[Artistic metal engraving] can add special value to an item.

Firstly, most often, such work is performed individually, you become the owner of an exclusive item.

Secondly, the artistic engraving looks very beautiful.

Thirdly, you can do it yourself, at home. Engraving is the application (transfer) of a design onto a metal object.

How to make engraving on metal at home, what tool or machine is needed? What is the price of engraving tools? You will learn about this in our article.

Assembling an electric engraver with a tripod and flexible shaft

An electric engraver is the most common type of this type of tool at home. To make a functionally complete device yourself, capable of competing with industrially produced analogues, you will need an electric motor that runs on 220 V alternating current. Such electric motors can be taken from the following equipment:

- Soviet-style reel-to-reel tape recorders;

- DVD players;

- washing machines;

- angle grinders;

- electric sewing machines.

The last option is optimal because it is possible to adjust the speed over a fairly wide range using the built-in rheostat.

Holding an electric motor from any of the listed types of equipment in one hand is inconvenient, and in most cases it is simply impossible. Therefore, you will need a flexible shaft for the engraver. In this case, the general view of the future device will turn out approximately as in the photo below.

The functionality of the created engraving device will depend on the materials and mechanisms used during assembly. The motor can be placed on a table, but it is more convenient to make a tripod for the engraver, or rather something similar.

Manufacturing of flexible shaft

With a flexible shaft everything is relatively simple. It can be done in several ways:

- from an old drive shaft, for example, from a dental drill;

- using the speedometer cable of a motorcycle or car.

The working attachment on the shaft can also be used from a drill or made independently from different materials, for example, wood, textolite, plastic pipes. A device (handle) for holding the equipment is made from textolite as follows:

- cut 2 textolite platinums (sheet thickness should be about 1 cm) measuring approximately 2 by 10 cm;

- connect them together and grind them with a file or emery from the outside to form a cylinder;

- grooves are machined from the inside;

- metal rings secure the parts to each other;

- a tube is inserted into the front part of the handle, under a cartridge consisting of two separate halves connected with a bolt.

The end result will be a handle like the one in the photo below.

Assembling the engraving unit

It’s very easy to make a tripod (a base for installing an electric motor) from plywood or the same PCB. To do this, do this:

- cut out several pieces (4 are enough) from a sheet of material corresponding to the size of the electric motor;

- a motor is attached to one of the fragments using clamps;

- assemble the box;

- A hole is drilled in the front part for the flexible shaft.

The created structure is hung on the wall.

It is convenient to use a factory holder on clamps for an engraver, if the dimensions of the electric motor allow. The mount connects to any table. But such a device will need to be purchased additionally.

Further assembly of the engraving device is carried out in the following sequence:

using a coupling made from a drilled bolt, connect the cable to the electric motor shaft;

put a rubber hose of the appropriate diameter on the cable and attach a handle made to it;

- install a start button;

- connect equipment to the network;

check the functionality of the device made.

When creating homemade straight grinders, you can also use electric motors designed for 380 V, but if they can be adapted for 220 V. In such cases, you will need to tinker a little more. There is a lot of information on this issue both on the Internet and in books on electrical engineering.

How to make it at home with your own hands?

Engraving on metal can be done not only in a special workshop, but also at home. Regardless of the conditions in which the work takes place, the main priority is to obtain a quality product. If you plan to do the work yourself, then the best option would be to purchase a special tool known as an engraver.

The process of processing a product at home consists of several steps.

- Before starting work, it is imperative to prepare an image or inscription. The product is placed using a marker, or you can outline the contours using a sharpened pencil.

- Engraving requires close attention. Any work can only be carried out if the room is sufficiently lit. Otherwise, you can not only damage the product, but also get injured during the metal finishing process.

- After all engraving work is completed, the surface that has been processed must be coated with a special varnish. If this is not enough, then to obtain the most lasting result you need to use wax, which is applied in a small layer.

Engraving on metal at home can also be done using electrochemical action. To carry out the work, a set of tools that any person has at hand can be used.

- The container used must fully match the dimensions of the product itself. The metal object should fit into the container without any problems, the neck should not stick out. If the product is not large in size, then a faceted glass can be used. Today, a glass jar continues to be the best option.

- Wires for connection with clamps. An excellent option would be to use household clothespins.

- A regular mobile battery will be sufficient.

Another fairly effective way to engrave metal at home is to use a drill. It should be noted that this tool is quite expensive, so it is worth buying it only if the processing will not be carried out on a one-time basis.

When using such a tool, its working part is capable of effectively removing a layer of metal using a special attachment. It is usually offered as a kit. Do not use the tool on the material immediately. It is best to try it on various workpieces.

In addition to the drill, you can use other equipment. For more than 5 thousand years, humanity has been inventing various devices capable of processing metal.

A distinctive feature of home laser engraving is that it can be carried out in combination with a paste solution. It is usually applied to the material before engraving begins. This must be done carefully so as to only touch the area being treated. An image or inscription is burned using a laser. This happens due to a change in temperature, which becomes possible as a result of a chemical process. This method is very effective and fast, however, its cost is quite high, so there is no point in purchasing such a device if you need to carry out a one-time engraving.

Thus, metal engraving allows you to put an image or inscription on an object, radically changing its appearance. There are many engraving methods available, each with its own strengths and weaknesses. The choice of a particular method depends not only on the skills of the person, but also on the characteristics of the material used.

Review of professional attachments for engravers

Professional tools constitute a separate (high-quality and expensive) category of equipment that can withstand significant operating loads without negative consequences. It is customary to equip such devices with appropriate consumables.

Experts who professionally engrave various materials recommend purchasing sets of attachments from well-known brands, such as Dremel or Dexter.

. The significant cost of the products of these companies is fully justified by the fact that their products are reliable, high quality and durable. The use of burrs for wood, metal and other materials produced by these companies increases the accuracy of workpiece processing.

Often, specialists have several sets of equipment designed to process different materials and perform various operations. Also, the individual elements that make up them have their own design features. Typically these sets include:

- cutters for metal, wood and other materials, of various designs;

- drill;

- felt, diamond, and abrasive cutters;

- wire brushes for cleaning surfaces;

- engraving rods;

- cutting discs.

The kits also include a straight edge cutter.

Straight edge cutter Topfix

Replacement equipment of the Dremel and Dexter brands can be used not only by workshop specialists, but also by home craftsmen who want to improve in the art of engraving.

Some engraving artists recommend products

, lower quality than Dremel or Dexter, but cheaper. The set can include up to 180 units of consumables of popular varieties. But products from Zubr, in general, fall into the semi-professional and household categories.

Typically, a milling attachment for an engraver is included with the purchased tool. But with constant use, it wears out over time. Also, cutters may be needed for specific operations - then you need to buy new burs in order to continue working with the Dremel.

The ideal option is to purchase products recommended by the engraver manufacturer.

In such cases, the warranty from the companies for the device in use is retained. But it happens that original consumables cannot be obtained for some reason, or they will be very expensive given the small volume of upcoming work operations. Then you will need to purchase analogues or even use homemade ones. In this case, the main rules of choice are as follows.

- the shank diameter

suitable for the Dremel chuck : most often it is 2.4 or 3.2 mm. - You need to purchase attachments for metal and other materials depending on the type of work you plan to perform.

- To engrave, you can also use inexpensive kits

, for example, made in China or Russia. - For constant, long-term work with a mini-drill (especially with hard materials), it is recommended to purchase high-quality, professional sets, and for occasional engraving, household ones are sufficient.

When learning various Dremel operations, inexpensive products are suitable. Over time, they should be abandoned in favor of better quality equipment.

Making a gravel for engraving on metal

Making a serger of the simplest design is possible for a home craftsman with metalworking skills. To do this, take as a basis:

- file or needle file;

- spring leaf;

- part of the bearing race.

The main thing is that the steel is high-strength and elastic. Strength is necessary for the graver to successfully cut the metal of the workpiece, not become dull for a long time and maintain the specified sharpening shape. Elasticity will allow the tool not to break under load.

A higher-quality cutter can be obtained by forging, but for this you must have good blacksmithing skills and have a forge. A file made from a needle file will be noticeably inferior to a forged one in both strength and flexibility.

Before you start sawing and forging metal, you should build a drawing of the tool. You will need not only a large-scale image of the cutter itself, but also a drawing of the handle.

General technology

The technique can be manual or mechanical (various equipment is used).

It is also divided into line and armor:

- The line engraving technique is performed by applying contour lines and strokes to an object. Metal carvings are not deep, affecting only the surface of the object;

- Defensive, otherwise called three-dimensional, mechanical deep technique allows you to achieve a three-dimensional pattern. See photo.

Incisive engraving is performed with a special tool – a graver.

If you ask yourself how to make it yourself and where to buy these tools, then the answer is simple: this tool is sold in the same stores where you can find various art supplies.

The finest lines are made with a Messer-Stichel. If you need to make parallel lines, they are made with a rap pen.

Photo:

To perform high-quality work, this tool must be sharpened; for this, a fine-grained whetstone is used, which is pre-moistened with water or oil.

The graver is brought “to readiness” with a leather product (you can take an old belt) coated with chromium oxide.

Manual processing of small items at home requires the presence of a special pillow; you can easily make it yourself: take two pieces of fabric of the same size (round or square), sew them together along the edge, stepping back from it a little, but you need to leave a small gap in order to so you can pour sand inside.

The cushion engraving tool is ready.

How to properly hold the instrument in your hand?

This should be done as if you were holding a regular ballpoint pen: the index finger should be on top of the blade (that’s what the metal part of the cutter is called), and the thumb should hold it on the side.

Work must be done on your own.

In the case when you need to change the direction of the pattern, unfold the pillow with the object on which the element is being applied, but do not change the direction of movement of the hand.

What else is useful to know about incisors?

To do your own engraving at home, it is advisable to first practice so that the carving turns out beautiful in the end.

It is better to purchase a set of tools: it is better to apply rounded lines with a square section of cutters, and it is better to make straight lines with a round section.

You can make the scraper yourself. To do this, you will need a file, from the edges of which you need to grind off the notch.

Before application, the surface must be cleaned with fine sandpaper and polished. A special polishing paste is used for polishing.

The paste can be easily replaced with chromium oxide (oil paint). The surface of the object must be thoroughly and vigorously rubbed. The paste is ground with a thick piece of leather.

This is interesting: Shtangenreysmas - purpose, verification, GOST

Purpose of the graver

For engraving, the master needs a set of metal stamps of different shapes to engrave various elements of the image. The most common are:

- Spitz is a wedge-shaped cutter with a slope of 30 to 40°, used to design the outline of an image and clear elements of great depth;

- Messer - resembles a knife, the wedge slope is from 15 to 30°, it is used to make fine details;

- flah - similar to a chisel blade 0.15-6 mm wide, used to select depressions in the design;

- bol - a rounded point with a radius of 0.2-0.6 mm; with its help, semicircular depressions are selected, from which text elements of the design are formed;

- hornbeam - diamond-shaped section, large elements on concave elements are chosen with it;

- facet - a trapezoidal section with a blade sharpening angle from 50 to 115°, used for forming images of high complexity;

- Shatir - the blade has a serrated shape with a distance between the teeth from 0.1 to 0.5 mm, it is used to obtain several parallel strokes.

Stichels for carving metal of other shapes are rarely used for restoration work and when making particularly complex images.

Soft varnish

This technique is a type of etching made with a soft acid-resistant varnish (also called tear-off). This varnish is created by adding fat to it.

To begin, the engraver coats the metal plate with a soft varnish and carefully attaches grainy paper to it. A drawing is created on paper with a hard pencil, which causes the varnish to stick in the areas of the resulting image.

But due to the fat contained in the composition, when removing a sheet of paper from a plate, these particles of varnish stuck to the paper easily become detached from the metal (torn off). After this, etching, traditional for etching, is performed, then the varnish is washed off, the resulting form is filled with paint and prints are made.

The main features of the soft varnish technique:

- the image retains the texture of the paper with which it was created;

- When examining the image, it is easy to notice dots of different shapes partially connected to each other.

D. Castiglione. Portrait of a man in a beret. Soft varnish. 1664

Engraving examples

Engraving on different objects has its own characteristics. Let's look at a few product examples.

Engraving on wedding rings

Usually they are engraved with words and inscriptions, but it is important that it is easy to read. But for this you need a suitable size of the product, because it will not be possible to apply such an inscription on a ring that is too narrow

Engraving can be applied to the front, inner side of the ring and its side edges.

Engraving in production

It is usually used in the manufacture of nameplates, plates, serial numbers, license plates and many other products.

But most importantly, do not forget that when producing industrial nameplates you must comply with the requirements established by law. Using markings, information about the product and manufacturer is applied to the nameplate. It includes technical characteristics of the device, manufacturer data, Rostest data, device serial number and a description of safety when working with the item.

The inscriptions are very thin and clear, so the nameplate itself is small. In addition, when applying inscriptions to a nameplate, their durability is important, so production uses exclusively laser marking methods. And thanks to the high speed of work, their production has no restrictions on circulation.

Lithography

Lithography (ancient Greek λίθος - stone and γράφω - to draw) is a technique of etching a design on stone, related to flat printing. To create an image, special types of stone (usually limestone) are selected that can repel paint after light etching with acid.

An impression from a stone during the lithography process.

During the work, the engraver prepares the stone plate (polishes it or, on the contrary, makes it rough). After this, a drawing is applied to it using a thick lithographic medium (pencil or ink). After lightly etching the plate with acid, the etched areas repel ink. Areas with a greasy pencil, on the contrary, easily attract paint.

At the next stage, the original image is washed off, and paint with drying oil is applied to the wet stone, which adheres to the unetched areas. After this, pressure printing is performed on paper using a lithographic press.

In the past, lithography was done on stones, but today mostly metal plates are used.

The main features of a lithographic print:

- no pressure in all details of the image, the paint is evenly distributed over the entire surface of the sheet;

- lithography on smooth stone is similar to ordinary brush or pen drawings, but does not have the characteristic accumulations of paint;

- In the lithography, strokes consisting of heterogeneous dots are visible on rooted (rough) stone.

F. Terzaghi. "Moscow. View of the Kremlin." Lithography. 1857

Pablo Picasso . “Bull” series of 11 lithographs. 1946

#114 Wood cutters from a feather drill

How to make wood cutters from a feather drill

(The photo shows the upper chisel made of bearing steel from the USSR HF set, placed specifically for comparison)

If you are thinking about making chisels for wood carving with your own hands, then you already know that it is now difficult to find good metal. These tips from Evgeny Korotin are for those who find it difficult to buy a real imported set of cutters because of its cost. The author always made the tool himself, you won’t believe it, but even from a bayonet shovel. Moreover, the latter has been working for many years.

This photo shows chisels made from feather wood drill bits with an SDS+ shank (RIGHT) for working with a rotary hammer or a SPARKY jackhammer for large sculptures.

About the choice of drills: Feather drills from 6 mm are now on sale. up to 55 mm. it turns out - practically take anything and make a cutter. And the author has a whole set made this way, plus a couple of jambs.

For forging, you can heat it in the flame of a gas stove with the flame divider removed, and then give it the desired shape.

About forging tools

Here is a photo of a homemade matrix that Evgeniy uses to make chisels from feather drills. It is made from a piece of rail.

The author's matrix was milled at the factory according to his sketches. The work took an hour and a half, there was such an opportunity.

Also for forging you need a hammer with a ball-shaped striker. Evgeniy made the hammer himself using a grinder.

How to forge a graver

Beginner engravers make do with purchased gravers or repurposed files. Mature craftsmen often feel the need for a reliable forged chisel.

Making a forged graver yourself requires intermediate level blacksmithing skills. Instructions on how to make a gravel using the hot forging method are given below.

Forging is divided into the following main stages:

- forging workpieces;

- hardening;

- final processing and finishing.

During forging, it is necessary to constantly monitor the temperature of the part. It is determined by a pyrometer or the traditional method - by the color of the glow. At the beginning of the process, the part should be light yellow, in the last operations it should be light red.

A well-heated workpiece must be grabbed from the forge with pliers and placed on the anvil. Light, frequent blows knock off the scale. To obtain a rectangle, the cross-broaching technique is used. To form a triangular shape of a part, it is pulled longitudinally on the edge of the anvil, turning it at the required angle. A similar technique is used for broaching for a trapezoidal section shape.

In a more complex way, the blacksmith achieves a diamond-shaped section. First, the tip is pulled in one direction, then the product is turned over and pulled in the opposite direction. In this case, part of the part will have to be cut off.

The next operation is broaching the tail part of the cutter. it must be additionally calcined and stretched until a pyramidal tail is formed.

You can move on to the next stage - hardening. Hardening of carbon alloys is carried out in the following sequence:

- heat the product to 805 ±15 °C;

- quickly immerse in cold water;

- check the degree of hardening with a file: if it slides over the metal without forming chips, then the required hardness has been achieved;

- When chips form, quenching should be repeated.

And the final stage is machining. The grinder is given its final shape on the abrasive wheel. Here the blade is sharpened to the required sharpness. The final finishing is done on a fine-grained wheel.

Is it possible to do engraving at home?

If we are talking about mechanical or manual engraving, then, of course, yes. It is enough to purchase only cutters and a drill.

But if you are planning to engage in laser engraving, then it is worth considering that the equipment for it is much more expensive, so it will only pay off if the craft becomes your business. Of course, for mass production it is better to allocate a special room, at least for safety reasons. After all, to work on laser equipment you will need voltage stabilization and grounding.

But we have several clients who use fiber markers at home for small production. Desktop markers with small dimensions are suitable for this.

Mezzotint

In the mezzotint technique (from Italian Mezzo - half, tinto - painted), which is also called the black style or the English style, the work is done not with creating recesses in the prepared plate, but with smoothing certain areas. For this purpose, the metal plate is roughened using a graining technique. That is, initially there are already grooves on it, and the engraver’s task is to rub over those areas that should be lighter (the paint almost does not linger on smooth areas). He works with the image using a scraper and a smooth planer. Engraving is carried out from the blackest color to the brightest light (hence the name black manner), which is the opposite of other mechanical engraving techniques.

Graining, smoothing and scraping the surface of the plate using the mezzotint technique.

The main features of engraving using the mezzotint technique:

- with sufficient magnification, small notches (grains) are visible;

- There are no sharp lines, the image is soft, with a velvety texture and a smooth change from one tone to another.

K.-V. Seeliger. Engraving "Allegory of the accession to the throne of Alexander I." Mezzotint. Around 1801

General technology

Carrying out engraving processes involves many types of techniques. The main methods are manual and mechanical, the latter is divided into the categories of defensive and line.

- A three-dimensional design can be obtained by using defense engraving; deeper processing involves three-dimensional engraving.

- When performing surface actions, the line technique is used. The process is carried out in several steps, the lines of the processing contour are drawn, and part of the metal is removed from the surface using dashed movements.

Carrying out incisive engraving yourself is done with a graver. A special tool can be purchased at art stores. Accessories for the manual process are divided into types:

- Messer - a graver is necessary for making fine lines.

- Engraving with parallel lines is done with a pen marker.

Tools for metal engraving cannot be used without high-quality sharpening of the gravel. For high-quality work, you need to sharpen the tool with a fine-grained whetstone, and then wipe it with a leather cloth.

When working with small objects, you will need a special pillow. You can make this tool with your own hands; material of the same size is connected with a thread along the edges. It is necessary to leave an intermediate space for filling with bulk material or sand. The workpiece is turned inside out, sand is poured into the hole formed, after which the rest of the pillow is sewn up with a stitch.

Using the tool will require careful handling and preliminary skills. You need to use the tool like a regular pen when writing, holding the tool to the side with the thumb of your working hand.

It is possible to apply a design to metal using laser engraving. A unique piece can be used as a gift or as a signature fitting. Changes in design and inscriptions on metal products are available using technology such as laser engraving.

General technology

The technique can be manual or mechanical (various equipment is used).

It is also divided into line and armor:

Incisive engraving is performed with a special tool – a graver.

If you ask yourself how to make it yourself and where to buy these tools, then the answer is simple: this tool is sold in the same stores where you can find various art supplies.

The finest lines are made with a Messer-Stichel. If you need to make parallel lines, they are made with a rap pen.

The graver is brought “to readiness” with a leather product (you can take an old belt) coated with chromium oxide.

Manual processing of small items at home requires the presence of a special pillow; you can easily make it yourself: take two pieces of fabric of the same size (round or square), sew them together along the edge, stepping back from it a little, but you need to leave a small gap in order to so you can pour sand inside.

The cushion engraving tool is ready.

How to properly hold the instrument in your hand?

This should be done as if you were holding a regular ballpoint pen: the index finger should be on top of the blade (that’s what the metal part of the cutter is called), and the thumb should hold it on the side.

Work must be done on your own.

In the case when you need to change the direction of the pattern, unfold the pillow with the object on which the element is being applied, but do not change the direction of movement of the hand.

What else is useful to know about incisors?

To do your own engraving at home, it is advisable to first practice so that the carving turns out beautiful in the end.

It is better to purchase a set of tools: it is better to apply rounded lines with a square section of cutters, and it is better to make straight lines with a round section.

You can make the scraper yourself. To do this, you will need a file, from the edges of which you need to grind off the notch.

Pneumostihel Sergei Valtman

and so, I played with these tubes and motors, gradually began to understand for myself what weight of pistons for what work, which compressor is better to take, the engine.

Well, there was an ambush with the turners, but my hands were itching terribly, I bought a lathe and started making my own version from a stainless tube. Based on my considerations, I chose the size of the tool holder and the intermediate impact element, to match the rubber bands that are available in the auto store, sat down and drew on graph paper, and this is the first option I got

The drawings were drawn by Rumen Radkov

Oleg has already posted the details on the forum. The pistons are only now different with fluoroplastic jackets

Of course, I ruined a couple of blanks, but then I got what I needed, well, of course, I sanded the .. raw .. stainless steel and carbonitrated the cylinder tube and lock nut, in the composition that I wrote about at the beginning, after two hours, the result was a beautiful black part like a weapon , with surface hardness, the file slides. Then I used felt and polishing paste to just add gloss and that’s it!

Color engraving

To make the drawing look more clear and beautiful, use a glass pencil or ink.

In order for the effect of using these tools to remain as long as possible, the surface is coated with colorless varnish.

You can make the drawing clearer using a needle and oil paints. This set allows you to scratch auxiliary lines of the pattern, which are subsequently covered with paint.

Artistic color engraving allows you to make the product colorful. To do this, those elements that do not need to be painted are coated with transparent varnish.

Video:

How to blacken a metal object? Special equipment is not used for this, but the following substances are required: sulfur and potash (potassium carbonate) in a ratio of 1:2.

This composition must be put on fire; to do this, it is poured into a tin can. The mixture must be constantly stirred, and the fire should not be high.

The mixture is removed from the heat when it turns black. Before this, it will need to be ground in a mortar; after the fire, it is also placed in a mortar and ground again (cooled).

Blackening occurs as follows:

- Water is added to the resulting mixture (1:9);

- A brass object is placed in the solution;

- It is heated until the product acquires the desired shade.

You can make the background dark before applying the drawing. In this case, varnish is not needed.

You can make an object brown with your own hands by keeping it in a solution of zinc chloride and copper sulfate with the addition of water (100g, 100g, 200g, respectively).

Hand painting in steel gray color is obtained from 1 liter of water, two grams of ordinary salt and two grams of a mixture of sulfur and potash.

The orange-red color is obtained from a solution of potassium sulphide: 1 gram of the substance per 250 grams of water.

Upon completion of work, the varnish is erased.

The blackening of an object and the blackness we know are two different things. The technique used to create niello is mechanical; it cannot be done with your own hands.

Dry needle

Drypoint engraving is so called because it occurs without coating the surface of the plate with varnish and without etching (chemical engraving techniques are presented below).

For this technology, needles of different sizes, a scraper and a smoother are used. First, the metal plate is prepared for work: it is ground, polished, and the edges and corners are processed. Then the desired design is applied to the plate using a graphite pencil or a thin needle and the engraving process begins.

Drawing an image using a needle.

The nature of the final image depends on the type of needle chosen and the degree of pressure on the instrument. If the master presses the needle weakly, then a line with clean edges is obtained; with strong pressure, the edges of the lines become torn with notches and burrs (barbs) rising upward. During printing, the ink fills these recesses and accumulates at the barb, resulting in a very rich and velvety image.

The nature of the line with high pressure on the needle.

Drypoint engraving can be distinguished by the following characteristics:

- the lines have sharp ends (often in the form of hooks);

- Velvety sagging of paint may appear on the strokes if the barbs were not erased due to numerous prints or were not removed forcibly;

- angular and straight lines predominate.

S. Maslovsky. Portrait of the artist's wife. Dry needle. 1905

Engraving with a graver on metal surfaces

Sticky engraving on metal requires the engraver to have a faithful eye, a steady hand and artistic taste, but above all, patience and perseverance. It is also necessary to decide on the material for the blanks. Copper and brass are more suitable for a novice craftsman. More experienced engravers work on other non-ferrous metals and soft steel alloys, using specific engraving methods and improved tools.

All that is needed for engraving tools and equipment is a work table and a set of gravers. At the first stage of mastering hand engraving technology, it is recommended to achieve stable quality of straight and curved strokes. When they begin to turn out confidently, you can move on to more complex elements of the image.

Before starting to engrave the workpiece, the master traditionally checks the sharpness of the sharpening pen by running it along the tip of the nail. If the strip can be cut without effort or pressure, the sharpness is sufficient. The handle is clamped in the working hand, the thumb and index fingers cover the incisor 10-20 mm from the tip.

The blade is pressed against the surface of the workpiece at an angle of 35-45°, then the angle is sharply reduced to 5-10°, while a piece of metal is cut out of the workpiece and a stroke is formed. For beginners, it is not recommended to limit their length to 3-4 mm. As you gain experience, you will begin to get longer ones.

Chisels

Let's call a chisel a fairly common tool. The best offer is considered to be the products of the Kirschen Studia company, but any modification costs no less than 1000 rubles. There are many different types of wood carving chisels. The classification is carried out as follows:

- Direct.

- Angular with V-shaped profile.

- Reverse with a convex working part.

- Curved.

Chisels for wood carving

A chisel for carving wood of low density can be made from inexpensive materials. If desired, you can purchase budget options from Japanese manufacturers. It is worth considering that models with a short working part are intended for manual work and are not easier to operate. Options with a longer working part are intended for impact work.

Saws can be used to work with solid wood

There are a variety of options for this instrument; when choosing, attention is paid to the following points:

- Tooth size.

- Length of the working part.

- Handle type and comfort.

- What metal is the working part made of?

Wood carving with a chainsaw

When considering a similar tool for cutting wood, it is worth considering that most are designed to change the length of the workpiece.

To improve the quality of the resulting end surface, you can use saws with a fine and frequent tooth arrangement.

General description of technology

Artistic engraving today is very popular not only when decorating gift items, but also in the process of processing everyday metal products.

The result obtained mainly depends on the equipment used and the skill of the person

In addition, the quality of the material itself is quite important. If it cannot boast of durability, then the final engraving result may not be very attractive.

Metal engraving can be done using many technologies. Among the main methods are manual and mechanical engraving, which can also be defensive and line engraving.

If the task is to make a three-dimensional image, then this can be accomplished using defense engraving. If it is necessary to do three-dimensional processing, the best solution will be the deepest possible finishing.

As for the line art technique, it is usually used for surface work. All this is done in a couple of steps. Before starting work, it is imperative to draw the contours of the image, as well as remove some of the metal from the surface to be treated.

Carrying out incisive engraving on your own is done using a graver. This unit can be found in almost any art store. Among the main devices for such metal processing are the following:

- Messerstihel, which is indispensable for making fine lines;

- repstikhel, considered the ideal solution for creating parallel contours.

In order for engraving to be carried out at a high level and the result to be acceptable, it is necessary to use a good sharpening for the gravel.

To work with small objects at the highest quality level, you need to use a special pillow, which is not difficult to make with your own hands. To do this, you will need to find material of the same size and connect it using a special thread. It is imperative to leave space in order to fill it with bulk material, such as sand. When using, the workpiece should be turned inside out to make it easier to use.

The use of engraving tools requires careful handling and preliminary skills. Otherwise, you can not only spoil the material, but also harm yourself.

The essence of the technology, how it is done, features, advantages

Laser engraving technology uses radiation in which the diameter of the focused beam and its power are regulated. By setting these parameters, you can not only cut the material, but also influence only the surface layer of the object being processed. The image is applied in two ways.

- The upper part of the surface is heated to the point of melting. During the transition from one state to another, physical and chemical processes occur in the material that change its structure. One of the associated effects is a change in surface color after crystallization. The contrast between the appearance of the surface treated and untreated by the laser beam creates an image on the object.

- This method involves changing the surface topography. Part of the surface layer is heated to a temperature at which the molten material is burned out through the evaporation process. The power of the beam can be used to regulate the depth of the part of the surface being photographed, thereby changing the relief of the image.

Laser engraving on metal The main advantages of laser technology over other types of engraving:

- Almost any material can be laser engraved;

- any, even the smallest, images are made with a clear, clearly visible outline;

- The images look very attractive from a design point of view;

- Due to the lack of direct mechanical contact with the cutting tool, the processed object is not subject to deformation and there is no need to secure it;

- When laser engraving, the material is thermally treated, which makes it resistant to abrasion, the image has an aesthetic appearance for a long time.

- the image takes on its final form immediately after laser engraving; there is no need for subsequent refinement.

Laser engraving easily adapts to automatic control. Working according to the program algorithm eliminates the possibility of subjective errors. When engraving by hand, the human factor does not eliminate the risk of making a mistake.

The image is applied according to control programs and is carried out using two methods - raster and vector.

- With the raster method, the laser head moves discretely in one direction of the engraving area, and then moves down/up/down in the smallest possible increments. By sequentially processing the surface with such points, we obtain the required image. In this way, images such as photographs and pictures are engraved.

- With the vector method, the laser moves along the direction of certain lines. This method is usually used to engrave inscriptions and other images in the form of lines. This method is much more productive than the raster method, but if you need to change the thickness of the lines, you cannot do without raster engraving.

Interesting: Laser cutting of aluminum, stainless steel, sheet metal and products

Application: logo application and more

Engraving fonts on aluminum. The property of laser engraving to preserve the appearance in its original form for a long time is used to apply logos to objects, where it becomes one with them. Some commonly used use cases:

- logos on souvenirs and gifts (pens, lighters, mobile phones, diaries and others);

- in jewelry, laser engraving is applied to products made of precious metals: bracelets, watches, rings, rings and others;

- applying inscriptions and images to various sports and other awards;

- some industrial manufacturers identify their products with logos made using laser technology;

- technical information is applied to the housings and instrument panels to make it easier for the user to operate them;

- production of seals and stamps using laser engraving;

- applying duplicate marks in Russian on keys and buttons of foreign-made equipment.

The technical capabilities of laser engraving raise the possibilities of advertising business to a higher level

In an overabundance of advertising products, the consumer will definitely pay attention to the originality of posters and signs, on which information is given in a clear, highly detailed image

Logo engraving on a metal keychain

Engraving of text and images on the plate

Engraving text on a metal plate

Purpose of the graver

For engraving, the master needs a set of metal stamps of different shapes to engrave various elements of the image. The most common are:

- Spitz is a wedge-shaped cutter with a slope of 30 to 40°, used to design the outline of an image and clear elements of great depth;

- Messer - resembles a knife, the wedge slope is from 15 to 30°, it is used to make fine details;

- flah - similar to a chisel blade 0.15-6 mm wide, used to select depressions in the design;

- bol - a rounded point with a radius of 0.2-0.6 mm; with its help, semicircular depressions are selected, from which text elements of the design are formed;

- hornbeam - diamond-shaped section, large elements on concave elements are chosen with it;

- facet - a trapezoidal section with a blade sharpening angle from 50 to 115°, used for forming images of high complexity;

- Shatir - the blade has a serrated shape with a distance between the teeth from 0.1 to 0.5 mm, it is used to obtain several parallel strokes.

Stichels for carving metal of other shapes are rarely used for restoration work and when making particularly complex images.

What are stichels?

Stickers are specially shaped cutters. Depending on what exactly you are going to do (for example, engraving watches with gravers or engraving with gravers on rings) and the type of metal being processed, cutters of various shapes are used. Each of these incisors has its own name. A prefix is added to the word “stichel” - spitz-, messer-, grab-, bol-, etc. If you seriously decide to start engraving with a gravel on metal, it is advisable to purchase a whole set of cutters of different shapes.

The shtikhel consists of three main components: a ring, a handle and a working part (blade). The handle is shaped like a mushroom. As a rule, it is made of wood - beech, oak, birch. A sleeve is placed on the thin part of the handle. It is necessary to prevent the handle from cracking when it is mounted on the blade. The blade shank is driven into the end part of the handle. The bottom part of the handle is cut off a little. This allows the master, when manually engraving metal with a graver, to hold the cutter at a certain angle to the workpiece and, as a result, remove very thin chips.

The length of the handle can vary from 3 to 7 cm - this is determined by the ease of use of a particular engraver and the size of his hand. The blades have different shapes, but are almost the same length. Taking into account the size of the shank, it is 10-12 cm.

Each stichel has a specific number. This number is determined by the cross-sectional size of the blade. The larger it is, the higher the number.

One of the important characteristics of the blade is the resistance of the blade to abrasion. It largely depends on the quality of sharpening and hardening. If it is not heated enough, the working part will quickly become dull, and overheating will lead to chipping of the edge. A high-quality gravel pen is resistant to impact and bending, the edge of its cutter is not deformed and does not become colored when engraving jewelry with a gravel pen.

Over time, the cutting edge inevitably wears out and must be sharpened again. This leads to a shortening of the length of the blade, and therefore the blade itself. Working with a short stylus is not very convenient. This problem can be solved by replacing the handle with a longer one, then with an even longer one - until the blade is completely worn out.

Engraving at home. Methods

The general technology for applying a pattern to a metal surface was presented above.

Engraving on metal at home can be done with any sharp object. Let's consider several ways.

Application is carried out using a special device

To create a high-quality drawing, it is better to use a tool called an engraver. You can purchase a whole set for creating lines of different thicknesses (see photo).

Photo:

Drawings on the surface of an object must be done using the following technology:

- You can make a pattern on an object yourself using a pencil or marker, or you can use a copy sheet;

- The next step is to apply the design with an engraver to the surface of the object. The cutters should be moved in one direction in good lighting;

- The resulting result is fixed with a thin layer of wax or colorless varnish.

Drawing using a set of materials at hand

What does the set include:

- nail polish;

- toothpick (match);

- salt;

- phone charger;

- glass and nail polish remover.

The price of such a set is minimal; no cutters are needed.

The item is coated with a thick layer of varnish. Use a toothpick (match) to scratch the pattern. You need to put 2 tbsp in a glass. l. salt, add water and stir.

Charging from the phone is applied to the object with a plus, and with a minus - to any second metal object.

This should be done for five minutes (a little less, depending on the desired etching depth). Upon completion of work, it is necessary to wipe off the varnish.

This method is good because it does not use cutters, paste or other tools, only what is at hand and the price will be low. Thus, at home you can make personalized spoons, forks, decorative sets, etc., all with your own hands.

Photo:

Engraving can be done with a drill

This instrument works on the same principle as the machine in the dentist's office.

The price of the device is about 5,000 rubles, so the machine is purchased when the products are planned to be made more than once.

In addition to the device itself, you need to purchase a set of attachments; the average price of one attachment is about 50 rubles.

Photo:

It should be noted that to operate a metal drill with your own hands, you need a milling set, and its price is also impressive.

The tool and machine are first tested to achieve good results.

gallery

Applying a pattern or relief to the prepared surface of a product using cutters (pencils) is called engraving. There are several engraving methods: planar (two-dimensional), niello engraving and armored (three-dimensional). Engraving is divided into manual...Applying a pattern or relief to the prepared surface of a product using cutters (pencils) is called engraving. There are several engraving methods: planar (two-dimensional), niello engraving and armored (three-dimensional). Engraving is divided into manual - with steel engraving pens and manual - with an electric drill. The most ancient method of engraving is manual, using gravers. To apply lines of different sizes and shapes, the gravers have different sections and sizes. The total length of the graver is 100-130 mm. The graver is inserted into a short mushroom-shaped wooden handle, cut off from the bottom for ease of use.

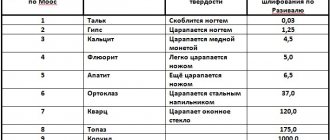

The cutters are made from high-quality steels U7, U8. If you need to make a hard tool, then it is best to use high-carbon or high-speed steel. The following main types of gravel sections are distinguished. A sharp incisor is a spitztichel. Its sides are slightly curved outward, the width of the back is 1-4 mm. It is used to perform most engraving operations: outlining a design, trimming corners in type work. Messerstichel - knife cutter. In cross section it has the shape of an acute triangle. They can apply thin lines of great depth. Facet shtikhel - facet cutter. Its side walls are parallel, and the cutting surfaces meet at an angle of 100°. Back width 1.5-3 mm. They can draw lines that are relatively wide and of insignificant depth. Justirshtikhel - adjusting cutter. Its curved sides in cross section form a sharp oval. Flachstichel is a flat cutter. The back and blade of this cutter are parallel; depending on the position of the sides, the back may be wider or narrower than the canvas. The width of the canvas is 0.2 -5 mm. They are used not only for drawing wide and flat lines, but also for leveling planes. Bolshtikhel is a semicircular incisor. The canvas may be narrower or wider than the back, but it is always semicircular; blade width 0.1-0.5 mm; used for strict fonts of various widths, when engraving recesses, with round and semicircular selections. Fadenstichel - thread cutter. It looks like a flat cutter, on the blade of which there are many longitudinal grooves; It is used for decorative crafts and to enliven drawings.

When working, the graver is held in the right hand, in a fist, so that its handle rests against the palm, and the thumb and index fingers support the graver in the working position. In this case, the elbow is suspended and only the thumb serves as a support for the hand, which limits the slipping of the graver forward. At the same time, use your index finger to regulate the force of pressure on the edge of the gravel and guide it along the lines of the drawing. The shtikhel is always carried only in a straight line from right to left, pushing it forward. When engraving curved lines and curves, rotation of the graver is allowed only within small limits, and all bends of the lines in accordance with the drawing are carried out with the left hand, turning the workpiece secured in the scraper (or block).

The graver must be well and correctly sharpened. The softer the metal, the smaller the cutting angle (sharper). When cutting soft materials (wood), the angle is 45°; for steel it reaches 60-65°. You cannot work with a dull stylus - it slips off the metal and can easily injure your left hand, which is constantly in front of the stylus. A sharp gravel easily cuts metal and takes normal shavings. Almost all metals are suitable for planar engraving, but brass, tombac, hallmark silver, and some steels are best suited for engraving. Bronze, zinc, nickel alloys are well engraved; worse - pure gold, pure silver, and also pure aluminum.

Armor engraving - a cutter is used to create a relief or even a three-dimensional figure. In armor engraving, there are two options: convex (positive) engraving - when the design, relief is higher than the background (the background is deepened); in-depth (negative) engraving - when the design or relief is lower than the background. Armor engraving is a more labor-intensive process compared to planar engraving, since this work requires removing a significantly larger mass of metal from the workpiece. Therefore, in addition to gravers, chisels, cores, splits, coins and punches are used in armor work. The working end of the chisel is forged and filed to the shape of a particular gravel. In addition to chisels and gravers, engraving hand tools include: a core used for marking; chops - flat chisels of various widths sharpened on one side; stampings - steel rods with different working ends for leveling the background and filling the texture and punches, which are usually made from tool steel rods with a thickness of 6, 7 and 10 mm, with a corresponding length of 65, 85, 100 mm.

The process of armor engraving consists of preparatory work and the engraving itself. Preparatory work includes transferring the drawing to metal, which is carried out in the following way. A thin layer of wax (or plasticine) is applied to the surface of the workpiece, covered with white paint. Then prepare the drawing by doing it with a pencil on tracing paper. When translating a drawing, you need to take into account how it should appear on the metal - direct or reverse (mirror). A mirror image is necessary when engraving seals, facsimiles and cliches intended for making impressions from them. The pencil drawing copied onto tracing paper is placed face down on the workpiece and rubbed in with the handle of a stencil; carefully peel off the tracing paper and a clearly visible imprint of the design remains on the wax surface. The first chip is then selected around the design. This work is carried out so that careless movements do not spoil the drawing. The next operation is background sampling. When deep cutting or engraving curves, use a chisel or a similar shaped chisel. After cutting down the entire field to the required depth, they begin to process the relief, which is cut or chopped with appropriate gravers or chisels, and if necessary, needle files and stampings are used.

To speed up work when engraving repeating elements or when making especially small and complex parts, punches and mother liquors are used, which are made in advance. With in-depth armor, the outer contour of the relief is drawn on the polished surface of the workpiece and outlined with a spitztichel. After this, they begin to cut out the metal inside the outlined pattern. Cutting is carried out with chisels of various shapes. You should cut in depth very carefully, with frequent checks and comparisons with the original. The test is carried out as follows: a piece of softened plasticine is squeezed into a pre-moistened cut-out mold and the resulting impression is compared with the original on which the work is being carried out. Basic depths are measured with a caliper or checked with a template.

In-depth armor requires high qualifications and skill from the engraver, since the work is mainly carried out by eye. The deeper the metal is chosen, the more carefully you need to work, since it is very difficult to correct an excessively deep cutting. When the relief is cut to the required depth, the cutting is stopped and finishing is begun with dies, embossings and punches. Part of the metal is removed, and part is compacted by blows of coins and punches. After final finishing (grinding and polishing of individual areas), the control cast must be identical to the model. For cleaning and trimming the bottom of the relief depression, bent gravers and grooves are used. Currently, in the manufacture of steel dies and molds, to facilitate work, you can use preliminary rough sampling of metal on milling machines or casting by a precision method of the entire matrix or mold. In the latter case, engraving work will be reduced only to cleaning and finishing the die cavity, which significantly speeds up and facilitates the work process. When engraving under niello in metal (mainly in silver), indentations are made with the help of gravers and chisels with a depth of 0.3-0.5 mm, and then the final processing of the design is carried out - the lines are aligned and the corners are trimmed. After this, the recesses are filled with black sealing wax and paint and varnish material, and the metal itself is heated and, after cooling, the process is repeated. Let's look at old and modern niello recipes and methods of processing products.

Caucasian niello (from old recipes) consists of “1 spool of 84-karat silver, ¼ pound of sulfur, 6 spools of red copper and 7 spools of lead.” The alloy is poured onto a cast iron or stone slab and, after cooling, it is pounded, washed in water and dried. The powder is ready for use. When covering with niello, you need to prepare a dough from niello powder (10% borax solution) and fill the indentations on the product with this composition, then put it in a forge to heat and melt the niello. After coating, the product is removed, cooled and polished.

Experts from Germany offer this method of blackening: add a small amount of borax to 1 part silver and 2 parts copper. 3 parts lead is melted in a steel crucible to add it to the silver-copper alloy. Liquid lead is slowly poured into the silver-copper alloy and mixed well. A tall crucible is filled to half with yellow powdered sulfur and heated: 1.2-1.5 parts of sulfur (by volume) are taken for 1 part of the alloy. The resulting ternary alloy is poured into heated sulfur powder with constant stirring. The crucible is kept heated so that the mixture does not harden. Sulfur partially burns, it must then be added to the composition. Vigorous stirring achieves good interaction of the parts, due to which silver and copper form a black compound with sulfur, which is poured into water. The resulting niello should be hard and brittle, like glass. If its pieces can still be bent, then it should be melted again. However, excessive heating or keeping it in the oven for too long can cause the sulfur to burn out. Then ammonium chloride powder is dissolved in hot distilled water, which serves as a flux. It is added to pieces of black and the mixture is ground in a porcelain mortar in the required quantity, since only fresh ammonium chloride porridge can be applied to the product. Modern blacksmiths first prepare silver sulfide, copper sulfide, and lead sulfide separately and then alloy them together.

To prepare silver sulfide, 20 g of powdered sulfur is taken from 97.8 g of pure silver in the form of crushed shavings, mixed and gradually heated in a graphite crucible to 300-400 °C. The sulfur diffuses into the metal and forms silver sulfide. The same method is used to obtain copper sulfide and lead sulfide. To do this, take 250 g of sulfur for 800 g of copper, and 75 g of sulfur for 400 g of lead. The resulting sulfur compounds are crushed and mixed in the following weight ratios: silver sulfide - 111.2 g, copper sulfide - 466.6 and lead sulfide - 422.2 g. The result is 1 kg of black, which is poured into a cold graphite crucible, poured on top dry charcoal and placed in a muffle furnace, heated to 800 ° C and after 30-40 minutes, when the black in the crucible is heated to 600-650 C, ammonium chloride is added to the crucible at the rate of 284 g of ammonium per 1 kg of black. Then the crucible is closed with a graphite lid and, after complete melting, the black is poured into a cast iron mold heated to 300 °C, in which the alloy slowly cools. There are other recipes for preparing niello, in which ammonium chloride, potash with table salt and borax are used as a flux.

There are two methods of applying niello - dry and wet. The dry method consists in moistening the surface to be blackened with an aqueous solution of potash, borax and table salt, and pouring finely ground black powder sifted through a sieve onto it; then the product is carefully dried. In this form, the product is fired, which is carried out in muffle furnaces at a temperature of 300-400 °C. The wet method differs in that the niello is applied to the product in the form of a creamy slurry diluted with water. It is very important that the recesses are clean and free of grease. A raw fine-powdered mixture of black, diluted in an ammonium chloride solution, is applied into the recesses with a brush or spatula. The mixture is placed as thick as possible and lightly compacted with a spatula. The recesses must be filled to the brim; For thin engraved designs, the entire surface should be covered with a niello mixture. The workpiece is dried for some time, as soon as the water has evaporated, it is pushed into the oven, and when the niello has melted and all the recesses have been filled, it is removed from the oven. It must be remembered that when overheated, sulfur particles burn out, the layer becomes porous and stains appear. Small volumes of black can be melted with a soldering iron. In this case, it is necessary to concentrate the heat flow on the base metal, heating it from the reverse side. When the mass melts, stop heating. If the molten black does not fill all the recesses, add the required amount and heat again.

Artistic forged metal was almost always combined with other materials, but most often with wood. Powerful forged walls with their shape and pattern echoed the ornamentation of a gate or wicket; handles, cylinders, ax locks and various latches also repeated the patterns of wooden objects and made up a single composition of metal and wood….

More details in the article “Forged metal in combination with wood, glass, ceramics and stone” Navrotsky A.G. "Artistic forging"

Metal engraving using various equipment

If you look into history, you can see that hand engraving on metal has been known to mankind for about five thousand years.

Above we discussed the general technology and methods by which you can do engraving yourself.

on metal is distinguished by its durability. In this case, a paste is used, which is applied to the object before processing. In this case, the paste is applied to the uncoated material.

The technology is as follows: the equipment directs a laser at an object, which, under the influence of temperature, melts a little, changes color and evaporates.

Using a laser, you can make designs of varying complexity and not only on metal. The price of laser engraved jewelry is high.

Photo:

Diamond engraving allows the product to “play” in the light due to the formation of tetrahedral pits.

Diamond engraving is performed using a special cutter, which removes the top layer of metal, forming those very pits.

Diamond engraving is considered durable and is widely used in jewelry and souvenirs. The price for such products is not fixed; most often, it is negotiated individually.

Photo:

You can apply a design to metal using a milling engraving machine, which you can not only buy, but also make yourself.

Milling in the form of such a machine is necessary in the case of small-scale production (your own business). Otherwise, it will be unnecessary expenses. The machine allows you to make an accurate drawing due to the rigidity of the entire structure.

In addition to metal, the engraving machine allows you to process wood, glass, MDF and other materials.

If we talk about small production, then such a machine will be simply irreplaceable; it is easy to use, the cutters move quickly and accurately. The human factor is excluded.

Engraving using this machine is accurate and durable.

Pencil style

This engraving technique uses chemical or mechanical engraving methods (rarely both). The pencil style got its name because the printed image resembles a pencil drawing.

In chemical engraving, a polished metal plate is treated with a hard acid-resistant varnish, and then designs are applied using a tape measure (other tools can also be used). It is a gear with notches that rotates on a metal rod. When a tape measure is rolled over a varnished plate, small indentations are left in it. After this, the areas of the plate freed from varnish are etched in acid.

Engraving tape for working in pencil style.

During mechanical engraving, burrs (lumps) form on a polished plate around the points pressed in with a tape measure. When printing with paint, not only the recesses are filled, but also the burrs, due to which the engraving becomes soft.

The main features of pencil engraving:

- if the engraving was done using a tape measure, then repeating chains of dots are visible on the printed image (grouped in the form of strokes and can be round, oval, or resemble commas);

- in the case of a chemical pencil style, the stroke turns out to be clean, in which the dots have a clear boundary and are spaced at equal intervals from each other.

L. Bonnet. Portrait of Catherine II. Pencil style. 1765

Features of engraving on wedding rings

Since ancient times, a distinctive feature of wedding rings has been engraving. The approach to the inscription or drawing occurs individually, according to the customer’s preferences. The most common methods are the recessed or grooved method. The most common work is done by hand on jewelry. Jewelers offer many options for writing text, as well as display methods. The complexity of the work is assessed individually with each customer.

Engraving on wedding rings

Laser engraving is also a common method. The beam burns out the top layer of metal and seals it with varnish.

It is important to remember that adjusting the size of a finished product is almost impossible; it is necessary to determine in advance the size and type of product