The remarkable physical and chemical properties of tungsten are widely used in industrial production. Tungsten is most widely used in the chemical industry and electrical engineering. For many decades, we did not know any other type of lighting other than incandescent light bulbs, the spiral of which was made of tungsten wire. This metal was chosen due to its ability to operate at high temperatures.

1 / 1

The remarkable physical and chemical properties of tungsten are widely used in industrial production. Tungsten is most widely used in the chemical industry and electrical engineering. For many decades, we did not know any other type of lighting other than incandescent light bulbs, the spiral of which was made of tungsten wire. This metal was chosen due to its ability to operate at high temperatures.

Tungsten as a welding material

The emergence of TIG welding and its introduction into various industries required new types of materials. Tungsten rightfully occupied this niche. Even people far from production could see tungsten electrodes when repairing refrigerators, cars and other household appliances. By the way, argon is not the only gas used in this type of welding. Carbon dioxide and various mixtures of gases are used with no less success.

Welding metals in a shielding gas environment not only allows you to obtain a high-quality, clean seam, but also extends the service life of the electrodes, which are given a certain shape. This is necessary to stabilize the arc when welding parts with a thickness of 0.1 mm or more, without restrictions on the maximum thickness of the structure.

Sequencing

Before you start TIG welding, the joints must be cleaned of grease, rust, etc. The metal must be perfectly clean, otherwise everything will remain in the weld, which will affect its quality.

Most steels are welded with direct current. Aluminum, magnesium, copper alloys with a high aluminum content are welded with alternating current .

The current strength is selected according to the tables, depending on the type of material, its dimensions and the thickness of the welding rod. If you select too high a current during TIG welding, the rod will melt. At low current the arc is unstable.

Recommended arc length is 1.5-3 mm. Increasing the arc length leads to an increase in the width of the seam and a decrease in the penetration depth.

When welding butts, the welding needle should extend from the nozzle by 3-5 mm, with corner welding by 5-8 mm.

Welding with a non-consumable electrode begins with the start of inert gas. The welding process ends by turning off the argon 10-15 s after the arc goes out. This is necessary so that the crystallization process occurs without air access.

For very important connections, a non-contact arc ignition method is used. Available in industrial equipment. Used for welding corrosion-resistant steels. This prevents tungsten from getting into the seam. For less critical connections, a device with a contact arc ignition method is used. It is usually found in domestic installations.

For TIG welding, it is enough to move the torch along the joint without oscillating movements, as in conventional electric arc welding. This results in a narrow seam and increases the welding speed.

When using filler wire, it is necessary to ensure that the melted end is under a stream of inert gas. The weld pool should have an elongated shape, not round.

Features of tungsten electrodes

Tungsten can operate in high-temperature environments, which positively distinguishes it from other metals. In addition, it has another remarkable ability: not to soften. The addition of alloying components expands the possibilities of using these products.

In addition, additives are added to improve arc stability or increase operating life at high temperatures. The amount and material of additives determine the brand and type of electrodes. You can view the full catalog of tungsten electrodes and buy them in the online store on the website. Here are the best samples from the manufacturer.

Characteristics of tungsten rods

Tungsten electrodes are called refractory rods , with the help of which an electric arc is formed, which is necessary to melt the edges of the filler material and the parts being connected during the welding process. They are used primarily for argon welding. They weld a variety of structures, including tubular ones. Tungsten was not chosen by chance for these purposes. It is the most refractory metal found in nature.

GOST specifies all the requirements for marking tungsten rods. This allows them to be classified as a certain type (no matter in which country they were produced). According to the requirements, the marking must contain, in addition to the type of product, the composition of the material.

Such electrodes can be identified by the first letter “W”, which is included in the designation. Most of these rods contain a small proportion of alloying additives. They allow you to increase the service life of the product and improve its technical characteristics. The second letter in the marking indicates the type of alloying substance.

Alloying additives are of the following types:

- "C" - cerium oxide . Tungsten electrodes containing this additive are universal. They are used for welding with any current, even at low values they maintain stable arc burning;

- "Z" - zirconium oxide . Electrodes containing zirconium oxide are used for welding with alternating current. When using them, you should ensure that there is not a drop of contamination in the weld pool. The arc formed by such rods is characterized by high power and stability. Compared to other products, tungsten electrodes containing zirconium oxide can withstand significant current loads;

- "L" - lanthanum oxide . Products with this additive provide high stability and easy ignition of the welding arc, as well as rapid re-ignition. When using them, the operating current significantly increases and the risk of burning through the connected elements is reduced. Such electrodes are durable. Compared to products made from pure tungsten, they pollute the weld pool less;

- "E" - thorium oxide . Electrodes with this additive are very popular. And all because of their merits. Such products are most often used for connecting stainless steel elements, which is carried out using direct current. When sharpening and welding in a closed room, the workplace should be provided with exhaust ventilation. And all because thorium is a radioactive metal, dust and vapors of which can have a negative effect on the human body. And when welding elements using alternating current, the arc can jump along protruding surfaces. And this factor worsens the quality of the connection;

- "Y" is yttrium . These products are the most durable. It is for this reason that they are used for welding particularly important structures. Welding is performed using direct current;

- "P" - pure tungsten . If this letter is present in the marking, it means that the product is 99.5% made of pure tungsten. Tungsten electrodes without any additives provide arc stability when welding with alternating current. They are used for argon welding of aluminum elements.

In order for a specialist to receive more detailed information about tungsten electrodes, the markings also contain numbers.

The first numbers after the letters indicate the exact percentage of alloying additive. For example, the number 15 means that the composition contains 1.5% alloying substance. The second numbers, which are separated from the first by a hyphen, indicate the length of the product in millimeters.

The most common length is 175 millimeters. But the length of the electrodes can be 50, 75 or 150 millimeters. Parts with different geometric parameters are welded using tungsten electrodes of different sections. The cross section value can be 1; 1.6; 2; 2.4; 3; 3.2; 4; 4.8; 5.6; 6.4 millimeters.

In order to be able to determine at first glance what the electrode is used for and what type it is, the ends of different brands are painted in certain colors.

The meaning of the colors in which the electrodes are painted:

- Dark blue. Electrodes WY-20. It contains 2% yttrium.

- Orange WT-40. Contains 4% thorium oxide.

- Purple - WT-30 grade, containing 3% thorium oxide.

- Red WT-20 contains 20% thorium oxide.

- Yellow WT-10 contains 10% thorium oxide.

- White WZ-8 contains 0.8% zirconium oxide.

- Blue WL-20 has 2% lanthanum oxide.

- Black WL-10. They contain 1% lanthanum oxide.

- WL-15 gold electrodes are enriched with 1.5% lanthanum oxide.

- Gray WC-20. They contain 2% cerium oxide.

- Green color indicates pure tungsten. It is designated WP.

Electrode marking

Tungsten electrodes are divided into two groups: for operation on direct and alternating current. They are classified and labeled according to the international standard EN 26848.

In Russia, such electrodes are produced with a diameter of 0.5 to 10 mm under the marking, in accordance with GOST 23949-80:

- EHF - made of tungsten;

- EVT - tungsten with thorium dioxide additive;

- EVL – tungsten with lanthanum additive;

- Computer - tungsten with yttrium additive.

Such products are not inferior in quality to their foreign counterparts.

Tungsten and its alloys

Tungsten is the most refractory metal , since its melting point is 3422 degrees C. There are several alloys with tungsten, for example, with cobalt and chromium, which are characterized by great hardness, durability and wear resistance.

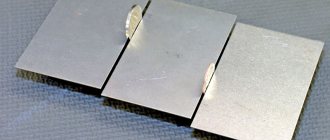

Alloys with silver and copper have high thermal and electrical conductivity, as well as wear resistance. They are used in the production of electrodes for spot welding. Welding with tungsten electrodes allows you to fulfill all the assigned production tasks and save the consumption of welding materials, including tungsten electrodes. The disadvantage of metal is its brittleness at 20 degrees C, so mechanical processing can be carried out at temperatures above the brittleness limit, that is, from 300 to 500 degrees C.

Areas of application

Knowledge of the areas of application of certain types of tungsten electrodes, as well as their features, will help you make the right choice.

Each type is created for a specific purpose that determines the types of production in which they are used:

- Electrodes without alloying

are used for welding nickel and aluminum. - WC-20

electrodes are used for welding tantalum, molybdenum, high-alloy steels, titanium, nickel, and copper. - Electrodes marked WL

can perform metal spraying and plasma welding of ordinary and stainless steels in an argon environment, using alternating or direct current of direct polarity. - WZ

electrodes can be used to weld nickel, aluminum, magnesium and their alloys in argon. - Electrodes with a red tip WT 20

are needed for welding copper, nickel, titanium and high-alloy steels. They have a good arc start and a long service life, but can be hazardous to health if welding gases and aerosols are inhaled.

Errors

Rapid consumption of tungsten rod occurs due to high current or insufficient inert gas during TIG welding. The welding rod oxidizes between welds due to premature switching off of the inert gas. It should run intensely for 10-15 seconds after the arc has gone out.

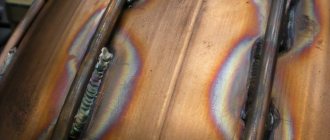

The welding rod may change color due to low shielding gas flow rate. A poor-quality weld occurs when water vapor enters the welding zone. This is often due to loose hose connections.

Tungsten welding

Advantages

Non-consumable tungsten electrode has the following advantages:

- stable welding arc;

- availability of a wide range with different characteristics;

- long operating time;

- high economic efficiency of application.

Sharpening

The shape of the tip determines the correct distribution of energy in the direction of the parts being welded and the amount of arc pressure, which, in turn, determines the shape of the seam. Therefore, sharpening must be approached seriously and competently. Sharpening can be done manually using electric sandpaper, but better results are achieved when using special devices.

The sharpening shape is determined by the brand of the electrode and the parameters of the workpieces being welded:

- WP

and

WL

brands must end with a ball; - On the WT

, the end of the electrode should have a slight convexity; - Other types are sharpened with a cone (like a pencil).

An interesting feature is observed when welding aluminum parts - a sphere is formed at the end of the electrode, and there is no need for sharpening. The length of the sharpened area is determined by the diameter of the rod multiplied by 2.5. This coefficient is constant.

For aluminum

The connection of aluminum parts must be light and durable. These requirements can be met using welding. But the problem is that despite excellent performance, aluminum is very difficult to weld.

Problems during welding are caused by the chemical and physical properties of the metal. There is always an aluminum oxide film on the surface of products, which has a melting point of more than 2000 °C, while aluminum itself melts at 650 °C. This requires the welder to remove and burn through the oxide film before heating the aluminum.

Aluminum in air, and even in a heated state, quickly oxidizes, which creates the prerequisites for the formation of a refractory film on the molten metal.

As a result, the seam is uneven. To eliminate this factor, it is necessary to ensure that there is no air access to the welding zone, which is what argon does with the tungsten method.

The fluidity of aluminum in the molten state requires the use of various heat-dissipating pads. Hydrogen escaping from the aluminum when heated creates many pores, leading to a weakening of the weld.

The large coefficient of thermal expansion and the resulting shrinkage during cooling leads to significant deformation of the product. The high thermal conductivity of the material requires the use of a current that exceeds the current required to connect more refractory materials.

For high-quality connection of welded parts, taking into account the above-described properties, the use of a tungsten electrode for argon arc welding of aluminum becomes the most appropriate. The best solution in this case is to use tungsten rods without additives.

To remove the oxide film on the surface of the material, welding must be carried out with a current of reverse polarity.

Welding Process Requirements

Welding technology and rules

For manual argon arc welding with tungsten electrodes, an inverter is most often used. This process is known worldwide as TIG. Not only inverters, but also other types of welding machines can operate in this mode. In addition, a distinction is made between operation on alternating current (AC) and operation on stabilized direct current (DC).

Welding is carried out in different directions with the torch positioned at different angles, depending on the thickness of the materials being welded. The main condition for a quality seam is maintaining a stable arc. The easiest way to get a good result is when working on direct current of straight polarity.

It is very important to feed the filler wire correctly and monitor the heating of the electrode during the sharpening process. When overheated, the electrode becomes brittle and may break.

Necessary equipment for welding

First of all, we need a power source and the best choice would be a welding inverter. The following tools and materials must be added to it:

- burner;

- gas hose;

- non-consumable tungsten electrode;

- protective gas - argon;

- filler wire - rod.

Helium can be used instead of argon. The choice of gas is decided by technologists depending on the material of the parts being welded. In addition to providing the process with all the necessary equipment, it is necessary not to forget about high-quality edge preparation.

Safety precautions

Tungsten welding in a protective gas environment is rightfully considered one of the safest methods of joining parts. This is due to the small amount of harmful substances released during the welding process. Despite this, it is necessary to strive to further reduce hazardous gases and mechanical dust. This is achieved by reducing the welding speed, reducing the welding current and preventing surfaces contaminated with oil from being welded.

Welders should be allowed to work only after undergoing all types of instruction and after checking the relevance of their permits. This is especially true for electrical safety approvals. The welder must know the specifics of using personal protective equipment and strictly use them in his work. Only this approach guarantees many years of work without harm to health.

Equipment

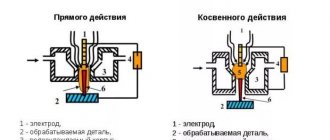

TIG welding equipment consists of several parts:

- DC or AC power source;

- welding torch with a non-consumable electrode;

- cylinders with inert gas with reducers;

- hoses for supplying it to the welding area.

The electrode is made of pure tungsten or its alloys and has a melting point of 3380 ⁰C. This allows you to weld any metal products.

It practically does not melt; periodically its end requires sharpening, which is necessary to obtain a high-quality, thin seam. It is a rod with one end sharpened.

The electrode is inserted into the collet and secured in the torch. The non-working part of the tungsten rod is covered with a special cap to prevent it from shorting to ground during work.

The TIG welding torch has a gas and voltage button. The head ends with a ceramic nozzle through which the pointed tip of a tungsten electrode peeks out. A gas hose is connected to the handle.

When the button is pressed, the gas exits through the nozzle, preventing the entry of air into the surrounding atmosphere. Due to this, there is no hydrogen from the atmosphere in the weld pool during TIG welding, which, as is known, leads to the appearance of pores in the weld during crystallization of the cooling product.

Which inverter is suitable for aluminum welding

The choice of inverter for aluminum welding depends on the volume and complexity of the work. If you have to do repairs infrequently, and there are no high demands on the quality of the connection, a cheap device is enough. Otherwise, preference is given to a model with MMA and TIG functions. This device makes connections using coated electrodes and argon arc welding. For home repairs, a current of 200 A is sufficient.

To simplify and speed up work at large volumes, you should pay attention to inverters with an oscillator that allows you to ignite the arc in a non-contact manner. The option of gradual arc decay, polarity balance control and pulse mode will be useful. If the inverter is expected to be moved frequently, preference should be given to compact models. They are more expensive than devices with similar functions, but are more convenient for transportation.