It is believed that every man needs to have an idea of how to sharpen a knife to a razor sharpness. However, despite the apparent simplicity of this process, absolutely not everyone can cope with such a task. And the reason is not the lack of skills to hold the blades at the right angles, but the special knowledge that is passed on from generation to generation. But in fact, every person can sharpen a knife correctly; the main thing is to have a correct understanding of the product, sharpening tools and the properties of the material from which it is made. The article will discuss all these important aspects, and also reveal the secrets of how knives are sharpened with a razor.

A bread slicer for each

Everyone has knives. Regardless of who you are—an experienced nymphomaniac who won’t go out on the street without three blades and a multi-tool, or an inveterate pacifist and non-resistance to violence—you definitely have a knife. If not with you, then at home in the kitchen. Or in the car. Expensive or cheap, warehouse, tourist, hunting, bought from a fashion catalogue, given to a friend “for a penny”, made in the zone or machined at a secret factory from a rocket nozzle - there are countless of them.

Typical “knife in the car just in case”

Three quarters of them are stupid. Sometimes you go with friends to the pampas, you need to cut something, and they’re like: “Oh! I have a knife in my glove compartment!” Something fearful is brought into the light of God, whose wit varies from “dumb as a Siberian felt boot” to “only used to cut up dead mongrels.” And what? They used this to open cans, chop nails on a dare, and pick at bricks. This is how it became. It’s easier for me - I always have a “folding bag” with me, for a quarter of a century now. And it's sharp.

Do you want the same? Learn to sharpen.

Main types of blades

Knives are divided by purpose: kitchen, hunting and others. For sharpening, it matters what material they are made of:

- carbon steel;

- chromium-containing stainless steel;

- high alloy knife alloy;

- ceramics.

Carbon steel tools were made in the last century. The blade quickly became dull, oxidized, and became covered with rust.

In addition to iron and carbon, stainless steel contains chromium and other alloying substances. The technological process of their manufacture affects the hardness of the blade. The knife alloy is highly wear resistant. It has a high abrasion resistance coefficient.

Ceramic holds the tip of a knife best. It has a beautiful design and decorative appearance. The disadvantage of the material is fragility. A knife can break if it falls from a table onto a tile or stone floor. Sharpening ceramic blades yourself is difficult. In case of sharp contact with the sharpener, it may burst.

Sharpening and editing

First, let's separate these two concepts. Sharpening is the formation of a cutting edge (CR), and editing is needed to bring this edge to working condition. At high magnification, the cutting edge of a knife sharpened on a large block looks, frankly, unimportant and resembles a rock ridge eaten away by erosion.

Editing the paint using a fine abrasive allows you to bring this visual nightmare to a more or less decent state. The knife begins not only to cut, but also to shave (if, of course, you did everything correctly).

What to do next?

At this stage, sharpening is carried out directly. Pressing lightly on the blade, pull it towards you several times in a criss-crossing motion. Then turn the knife over to the other side and repeat the procedure. These actions are performed until a new, smooth, shiny strip is formed on the cutting edge. The same strip must be on the second side of the knife. Now all you have to do is replace the used bar with a fine-grained analogue. It is used to sharpen the blade by performing light sliding movements without pressure. To check the sharpness of the knife, try cutting a vertical sheet of newspaper. If the blade cuts it easily, then the sharpening was done efficiently. If the sheet wrinkles, then carry out the sharpening procedure again. Finish sharpening on the back of the belt. It will be enough to run the blade several times without pressing along the leather surface.

About the bars

The oldest and most common way to make a knife sharp is by hand sharpening on abrasive stones. A set of decent whetstones is necessary for any thoughtful knife lover, because it is not only a working tool, but also a reason for pride. For home and family, it is recommended to have two or three bars of different grain sizes, as well as a piece of leather rubbed with GOI paste for removing burrs (more on that another time) and final finishing of the blade.

Professional sharpeners, depending on their qualifications, can use up to a dozen natural stones of different characteristics, but the average person has no need for such delights.

Set of Japanese water stones of various grain sizes

In everyday life you can easily do without such a set. The cutting edge on the blade can be shaped quite successfully using a flat "velvet" file or a piece of sandpaper glued to a piece of wood. In “street” conditions, I even had to sharpen cheap Chinese knives on a concrete curb block, and edit them on river pellets.

Editing the blade on the belt

But this is completely extreme, and if you decide to master the “correct” manual sharpening, then for starters you can buy an inexpensive combined (double-sided) stone, which is now a dime a dozen in Chinese online stores. Their quality is uneven, but it is quite possible to find very decent samples. I don’t recommend using diamond-coated whetstones - they eat up the blade too much, and there’s a high chance of getting damaged.

About sharpening on an abrasive stone. Which option should I choose?

Judging by numerous consumer reviews, this is the most affordable and quite effective method. It is ideal for those who decide to sharpen their blade at home. How to sharpen a hunting knife at home using an abrasive surface? First of all, buy a stone. They are sold in a fairly large assortment in hardware stores. However, for a hunting blade, you should give preference to an option that has a wide and perfectly flat surface. It is desirable that the length of such a stone be at least 250 mm. The abrasive must have a fine or medium-grained structure.

How to do it manually?

Regardless of whether you decide to master manual sharpening or use small-scale mechanization means, the right thing to do is start with a block of the coarsest grain size and move on to finer ones. It is advisable to hold the knife perpendicular to the block. The most important thing is to maintain the same angle of inclination of the blade to the surface at all times. Movements when sharpening should be uniform and monotonous. The sharpening stone and the surface on which it rests should not move. To do this, you can put a piece of sheet rubber on the table, or, failing that, a moistened sheet of paper.

Grinding the first third of the knife edge "G. SakaiFoldingHunter" on a 600 grit water stone (before starting work, a block of natural stone is soaked in water for 15 minutes, and then its surface is lubricated with soapy water)

Don’t forget to periodically check how much metal is being removed from the handle, and don’t press the knife too hard - the pressing force against the block should be small but constant. Moving the knife away from you or towards you is a matter of taste; to save time, I do it in both directions. To begin with, you should practice using a regular board instead of a sharpening stone, and, say, a short ruler instead of a knife. Hands will remember.

Many consider the sharpening process to be a kind of movement meditation; in principle, that’s how it is. The need for constant control and concentration on the task at hand forces you to disconnect from external factors. It turns out to be a kind of zen.

About knife defects

Undoubtedly, working with a properly sharpened blade will be much more convenient than using a cutting product with a blunt edge. Before you become interested in how to properly sharpen a hunting knife, you need to learn about possible defects in knives. For example, after improper use, upon detailed inspection, you will notice that the blade has jagged edges and microscopic cracks. There are also obvious signs such as a bent or broken tip, broken handle or tang. As a result, such a product will be unusable. To prevent this, use and store the knife correctly and do not forget to sharpen it regularly. Read more about how to properly sharpen a hunting knife below.

About angles

Holding a knife at the desired angle while sharpening is not as easy as it might seem at first glance. And what is this corner like? For the vast majority of the inexpensive knives mentioned above, the sharpening angle is 20-30 degrees. There are many ways to “calculate with your hands” the desired tilt of the blade; The simplest one is to fold a sheet of thick paper into a triangle, one fold is 45 degrees, the second is half as much, 22.5. We place the resulting pyramid on the block, carefully press the blade against it and remember the tilt and position of the hands.

20-25 degrees is a good angle for a well-worn carbon OpinelFor the same purposes, you can use special wooden corners or several coins glued with superglue. Or simply buy a special clip for the blade, which will prevent the edge from being too “collapsed”.

True, if the steel is completely “plasticine”, they try to increase the angle as much as thirty-five degrees - cutting such a product will be quite lousy, but it will take a long time. Here you can also play with a sheet of paper, but you will have to fold it not in four, but in three - as a result you will get a corner with a working side close to 33 degrees.

For soft steels there is another trick: the angle is maintained around 30 degrees, but one side of the cutting edge is smoothed almost “into a mirror”, and the other is sharpened on a rough, coarse-grained whetstone. This method is popularly called “gypsy”; at the industrial level, it degenerated into the notorious “laser-sharpened knives” (although, of course, there was no smell of laser there).

Small teeth on one side, a smooth surface on the other, and even the top layer of steel is carburized to increase hardness - it cuts well until it gets dull. For cheap domestic stainless steels such as 40X13, 65X13 or the favorite of Chinese manufacturers 420J2, this method works well - try it yourself.

The procedure for using sharpening devices and objects at home using the example of a kitchen knife

Let's take a closer look at the work of sharpening a kitchen knife that is common for daily use, giving as an example the described sharpening methods:

Sharpening stone:

- soak the stone in water for 15 – 25 minutes;

- the knife is installed perpendicular to the stone;

- the sharpening angle is set to 30 degrees, determined visually (90 degrees divided by 3 hours

- ti);

- the blade is directed away from itself by the cutting edge;

- reciprocating movements from the handle to the tip of the knife are carried out along the entire plane of the stone on both sides of the blade until the desired result is obtained.

Dishes as a New Year's gift: 5 options that will please almost any woman

Mechanical sharpener - use the step-by-step instructions described above.

Electric sharpener - similar to the point above.

Musat:

- holding the handle, the device is installed in a vertical position;

- the knife blade is leaned at an angle of 30 degrees;

- circular movements are made with the blade while smoothly lowering from top to bottom;

- the actions are repeated on both sides of the knife until the desired result is obtained.

Sharpening and grinding machines:

- protective equipment (glasses, overalls) must be used;

- the sharpening angle of 30 degrees is visually determined;

- the pressing force of the sharpened tool against the rotating abrasive is below average;

- Constant control of blade overheating occurs by immersion in coolant;

- processing is carried out on both sides of the blade, to the required condition.

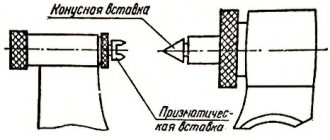

Lansky sharpener:

- the blade is fixed in an aluminum clamp;

- the guide with the stone holder is inserted into the marked hole on the holder corresponding to the desired sharpening angle, and the desired cutting angle of the blade is formed;

- reciprocating movements are performed in the required quantity on both sides of the blade until sufficient sharpness is obtained.

I don’t want to study, I want it straight away!

Japanese masters said: “Out of a hundred students sent to be sharpeners, only one has the ability, and out of a hundred capable ones, only one will become a decent master.”

Well, they are all to hell with this approach! After all, the meat for shish kebab needs to be cut right now!

So, if you are learning Zen in other ways, or you don’t have enough time/patience, or, finally, you suffer from an acute form of upper limb aphedronality, don’t despair. Especially for such cases, there are a lot of simple but effective devices that help keep the cutting tool in very good condition. Twenty years ago, the pioneer and main manufacturer of such devices was the American company Lansky; its Lansky Sharpening System (LSS) set was a kind of standard on the market. Today, our dear Chinese comrades offer exact copies of the “system” at half or three times the price. The stones, of course, are of a lower grade, but otherwise the thing is quite suitable.

American and Chinese sets - the choice is yours

And here's how they sharpen it:

As you can see, everything is very simple and effective. Anyone can do it. However, more complex sharpening devices are now available, real machines with a bunch of adjustments and replaceable whetstones.

But LSS remains a timeless classic. In our area it was dubbed the “Lansky corner” - and be careful not to confuse it with the “Lansky flyer”. The flyer is also a simple device from the same company and it also helps in maintaining the sharpness of the knife. However, it is not suitable for sharpening, but for editing it is the sweetest thing. “CrockStick” are two pairs of metal-ceramic rods of different grain sizes in a wooden box-stand.

Place a pair of rods at the desired angle, take the knife with your “working hand”, and hold the base of the sharpener with your weak hand. Hold the pre-sharpened blade vertically and move it downwards, as if cutting a piece of sausage - the cermet will quickly bring the edge to a razor sharpness.

The “corner + flyer” pair is an almost ideal option for anyone who doesn’t want to bother with bars. However, there are a lot of “bagels” on the market now, from famous manufacturers to budget Chinese. Choose according to your taste and wallet.

Other scissors...

Manual and mechanical, of various designs - the knife-loving public has come up with a lot of things, but personally I respect only two varieties.

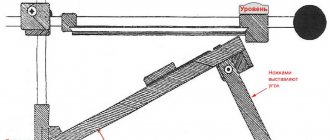

Firstly, the grinder. This is a belt surface grinding machine that allows you to perform a variety of operations - from sharpening a blade to making a knife (and other useful things made of wood and metal) in general.

Making a grinder with your own hands is especially chic; many topics are devoted to this on specialized forums. With proper practice, sharpening a knife with this device is literally a matter of minutes. I don't have a grinder, but I want one. Of course, there is nowhere to put it... But I still want to.

Secondly, musat. In essence, it is a round (less often semicircular or oval) file with a very fine notch. Musats are made of steel (including diamond-coated) and metal-ceramic.

Despite all its primitiveness, it is the musat that is the primary tool for straightening knives in the kitchen. However, it all depends on practice: in the same way, it is necessary to maintain a constant correct angle in relation to the blade. Whether to steer the blade towards yourself or away from you is your own choice. The main thing is to develop the correct movement.

I almost never use other “sharpeners” and don’t see much point in them. It will be interesting - I'll tell you next time.

What mistake do newbies make?

Very often, due to ignorance, owners of hunting knives render their cutting products completely unusable. The fact is that such consumers do not pay attention to the sharpening angle and the degree of grain size of the abrasive. They don’t look at the size of the grains, but simply use a block that comes to hand. Moreover, their movements are chaotic. After making several passes with one side of the blade, they proceed to the second. Beginners may think that the knife is already sharp enough, and therefore they immediately start working with it. As a result, an insufficiently sharpened blade becomes even more dull. After a few days, without re-sharpening, it will no longer be usable.