Universal Company LLC has extensive experience in the sale of materials for packaging any cargo and has managed to establish itself as a reliable, responsible supplier. If you need a metal tie-down tape, then the online product catalog presented in the current section of the site will help you choose and buy the necessary material for tie-down of containers with optimal parameters at a price that is comfortable for you. The steel packaging tape that you see on this page is a durable and safe material for ensuring the safety of cargo during transportation and storage. We guarantee that any metal packaging tape will be a profitable solution for working with goods of any kind. Products are supplied by trusted manufacturers from Russia and foreign countries. Metal packaging tape complies with established standards and is accompanied by a guarantee.

Classification

Metal tape is classified according to a number of parameters.

- Based on the nature of the material, the products form subgroups: highly cold-worked (designated VN), cold-worked (designated PN), soft (designated M) and extra-soft (designated OM).

- Precision manufacturing forms three groups of products: increased precision (designated PT), high precision (designated VT) and normal accuracy (designated NT).

- According to the crescent shape of the planes, they are divided into classes A (with control) and B (without control).

- According to the quality of the surface of the product, they form classes A, B, C, D, D, E.

At the same time, the tape is distinguished by the manufacturing method into hot-rolled and cold-rolled. The first is made from carbon steel, the second is made by longitudinal cutting of blanks (sheets).

Steel Tape Packing

Before shipping to the customer, metal packaging tape is stacked in stacks of several rolls each. Each stack is then wrapped with strips of metal or wire.

They can be pre-treated with a special substance to provide protection from the negative effects of the external environment. Polymer film or waxed paper can be used for packaging .

Hard-worked and soft type

Cold-worked steel strip is characterized by increased rigidity and strength. It is advisable to use such a product when transporting heavy objects.

Cold-worked packaging is produced by squeezing steel without preheating. As a result, it becomes softer and acquires the necessary plasticity, but its surface, on the contrary, hardens and becomes stronger.

The mild type is produced from low carbon steel by cold rolling. The strength of such a product is quite high, but during transportation it can stretch and lengthen, which will inevitably lead to its weakening. Suitable only for working with medium-heavy loads.

If the base material, that is, steel, is coated with a zinc or polymer protective layer, then its original positive properties will not be lost even after many years. Material with an anti-corrosion coating easily withstands the negative effects of water and humid air, and is also not afraid of temperature changes.

Application

The use of tape in certain areas of industry depends on its characteristics. The most popular is metal packaging tape. These products are usually used in cold weather outdoors, when the use of polyester and polypropylene tapes is not possible. Due to its strength, steel packaging tape is successfully used both for storing products and for transporting them (including oversized cargo).

The stamping tape is made of low carbon steel. It is used for stamping various parts.

Nichrome tape, unlike its many analogues, has high electrical resistance and resistance to high temperatures. Thanks to these properties, the products have found wide application in the production of various heating elements.

High-strength steel grades are used to produce tape for armoring ships and ships. Such specific products, which are entrusted with such important tasks, must have improved characteristics. Therefore, this type of tape is most often made galvanized. Galvanized steel tape can be used for the manufacture of both flat and profile armor.

Metpromko company consultants will be happy to help you navigate the variety of rolled metal products, select the optimal type, inform you about prices and the discount system, and create an economical route for product delivery.

Packing steel tape, from 55 rubles per kg.

Packaging cold-rolled steel tape , made from low-carbon high-quality steel, is ideal for enterprises and firms that regularly deal with tying various types of reinforcement, construction products, rolled metal (for example, stainless pipes), transporting double-glazed windows and other fragile items that require careful handling during transportation.

Cold-rolled steel packaging tape is not afraid of the influence of aggressive chemical compounds and dampness, since most of it is produced with a special polymer coating made of galvanized material, which perfectly protects the product from external influences throughout the entire period of its use. GOST 3560 divides packaging tape into several types according to the following indicators:

- in terms of production accuracy: W - increased accuracy in width and T - in thickness, standard accuracy according to the specified parameters (the product is sold without applying additional markings);

- according to the condition of the material: N - hard-worked, PN - semi-hardened, M - soft.

The thickness of the tape varies from 0.2 to 1.8 mm, width - from 15 to 50 mm. Permissible deviations in product dimensions depend on their specific parameters and accuracy class; they can range from 0.02 to 0.15 mm in length and from 0.5 to 2 mm in width. By agreement with the buyer, the product can be produced with a non-standard width (for example, 321, 137, 239, 120 mm), but provided that its thickness is within 0.25–0.4 mm (width deviation in this case should not exceed 1 mm).

The relative elongation of strips made of semi-work-hardened material should be more than 7% (of soft material - more than 17%), elongation for strips of cold-worked metal is not provided. The packaging product, in addition, must have the following indicators of (temporary) resistance to tearing:

- cold-worked material – from 60 N/mm2;

- semi-hardened – from 35 N/mm2;

- soft - from 25 N/mm2.

Steel with low carbon content (51HFA, 70, 10, 08kp 1ps, 60S2A, 45, 08ps and others) for the production of packaging tape must comply with the provisions set out in State Standards 1050-88, 380-88, 16523-89. In some cases, it is possible to manufacture products from carbon steels, if the consumer’s consent is obtained.

Special requirements for the characteristics of the finished product:

- absence of delaminations and flaws on the surface of the product;

- weight of one roll: 40–200 kg with a tape width of more than 20 mm and 20–80 kg with a width of up to 20 mm;

- small individual dents on the edges of the product are possible, but they should not have dimensions exceeding more than half the permissible deviations in width;

- per 1 m of tape length, a crescent shape of up to 5 mm is allowed.

| Name | Thickness, mm | Width, mm | Price |

| Steel packaging tape | 0.3 | 20 | Check price |

| Steel packaging tape | 0.3 | 45 | Check price |

| Steel packaging tape | 0.4 | 20 | Check price |

| Steel packaging tape | 0.5 | 19 | Check price |

| Steel packaging tape | 0.5 | 20 | Check price |

| Steel packaging tape | 0.7 | 19 | Check price |

| Steel packaging tape | 0.7 | 20 | Check price |

| Steel packaging tape | 0.8 | 19 | Check price |

| Steel packaging tape | 0.8 | 20 | Check price |

| Steel packaging tape | 0.9 | 20 | Check price |

| Steel packaging tape | 0.9 | 30 | Check price |

| Steel packaging tape | 0.2 | 15 | Check price |

| Steel packaging tape | 0.2 | 20 | Check price |

| Steel packaging tape | 0.2 | 30 | Check price |

| Steel packaging tape | 0.2 | 40 | Check price |

| Steel packaging tape | 0.2 | 50 | Check price |

| Steel packaging tape | 0.25 | 15 | Check price |

| Steel packaging tape | 0.25 | 20 | Check price |

| Steel packaging tape | 0.25 | 30 | Check price |

| Steel packaging tape | 0.25 | 40 | Check price |

| Steel packaging tape | 0.25 | 50 | Check price |

| Steel packaging tape | 0.3 | 15 | Check price |

| Steel packaging tape | 0.3 | 30 | Check price |

| Steel packaging tape | 0.3 | 40 | Check price |

| Steel packaging tape | 0.3 | 50 | Check price |

| Steel packaging tape | 0.4 | 15 | Check price |

| Steel packaging tape | 0.4 | 30 | Check price |

| Steel packaging tape | 0.4 | 40 | Check price |

| Steel packaging tape | 0.4 | 50 | Check price |

| Steel packaging tape | 0.5 | 15 | Check price |

| Steel packaging tape | 0.5 | 30 | Check price |

| Steel packaging tape | 0.5 | 40 | Check price |

| Steel packaging tape | 0.5 | 50 | Check price |

| Steel packaging tape | 0.7 | 15 | Check price |

| Steel packaging tape | 0.7 | 30 | Check price |

| Steel packaging tape | 0.7 | 40 | Check price |

| Steel packaging tape | 0.7 | 50 | Check price |

| Steel packaging tape | 0.8 | 30 | Check price |

| Steel packaging tape | 0.9 | 15 | Check price |

| Steel packaging tape | 0.9 | 40 | Check price |

| Steel packaging tape | 0.9 | 50 | Check price |

| Steel packaging tape | 1 | 20 | Check price |

| Steel packaging tape | 1 | 30 | Check price |

| Steel packaging tape | 1 | 40 | Check price |

| Steel packaging tape | 1 | 50 | Check price |

| Steel packaging tape | 1.5 | 30 | Check price |

| Steel packaging tape | 1.5 | 40 | Check price |

| Steel packaging tape | 1.5 | 50 | Check price |

| Steel packaging tape | 1.8 | 30 | Check price |

| Steel packaging tape | 0.5 | 13 | Check price |

Standard sizes and prices of cold-rolled tin-plated low-carbon steel strip

| Name | Dimensions, mm | Price |

| Cold-rolled tin-plated steel strip | 0.11x43-45 | Check price |

| Cold-rolled tin-plated steel strip | 0.30x52.7 | Check price |

| Cold-rolled tin-plated steel strip | 0.30x130 | Check price |

| Cold-rolled tin-plated steel strip | 0.35x59-70 | Check price |

| Cold-rolled tin-plated steel strip | 0.35x100 | Check price |

| Cold-rolled tinned strip | 0.3x52.7 | Check price |

| Cold-rolled tinned strip | 0.3x130 | Check price |

| Cold-rolled tinned strip | 0.35x70 | Check price |

| Cold-rolled tinned strip | 0.35x59 | Check price |

| Cold-rolled tinned strip | 0.35x100 | Check price |

Standard sizes and prices of cold-rolled low-carbon steel strip

| Name | Thickness, mm | Width, mm | Price |

| Cold-rolled strip made of low-carbon steel 0.10-0.49x38 | 0,10-0,49 | 38 | Check price |

| Cold-rolled strip made of low-carbon steel 0.50-0.99x36 | 0,50-0,99 | 36 | Check price |

| Cold-rolled strip made of low-carbon steel 1.00-2.00x34 | 1,00-2,00 | 34 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.4x15 | 0,4 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.5x15 | 0,5 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.8x15 | 0,8 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.9x22 | 0,9 | 22 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.0x24 | 1,0 | 24 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.2x30 | 1,2 | 30 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.5x34 | 1,5 | 34 | Check price |

Standard sizes and prices of steel tape for cable armoring

| Name | Thickness, mm | Price |

| Steel tape for cable armoring (galvanized) | 1,00 | Check price |

| Steel tape for cable armoring (galvanized) | 0,80 | Check price |

| Steel tape for cable armoring (galvanized) | 0,50 | Check price |

| Steel tape for cable armoring (galvanized) | 0,40 | Check price |

| Steel tape for cable armoring (galvanized) | 0,30 | Check price |

Tape Tightening Tools

When using bandage metal strips, manual, pneumatic, and mechanical devices are used. The market offers various models produced by well-known manufacturers. These machines greatly facilitate work with packaging material and provide reliable fastening of goods with sharp edges and corners.

Enterprises that produce products in small volumes use hand-held tools. Manual packaging machines like M4K-10 are relatively inexpensive. The mechanisms are easy to operate, do not require special skills, are reliable and durable.

Tip: Experienced craftsmen recommend using designs with a ratcheting mechanism. These manual machines are easy to use. The working material does not need to be pushed, it is fed using a ratchet mechanism, the design includes a long handle and a built-in cutter.

To perform packaging operations in large volumes in a short time, more complex tools are used: mechanical or pneumatic.

These devices are much more productive than their manual counterparts and work with large-sized products. When packing large, heavy loads, it is advisable to use mechanized tools that evenly secure the bandage tape in each zone.

Power tools

Depending on the shape and weight of objects, locking and lockless devices are used, powered by mechanical or pneumatic drives.

Objects with flat surfaces are tied with steel tape using the punched fastening method using combined tools that are in demand when tying various building materials:

- pipes;

- lumber;

- furniture blanks;

- reinforced concrete slabs;

- fittings;

- double-glazed windows, etc.

When tying large-sized round-shaped loads or other complex configurations, locking machines with tensioner-seals are used. Here the ends of the tape are secured using special metal locks.

Important: Universal combined mechanisms perform several functions in one cycle: tensioning, fastening, cutting the ends of steel strips, forming locking joints called “dovetails”. “3 in 1” devices are easily adjusted to the parameters of steel belts: thickness, width. Such tools are easy to use; the master does not have to put in too much effort.

What materials is the bandage tape made from?

The main raw material is high-quality low-carbon steel or stainless steel AISI 201, A-2, which has high strength and resistance to adverse weather conditions (temperature changes, high humidity).

The most common grades of low-carbon steels are manufactured according to GOSTs 380-88, 1050-88, 16523-89:

- Steel 70.

- Steel 10.

- 08 KP.

- 08 PS.

- 1 PS.

- Steel 45.

- 60С2А.

- 51HFA.

Steel strips that have undergone additional heat treatment maintain geometric parameters, retain the shape of the packaged product, and do not deform it during loading/unloading, transportation, or storage. Metal packaging does not change its properties and retains its original shape in frost and heat.

Metal tapes treated with zinc, anti-corrosion varnish or special polymer coatings are used to fasten products that are stored for a long time in the open air or in large refrigerated compartments.

Galvanized products do not rust, remain unchanged when in contact with aggressive chemicals, and have increased strength and tear resistance.

Main advantages

One of the most important benefits of steel packaging tape is its strength. This product withstands various mechanical impacts well and does not deform during transportation. All this guarantees that the cargo will remain safe and sound during transportation.

Another significant advantage is low temperature resistance. Even in extreme cold, the properties of the product do not change, so you can safely use it even when you need to transport some cargo in winter.

The high popularity of steel packaging tape is also due to the fact that these metal strips are easy to use. Even at the production stage, special holes are made on its surface to simplify the packaging of goods.

To connect the ends of the tape, you may only need staples, but often you can do without any additional materials at all.

Types of steel packaging tapes

Depending on the accuracy of execution, the packaging material is marked with the letters T and Ш:

- W – accuracy of tape width 15 – 50 mm;

- T – thickness accuracy 0.2–1.8 mm;

- There are no markings on standard precision products.

Classification of low-carbon steels depending on the physical state of the material:

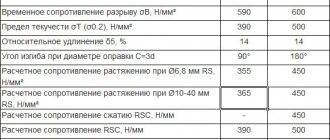

| Tensile strength (N/mm2) | Elongation level (%) | |

| N – hard-worked | 60 | not indicated |

| PN – semi-hardened | Z5 | from 7 |

| M – soft | 25 | from 17 |

Steel strips are produced in three stages:

- Cutting.

- Heat treatment, galvanizing.

- Applying varnish or other coatings.

- Packing in rolls.

Winding of rolls is carried out in several ways: single-, double-, multi-row, “jumbo”. The ends of the winding are fixed with interlocking perforated joints.

Advice: When choosing packaging material, you need to know the technical characteristics of the goods (dimensions, weight, product category). It also doesn’t hurt to know the quality of the road surface, distance, travel time.

What is cold-worked steel

Metal hardening (hardening of the surface layer) is performed in two ways:

- Mechanical processing (plastic deformation of metal workpieces by external mechanical influence, for example, cold hardening, “firing” of parts with shot from hard grades of steel).

- Heat treatment (plastic deformation, stamping of soft plastic tape, annealed in a special furnace).

A little theory: As a result of hardening, the internal parameters of the metal change: the structure of low-carbon steels, the crystal lattice, the phase composition. The outer layer of cold-worked metal acquires additional strength and hardness.