Brief designations:σв— temporary tensile strength (tensile strength), MPaε— relative settlement at the appearance of the first crack, %σ0.05— elastic limit, MPaJк— ultimate torsional strength, maximum shear stress, MPaσ0.2— conditional yield strength, MPaσben— ultimate bending strength, MPa δ5,δ4,δ10— relative elongation after rupture, %σ-1— endurance limit during bending test with a symmetrical loading cycle, MPaσco0.05 And σcom— compressive yield strength, MPaJ-1— endurance limit during torsion testing with a symmetrical loading cycle, MPaν— relative shift, %n— number of loading cycless in— short-term strength limit, MPaR And ρ— electrical resistivity, Ohm mψ— relative narrowing, %E— normal modulus of elasticity, GPaKCU And KCV— impact strength, determined on a sample with concentrators of the types U and V, respectively, J/cm 2T— temperature at which properties were obtained, degreess T— proportionality limit (yield strength for permanent deformation), MPal And λ— thermal conductivity coefficient (heat capacity of the material), W/(m °C)HB— Brinell hardnessC- specific heat capacity of the material (range 20 o - T), [J/(kg deg)]H.V.— Vickers hardnesspn And r- density kg/m 3HRСе— Rockwell hardness, scale CA— coefficient of thermal (linear) expansion (range 20 o - T), 1/°СHRB— Rockwell hardness, scale Bσ t T— long-term strength limit, MPaHSD- Shore hardnessG— modulus of elasticity during torsional shear, GPa

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Source: metallicheckiy-portal.ru

Aluminum production

To produce aluminum, bauxite is used - a rock that contains aluminum oxide hydrates. The world's reserves of bauxite are almost unlimited and are incommensurate with the dynamics of demand.

Bauxite is crushed, ground and dried. The resulting mass is first heated with steam and then treated with alkali - most of the aluminum oxide passes into the alkaline solution. After this, the solution is stirred for a long time. At the electrolysis stage, alumina is exposed to an electric current of up to 400 kA. This allows the bond between the oxygen and aluminum atoms to be broken, leaving only liquid metal. The aluminum is then cast into ingots or various elements are added to it to create aluminum alloys.

Aluminum alloys

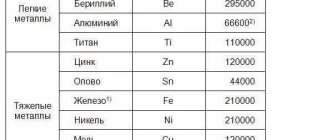

The most common elements in aluminum alloys are copper, manganese, magnesium, zinc and silicon. Less common are alloys with titanium, beryllium, zirconium and lithium.

Aluminum alloys are conventionally divided into two groups: cast and wrought.

To make casting alloys, molten aluminum is poured into a mold that matches the configuration of the resulting product. These alloys often contain significant silicon impurities to improve castability.

Wrought alloys are first cast into ingots and then shaped into the desired shape.

This happens in several ways depending on the type of product:

- By rolling, if necessary, to obtain sheets and foil.

- By pressing, if you need to obtain profiles, pipes and rods.

- Molding to obtain complex shapes of semi-finished products.

- Forging, if you need to obtain complex shapes with increased mechanical properties.

Aluminum alloy grades

To mark aluminum alloys in accordance with GOST 4784-97, an alphanumeric system is used, in which:

- A - technical aluminum;

- D - duralumin;

- AK - aluminum alloy, malleable;

- AB - avial;

- B - high-strength aluminum alloy;

- AL - cast aluminum alloy;

- AMg - aluminum-magnesium alloy;

- AMts - aluminum-manganese alloy;

- SAP - sintered aluminum powders;

- SAS - sintered aluminum alloys.

After the first set of characters, the alloy grade number is indicated, and after the number is a letter that indicates its condition:

- M - alloy after annealing (soft);

- T - after hardening and natural aging;

- A - clad (a pure layer of aluminum is applied);

- N - hard-worked;

- P - semi-hardened.

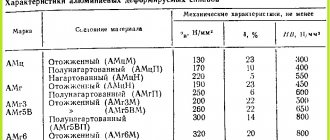

Wrought aluminum alloys

AMts (1.0-1.6% Mn, 0.6% Si 0.7% Fe) has high ductility ( Table 2.7 ) in the annealed state (AMtsM) and low in the cold-worked state (AMtsN), can be welded well by gas, atomic -hydrogen and resistance welding, used for the manufacture of tanks, gasoline and oil pipelines, necks of brackets, pipes and flanges of necks and lightly loaded parts. It is not hardened by heat treatment. Annealing at 350-410° C, cooling in air. Forging and stamping temperature is 420-475° C.

AMg (2.0-2.8% Mg, 0.15-0.40% Mn, 0.4% Si, 0.4 Fe) has the same plastic properties as AMts, and is well welded by atomic-hydrogen and resistance welding , satisfactory - gas. In the annealed state it has unsatisfactory machinability, while in the semi-worked and cold-worked state it has satisfactory machinability. It is used for the manufacture of tanks, gasoline and oil pipelines, walls of inlet pipes, guide cones of plugs and other moderately loaded aircraft parts. It is not hardened by heat treatment. Annealing at 350-410° C, cooling in air. Forging and stamping temperature is 420-275°C.

AMg5P (5.2 Mg, 0.4% MP) has high ductility in the annealed state, is not strengthened by heat treatment, is satisfactorily welded by atomic hydrogen, spot and gas welding, has high corrosion resistance, is supplied in the form of wire, and is used for the manufacture of rivets for riveting structures made of magnesium alloys. Rivets are installed in an annealed state. Annealing temperature 340-410°C with air cooling.

AB (0.2-0.6% Cu, 0.45-0.95% Mg, 0.15-0.35% Mn, 0.5-1.2% Si) has high ductility in the annealed state (AVT ) and medium after hardening and aging (AHT), can be welded well by spot and atomic-hydrogen welding, satisfactorily by gas welding, and is used for the manufacture of parts that require good ductility in the cold and hot state of stamped and forged parts of complex shapes. Forging and stamping temperature 470-475° C

Heat treatment: hardening from 010-525 ° C in water, natural or artificial aging at 150 ° C for 6 hours, annealing at 350-370 ° C, cooling in air (Fig. 2.2 ).

D18P (2.6% Cu, 0.35% Mg) - duralumin with increased ductility.

It is used for the manufacture of rivets, which are installed after hardening and natural aging. Hardening at 490-505° C in water and natural aging for at least 4 days (Fig. 2.3) .

D3P has high ductility in the annealed state; used for the manufacture of rivets, which are placed in a freshly hardened state no later than 3 hours after hardening (D3P alloy is replaced by D18P alloy). Heat treatment: hardening at 490-500°C in water, natural aging for at least 4 days, annealing at 340-370°C, cooling in air.

B65 (4.2% Cu, 0.2% Mg, 0.4% Mn) is an alloy for rivets that are installed in a hardened state and aged, since its ductility is satisfactory and the rivets do not need to be softened by installation. Replaces alloys D1 and D16. Heat treatment: hardening at 510-520° C in water, aging at room temperature for 10 days at a temperature of 50° C for 3 days

D7A alloy for chassis wheel rims, used after hardening and aging.

D1 (4.3% Cu, 0.6% Mg, 0.6% Mn, >=0.7% Si, >=0.7% Fe) has average ductility table. 2.8 Cutting machinability is satisfactory after hardening and aging (D1T) and reduced after annealing. It is used for the manufacture of power elements of medium strength: frame parts, stamped fastening units, screw blades, rivets (the latter are installed in a freshly hardened state no later than 2 hours after hardening). Heat treatment: hardening at 490-510°C in water and natural aging for at least 4 days, annealing at 350-370°C, cooling in air.

D16 (3.8–4.9% Cu, 1.2–1.8 Mg, 0.3–0.9% Mn)—high-strength duralumin. Plasticity in the annealed and freshly hardened state is average, machinability of D16T and D16TN is satisfactory, D16M is reduced. It is used for the manufacture of load-bearing structural elements: frame parts, sheathing, frames, ribs, spars, rivets. When manufacturing heavily loaded parts, it is recommended to replace them with alloy B95. Rivets are placed in a freshly hardened state no later than 20 minutes after hardening. Heat treatment: hardening at 495-505°C in water, natural aging for at least 4 days, annealing at 350-370°C, cooling in air. Annealing of D16TN should be preceded by heating at 450-500° C.

B95 (5-7% Zn, 1.8-2.8% Mg, 1.4-4.0% Cu, 0.2-0.6% Mn, 0.10-0.25% Cr) - high strength aluminum alloy ( Table 2.9 ). Plasticity in the annealed and freshly quenched states is the same as that of the D16 alloy in the same states. In an aged state it is much lower. Cutting machinability and weldability by spot welding are good, while gas welding is unsatisfactory. It is used for the manufacture of structural structural parts: spars, stringers, frames, skins, ribs. Heat treatment; hardening from 465-475°C, cooling in water, artificial aging of clad products at 120°C for 24 hours, unclad ones - at 140°C for 16 hours, annealing at 420°C, cooling in an oven to 150°C and then in the air.

AK4 (1.9-2.5%, Cu, 1.4-1.8% Mg, <=0.2 Mn, 1.0-1.5% Fe, 0.5-1.2% Si, 1.1-1.6% Ni) is a heat-resistant deformable aluminum alloy, has reduced ductility in the hot state, and can be welded satisfactorily by atomic-hydrogen welding. Machinability is satisfactory. It is used for the manufacture of engine parts and other products operating at temperatures up to 350°C. Heat treatment: hardening at 515±5°C, in water, aging at 170°C for 16 hours.

AK4-1 (1.9-2.5% Cu, 1.4-1.8% Mg, <=0.2% Mn, 1.0-1.5% Fe, 1.0-1.5 Ni ) is a heat-resistant wrought alloy. Modifications of AK4 alloy. It has higher (compared to AK-4) strength characteristics, has satisfactory ductility in a hot state, can be welded and processed satisfactorily by cutting. Heat treatment: hardening from 525-535°C, artificial aging at 170°C for 16 hours.

AK6 (1.8-2.6% Cu, 0.4-0.8% Mg, 0.4-0.8% Mn) - high-strength aviation material (Table 2.10), used for the manufacture of stamped and forged parts of complex shape and medium strength: compressor and fan impellers, intakes, diffuser blades and other parts. Heat treatment: hardening at 500-515°C in water and artificial aging at 150-160°C for 12-15 hours.

AK6-1 (2.2% Cu, 0.6% Mg, 0.6% Mn, 0.9% Si, 0.1% Ti, 0.2% Cr) alloy is more ductile than AK6 alloy; used for the manufacture of forged and stamped parts of complex shapes: compressor wheels, impeller intakes and other parts.

AK8 (4.4% Cr, 0.6% Mg, 0.7 Mn, 0.9 Si) is an alloy with high strength but worse than AK6-1. It is processed by hot pressure and therefore can be used for stamping highly loaded aircraft parts of less complex shapes: frames, fittings, etc.

The disadvantage of the alloy, which limits its use for thin-walled parts, is the tendency to intergranular corrosion in an artificially aged state.

Types and properties of aluminum alloys

Aluminum-magnesium alloys

These ductile alloys have good weldability, corrosion resistance and a high level of fatigue strength.

Aluminum-magnesium alloys contain up to 6% magnesium. The higher its content, the stronger the alloy. Each percent increase in magnesium concentration increases the tensile strength by approximately 30 MPa and the yield strength by approximately 20 MPa. Under such conditions, the relative elongation decreases, but only slightly, remaining within 30–35%. However, when the magnesium content exceeds 6%, the mechanical structure of the alloy in the cold-worked state becomes unstable, and corrosion resistance deteriorates.

To improve strength, chromium, manganese, titanium, silicon or vanadium are added to the alloys. Impurities of copper and iron, on the contrary, negatively affect alloys of this type - they reduce weldability and corrosion resistance.

Aluminum-manganese alloys

These are strong and ductile alloys that have a high level of corrosion resistance and good weldability.

To obtain a fine-grained structure, alloys of this type are alloyed with titanium, and manganese is added to maintain stability in the cold-worked state. The main impurities in Al-Mn alloys are iron and silicon.

Aluminum-copper-silicon alloys

Alloys of this type are also called alcusines. Due to their high technical properties, they are used in sleeve bearings, as well as in the manufacture of cylinder blocks. They have high surface hardness, so they are difficult to break in.

Aluminum-copper alloys

The mechanical properties of alloys of this type in a heat-strengthened state sometimes even exceed the mechanical properties of some low-carbon steels. Their main drawback is their low corrosion resistance, which is why these alloys are treated with surface protective coatings.

Aluminum-copper alloys are alloyed with manganese, silicon, iron and magnesium. The latter has the greatest influence on the properties of the alloy: alloying with magnesium significantly increases the yield strength and strength. Adding iron and nickel to the alloy increases its heat resistance, and silicon increases its ability to undergo artificial aging.

Aluminum-silicon alloys

Alloys of this type are otherwise called silumins. Some of them are modified with additions of sodium or lithium: the presence of literally 0.05% lithium or 0.1% sodium increases the silicon content in the eutectic alloy from 12% to 14%. The alloys are used for decorative casting, the manufacture of mechanism cases and elements of household appliances, since they have good casting properties.

Aluminum-zinc-magnesium alloys

Durable and well processed. A typical example of a high-strength alloy of this type is B95. This strength is explained by the high solubility of zinc and magnesium at a melting point of up to 70% and up to 17.4%, respectively. When cooled, the solubility of elements decreases noticeably.

The main disadvantage of these alloys - low corrosion resistance during mechanical stress - is corrected by alloying with copper.

Avial is a group of alloys of the aluminum-magnesium-silicon system with minor additions of other elements (Mn, Cr, Cu). The name is derived from the abbreviation of the phrase “aviation aluminum”.

Avial began to be used after the discovery by D. Hanson and M. Geiler of the effect of artificial aging and thermal hardening of this group of alloys due to the release of Mg2Si.

These alloys are characterized by high ductility and satisfactory corrosion resistance. Forged and stamped parts of complex shapes are made from aircraft. For example, spars of helicopter rotor blades. To improve corrosion resistance, the copper content is sometimes reduced to 0.1%.

The alloy is also actively used to replace stainless steel in mobile phone cases.

Cast aluminum alloys

These alloys are rarely used for repairs, but in aircraft construction alloys AL1 AL2, ALZ, AL4, AL5, AL6, AL7, AL8, AL9, VI-113, AL 19, B300, V14A are used (Table 2.11).

AL4 and AL5 are used for the manufacture of large and medium-sized engine parts subject to significant loads (oil injector housings, flanges, trusses, crankcases, cylinder heads). The disadvantages of alloys include their low heat resistance. Therefore, they are unsuitable for the manufacture of parts operating at temperatures above 200-250 ° C.

ALZ and AL8 with good casting properties, but with average mechanical strength. Used for medium and small parts of engines and equipment that are not subject to significant loads (instrument housings, carburetors, fittings, etc.).

AL7 AL 8, AL9 are used for casting aircraft parts, rocking chair brackets, pedals, etc.

VI-11-3 has high corrosion resistance, good casting properties and increased strength, is hardened by T4 mode, has satisfactory weldability by gas welding and good machinability by cutting, and is used for the manufacture (by earth casting, mold casting or under pressure) of parts with increased corrosion resistance.

AL19 has low corrosion resistance, low casting properties, but high mechanical qualities and heat resistance. Strengthening heat treatment in modes T4 and T5 Well welded and machined by cutting, used for the manufacture of aircraft parts by casting in the ground, operating at temperatures of 175-300 ° C

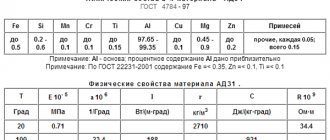

Chemical composition of aluminum alloys

| Aluminum alloys | |||||||||||||

| Brand | Mass fraction of elements, % | Density, kg/dm³ | |||||||||||

| GOST | ISO209-1-89 | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other | Aluminum no less | ||

| Every | Sum | ||||||||||||

| AD000 | A199.8 1080A | 0,15 | 0,15 | 0,03 | 0,02 | 0,02 | 0,06 | 0,02 | 0,02 | 99,8 | 2,7 | ||

| AD00 1010 | A199.7 1070A | 0,2 | 0,25 | 0,03 | 0,03 | 0,03 | 0,07 | 0,03 | 0,03 | 99,7 | 2,7 | ||

| AD00E 1010E | EA199.7 1370 | 0,1 | 0,25 | 0,02 | 0,01 | 0,02 | 0,01 | 0,04 | Boron:0.02 Vanadium+titanium:0.02 | 0,1 | 99,7 | 2,7 | |

Application of aluminum

Jewelry

In the distant past, due to the high cost of aluminum, it was used to make jewelry. Thus, scales with aluminum and gold bowls were presented to D. I. Mendeleev in 1889.

When the cost of aluminum decreased, the fashion for jewelry made from this metal passed away. But even today it is used to make jewelry. In Japan, for example, aluminum is used to replace silver in the production of national jewelry.

Cutlery

Aluminum cutlery and cookware continue to be popular. In particular, aluminum flasks, pots and spoons are widely used in the army.

Glass making

Aluminum is widely used in glass making. High reflectivity and low cost of vacuum deposition are the main reasons for using aluminum in the manufacture of mirrors.

Food industry

Aluminum is registered as a food additive E173. It is used as a food coloring and also to preserve food from mold. E173 colors confectionery products in a silver color.

Military industry

Due to its light weight and low cost, aluminum is widely used in the manufacture of small arms - machine guns and pistols.

Rocketry

Aluminum and its compounds are used as rocket fuel in two-component rocket propellants and as a combustible component in solid rocket propellants.

Aluminum energy

In the aluminum energy industry, aluminum is used to produce hydrogen and thermal energy, as well as to generate electricity in air-aluminum electrochemical generators.

Source: ferrolabs.ru

The most common aluminum alloys

Most aluminum items are actually made from aluminum alloys. The mechanical strength of pure aluminum, as a rule, is not enough to solve even the simplest household and technical problems.

Adding alloying elements to aluminum significantly changes its properties. Some qualities increase - strength, hardness, heat resistance. Others decrease - electrical conductivity, corrosion resistance. Density almost always increases as a result of doping. The exception is alloying with manganese and magnesium.

According to the method of application, aluminum alloys can be divided into wrought and cast alloys. Deformable alloys have high ductility when heated. Foundry - capable of effectively filling foundry molds.

The raw material for producing alloys of both types is not only technically pure aluminum, but also silumin - an alloy of aluminum with silicon (10-13%). Silumin in Russia is usually labeled as SIL-00 (the purest in terms of impurities), SIL-0, SIL-1 and SIL-2 and is supplied in the form of smooth ingots or ingots with pinches weighing 6 and 14 kg.

Their structure (homogeneous solid solution) provides the greatest plasticity and the lowest strength during pressure treatment under heat. The main alloying elements are copper, magnesium, manganese and zinc. In small quantities - silicon, iron, nickel, etc. Wrought aluminum alloys are usually divided into hardenable and non-hardenable. The strength of the former can be increased by heat treatment.

Typical hardenable alloys are duralumin - alloys of aluminum with copper (2.2 - 7%) containing impurities of silicon and iron. They can be alloyed with magnesium and manganese.

The names of duralumin brands consist of the letter “D” (it is always the first) and the alloy number. Nowadays, there are five main grades of duralumin that are most common:

Source: tdsm.ru

Aluminum. Aluminum grades

Home -> Directory -> Non-ferrous metals and alloys -> Aluminum. Aluminum gradesAluminum and deformable aluminum alloys in the Russian Federation are regulated by GOST 4784. According to this document, marking of aluminum alloys can be done in three different ways:

- in alphanumeric form;

- in digital form;

- according to the requirements of the ISO 209-1 standard (international marking).

Digital marking according to GOST differs from digital marking according to ISO 209-1 and indicates from left to right: the first digit is the base metal (1-aluminum); the second digit is the alloying system; the third and fourth numbers are the brand and modification.

| 1000-1018 | Technical aluminum |

| 1019,1029, etc. | Powder alloys |

| 1020-1025 | Foamed aluminum |

| 1100-1190 | Al-Cu-Mg, Al-Cu-Mg-Fe-Ni |

| 1200-1290 | Al-Cu-Mn, Al-Cu-Li-Mn-Cd |

| 1300-1390 | Al-Mg-Si, Al-Mg-Si-Cu |

| 1319,1329 | Al-Si powder alloys SAS |

| 1400,1419 | Al-Mn, Al-Be-Mg |

| 1420-1490 | Al-Li |

| 1500-1590 | Al-Mg |

| 1900-1990 | Al-Zn-Mg, Al-Zn-Mg-Cu |

In this case, with alphanumeric marking, deformable aluminum alloys are designated by the letters D, AD, AK, AM, AB. In turn, foundries are AL. Duralumin alloys are designated by the letter D (D1, D16). The presence of a combination of letters AMg in the marking means that it is an alloy of aluminum with magnesium, and the numbers following this designation indicate the percentage of magnesium. In turn, AMts is an alloy of aluminum and manganese. Pure deformable aluminum is designated by the letters AD, and in terms of purity it can be of three types:

- almost pure(pc);

- pure (H);

- very clean (Very).

The four-digit designation system developed by the Aluminum Association (AA) has been adopted as the world standard for the designation of aluminum wrought alloys. According to this system, the first digit means the alloying system; the bark refers to the alloy:

- 1000 - pure aluminum minimum share of 99%;

- 2000 - copper-alloyed duralumin;

- 3000 - alloy alloyed with manganese;

- 4000 - silumins (silicon doped);

- 5000 - alloy alloyed with magnesium;

- 6000 - alloys alloyed with magnesium and silicon;

- 7000 heat-strengthening alloys alloyed with zinc and magnesium.

The second digit indicates the serial number of the modification of the alloy relative to the original alloy (in the original alloy the second digit is “0”) or indicates the purity of the alloy in terms of impurities. The last two digits directly indicate the alloy and provide information about its purity. In the case when an experimental alloy is used, an “X” index is added and the marking becomes five-digit.

| Series | Designation according to ISO | Designation according to GOST |

| 1000 | 1050 | AD0 |

| 1060 | — | |

| 1070A | AD00 | |

| 1080A | AD000 | |

| 1200 | HELL | |

| 1350 | AD0E | |

| 1370 | AD00E | |

| 2000 | 2017 | AD1 |

| 2024 | D16 | |

| 2117 | D18 | |

| 2024 | AD16h | |

| 2618 | AK4 | |

| 2219 | 1201 | |

| 3000 | 2014 | AK8 |

| 3003 | AMts | |

| 3004 | D16 | |

| 3005 | MM | |

| 5000 | 5005 | AMg1 |

| 5050 | AMg1.5 | |

| 5251 | AMg2 | |

| 5052 | AMg2 | |

| 5754 | — | |

| 5154 | AMg3 | |

| 5086 | AMg4 | |

| 5083 | AMg4, AMg5 | |

| 5056 | — | |

| 6000 | 6063 | AD31 |

| 6101 | AD31E | |

| 6061 | AD33 | |

| 6082 | AD35 | |

| 6151 | — | |

| 7000 | 7005 | 1915 |

| 7075 | — | |

| 7175 | — |

- Application of aluminum in bridge construction

Varieties of aluminum and its alloys

In most cases, aluminum is used in the form of alloys - 20% cast and 80% wrought. Based on the brand, you can determine the method of its production, as well as its main properties.

This metal can be divided into several main categories:

- primary (A999, A95, A7E A6, etc.);

- technical (AD000, AD1, ADS);

- for deoxidation (AV97F, AV86, AV91);

- foundry (AMg11, VAL10M, AK12pch);

- deformable (D1, 1105, AMg2, SvAMg6);

- antifriction (AMK, ASM, AO9-2B);

- alloys (AlBi3, AlZr5(B), AlNi10 and others).

How is the marking deciphered?

Deformable alloys are designated accordingly - AD. If there is a 1 after the abbreviation, it means that purer aluminum was used. The letter A in combination with Mts and Mg is an alloy with manganese or magnesium. The number after the marking indicates the percentage content of a particular chemical element. AK is aluminum for forging, and the number at the end is the alloy number.

In semi-finished products, the main abbreviation is followed by letters (for example, AMtsAM), which are deciphered as follows:

- A – high-quality alloy, made from pure grades of aluminum;

- B – rolled products with technological cladding or without it at all;

- UP – with thickened cladding;

- M – soft;

- N – hard-worked;

- P – semi-hardened;

- H1 – heavily cold-hardened;

- B – high-quality rolling out of aged and pre-hardened sheets;

- О – high quality of rolling out annealed sheet metal;

- GK – hot-rolled steel;

- TPP – hardened, aged rolled steel of increased strength.

The abbreviation AL means that it is cast aluminum. Depending on the heat treatment modes, it is designated T, after which the following numbers may appear in the stamps:

- 8 – hardened and softened tempered;

- 7 – hardening with stabilizing tempering;

- 6 – hardening and aging to the highest hardness;

- 5 – hardening and partial aging;

- 4 – hardened;

- 2 – annealed;

- 1 – aged.

“D” in the main marking is duralumin. Designation type B or VD (alcledes) - indicates that duralumin is coated with a layer of pure aluminum in order to increase corrosion resistance. High-strength alloys with magnesium and zinc are marked “B” and a number (for example, 96 or 94), the 2nd digit of which indicates the alloy number.

Source: www.hugebuilding.ru

Marking of aluminum and aluminum alloys

Pure aluminum is marked depending on the content of impurities in it, varies;

- A999 - high purity aluminum;

- A995, A99, A97, A95 - high purity aluminum;

- A85, A8 , ... - aluminum of technical purity.

High purity aluminum is used in the production of semiconductor devices and for research work.

High purity aluminum is used for cladding parts of electrical and radio equipment.

Aluminum of technical purity is used for the preparation of aluminum alloys, the manufacture of wires, gaskets

Technical aluminum is designated by the letters AD (deformable aluminum) , in the case of using purer aluminum the number 1 is given. The combination of the letters AMg and AMts means an alloy of aluminum (A) with magnesium (Mg) and manganese (Mz). For aluminum alloys with magnesium, the number indicates the percentage of magnesium. For example, alloys of the AMgZ, AMg5, AMg6 brands contain 3, 5 and 6% magnesium, respectively.

Alloys in the form of semi-finished products are designated by letters that are placed after the alloy marking: A - means that the alloy is of improved quality, made from the best aluminum; M - soft, annealed; P - semi-coloured (compression degree 40%): N - cold-worked (compression degree 80%). Thus, annealed alloys are designated ADM, AMtsAM, semi-hard-worked alloys - AMgAP and cold-worked alloys - AD1N. AMgZN.

Duralumin is designated by the letter D and a number indicating the conventional number of the alloy, for example alloy D1, D16, D18, D20. Some alloys, developed recently, with the marking B65 VD17 (duralumin coated with a thin layer of pure aluminum to give the alloy corrosion resistance) are called alkled (Alkled is a term, a trademark)

A high-strength alloy of aluminum with zinc and magnesium is designated B94, B95, B96 (the second digit indicates the alloy number).

The condition of semi-finished high-strength alloys and the nature of the plating also have alphanumeric markings: M—soft, annealed; T—heat-treated, hardened and naturally aged. T1 - heat treated, hardened and artificially aged; N - cold-worked (colour-working of duralumin sheets is about 5-7%, and B95-3% alloys); H1—heavily cold-coloured (sheet cold-working is about 20%); B - increased quality of rolling out hardened and aged sheets; O - increased quality of rolling out annealed sheets; B - sheets without cladding or with technological cladding; UP - thickened cladding (8% per side); GK - hot-rolled sheets, slabs; TPP - hardened and aged profiles of increased strength (for D16).

Geometric markings . At the end of the marking for sheet material its thickness in millimeters is indicated, and for profiles - a conventional digital designation of the cross-sectional shape and dimensions. For example, the marking D16ATNVL2.5 means that the clad sheet duralumin D16 is of improved quality, heat-treated, cold-worked and has an improved rolling quality. Sheet thickness 2.5 mm.

Rivet alloys. Alloys used for the production of rivets are marked with the letter P (alloy for wire), for example DZP, D16P.

Aluminum alloys for forging and hot stamping are designated by the letters AK (aluminum forging) and a number - the conventional number of the alloy, for example alloys AK4, AK4-1, AK6, AK6-1, AK8. The additional number -1 shows that the alloy is a close modification of the alloy without the number.

Recently developed forging alloys have non-standard markings, for example alloy D20.

Cast aluminum alloys are designated by the letters AL (aluminum casting) and a number indicating the conventional number of the alloy, for example, AL2, AL4 alloy. AL9, etc. The exception is the new grades of casting alloys VI-11-3, V300, V14-A.

Silumins. Depending on the composition, all aluminum casting alloys are divided into silumins, which are alloys of aluminum and silicon (AL2, AL4, AL9), and alloyed silumins - alloys of aluminum and silicon with the addition of copper (ALZ, AL5, AL9) or magnesium (AL 13, VI-11-3). Altmag - an alloy of aluminum and magnesium (AL8) - and alloys of aluminum and copper (AL7, AL 19) are also used.

Heat treatment modes . For cast aluminum and magnesium alloys, the following designations for heat treatment modes are used: T1—aging; T2 - annealing; T4 - hardening; T5 - hardening and partial aging; T6 - hardening and complete aging to maximum hardness; T7 - hardening and stabilizing tempering; T8 - hardening and softening tempering. For example, the designation AL4T6 shows that the AL4 alloy is subjected to heat treatment according to the T6 regime, consisting of hardening and complete aging.

How to determine the grade of aluminum

AlumoDec - Aluminum anodizing.

Samara Tel:+7(927)- 738-36-69 Mail: This email address is being protected from spambots. You must have JavaScript enabled to view it.

Tolyatti Tel:+7(937)- 236-09-86 Mail: This email address is being protected from spambots. You must have JavaScript enabled to view it.

- Home

- News

- Last news

- How to choose the brand of aluminum alloy for your products.

How to choose the brand of aluminum alloy for your products.

Details Published 01/16/2016 10:03

In this article we will consider the issue of choosing a grade of aluminum alloy from the point of view of further decorative processing of products made from this material.

There are a large number of grades of aluminum alloy, which are divided into two main types: cast and wrought . Cast alloys include AL and AK type alloys (for example AL4, AL9, AL33, AL19, AK9, AK5, etc.), which in turn are divided into groups based on the formation of systems (for example aluminum-silicon, aluminum-silicon-copper, aluminum-magnesium, aluminum-copper). Deformable alloys include alloys of the AD, AMG, AMts, D type (AD0, AD1, AMg5, AMg6, D16, D18, etc.) they are divided according to strength properties (according to one of the types of properties): soft, alloys of moderate strength and high strength. The variety of grades of aluminum alloys is large and complex, so their description will be very capacious; suffice it to say that all alloys have their own unique chemical composition and, as a result, the content of certain alloying elements in the alloy affects its physical properties.

If it is necessary to carry out anodizing processes, the choice of material grade is one of the key points if products need to be given a decorative appearance using this treatment. The main role in this case is played by the chemical composition of the alloy, because the content of certain components may adversely affect the appearance of the products. So, for example, cast alloys (or silumins) with a high silicon content in their composition practically do not “give in” to anodizing and coloring; this results in the formation of a loose and thin anodic film that cannot be painted in dye solutions. Unfortunately, it is for these reasons that many owners of cars and motorcycles are unable to carry out external transformations of certain components of their vehicles. However, there are processes that make it possible to anodize silumins, but they are so complex, expensive and rare that one can say “virtually absent”.

For grades of wrought alloys , the content of some elements that are introduced to improve mechanical and anti-corrosion properties may be too high and the anodic film acquires various shades and defects:

A high iron content can lead to the formation of a gray precipitate and black stripes on products, manganese - to a brown tint of the film, magnesium and zinc to a dark gray tint, chromium to a yellow tint of the film, and a high titanium content to a decrease in the brightness of the anode film. When anodizing and painting in light tones, these defects can be significant, however, when painting black, these defects become less noticeable.

It is worth mentioning products made from sheet material. Regardless of the brand of material, most “aluminum metal”, which comes in the form of sheets, is applied by the manufacturer with a so-called cladding layer (cladding is coating the surface with a thin layer of pure aluminum) to create additional anti-corrosion protection. In this case, an additional letter “A”, “B” or “U” appears in the alloy code (for example D16 AT, AMg6BM) which informs about the thickness of the cladding layer: 2-4%, 1.5%, 4-8%, respectively (percentage of the thickness sheet). Due to the peculiarity of applying this layer to metal, when anodizing it is not always possible to achieve the required color of the products (they come out several tones lighter than the required one), variations in color may appear in the form of spots or color transitions. It is also worth saying that polishing such sheet material can also lead to stains.

All of the above is of great importance when carrying out decorative anodizing, however, when applying an anodic film for technical needs, this in no way affects the properties of the applied film.

And as recommendations for choosing the brand of aluminum alloy for anodizing with further painting for your products, we can offer the following:

— for the manufacture of parts with a mirror finish, aluminum grades A99, A97, A95 or A7 can be used. The surface of parts made of aluminum grades A6, AD1 or aluminum alloys AMg3, AD31, AD33 has a slightly lower shine.

- for the manufacture of parts that do not require a shiny surface, deformable aluminum alloys can be used (for example, V95, D16, AMts or their analogues)

— when choosing the Amg6 brand (due to the peculiarity of the chemical composition), painting can only be done in black.

— to create a matte surface (in particular for a black matte surface), the parts must be sandblasted (the best result is achieved by sandblasting with corundum).

When choosing a grade of aluminum for parts, you must keep in mind that the purer the chemical composition of the aluminum, the higher the quality of the finish.

Source: alumodec.ru

Classification and marking of aluminum alloys

.

In industry, aluminum is used both in pure form and in the form of various alloys. The aluminum marking begins with the letter A, followed by a number indicating the aluminum content in hundredths of a percent. For example, A97 contains 99.97% aluminum, the rest being controlled impurities [14].

Permanent aluminum impurities are Fe, Si, Cu, Zn and Ti. Depending on the impurity content, primary aluminum is divided into three classes:

1) special purity grade A999 ;

2) chemically pure grades A995 , A99 , A97 , A95 ;

3 ) technically pure grades A85 , A8 , A7 , A6 , A5 , A0 and A.

In electrical engineering, aluminum grades A7E , A6E , A5E and AE , where the letter E indicates its electrical purpose. Technical aluminum produced in the form of deformable semi-finished products (sheets, profiles, rods, etc.) is marked AD0 and AD1 . Aluminum wire, depending on the initial mechanical properties, is produced in several grades, which are labeled ATP , AT , APT and AM - respectively, hard with increased strength, hard, semi-hard and soft.

Due to low strength and insignificant hardening during cold plastic deformation, pure aluminum is used relatively rarely as a structural material. Aluminum alloys are more widely used, which are characterized by high specific strength, the ability to resist static and dynamic loads, including at elevated temperatures, and are distinguished by good manufacturability. The classification of the most famous aluminum alloys is shown in Fig. 3.2.

Fig.3.2. Classification of aluminum-based alloys

The main alloying elements of aluminum alloys are Cu, Mg, si, Mn, Zn, and less commonly Li, Ni, Ti [15]. Elements such as Cu, Zn, Mg, Ni, Fe and Mn are involved in the formation of strength properties, and Mn simultaneously increases corrosion resistance. Silicon is the main alloying element in a number of casting alloys (silumins), since it participates in the formation of eutectic. Elements such as Ni, Ti, Cr, Fe increase the heat resistance of alloys by inhibiting diffusion processes and forming stable complex-alloyed strengthening phases. Lithium in alloys contributes to an increase in their elastic modulus. Magnesium and manganese reduce the thermal and electrical conductivity of aluminum, and iron reduces its corrosion resistance. Aluminum alloys can be divided into structural and electrical alloys.

Marking of structural aluminum alloys . Currently, two alloy markings are in effect simultaneously: the old alphanumeric (Table 3.2.) and the new digital (Fig. 3.3.).

Table 3.2.

Alphanumeric marking of aluminum alloys

| Principle of classification | Alloy | |

| By chemical composition | — | Amg, Amts |

| According to the purpose of the alloy | Duralumin | D1, D6 |

| By technological purpose | Forging | AK6, AK8 |

| By properties | High strength | B95, B96 |

| According to the method of obtaining semi-finished products and products | Sintered foundry | SAP, SAS, AL2 |

| By type of semi-finished products | Wire | Amg5P* |

* The letter P included in the alloy marking indicates that the alloy is wire

Different organizations, when assigning alphanumeric grades to alloys, were guided by different principles. There are grades that characterize the composition of the alloy, for example Amg2 (aluminum + 2% magnesium), Amts (aluminum + 1% manganese). Other brands reflect the technology for producing products: AL2 , AL4 , AL7 , where the letters Al indicate that the alloy is aluminum casting, and the numbers after the letters are the serial numbers of the alloys, which do not carry any useful information about the alloy; AK4 , AK6 – aluminum alloys for forging. The brands of many alloys reflect the organization that developed them: VAL8 , VAL10 , VAL14 are casting alloys developed at VIAM (All-Union Institute of Aviation Materials), VAD1 , VAD3 are wrought alloys developed at VIAM.

Since 1970, a unified digital system has been introduced for marking any aluminum alloys [13]. In accordance with the digital marking, the first digit shows the base of the alloy (for aluminum 1), the second digit indicates the alloying system (shows the main alloying components), the third and fourth digits indicate the serial number of the alloy and the technology for producing products.

| Base (A1) Alloy serial number Main alloying elements | Designation | Material |

| 0 or odd digit | Deformable | |

| Even digit | Casting | |

| Metal-ceramic | ||

| Wire |

Rice. 3.3. Principles of digital marking of aluminum alloys

In this case, for wrought alloys the last digit should be 0 or an odd digit, and for casting alloys - an odd digit. Thus, the main information about the composition of the alloy is determined by the second digit of the brand. For the numbers that appear in the second place on the stamp, the following designations are accepted:

· 0 – there are no alloying elements, there are only impurities, i.e. designation of different grades of technical aluminum;

· 1 – alloys of the Al-cu-Mg and al-Mg-Fe-Ni systems;

· 2 – alloys of the Al-cu-Mn and al-Li-Cd-Mn systems;

· 3 – alloys of the Al-Mg-Si and Al-Mg-Si-Cu systems;

· 4 – alloys alloyed with Li, as well as components Mn, Cr, Zr, Ni, Be, etc., which are poorly soluble in aluminum;

· 5 – alloys of the Al-Mg system;

· 9 – alloys of the Al-Zn-Mg and Al-Zn-Mg-Cu system.

The numbers 6 , 7 and 8 (in second place) are not yet used for marking aluminum alloys. Examples of designating alloys using alphanumeric and digital markings are given in table. 3.3. Digital marking has not become widespread and is used primarily to mark new generation wrought aluminum alloys. For cast aluminum alloys, digital marking has not found application at all. A unified alphanumeric marking system has been developed and introduced for them [16]. This system is similar to that used for steels, however, the designations of chemical elements have their own characteristics (Table 3.4.).

Table 3.3

Examples of markings of aluminum alloys

| Alloying elements | Marking | Alloying elements | Marking |

| Alphanumeric | Digital | Alphanumeric | Digital |

| Al | AD00 | Cu Mg Mn Si | AK6 AK8 |

| Mn | AMts | Cu Mg Fe Ni Si | AK4 AK4-1 |

| Mg-Mn | Amg1 Amg5 | Zn-Mg | — |

| Mg-Si | AB | Zn-Mg-Cu | V95 V96TS1 |

| Cu-Mg | D1 D16 VAD1 D18 | Cu-Mn | D20 |

As a result, the alloy grade is written as follows: the first letter, A , shows aluminum, subsequent letters indicate the main alloying elements, and the numbers after the letters show the average content of this component as a percentage by weight.

Table 3.4

Symbols of alloying elements

in grades of aluminum alloys

| Chemical symbol | Name of alloying element | Symbol in the brand |

| Al | Aluminum | A |

| Si | Silicon | TO |

| Cu | Copper | M |

| Mg | Magnesium | Mg |

| Mn | Manganese | Mts |

| Ni | Nickel | N |

| Zn | Zinc | C |

If the content of a component is less than one, the letter designating this component is usually not indicated in the brand.

Examples of recording grades of cast aluminum alloys are as follows: AK5M , AK12M2MgN , AMg5Mts , Ats4Mg , AK21M2 , 5N2.5 .

The letters CH (pure) or ОЧ (extra purity) are placed at the end of the marking and indicate the increased purity of the alloys due to impurities of iron and silicon.

Along with the considered marking systems for aluminum alloys, there is an alphanumeric marking for technological processing of semi-finished products and products, which qualitatively reflects the mechanical, chemical and other properties of the alloy (Table 3.5).

Table 3.5

Alphanumeric marking of technological processing

wrought and cast alloys

| Designation | Type of processing, characteristics of material properties | |

| Wrought alloy | Casting alloy | |

| M | Soft, annealed | Modified |

| T | Tempered and naturally aged | — |

| T1- | Hardened and artificially aged for maximum strength | Aged- |

| T2- | Hardened and artificially aged under a softening regime to increase fracture toughness | Annealed- |

| T3- | Hardened and artificially aged under a softening regime to increase resistance to stress corrosion | — |

| T4 | — | Tempered |

| T5- | — | Hardened and partially aged |

| T6- | — | Hardened and fully aged for maximum hardness |

| T7- | — | Quenched followed by stabilizing tempering |

| T8- | — | Hardened with subsequent softening tempering |

| N | Hard-worked (5 – 7%) | — |

| P | Semi-hardened | — |

| H1 | Heavily cold-hardened (20%) | — |

| TN | Hardened, naturally aged and cold-hardened | — |

| T1N | Hardened, cold-hardened and artificially aged | — |

| Chamber of Commerce and Industry | Hardened and naturally aged, increased durability | — |

| GK | Hot rolled (sheets, plates) | — |

| A | Normal plating | — |

| U | Thickened plating (8% per side) | — |

Marking of electrical aluminum alloys . For these alloys there is an alphanumeric marking system [17].

For the manufacture of cold-drawn electrical wire, aluminum of the AD1 and aluminum wrought alloys of the grades Amts , Amg2 , Amg5P , D1P , D16P , D18 and V65 , where A denotes aluminum, D is a wrought alloy, Mts is Manganese, Mg is magnesium, P is a cold alloy upsetting (a type of pressure treatment), B – high-strength wrought alloy. The number behind the element's designation shows its content as a percentage.

Of the electrical alloys of the Al-Mg-Si-Fe system, the most famous is the Aldrey

(

AB ), which is used for the production of contact wires.

3.3. Classification and marking of titanium alloys .

In industry, titanium is used both in pure form and in the form of various alloys. Technical titanium is marked with the letters VT, immediately followed by the number 1 ( VT1 ). Next, a number characterizing the purity of technical titanium is placed through the dash. Controlled impurities in titanium are the following elements: Fe, Si, C, Cl, N2 and O2. If the total impurity content is less than 0.10%, then such titanium is classified as the purest (iodide) and is labeled VT1-00 . Further, according to the degree of purity (in descending order), the following grades of technical titanium are distinguished : VT1-0 , VT1-1 and VT1-2 [18].

The classification of the main titanium alloys is shown in Fig. 3.4. Like any classification, it cannot be considered complete, since titanium

Alloys are often classified according to structure, composition, tendency to hardening, strength, etc. In some cases, classification is used according to elements - stabilizers of the corresponding phases. However, all these classifications are very complex and have limited departmental application.

Fig.3.4. Classification of titanium-based alloys

There are no special system-forming symbols in the marking of titanium alloys. All industrial wrought titanium alloys are marked with two letters VT , OT , PT and AT , immediately followed without a gap by a number indicating the serial number of the alloy and not giving any useful information about it. Examples of recording grades of deformable titanium alloys are as follows: VT3, VT6 , PT7 , OT4 , AT6 , VT22 , VT35 .

Cast titanium alloys are similar in composition to wrought ones. For them, the letter L , for example: VT1L , VT5L , VT21L .

In order to find out the chemical composition of a titanium alloy and determine its structural affiliation, it is necessary to refer to special reference literature, which provides data on all known titanium alloys.

.

In industry, aluminum is used both in pure form and in the form of various alloys. The aluminum marking begins with the letter A, followed by a number indicating the aluminum content in hundredths of a percent. For example, A97 contains 99.97% aluminum, the rest being controlled impurities [14].

Permanent aluminum impurities are Fe, Si, Cu, Zn and Ti. Depending on the impurity content, primary aluminum is divided into three classes:

1) special purity grade A999 ;

2) chemically pure grades A995 , A99 , A97 , A95 ;

3 ) technically pure grades A85 , A8 , A7 , A6 , A5 , A0 and A.

In electrical engineering, aluminum grades A7E , A6E , A5E and AE , where the letter E indicates its electrical purpose. Technical aluminum produced in the form of deformable semi-finished products (sheets, profiles, rods, etc.) is marked AD0 and AD1 . Aluminum wire, depending on the initial mechanical properties, is produced in several grades, which are labeled ATP , AT , APT and AM - respectively, hard with increased strength, hard, semi-hard and soft.

Due to low strength and insignificant hardening during cold plastic deformation, pure aluminum is used relatively rarely as a structural material. Aluminum alloys are more widely used, which are characterized by high specific strength, the ability to resist static and dynamic loads, including at elevated temperatures, and are distinguished by good manufacturability. The classification of the most famous aluminum alloys is shown in Fig. 3.2.

Fig.3.2. Classification of aluminum-based alloys

The main alloying elements of aluminum alloys are Cu, Mg, si, Mn, Zn, and less commonly Li, Ni, Ti [15]. Elements such as Cu, Zn, Mg, Ni, Fe and Mn are involved in the formation of strength properties, and Mn simultaneously increases corrosion resistance. Silicon is the main alloying element in a number of casting alloys (silumins), since it participates in the formation of eutectic. Elements such as Ni, Ti, Cr, Fe increase the heat resistance of alloys by inhibiting diffusion processes and forming stable complex-alloyed strengthening phases. Lithium in alloys contributes to an increase in their elastic modulus. Magnesium and manganese reduce the thermal and electrical conductivity of aluminum, and iron reduces its corrosion resistance. Aluminum alloys can be divided into structural and electrical alloys.

Marking of structural aluminum alloys . Currently, two alloy markings are in effect simultaneously: the old alphanumeric (Table 3.2.) and the new digital (Fig. 3.3.).

Table 3.2.

Alphanumeric marking of aluminum alloys

| Principle of classification | Alloy | |

| By chemical composition | — | Amg, Amts |

| According to the purpose of the alloy | Duralumin | D1, D6 |

| By technological purpose | Forging | AK6, AK8 |

| By properties | High strength | B95, B96 |

| According to the method of obtaining semi-finished products and products | Sintered foundry | SAP, SAS, AL2 |

| By type of semi-finished products | Wire | Amg5P* |

* The letter P included in the alloy marking indicates that the alloy is wire

Different organizations, when assigning alphanumeric grades to alloys, were guided by different principles. There are grades that characterize the composition of the alloy, for example Amg2 (aluminum + 2% magnesium), Amts (aluminum + 1% manganese). Other brands reflect the technology for producing products: AL2 , AL4 , AL7 , where the letters Al indicate that the alloy is aluminum casting, and the numbers after the letters are the serial numbers of the alloys, which do not carry any useful information about the alloy; AK4 , AK6 – aluminum alloys for forging. The brands of many alloys reflect the organization that developed them: VAL8 , VAL10 , VAL14 are casting alloys developed at VIAM (All-Union Institute of Aviation Materials), VAD1 , VAD3 are wrought alloys developed at VIAM.

Since 1970, a unified digital system has been introduced for marking any aluminum alloys [13]. In accordance with the digital marking, the first digit shows the base of the alloy (for aluminum 1), the second digit indicates the alloying system (shows the main alloying components), the third and fourth digits indicate the serial number of the alloy and the technology for producing products.

| Base (A1) Alloy serial number Main alloying elements | Designation | Material |

| 0 or odd digit | Deformable | |

| Even digit | Casting | |

| Metal-ceramic | ||

| Wire |

Rice. 3.3. Principles of digital marking of aluminum alloys

In this case, for wrought alloys the last digit should be 0 or an odd digit, and for casting alloys - an odd digit. Thus, the main information about the composition of the alloy is determined by the second digit of the brand. For the numbers that appear in the second place on the stamp, the following designations are accepted:

· 0 – there are no alloying elements, there are only impurities, i.e. designation of different grades of technical aluminum;

· 1 – alloys of the Al-cu-Mg and al-Mg-Fe-Ni systems;

· 2 – alloys of the Al-cu-Mn and al-Li-Cd-Mn systems;

· 3 – alloys of the Al-Mg-Si and Al-Mg-Si-Cu systems;

· 4 – alloys alloyed with Li, as well as components Mn, Cr, Zr, Ni, Be, etc., which are poorly soluble in aluminum;

· 5 – alloys of the Al-Mg system;

· 9 – alloys of the Al-Zn-Mg and Al-Zn-Mg-Cu system.

The numbers 6 , 7 and 8 (in second place) are not yet used for marking aluminum alloys. Examples of designating alloys using alphanumeric and digital markings are given in table. 3.3. Digital marking has not become widespread and is used primarily to mark new generation wrought aluminum alloys. For cast aluminum alloys, digital marking has not found application at all. A unified alphanumeric marking system has been developed and introduced for them [16]. This system is similar to that used for steels, however, the designations of chemical elements have their own characteristics (Table 3.4.).

Table 3.3

Examples of markings of aluminum alloys

| Alloying elements | Marking | Alloying elements | Marking |

| Alphanumeric | Digital | Alphanumeric | Digital |

| Al | AD00 | Cu Mg Mn Si | AK6 AK8 |

| Mn | AMts | Cu Mg Fe Ni Si | AK4 AK4-1 |

| Mg-Mn | Amg1 Amg5 | Zn-Mg | — |

| Mg-Si | AB | Zn-Mg-Cu | V95 V96TS1 |

| Cu-Mg | D1 D16 VAD1 D18 | Cu-Mn | D20 |

As a result, the alloy grade is written as follows: the first letter, A , shows aluminum, subsequent letters indicate the main alloying elements, and the numbers after the letters show the average content of this component as a percentage by weight.

Table 3.4

Symbols of alloying elements

in grades of aluminum alloys

| Chemical symbol | Name of alloying element | Symbol in the brand |

| Al | Aluminum | A |

| Si | Silicon | TO |

| Cu | Copper | M |

| Mg | Magnesium | Mg |

| Mn | Manganese | Mts |

| Ni | Nickel | N |

| Zn | Zinc | C |

If the content of a component is less than one, the letter designating this component is usually not indicated in the brand.

Examples of recording grades of cast aluminum alloys are as follows: AK5M , AK12M2MgN , AMg5Mts , Ats4Mg , AK21M2 , 5N2.5 .

The letters CH (pure) or ОЧ (extra purity) are placed at the end of the marking and indicate the increased purity of the alloys due to impurities of iron and silicon.

Along with the considered marking systems for aluminum alloys, there is an alphanumeric marking for technological processing of semi-finished products and products, which qualitatively reflects the mechanical, chemical and other properties of the alloy (Table 3.5).

Table 3.5

Alphanumeric marking of technological processing

wrought and cast alloys

| Designation | Type of processing, characteristics of material properties | |

| Wrought alloy | Casting alloy | |

| M | Soft, annealed | Modified |

| T | Tempered and naturally aged | — |

| T1- | Hardened and artificially aged for maximum strength | Aged- |

| T2- | Hardened and artificially aged under a softening regime to increase fracture toughness | Annealed- |

| T3- | Hardened and artificially aged under a softening regime to increase resistance to stress corrosion | — |

| T4 | — | Tempered |

| T5- | — | Hardened and partially aged |

| T6- | — | Hardened and fully aged for maximum hardness |

| T7- | — | Quenched followed by stabilizing tempering |

| T8- | — | Hardened with subsequent softening tempering |

| N | Hard-worked (5 – 7%) | — |

| P | Semi-hardened | — |

| H1 | Heavily cold-hardened (20%) | — |

| TN | Hardened, naturally aged and cold-hardened | — |

| T1N | Hardened, cold-hardened and artificially aged | — |

| Chamber of Commerce and Industry | Hardened and naturally aged, increased durability | — |

| GK | Hot rolled (sheets, plates) | — |

| A | Normal plating | — |

| U | Thickened plating (8% per side) | — |

Marking of electrical aluminum alloys . For these alloys there is an alphanumeric marking system [17].

For the manufacture of cold-drawn electrical wire, aluminum of the AD1 and aluminum wrought alloys of the grades Amts , Amg2 , Amg5P , D1P , D16P , D18 and V65 , where A denotes aluminum, D is a wrought alloy, Mts is Manganese, Mg is magnesium, P is a cold alloy upsetting (a type of pressure treatment), B – high-strength wrought alloy. The number behind the element's designation shows its content as a percentage.

Of the electrical alloys of the Al-Mg-Si-Fe system, the most famous is the Aldrey

(

AB ), which is used for the production of contact wires.

3.3. Classification and marking of titanium alloys .

In industry, titanium is used both in pure form and in the form of various alloys. Technical titanium is marked with the letters VT, immediately followed by the number 1 ( VT1 ). Next, a number characterizing the purity of technical titanium is placed through the dash. Controlled impurities in titanium are the following elements: Fe, Si, C, Cl, N2 and O2. If the total impurity content is less than 0.10%, then such titanium is classified as the purest (iodide) and is labeled VT1-00 . Further, according to the degree of purity (in descending order), the following grades of technical titanium are distinguished : VT1-0 , VT1-1 and VT1-2 [18].

The classification of the main titanium alloys is shown in Fig. 3.4. Like any classification, it cannot be considered complete, since titanium

Alloys are often classified according to structure, composition, tendency to hardening, strength, etc. In some cases, classification is used according to elements - stabilizers of the corresponding phases. However, all these classifications are very complex and have limited departmental application.

Fig.3.4. Classification of titanium-based alloys

There are no special system-forming symbols in the marking of titanium alloys. All industrial wrought titanium alloys are marked with two letters VT , OT , PT and AT , immediately followed without a gap by a number indicating the serial number of the alloy and not giving any useful information about it. Examples of recording grades of deformable titanium alloys are as follows: VT3, VT6 , PT7 , OT4 , AT6 , VT22 , VT35 .

Cast titanium alloys are similar in composition to wrought ones. For them, the letter L , for example: VT1L , VT5L , VT21L .

In order to find out the chemical composition of a titanium alloy and determine its structural affiliation, it is necessary to refer to special reference literature, which provides data on all known titanium alloys.