The range of pipes for communication devices is extensive. The manufactured products differ significantly in their characteristics: material, flexibility, strength, durability. It is often difficult for the user to determine which pipe to choose for water supply to a house or apartment.

The type of pipeline and transported medium, the number of plumbing points in the network - all these are factors that tip the balance in favor of choosing one type or another.

In our material we will try to understand the subtleties of choice, and also tell you how to determine the optimal diameter of the pipeline.

Basic requirements for water pipes

The characteristics of the installed communications must meet the requirements for water supply systems:

- Resistance to corrosion and aggressive impurities;

- Resistance to the formation of sediments and scale on the internal surfaces of pipes, which reduce the effective cross-section;

- Mechanical strength, ability to withstand water pressure;

- Heat resistance;

- Long service life;

- Simplicity of pipe connections during installation;

- Dimensions and weight;

- Reasonable cost;

- Satisfactory appearance.

Copper

The throughput of copper water supply is higher than that of others. This is achieved due to a smoother internal surface, so smaller diameter pipes can be used. Copper has disinfectant properties, due to which copper pipes are widely used for drinking water supply systems.

The undoubted advantages of copper products include their presentable appearance, resistance to corrosion and long service life, which can reach 70-100 years.

However, the high cost of copper pipes and installation work is not affordable for everyone. Such water pipes are usually found in luxury homes, where luxury is considered one of the important indicators.

In order to competently design and arrange a water supply system, it is necessary to carefully examine various types of water pipes, comparing their technical, operational and aesthetic characteristics. In this case, the choice of pipe type will depend on its purpose: either an internal water supply and drainage system (sewerage) is planned, or installation of external communications is required.

There are quite a lot of options, so it is worth considering this issue in detail to avoid unnecessary mistakes and extra costs. Pipes for water supply. Main characteristics of water pipes First of all, you should take into account the types of water supply and sewerage networks (sewage systems). They are divided into: external networks, internal networks. In both options, pressure pipes are used, designed to supply hot and cold water under the appropriate pressure. The pipes are connected using a special soldering machine. The main operational characteristics of water pipes include the following parameters: corrosion resistance; chemical resistance; service life; resistance to different temperature operating conditions; throughput. Classification of water pipes by material All pipes for supplying and discharging water are divided into three main classes: Metal pipes (cast iron, steel, copper). Polymer pipes (plastic). Metal-plastic pipes (polymer materials are combined with metal). Each type has its own advantages and disadvantages due to the physical properties of the material. Metal pipes Types of plastic water pipes have a long service life. Cast iron water supply. Due to the fragility of this material, communications made of cast iron require special care during installation and transportation.

Connection and sizing pose a major challenge for installers. Although, in comparison with water pipes made of steel, cast iron pipes last longer (according to some estimates, up to 80 years) and do not “overgrow” so much from the inside, the use of cast iron in the construction of water pressure systems is gradually being reduced. Steel water pipes. The disadvantage of this type of pipe is its short service life - approximately 20 years.

Low corrosion resistance over time leads to the formation of rust inside the pipe, which significantly deteriorates the quality of drinking water supplied to the system. Reduced communications flow negatively affects the costs of supplying water to the consumer. Compared to Europe, the cost of water supply in our country is 1.5 times higher.

Metal corrosion leads to accidents and breakdowns during the use of steel systems. It is also worth noting the high labor intensity when installing and replacing sections of steel water supply. The method of connecting such pipes is either threaded adapters or welding joints.

All this increases the time and cost of installation and maintenance of such systems, however, one should pay tribute to the high strength and relatively low cost (compared to copper) of this type of pipe. Copper pipes. As a rule, they are used only indoors due to the high cost and specific connections. This type of pipe is not compatible with galvanized steel products, which makes them difficult to replace or repair (professional help is required).

Nevertheless, the durability of copper water pipes exceeds all other metal systems (operation without leaks is possible for a whole century). This material has an unusually smooth internal surface and, as a result, there is no corrosion “overgrowth” and a decrease in throughput. The absence of corrosion keeps drinking water clean and makes this type of pipe very popular when installing both hot and cold water supply systems and heating systems. Such pipes are today most often used in water supply systems around the world.

What is the reason for such popularity? Let's consider the main advantages of these types of pipes: the service life is very long (plastic does not deteriorate for centuries); the smooth inner surface does not contribute to “overgrowth”; the low sound conductivity of plastic reduces the noise characteristic of water pipes; the quality of water does not deteriorate because there is no corrosion; the material is lightweight, therefore transportation and installation work have a low cost (assembly is carried out by simple cutting and subsequent connection using soldering or fittings); high strength; low cost of the pipes themselves; these advantages encourage specialists to willingly design networks with polymer types of pipes; in fairness, it is worth noting some disadvantages, which types of polymer materials have: with increasing temperature, an increased coefficient of change in the dimensions of the product is observed; diffusion (penetration) of oxygen through the walls of pipes, affecting the quality of operation. Types of polymer pipes The connection of pipes must be as tight as possible. Polyvinyl chloride (PVC) pipe - used for both internal communications and external ones. An economical option due to the low cost of products. Polypropylene pipes are widely used not only for plumbing systems, but also for sewerage, heating, and irrigation. Polyethylene pipes are used in seismically active areas (for example, in Japan), because polyethylene is very elastic and can stretch up to 7% of its volume without collapsing.

The same property makes polyethylene systems indispensable in conditions of low temperatures and during water hammer. Pipes made of cross-linked polyethylene (PEX) - polyethylene produced under high pressure is used. The material has improved characteristics of resistance to high temperatures and loads. Used in hot water supply and heating (including for “warm” floors). Metal-plastic pipes (PEX-AL-PEX) This type of pipe is increasingly being used, since, thanks to the reinforcement of a conventional polyethylene pipe with aluminum, its protection from diffusion, resistance to high pressure (10 bar), high temperature (up to 95°) and deformation. Although this type has a slightly higher cost than conventional plastic pipes, its quality characteristics make these products indispensable when constructing open systems. Share a useful article :Similar articles:

Today, the choice of pipes for installing a water supply system in an apartment or private house is so large that it is very difficult for an ordinary buyer to make a choice. In order to choose the right option, you need to take into account: the temperature and pressure of the liquid, the diameter of the pipes, the cost of the elements and the required service life of the system, the ease of its installation. Let's consider the main types of pipes for the water supply system in the house.

Purpose of water pipelines

The supplied water can be used for different purposes:

- For drinking, cooking, personal hygiene purposes - residential premises, catering establishments, medical and educational institutions and others;

- For hot water supply to residential and industrial premises and structures;

- For heat supply;

- For the technical needs of industrial enterprises;

- For irrigation systems and watering in agriculture

Copper

They are beautiful, durable, and are not afraid of temperature changes or rust. They are light, plastic, flexible, have a long service life, and are not afraid of a single freeze. Used for drinking water and heating systems.

Important! Copper pipes are not used for acidic liquids, for water with solid impurities, or at high fluid flow rates. They are not recommended to be connected to aluminum radiators.

Mounted using threaded connections or special welding.

Materials used for making pipes

Depending on the purpose and operating conditions, metal, polymer, metal-plastic and asbestos-cement pipes are used.

Metal pipes are made from:

- Cast iron;

- Structural steel;

- Galvanized steel;

- Of stainless steel;

- Copper

The most common materials for non-metallic pipes are:

- Polypropylene;

- Polyethylene;

- PVC;

- Metal-plastic;

- Asbestos cement

Briefly about the main thing

It is not difficult to choose a material for installing a water supply system if you know all the features of pipes, methods of their assembly and changes in characteristics under different operating conditions. For example, if you need to choose which pipes are best for underground water supply in a private house, then HDPE or PP pipes would be the ideal solution. All types of plastic and metal-plastic products are suitable for internal wiring, with the exception of pipes made of low-density polyethylene, as well as copper ones. Traditional steel pipes can also be used, but you need to be prepared that hard water will quickly damage them, and their appearance will have to be maintained by regular painting.

Pipe parameters

According to the operating pressure they are divided into pipes:

- Low pressure – up to 12 atm. The minimum pressure for residential premises is 2 atm.

- Medium pressure - from 12 to 25 atm.

- High pressure – more than 25 atm.

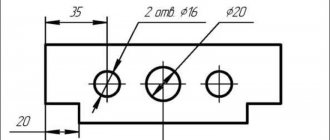

The most important characteristics of pipes are the diameter and wall thickness.

The following diameters are available:

- Outer;

- Interior;

- Conditional or internal passage.

The internal diameter is calculated as the difference between the external diameter and twice the wall thickness.

The internal passage is numerically equal to the internal diameter, rounded up.

The maximum operating pressure depends on the wall thickness.

Based on the diameter of the pipe, they are divided into:

- Small diameter - up to 114 mm, used for installation in residential premises;

- Medium – from 114 to 530 mm, city water supply systems;

- Large - over 508 mm, main water pipelines, oil pipelines, gas pipelines.

The connection of pipes of different diameters with each other and changing the direction of laying at different angles is carried out using special fittings - fittings, angles, tees, etc.

At a water temperature of up to 46°C, water supply systems are considered sources of cold water supply (CWS), and above this value - hot water supply (DHW).

Stainless

*

Pipes made of alloyed corrosion-resistant steel are durable and not subject to the destructive effects of water. They can last up to 400 years. Oxidation products do not accumulate on the wall and do not enter the household water supply. Increasingly, stainless steel products are replacing conventional carbon steel, despite the higher price of the material and the complexity of installation.

Their stainless steel profiles

Stainless steel structures comply with sanitary and hygienic standards, withstand water shocks well, and are resistant to critical temperatures. Water with excess chlorine can damage stainless steel, so after disinfection it is recommended to thoroughly rinse the system.

Stainless steel pipes are used in various fields:

- water, heat and gas supply;

- fire fighting;

- installation of ducts for air conditioning;

- laying “warm floor”;

- for protecting power electrical cables.

The water supply is assembled using press fittings, also made of stainless steel, by welding with a tungsten electrode in an inert environment. In industrial conditions, laser welding is used.

Water supply systems made from flexible corrugated pipes are becoming increasingly common. Their advantages are the possibility of laying in hard-to-reach places, installing long-distance lines, and resistance to dynamic or vibration loads.

Water pipelines made of plastic pipes

Plastic pipes, regardless of the material used, have a number of common advantages and disadvantages compared to metal water pipes.

Advantages:

- The service life of metal-plastic is 35-50 years, for other materials at least 50 years;

- Very high corrosion resistance;

- Due to the low thermal conductivity of the material, they have low heat losses;

- Light weight;

- There is practically no internal “overgrowing” due to salt deposition;

- Easily machined;

- Installation does not require complex equipment and highly qualified plumbers performing the work;

- Cheaper than metal ones.

Flaws:

- Mechanical strength is lower than that of metal pipes;

- They are not resistant to ultraviolet radiation.

Video description

The secrets of installing PP pipes are revealed in this video:

Polyvinyl chloride

The main advantage of PVC is its small coefficient of thermal expansion and stability of linear dimensions when transporting hot water. But such pipes are very fragile, especially at low temperatures, and have high thermal conductivity. Due to the impossibility of threaded and welded connections, their assembly is carried out using glue, which is not always convenient and takes a lot of time.

For reference! PVC pipes are considered an ideal material for sewer systems.

Adhesive connection of PVC pipes Source strojdvor.ru

Selection of pipes for water supply

The choice is made taking into account many factors: installation and operating conditions, maximum pressure and temperature of the transported liquid, length and throughput of the pipeline, expected service life, cost, ergonomic requirements, etc.

When using polymer pipes, pressure and temperature restrictions must be taken into account. The most durable plumbing systems are made from steel pipes.

- For internal wiring of residential premises, polypropylene pipes are most often used, as they best meet the quality and cost requirements.

- For external installation, it is necessary to use pipes with high corrosion resistance.

- If there is a danger of deep freezing, then you should not use stainless steel pipes

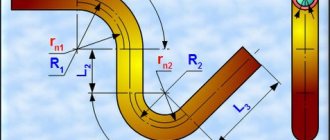

A very important point is to determine the diameter of the pipes, taking into account the required flow rate.

It must be borne in mind that a large length, numerous bends and the presence of connecting fittings lead to an increase in hydraulic resistance and a decrease in the actual pressure in the pipelines.

Roughly, we can assume that for a home water supply system up to 10 meters long, it is enough to have a pipe with a diameter of 20 mm, for a length from 10 to 30 m - 25 mm, for more than 30 m - at least 32 mm.

With a complex configuration and difficult installation conditions, it is better to entrust the calculation and selection of pipes and fittings to a specialist who can make the necessary hydraulic calculations.

This will allow you to subsequently avoid various alterations and unnecessary material costs.

Hydraulic calculation

To determine the most economical sections of the water supply system, a hydraulic calculation is carried out. The condition must be met to ensure the required water flow, maintain pressure and minimize pressure losses. Taken into account:

- calculated direction of water movement;

- consumption according to water consumption standards;

- characteristics of water fittings and number of points;

- housing overcrowding ratio;

- pressure loss due to friction along the entire length of the pipe.

Based on the calculation results, the diameter of the water pipes is selected based on the table of sizes and product range.

To determine pressure losses, use Shevelev tables or online programs.

The tables for hydraulic calculations of steel, cast iron, asbestos-cement, plastic and glass water pipes contain ready-made indicators depending on the diameter, material, line length, and network pressure. Losses are determined at each site and summed up. Based on the value found, the required flow rate and pump power are determined.

Example of hydraulic calculation using Shevelev tables

The water supply system is a complex engineering communication. It is important to select pipes taking into account their technical characteristics and perform installation correctly.

Photos of all types of water pipes

Polyethylene pipelines – areas of application

The key difference between HDPE pipes is their environmental friendliness, biological neutrality, resistance to deposits on the walls and most chemicals, including acids and alkalis. Features of production (as in other types of pipe products) are reflected in the marking code, deciphering which will help in choosing the right type from the presented assortment.

Connection options

The last point worth highlighting is the available connection options. They can be:

- welded (only for rolled steel),

- soldered (for copper and plastic),

- threaded,

- press

The only option that can be easily dismantled and replaced is a threaded connection. However, it cannot be used when concreting in walls or floors, that is, the pipeline fittings must remain open.

Technical characteristics GOST 18599 2001

Estimated weight of 1 meter of PE32 pipe in kg

| Outer diameter (nominal), mm | ||||

| SDR 6.0 | SDR 9.0 | SDR 13.60 | SDR 21.0 | |

| Wall thickness Sst., mm | ||||

| 2,50 | 4,0 | 6,30 | 10,0 | |

| 160 | 8,13 | 5,61 | 3,77 | |

| 140 | 6,24 | 4,29 | 2,89 | |

| 125 | 6,90 | 4,96 | 3,42 | 2,29 |

| 110 | 5,34 | 3,84 | 2,66 | 1,78 |

| 90 | 3,58 | 2,59 | 1,80 | 1,19 |

| 75 | 2,48 | 1,79 | 1,25 | 0,831 |

| 63 | 1,75 | 1,27 | 0,885 | 0,582 |

| 50 | 1,10 | 0,798 | 0,552 | 0,376 |

| 40 | 0,713 | 0,511 | 0,358 | 0,249 |

| 32 | 0,459 | 0,329 | 0,233 | 0,197 |

| 25 | 0,280 | 0,201 | 0,151 | |

| 20 | 0,182 | 0,134 | ||

| 16 | 0,116 | 0,92 | ||

| 12 | 0,065 | |||

| 10 | 0,052 | |||

Areas of application

Marking with a colored line - indicates the scope of application and average characteristics:

- Causes of noise in water supply pipes

- Soundproofing of water supply pipes in an apartment

- Do-it-yourself insulation of water supply pipes on the street

- blue stripe - for water supply;

- yellow stripe – for gas transportation.

Gas pipes with yellow stripe

Other values are allowed.