Home / Welding technique

Back

Reading time: 2 min

0

558

One of the criteria by which reverse step welds are divided is their duration. This nuance affects the way the seam is formed.

Depending on the duration, they are divided into three groups. Short, medium and long welded joints.

- Types of seams by duration

- Voltage and distortion

- Reverse-stage cooking is divided into different types

Reverse step method - welding

The reverse-stage welding method is used for single-layer and multi-layer seams.

[1] With a multilayer reverse-step welding method, the beginnings and ends of individual steps in each pass should be shifted relative to the previous ones by 20 - 40 mm. [3]

When welding long seams of sheet structures, a reverse-stage welding method is used. [4]

The method shown in Fig. 60 d, preferable, it is called this: a reverse-stage method of welding from the middle to the edges of the seam in a staggered manner. [5]

To avoid the occurrence of significant deformations, the following rules must be observed: use large-diameter electrodes and large current values; welding simultaneously by two welders; use a reverse-stage welding method. [7]

When automatically welding single-layer seams of any length and when welding short seams (up to 300 mm), they are manually welded from start to finish - one-by-one. With the reverse-step welding method, the entire seam is divided into separate sections 100 - 300 mm long. [9]

During welding and especially surfacing, continuous heat supply in one direction must be avoided. For this purpose, the reverse-stage welding method, welding and random surfacing are used. When surfacing large surfaces, they are divided into a number of equilateral triangles or rectangles with side lengths of 130 - 150 mm. Each of these small sites is fused with parallel beads, but when moving from site to site, the direction of the fused beads is changed. Surfacing intermittently is recommended. In this case, the possibility of a continuous and intensive increase in internal stresses and deformations is excluded. [10]

Welding is carried out from the center to the edges. The best results are obtained with the reverse-stage welding method. [eleven]

When installing lattice metal structures, assembly seams are welded using manual electric arc welding, semi-automatic flux-cored wire and in a protective atmosphere of carbon dioxide. When welding crane runway rails, bath welding is used. In this case, welding of low-carbon steels is carried out in all spatial positions with electrodes E42, E42A, E46 and E50 using existing techniques and technology of manual electric arc welding - transverse oscillation of the electrode across the opening angle of the seam, a reverse-stage method of welding long seams, welding with a slide and the cascade method, as well as Welding at an angle back and forth. Flux-cored wire welding is used only in the lower position. [12]

The length of the section is chosen such that welding can be carried out with a whole number of scrap electrodes. When welding thin metal, the sections are made shorter, when welding thicker metal, the sections are made longer. Welding of each section (stage) is carried out in the direction opposite to the general direction of welding. The reverse-stage welding method has several varieties. Medium-length seams are welded in a reverse-step manner from one end of the seam to the other. Welding of each stage is carried out in the direction of the previous welded section in such a way that the end of each stage is welded to the beginning of the previous one. [13]

You can also take a flux consisting of a mixture of 50% borax and 50% boric acid or 80% borax and 20% silicon oxide. The flux is mixed with water until it reaches the consistency of sour cream. It is applied to the edges of the product 15 - 20 minutes before welding. Flux must be applied to the front and back sides of the edges. To reduce warping, a reverse-stage welding method is used, and welding begins at a distance of 75 - 100 mm from the edge of the product. It is also advisable to place the arch on a copper or steel lining, which enhances heat removal from the seam. Welding should be carried out quickly and in one pass, and the wire should not vibrate. The weld pool should be covered with a thin layer of slag, and the end of the wire should be immersed in the pool. Welding is done using both left and right methods. [14]

After acceptance of the condenser-refrigerator assemblies, the assemblies and parts of the box are sorted, taking into account the sequence of their assembly and installation. Assembling the box begins with assembling the bottom. The bottom sheets are assembled end-to-end with a gap of 3–4 mm using tacks every 300–400 mm. After the bottom assembly is completed, the bottom plates are welded using mainly semi-automatic or automatic welding. The seams are welded without cutting the edges on the remaining steel backing 2–3 mm thick and 300–400 mm wide, which is tacked before joining the sheets. Welding is carried out from the center to the edges. The best results are obtained with the reverse-stage welding method. [15]

Iron laboratory

Posted by Welder | January 13, 2011

It is undesirable to have welding stresses and deformations in steel structures, since too high welding stresses can cause cracks to appear in the seams, with their transfer to the base metal. Deformations distort the geometric shape of the elements, which either leads to a decrease in their strength or complicates installation. It is impossible to completely eliminate welding stresses and deformations. Studying the nature and causes of the formation of welding stresses and deformations made it possible to develop measures that significantly reduce them. During assembly and welding, it is necessary to carry out the following basic design and technological measures. 1. In projects of steel structures, an oversized cross-section of welds should not be specified. The opening of chamfers in butt welds should be the minimum permissible according to technical conditions. During welding, the cross-section of the seams should not be allowed to increase compared to the design. 2. When welding sheet structures, it is necessary to use predominantly butt welds rather than overlap welds, since the force flow is unevenly distributed in overlap welds. 3. The seams must be positioned symmetrically with respect to the central axis of the element so that the welding stresses can be balanced. 4. Parts of structures, the geometric shape of which must be preserved without distortion, must be secured for welding in rigid jigs and devices in which they must remain until the product has completely cooled. 5. In cases of asymmetrical arrangement of seams relative to the central axis of the product, structures or parts must be given preliminary curves opposite to those formed after welding.

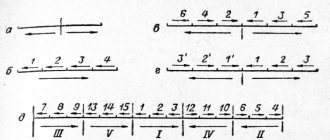

6. Welding of long seams is carried out using a reverse-step method. The seam is divided into sections 150-200 mm long. With a single-layer seam, welding is carried out from the middle to the ends in separate sections, as indicated in the figure; multi-layer seams are welded in cascades.

a - reverse-stage method, b - cascade welding

7. When welding a joint in rolled I-beams and channels, you must first weld the wall, and then the flanges. 8. When welding pipes consisting of several shells, the longitudinal joints should be welded first and only then the circumferential seams should be welded. 9. When assembling rods of an H-shaped section, it is necessary to first assemble separately the walls and shelves of the parts from which they consist, weld the joints, clean the seams on the shelves at the places where the walls adjoin, and only then assemble the element rods from the sheets. 10. When welding a joint in rods of an I-beam composite section, the longitudinal seams attaching the flanges to the wall of the rod should not be brought to 500-700 mm to the joint. First, the joint of the vertical wall is welded, then the joints of the shelves are welded, and lastly, the sections of the seams connecting the wall with the shelves are welded.

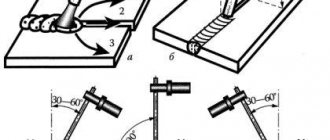

11. When welding lattice corners to gussets or to waist corners in a lattice structure, welding must be carried out towards the end of the corner, as indicated by the arrows in the figure.

a - welding a joint in a sheet rod of an H-shaped section, b - welding corners in a truss assembly

12. Welding of stiffeners should be carried out from the middle to the ends. 13. Welding of a crack in the metal should be carried out only after preliminary preparation for welding. First you need to open the crack as much as possible. There are two ways to open a crack: mechanical and thermal. In both cases, two holes are drilled at the end of the seam to eliminate stress concentrations and prevent further propagation of the crack.

With the mechanical method of opening a crack, two corners are welded on both sides, which are tightened with the greatest effort with bolts. In this case, elastic tensile stresses arise in the crack zone. Then the crack is welded and the bolts are removed, as a result of which the expanded edges of the crack move freely to their original position while the cooling seam shrinks.

a - mechanical method of opening a crack, b - thermal method of opening a crack

The thermal method consists of opening a crack by heating a section of metal behind the ends of the crack to a temperature of 150-200°. Heating is carried out by gas burners. The metal in heated zones tends to expand; compressive stresses are created in the crack zone, as a result of which the edges of the crack diverge. When heating the metal, it is necessary to ensure that the edges of the crack do not heat up. The edges are cooled by applying wet asbestos strands. After welding the crack, the seam cools down simultaneously with the heated areas of the metal. The edges of the crack move closer together, reducing stress in the contracting seam.

iron-lab.ru

Types of seams depending on the length (extent)

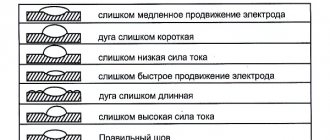

Short seams have a length of up to 300 mm. The average seam length ranges from 300 to 1000 mm. Seams longer than 1000 mm are called long or long seams. Each type has its own characteristics that you need to know about during the welding process.

Short welds are welded in one direction. The middle seams are divided into several zones, each of which is welded in the direction opposite to the previous one. In this case, you need to choose a zone length such that two to four electrodes can be used on it. To weld medium-length seams, a reverse-stage welding method can be used. The use of long seams occurs in tank construction and shipbuilding. In this case, reverse-stage welding is also used.

Reverse-stage welding is used to minimize welding deformations and stresses during welding work with medium and long seams, as well as to avoid warping of parts.

Advantages of the method

It is important to understand for what purposes the reverse step welding scheme is used. Reverse welding is an effective method of minimizing the deformations and stresses that occur during operation. In addition, this method helps to avoid warping of the welded parts.

Stress inside a part appears due to unequal heating and lowering of the temperature of its various parts when they contract and expand. Reducing the size of the weld pool as a result of its shrinkage can lead to deformation of parts of metal products bordering the seam. This happens because when it cools, it narrows, which leads to stretching of the nearest layers of metal and the appearance of distortions in them.

If the work is carried out correctly, the stresses inside, although present, do not cause severe deformations of the welded products. This method reduces internal stress. When adjacent small sections of the seam are applied, the deformations in them have opposite directions.

Reverse step method - welding

The reverse-stage welding method is used for single-layer and multi-layer seams. [1]

With a multilayer reverse-step welding method, the beginnings and ends of individual steps in each pass should be shifted relative to the previous ones by 20 - 40 mm. [3]

When welding long seams of sheet structures, a reverse-stage welding method is used. [4]

The method shown in Fig. 60 d, preferable, it is called this: a reverse-stage method of welding from the middle to the edges of the seam in a staggered manner. [5]

To avoid the occurrence of significant deformations, the following rules must be observed: use large-diameter electrodes and large current values; welding simultaneously by two welders; use a reverse-stage welding method. [7]

When automatically welding single-layer seams of any length and when welding short seams (up to 300 mm), they are manually welded from start to finish - one-by-one. With the reverse-step welding method, the entire seam is divided into separate sections 100 - 300 mm long. [9]

During welding and especially surfacing, continuous heat supply in one direction must be avoided. For this purpose, the reverse-stage welding method, welding and random surfacing are used. When surfacing large surfaces, they are divided into a number of equilateral triangles or rectangles with side lengths of 130 - 150 mm. Each of these small sites is fused with parallel beads, but when moving from site to site, the direction of the fused beads is changed. Surfacing intermittently is recommended. In this case, the possibility of a continuous and intensive increase in internal stresses and deformations is excluded. [10]

Welding is carried out from the center to the edges. The best results are obtained with the reverse-stage welding method. [eleven]

When installing lattice metal structures, assembly seams are welded using manual electric arc welding, semi-automatic flux-cored wire and in a protective atmosphere of carbon dioxide. When welding crane runway rails, bath welding is used. In this case, welding of low-carbon steels is carried out in all spatial positions with electrodes E42, E42A, E46 and E50 using existing techniques and technology of manual electric arc welding - transverse oscillation of the electrode across the opening angle of the seam, a reverse-stage method of welding long seams, welding with a slide and the cascade method, as well as Welding at an angle back and forth. Flux-cored wire welding is used only in the lower position. [12]

The length of the section is chosen such that welding can be carried out with a whole number of scrap electrodes. When welding thin metal, the sections are made shorter, when welding thicker metal, the sections are made longer. Welding of each section (stage) is carried out in the direction opposite to the general direction of welding. The reverse-stage welding method has several varieties. Medium-length seams are welded in a reverse-step manner from one end of the seam to the other. Welding of each stage is carried out in the direction of the previous welded section in such a way that the end of each stage is welded to the beginning of the previous one. [13]

You can also take a flux consisting of a mixture of 50% borax and 50% boric acid or 80% borax and 20% silicon oxide. The flux is mixed with water until it reaches the consistency of sour cream. It is applied to the edges of the product 15 - 20 minutes before welding. Flux must be applied to the front and back sides of the edges. To reduce warping, a reverse-stage welding method is used, and welding begins at a distance of 75 - 100 mm from the edge of the product. It is also advisable to place the arch on a copper or steel lining, which enhances heat removal from the seam. Welding should be carried out quickly and in one pass, and the wire should not vibrate. The weld pool should be covered with a thin layer of slag, and the end of the wire should be immersed in the pool. Welding is done using both left and right methods. [14]

Reverse-stage welding

95. Reverse-stage welding

Welding in which the weld is made in successive sections in the direction opposite to the overall increment in the length of the seam

5.1.11 reverse step welding:

Welding in which short sections of the seam are performed in the direction opposite to the overall increment in the length of the seam, so that the end of one section overlaps the beginning of the previous section (see Figure 54).

1

– gas flame;

2

– workpiece;

3

– filler rod;

Figure 54 – Reverse-stage welding

Dictionary-reference book of terms of normative and technical documentation. academic.ru. 2015.

See what “Reverse-stage welding” is in other dictionaries:

reverse-step welding - Welding in which the weld is performed in successive sections in the direction opposite to the overall increment in the length of the seam. [GOST 2601 84] [Terminological dictionary for construction in 12 languages (VNIIIS Gosstroy USSR)] Topics: welding, ... ... Technical Translator's Guide

Reverse-step welding is a welding process in which the weld is made in successive sections in the direction opposite to the overall increment in the length of the seam. [GOST 2601 84] Term heading: Welding Encyclopedia headings: Abrasive equipment, Abrasives,... ... Encyclopedia of terms, definitions and explanations of building materials

Welding is the production of permanent connections by establishing interatomic bonds between the parts being connected when they are heated and (or) plastically deformed. [GOST 2601 84] Welding - obtaining permanent connections by means of... ... Encyclopedia of terms, definitions and explanations of building materials

block welding - Reverse-stage welding, in which a multilayer seam is performed in separate sections with each of them completely filled [GOST 2601 84] [Terminological dictionary for construction in 12 languages (VNIIIS Gosstroy USSR)] Topics: welding, cutting,... ... Technical Translator's Guide

WELDING BY BLOCKS - reverse-stage welding, in which a multilayer seam is performed in separate sections with each of them completely filled (Bulgarian language; Български) multilayer welded in separate sections (Czech language; Čeština) svařování po blocích... ... Construction Dictionary

Welding - 1. Welding Obtaining permanent connections by establishing interatomic bonds between the parts being connected when they are heated and (or) plastically deformed Source: GOST 2601 84: Welding of metals. Terms and definitions of basic concepts... Dictionary-reference book of terms of normative and technical documentation

Block welding - 96. Block welding Reverse-stage welding, in which a multilayer weld is performed in separate sections with each of them completely filled Source: GOST 2601 84: Welding of metals. Terms and definitions of basic concepts... Dictionary-reference book of terms of normative and technical documentation

REVERSE STEP WELDING - welding in which the weld is performed in successive sections in the direction opposite to the overall increment in the length of the seam (Bulgarian language; Български) reverse-stick welded (Czech language; Čeština) svařování vratným krokem... ... Construction Dictionary

GOST R ISO 857-1-2009: Welding and related processes. Dictionary. Part 1. Metal welding processes. Terms and definitions - Terminology GOST R ISO 857 1 2009: Welding and related processes. Dictionary. Part 1. Metal welding processes. Terms and definitions original document: 6.4 automatic welding: Welding in which all operations are mechanized (see table 1).... ... Dictionary-reference book of terms of normative and technical documentation

GOST 2601-84: Welding of metals. Terms and definitions of basic concepts - Terminology GOST 2601 84: Welding of metals. Terms and definitions of basic concepts original document: 47. Friction welding Welding using pressure, in which heating is carried out by friction caused by the relative movement of the welded... ... Dictionary of terms of normative and technical documentation

Welding work: A practical guide for electric and gas welders (24 pages)

Rice. 66. Methods for making a seam: a – welding seams “on the pass”; b – welding of medium-length seams; c – welding of seams using a reverse-step method; d, e – welding long seams

Short seams along the length are usually welded “for passage” (Fig. 66, a). Medium-length seams are welded from the middle to the edges (Fig. 66, b) or in a reverse-step manner (Fig. 66, c). Long seams of single-pass butt joints and the first pass of multi-pass welds are welded from the middle to the ends in a reverse-step manner (Fig. 66, d), and in joints with fillet welds also from the middle to the ends in a reverse-step manner (Fig. 66, e).

Reverse-stage welding is the most effective method of reducing residual stresses and deformations.

The previous seam cools to a temperature of 200-300 °C. During cooling, simultaneously with a decrease in the width of the seam, the initially expanded gap also decreases, which is why residual deformations become minimal.

When welding butt or fillet welds of large cross-section, the seam is made in several layers (Fig. 67). In this case, each layer of the middle and upper part of the seam can be performed either in one pass (Fig. 67, a) or in two or more passes (Fig. 67, b).

From the point of view of reducing residual deformations, welding in one pass is preferable. If the seam width reaches 14-16 mm, then a multi-pass seam welding method is more often used.

Return wire

It is necessary to understand such subtleties as the return wire, and what is acceptable to use as it when welding. The return wire during welding is a wire that provides connection to current sources. It is used as:

- wires - rigid and flexible;

- tires in the form of strips with a minimum section of 40x4 mm made of steel or aluminum;

- welding plates.

The return wire must have the same insulation as the forward wire. The elements that are used for it must be securely connected to each other.