

You can place an order for any type of cable in ours. If you need to buy hemp, jute or sisal rope, you can place an order on our portal.

For additional information about the characteristics and properties of cables, please contact our consultants, who will be happy to answer all your questions.

Examples of markings for imported ropes:

Steel rope FlexPack 34(W) x K7 WCS

Steel rope DRUMET 6x36WS+IWRC

Steel rope 6xWS36+IWRC, 1960 N/mm2, B-sZ

Steel rope 35×7, 1960 N/mm2, U-zZ

In this article, we have indicated the main six parameters that you should pay attention to when selecting imported steel rope. A correctly selected imported rope will serve you for many years.