Cold welding "Almaz" - a series of adhesives. The manufacturer offers several types: for plumbing products, wooden materials, automotive parts, metal elements. The work can be done independently. It is possible to connect oiled and wet parts. The product is not intended for use in industrial environments.

Advantages and disadvantages of Almaz cold welding

Competitive advantages of glue:

- versatility of use in everyday life;

- the possibility of using glue if there is no experience working with such substances;

- no need for additional tools and equipment;

- packaging in tubes with different volumes (you can purchase a suitable type of adhesive);

- relatively low price (compared to analogues);

- unpretentiousness in transportation and storage (no special storage conditions are required).

When using Almaz cold welding adhesive, users encounter the following disadvantages:

- after the composition hardens, there is a high probability of breakage of the dried mass, because she is too fragile;

- Can only be used at home, because Almaz cold welding is not intended for use in production and industrial environments.

- there is a possibility of lumps forming in the adhesive during use, which will negatively affect the reliability of the connection;

- the substance sticks strongly to unwetted surfaces;

- relatively short service life (especially under negative operating conditions).

Precautionary measures

To avoid skin irritation, work with the liquid composition should be done with gloves. If the composition gets on open areas of the body or mucous membrane, immediately rinse the contaminated areas with water. The glued parts should not be subjected to loads until the resin has cured. If you heat the composition, it will harden faster. Welds produced by this method do not have the same high characteristics as those achieved with conventional welding. Their permissible tensile stresses are much lower. Therefore, there is no need to subject the products to tearing forces.

Characteristics and properties

Cold welding "Almaz" includes:

- epoxy resin;

- hardener;

- mineral filler;

- metal filler.

The following performance characteristics of the Almaz universal cold welding can be distinguished:

- Application temperature (recommended by the manufacturer): +50° C.

- Hardening: 20 min.

- Hardening: 24 hours.

- Brinell hardness: 120.

- Maximum operating temperature: +145° C.

- Peel strength: 120 kg/cc.

Bonding technology

The use of glue (gluing technology) can be divided into three main stages.

Surface preparation

This stage includes cleaning from dust and dirt. The metal surface is treated with sandpaper: rust will not provide reliable adhesion. After cleaning, the bonded surfaces are degreased.

Preparation of the adhesive composition

Mixing the glue components is the most important step. To mix the ingredients you will need a small container, a wooden or plastic spatula, and two syringes.

General mixing recommendations:

- It is recommended to heat the resin to 30–35 °C to make it more fluid.

- The resin and hardener are drawn into two different syringes.

- The two components in the required proportion are squeezed into the prepared mixing container, where they are thoroughly mixed.

- When preparing glue in large volumes, the hardener should be added gradually, constantly stirring the resin. Here you cannot do without heating the resin, since it is easier to mix air bubbles out of the liquid composition.

Gluing process

To glue two elements, glue is applied to one of the parts with a brush or other object. The halves are connected and pressed against each other with medium force for 10–15 minutes for initial setting. After the glue has completely hardened according to the instructions (from 2–3 to 12 hours), the product can be used.

When sealing cracks in the floor or other surfaces, glue is poured into the crack and left until it hardens completely. When repairing pipes, the damaged area is thickly coated with epoxy, after which the pipe is wrapped with fum tape or a strip of fabric, which can also be coated with glue.

Almaz cold welding classification

Cold welding of the Almaz-press series has high adhesion rates with different materials

(wood, metals, ceramics, plastic, etc.). The manufacturer produces the following types within the series:

- "Universal". Suitable for joining metal and non-metal parts and products. Can be used for repair work in hard-to-reach places.

- "For woodworking." The composition allows you to firmly connect and fix various types of wood, plywood, veneer, bars and other wooden materials. Can be used for repair and restoration work on furniture. Has a natural wood tone.

- "For plumbing repairs." Used to restore ceramics, earthenware, porcelain and other materials from which plumbing fixtures and decorative elements are made. It has a white tint, which allows you to hide the places where repair work is being carried out.

- "To repair a car." Used for sealing cracks, eliminating chips, restoring threads, sealing various surfaces, and fixing decorative elements on car surfaces.

- "With steel filling." This type of Almaz cold welding contains steel filler. The substance is used for gluing metal products (cast iron, steel, copper, aluminum and other types of ferrous and non-ferrous metals).

general information

Almaz cold welding is produced in polymer cylindrical tubes. The glue is additionally protected by cellophane. The manufacturer produces tubes of different sizes for consumer convenience.

Application area

Cold welding "Almaz" according to the instructions has the following scope of use:

- Connecting wooden, ceramic, plastic, concrete, glass, metal parts.

- Connection of products, parts and surfaces made from different materials.

- Elimination of leaks in pipelines, containers, tanks.

- Repair of garden and sports equipment.

- Repairs in hard-to-reach areas or when it is impossible to dismantle or disassemble equipment and structures.

Disadvantages of Mastix

- The drying time is a little higher than other brands, so there may be some problems when working with it at different temperatures;

- During preparation, lumps may form, which reduces the quality of the connection and may lead to the need for rework.

Application area

Mastix cold welding for metal is used both at home and in various professional repair procedures, depending on the type of material. It is mainly used as ordinary glue, which should connect metal, wood, plastic, stone and other things that are difficult to glue

An equally important function is the repair of pipelines, various containers, car parts and other things. By applying a plastic mass, cracks can be sealed, penetrating into the internal parts

Cold welding Mastix for metal

If the product is not used at temperatures above 150 degrees Celsius, then it can repair chips, restore parts and perform other repair procedures. The main thing is to withstand the time it takes for the cold weld to dry, after which you can put the part into operation. The strength properties here are not so strong as to withstand strong impacts, but vibration loads, which are often found in moving mechanisms, are tolerated quite normally.

Compound:

- Mineral fillers;

- Metal fillers;

- Amine resin;

- Epoxy resin.

Kinds

For metal – it has a metal filler in its composition, which improves the quality of connection with metal surfaces. It tolerates contact with moisture well, so it can be used in plumbing repairs. It is not highly sensitive to surface cleanliness, so it can be used with wet and oily parts.

Cold welding Mastix for metal welding

Universal - the mixture is used for quick repair of any surfaces. Has a wide range of operating temperatures. This is the most popular and frequently used option that may be needed in every home.

Universal cold welding Mastix

Heat-resistant - this cold welding has the highest destruction temperature, which is 250 degrees Celsius. It is used to join metals, both ferrous and non-ferrous, used in thermally active applications.

Heat Resistant Cold Welding Mastix

For plumbing – glue is used for working in damp conditions. Most often, this is a plumbing repair that requires high moisture resistance and the ability to withstand work under pressure. Connects metal, porcelain, can be used to restore carvings, and so on.

Cold welding Mastix for welding plumbing fixtures

Cold welding Mastix fast steel - contains a steel filler, which improves the quality of the connection and the restoration of lost elements with steel.

Cold welding fast steel Mastix

Mastix cold welding for aluminum – contains aluminum filler, which makes the connection to this metal stronger.

Cold Welding Mastix for Aluminum Welding

Properties and characteristics of Mastix

Before using Mastix cold welding, you should study its characteristics:

| Parameter | Parameter value |

| Package weight | 55 grams |

| Minimum operating temperature | -60 degrees Celsius |

| Maximum operating temperature | +150-250 degrees Celsius |

| Storage temperature | up to +30 degrees Celsius |

| Drying start time | from 7 minutes |

Features of use

Instructions for use of Mastix cold welding require adherence to all rules. At the initial stage, you need to clean the surface on which you will work.

After this, you need to cut off the part that you will use from the total mass. Here it should be taken into account that both components are equal. After this comes kneading and application to the surface. Next, you need to wait from 20 minutes to an hour for everything to set securely.

Rules of application

Instructions for using the adhesive:

- Cleaning from dirt, degreasing, sanding joints.

- Mixing the glue components together (you must use gloves soaked in water) - you need to get a mass of a uniform shade. The composition must be warmed in your hands so that it becomes sticky and plastic.

- Applying glue to the elements to be joined, fixing them for 15-20 minutes with a tourniquet or clamp.

The adhesive will harden within 60 minutes - it can be painted, threaded,

drilling and other types of processing. Maximum strength of the adhesive will be achieved 1 day after application (constructive loads are allowed).

If work is carried out on a wetted surface, it is necessary to press and smooth the composition until it begins to stick or until it stops flowing. To speed up the hardening of the glue, it is recommended to heat the joint area (this approach will improve the reliability of bonding surfaces). To ensure heating, it is recommended to use a regular hair dryer to dry your hair.

Work on applying Almaz cold welding must be carried out in a ventilated area or in rooms with good ventilation. Gloves are required. If the substance gets on your skin or eyes, rinse them with cold running water. If necessary, consult a doctor.

How to use?

Almaz glue should be used according to the following scheme:

- Prepare the surface (clean and degrease, preferably sand).

- Separate the required amount of glue (in equal proportions from the inner and outer parts).

- Knead thoroughly until the mass acquires a soft consistency.

- Fashion the necessary parts, distribute them in place of the hole, going to the edges, or distribute them in a thin or medium layer and press the parts to be fastened.

Advice! It is recommended to mix the components with each other while wearing gloves, wetting them in water. Then the glue will not stick to the rubber or leave an unpleasant odor on the skin.

After completing the repair work, it is recommended not to subject the part to loads for 24 hours. The remaining part of the consistency should be wrapped in film, secured on top with an elastic band and placed in the package.

Using the product, you can perform minor repairs on items that are out of order. By following the recommendations for using glue, it will not be difficult to carry out quality repair work.

General recommendations

There are many ways to fix a radiator leak available to the owner, and he can choose the most suitable option based on the equipment available. However, the above recommendations make it possible to urgently solve problems in the winter season, when it is not possible to turn off the heating system for a long time and carry out major repairs of heating devices. It is quite natural that homeowners have a question: the heating battery is leaking, what to do in the summer? Having survived the winter with a hastily patched radiator, in the summer you should remove the battery from its mounts, inspect for damage and carry out a number of measures:

- remove old patches;

- clean leaks with a wire brush;

- treat cracks and holes with a grinder and a cleaning wheel;

- eliminate the defect by soldering or welding.

Next, you should paint the battery (you can read about paint for radiators here) and install it in place

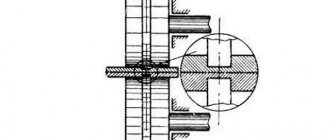

In this case, it is important to follow the installation rules - use tow, FUM tape, high-quality shut-off valves and pay special attention to the joints

Having installed the battery in the circuit, it is worth filling the system with water and checking the tightness of the heating device

It is important to carry out this step while the boiler is running, since the circulation of coolant under pressure can reveal leaks and weak points in connections. If no leak is detected during intensive use of the heating system during the day, then the problem can be considered solved

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

How to properly drain water from a heating battery? Effective flushing of the heating system: methods and recommendations Pressure testing of the heating system with air according to SNiP standards What is pressure testing of the heating system and when is it needed?

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts