Physical properties

- Colorless tetragonal crystals.

- Density: 228 (+20 °C, g/cm3).

- Specific heat capacity at constant pressure (in J/g·K): 0.92 (+20–325 °C).

- Standard enthalpy of formation ΔfH (298 K, kJ/mol): −62.8 (t).

- Standard Gibbs energy of formation ΔfG (298 K, kJ/mol): −67.8 (t).

- Standard entropy of formation S (298 K, J/mol·K): 70.3 (t).

- Standard molar heat capacity Cp (298 K, J/mol·K): 62.34 (t).

- Melting enthalpy ΔHmelt (kJ/mol): 32.2.

- Calcium carbide has a strong garlicky odor.

What is carbide?

Homemade bombs. This is what comes to mind first when we hear the word carbide. And no, the production of these dangerous toys was not carried out by defense industry enterprises, but, as a rule, by boys, about ten years old.

Twenty years ago it was a favorite pastime among teenagers. Now everyone sits at their tablets, but back then the world was ruled by the inquisitive mind of a child who strove to try everything in practice.

In order to feel like Rimbaud, you needed to get one miracle stone. Children most often found them at construction sites. And then everything was simple: a plastic vessel, a stone, water, a tightly screwed cap. All this was zealously shaken, and at best, thrown away. And in the worst case, the “shell” exploded right in the hands, then injuries could not be avoided.

Calcium carbide

There were also safer ways to use the find, for example, simply throwing it into a puddle, then you could observe something similar to the effect of modern bath bombs. So what kind of popular “toy” is this? Most of us believed that nature produced carbide as we know it. But actually it is not. And today you will see this.

So, this substance is always very hard, plus, in order to melt it, you need to make a remarkable effort. They look like dark, light, greenish stones, or powder, it all depends on the composition. Its shelf life is short, usually six months. It will not be possible to place containers in a general warehouse; such potentially dangerous substances must have their own compartment.

As you already know, carbide constantly strives to explode. Moreover, some connections do not even need special conditions. It is enough just to pour the powder from container to container, and it can suddenly explode.

Properties and composition

To obtain this stone, you need at least two elements. First is carbon. Its presence is mandatory. And then there is a choice: metal or non-metal. The main thing is that the rule is followed: the electronegativity (the force with which the atoms of an element attract foreign electrons) of the required component is higher than that of its “partner”. Otherwise you will get completely different connections.

Calcium Carbide Formula

This connection was first discussed in England back in the 19th century. However, the fame of the discoverer went to the Frenchman, thanks to whose experiments the substance was officially recognized; this happened only towards the end of the century. And now about what qualities are inherent in this compound:

- The material is unusually hard. According to this indicator, it almost caught up with diamond. Among the record holders is tungsten carbide (9 out of 10 possible points). This opens up hundreds of ways to use it.

- It will take a lot of effort to melt the stone. After all, for this it is necessary to heat it to 2, or even 3 thousand degrees Celsius. This figure will be higher than the values necessary to change the state of metallic substances before they were included in the carbide.

- This is a very “non-contact” connection. Thus, the reaction of carbide to many substances will be zero. This requires special conditions. Therefore, they are not afraid of acids and other substances that promote corrosion.

- But the previous point does not apply to water. As you already understood from the story above, carbide and water often go hand in hand. In the case, for example, when calcium carbide is involved, absolutely any moisture is suitable for this, no conventions are needed. If the work is silicon carbide, then there is no way without heating - you need hot steam (1800 degrees).

Kinds

Science knows three types of such compounds:

- Covalent

What sets them apart is the very strong bonds between atoms. When this type is mentioned, we are talking about only two elements adjacent to carbon: the first is bromine, the second is silicon. All of the above properties in these compounds are “set” to the maximum. This is both unprecedented hardness and durability. If you want to dissolve it, it won’t be possible without the participation of caustic acids of enormous concentration. The same applies to interaction with oxygen. It just won’t work, you need heating, and not too bad – up to 1000 degrees.

- Salt-like or ionic

Here, either aluminum or metal comes into contact with carbon, but not just any metal, but only from 1-2 chemical groups. tables. It is still not very easy to give such a compound a liquid form; extreme heating is required. But the acid will not go unnoticed; as a result of such a “meeting,” the carbide will disintegrate.

- Metal-like

They are obtained from metals belonging to groups 4-8, this also includes cobalt, as well as nickel, and, of course, iron. If we consider their chemical structure, we will see that the carbon atoms are literally scattered, there are no bonds between them, they are like inclusions in the gaps formed in the metal. Because they are very refractory, one might even say they are champions in this matter. This allows them to be used in the manufacture of drills (pobedite drills).

Application

As already mentioned, this substance can most often be found at construction sites. And there they find dozens of ways to use it. It is difficult to do without this material in grinding; special materials are produced from it. disks. But it is good not only as an abrasive, but also in the form of sharp cutting wheels, knives and the like.

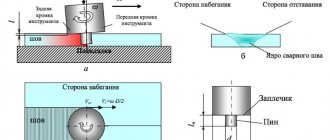

Acitylene generator for gas welding, inside of which calcium carbide is poured

Mechanical engineering is another opportunity to use this connection. Not only various car parts are made from carbide, but also spare parts. parts for radio devices. And thanks to its thermal conductivity, it will also cope well with heating tasks. Even in the nuclear industry it is impossible without such a component. All this requires special strength, so here we are most often talking about covalent types.

Those compositions that contain iron carbide make it possible to obtain steel, and the well-known cast iron. Silicon compounds are also valued by jewelers and manufacturers of lighting elements. Artificial rubber and resins, and even acetic acid - such is the wide range of applications of carbides.

But the matter does not stop there. This artificial mineral is also important for gardeners. After all, with its help a special type of fertilizer is obtained. They are able to regulate the growth rate of various crops.

But perhaps the most popular of all is calcium carbide. After all, it is precisely this that welders actively use in their work. It would seem, how can this dark pebble with a garlic aroma be involved in such a process?

It’s very simple, because gas welding, which is logical, requires flammable gas. In our case it gives acetylene carbide. As soon as it “meets” oxygen, we get a very intense flame; its temperature exceeds three thousand degrees.

If you take ready-made volatile gas, then special packaging is used for it. containers in which the substance is delivered to the site of action. There should be no shaking or shock during such a trip - it is deadly.

This raw material can flare up, even without extra “help”, so attention should always be at the limit. If the fire could not be avoided, do not use any moisture when extinguishing it. Only powder extinguishing methods should be used.

There is a second way - to produce this “fuel” right at the work site. To do this, you need to know what hydrolysis of carbides is. Simply put, it is the reaction of a compound upon contact with water. Moreover, even one drop can cause this very reaction.

Therefore, if you are planning to carry out welding work, very carefully open the sealed container with carbide. It is especially important that there are no signs of fire in the neighborhood, otherwise an emergency is guaranteed. You should completely forget about cigarettes.

Also, make sure that even the smallest crumbs do not end up on your skin, especially on the mucous membranes, otherwise, at best, there will be irritation, at worst, burns and swollen parts of the body. So arm yourself with special equipment. uniform: everything needs to be protected, from head to toe, including the respiratory tract. First aid, if contact cannot be avoided: pour plenty of water on the affected area, cover it with thick cream. If necessary, call a doctor.

If we talk about consumption, if the mass of carbide is one kilogram, then this makes it possible to produce up to three hundred cubic decimeters of gas. These are quite good indicators. Also, this amount of raw material will require approximately 20 liters of water, although manufacturers say that half a liter will be enough. How long this all takes depends on the size of the compound fractions and their purity.

After the work is finished, the remaining waste, and this is lime slag, is not left anywhere, but is disposed of. For such work you will need a specialist. generator. They come in impressive sizes and are installed in one place, for example, when large-scale work is planned. But there is also a mini version, portable.

First, fill the compartment in which the gas should form with water, then add carbide there. The reaction takes place, and the resulting acetylene flows through a soft tube directly to the gas burner. This path must be long enough; the hose must be chosen no shorter than ten meters.

Boron carbide

Boron carbide is also used. Items based on it provide reliable protection against fire. And not only from fire, by the way, because such products are actively used by manufacturers of body armor. Firstly, it “catches” bullets, and secondly, it will not allow radiation to pass through. As for such a union as aluminum carbide, the sparkling sparks during fireworks are its merit. But in appearance it is an unremarkable yellow powder.

How is carbide obtained?

First about calcium carbide. Its production is in demand. And although such factories require large expenses, especially when it comes to electricity, enterprises do not abandon the usual manufacturing method. Because the demand for such products is in no hurry to fall. After all, it is hardly possible to imagine at least a single construction site without acetylene. To save on electricity, such enterprises are opened in countries with a large number of hydroelectric power stations, in Canada, for example.

Why not switch to working with methane, since such a volatile gas can also be obtained from it? Yes, because calcium carbide produces an almost pure product, it is not difficult to bring it to 98 percent gas. And it is much easier to transport than the one obtained with the participation of methane.

The main object in such industries are electric furnaces. They are loaded with hard coal, which is also called coke, and calcium oxide (lime, any kind of lime will not work, it needs to be purified and homogeneous). All this heats up to 2 thousand degrees. And voila, the reaction started.

The result is a liquid substance, which will then become a familiar compound to us. But first it needs to cool in the molds. After the degree is reduced, these layers are crushed into pieces that are more convenient to use.

Now about the silicon version. We got it absolutely by accident, as usually happens. An American scientist tried to create an artificial diamond. As a result of the experiments, silicon carbides were obtained (by the way, they are in second place in hardness after uncut diamonds).

He patented it and opened the first plant for the production of the material. It’s impossible to say that technology has changed a lot since then. Unless sand and salt were excluded from it, what remained was carbon and silica, which are still heated to maximum temperatures in furnaces.

Appearance and characteristics of technical calcium carbide

Calcium carbide is produced by fusing coke and quicklime in electric furnaces. Molten calcium carbide is released from the furnace into special forms - molds, in which it hardens. The solidified calcium carbide is crushed and sorted into pieces of certain sizes.

Technical calcium carbide is a solid crystalline substance. In appearance, calcium carbide is a dark gray or brown solid. It produces a gray crystalline fracture with varying shades depending on purity. Calcium carbide greedily absorbs water. When interacting with water, even in the cold, calcium carbide decomposes with the rapid release of acetylene and a large amount of heat. The decomposition of calcium carbide also occurs under the influence of atmospheric moisture.

According to GOST 1460-56, the following dimensions (granulation) of calcium carbide pieces are established: 2×8; 8x15; 15×25; 25x80. Technical calcium carbide contains up to 80% of chemically pure calcium carbide, the rest is made up of impurities - quicklime, carbon, silicic acid and more.

Production

Calcium carbide is industrially produced in an electric arc furnace from a mixture of lime and coke at approximately 2200 °C (3990 °F).[5] This endothermic reaction requires 110 kilocalories (460 kJ) per mole[6] and high temperatures to remove carbon monoxide. This method has not changed since its invention in 1892:

CaO + 3 C → CaC2 + CO

The high temperature required for this reaction is practically unattainable with traditional combustion, so the reaction is carried out in an electric arc furnace with graphite electrodes. The resulting carbide product typically contains about 80% calcium carbide by weight. The carbide is crushed, forming small lumps ranging in size from a few to 50 mm. Impurities are concentrated in smaller fractions. CK2 Product content is determined by measuring the amount of acetylene formed during hydrolysis. For example, British and German standards for larger fractions are 295 L/kg and 300 L/kg respectively (at 101 kPa pressure and 20 °C (68 °F)). Impurities present in carbide include phosphide, which produces phosphine upon hydrolysis.[7]

This reaction was an important part of the Industrial Revolution in chemistry, and it was made possible in the United States as a result of the huge amount of low-cost hydroelectric power produced at Niagara Falls before the turn of the 20th century.[8]

The electric arc furnace production method was discovered in 1892 by T. L. Wilson and independently by H. Moissan in the same year.[9][10][11] In Bosnia and Herzegovina, the city of Jajce, the Austrian industrialist, Dr. Josef Kranz and his “Bosnische-Elektrizitäts AG”

the company, which was later succeeded by

Elektro-Bosna

, opened the largest chemical plant in Europe for the production of calcium carbide in 1899. Hydroelectric power station on Pliva to supply the plant with electricity was built along the river with an installed capacity of 8 MW. It was the first power station of its kind in South-Eastern Europe and was commissioned on 24 March 1899.[12]

Transportation and storage

Due to the fact that moisture instantly decomposes carbide with the release of a large amount of heat and the formation of explosive acetylene gas, the substance must be stored in hermetically sealed drums or cans. It should be remembered that acetylene is lighter than air and can accumulate in the upper areas of the room. This gas, in addition to its narcotic effect, has the ability to spontaneously ignite. Therefore, calcium carbide must be used with great care. Special attention is paid to packaging in production. The finished substance is placed in special drums (containers resembling tin cans). This packaging requires careful opening. In this case, a tool that does not lead to the formation of sparks (a hammer or a special knife) should be used. If carbide gets on the skin or mucous membranes, immediately rinse the affected area with water and treat the area with Vaseline or greasy cream. Transportation of the connection is carried out using only covered modes of transport. Air delivery of carbide is prohibited. The premises where CaC2 is stored must be well ventilated. It is also not allowed to store carbide together with other chemicals. This can lead to unwanted, and possibly dangerous, reactions. The shelf life of carbide is six months.

Safety precautions and storage

Calcium carbide belongs to hazard class 1 based on the degree of impact on the body. Its dust irritates the skin, mucous membranes and respiratory tract. The reagent is very dangerous if inhaled (symptoms: intermittent breathing, cough, runny nose, feeling of suffocation, pulmonary edema), contact with the skin (burns, ulcers) and in the eyes (soreness, lacrimation, swelling of the eyelids).

When using the material, it is necessary to use special protective clothing, a gas mask, gloves and special shoes. Work only in well-ventilated areas. In case of contact with skin, rinse the affected area with plenty of water, lubricate with a rich cream and call a doctor.

Store in sealed containers in a vertical position (no more than 3 rows) in fireproof, well-ventilated warehouses or in open areas under a canopy, protecting from moisture. Shared storage with other substances is not allowed. Shelf life – 6 months from the date of production.