On the issue of fixation

Half-timber joinery joints do not have a mechanical connection, so they are secured using gluing. We discussed in detail how to properly glue wood and choose the appropriate glue in previous materials.

While drying, the structure must be secured with clamps. When placing the clamps, make sure that their pressure is distributed evenly. An incorrectly installed clamp can deform parts or disrupt the fit of the connection.

Unlike frame structures, logs or beams are strengthened using a different technology. In this case, screws, dowels or dowels are used to secure the connection.

The type of connection based on the insertion of a tenon into a groove appeared in Europe almost simultaneously with floorboards and lining. The finishing material is simple and easy to install and has a lot of advantages. True, the cost is more expensive than ordinary boards and strips, but the joints are much neater, and the service life is much longer.

The groove connection increases the strength of the coating.

What does drying out lead to?

A typical case: you made a shed at your dacha to store household equipment and for other needs.

They did it for themselves, so they pulled together the boards from which the walls were made, carefully, without the slightest crack. Two or three months pass; the boards dry out and the entire wall glows with cracks. In winter, snow blows through them; in summer, the wind blows dust inside the barn. To prevent this from happening, you need to use quarter boards for wall cladding. A wall covered with such boards will never have through gaps. With their quarters, neighboring boards overlap each other and when they dry out, through cracks no longer appear.

Unfortunately, lumber is very rarely sold with a quarter finished. Therefore, an amateur craftsman should know the ways in which boards can be modified if necessary.

Marking of the second part

Tenon joint elements.

After this, we move on to marking the second part of the connection. To do this, you need to take the two parts that are supposed to be connected and attach them tightly to each other. In this case, you need to ensure that it matches the lines of the cuts. When the parts are perfectly attached to each other, it is recommended to clamp them in a vice so that they do not move.

Now that the parts are properly fastened, you need to apply marks with a pencil on the second part that has not yet been marked, and then make the initial cuts with a file. These will not be solid lines, but just thin marks, similar to scratches. But it is still necessary to do them, since it will be easier to work later. Only when making marks, try to do it in such a way as to achieve perfect evenness and avoid bending.

Related article: Technology of interior finishing with gypsum bricks

After this, it is necessary to release the parts and move them further relative to each other. It is important to take this into account. If you move the parts just a little by the width of the file, the connection will turn out to be quite rigid. And if you make the shifts a little more, it will be freer.

However, it cannot be said that any of the options is bad. It all depends on the nature and size of the parts being connected. And also on the specific type of wood used. If you use plywood, then you can make shifts only along the width of the cut, since in any case it will not be subject to severe deformation.

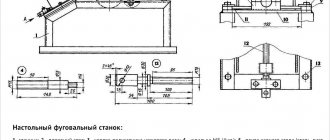

OPERATING THE DEVICE

Marking the grooves is very simple. Determine the shoulder line for each groove by making a pencil mark on the face of the piece to be worked. You can put the two side walls together and mark all the grooves at once, or mark the second side wall after routing the first.

Once the jig is aligned and the cuts are marked, align the straight edge with the mark (photo C), lightly tighten the clamps and make a pass with the router, then move the jig to the next mark. A well-chosen groove should fit the tenon without gaps or backlash (photo D).

Making planks with grooves at home

Often you have to make furniture or make repairs at home, using the simplest methods and what is at hand.

If you need to make a groove in the board with your own hands, be patient and have the necessary tools:

- A circular saw. The most practical tool, but, unfortunately, not everyone has it.

- A regular hacksaw for wood. It will take longer to work with it, but this accessory can be found in every home.

- Electric drill. It is also quite accessible, but before making a groove in a board with a drill, it is advisable to practice on an unnecessary block, practicing the skill.

Making a groove with a circular saw

Making a groove with a circular saw.

The optimal materials are wooden boards, bars and the like. The price of raw materials is minimal; in extreme cases, what is available on the farm is used. The most successful solution is a through, single open straight end connection.

The joint will be strong and reliable:

- It is recommended to make tenons with a thickness of ¼ of the thickness of the plank and a groove of the same size.

- The height and length of the groove must correspond to the dimensions of the plank.

- Prepare a pencil and ruler for marking.

- Decide on the coordinates of the cut and mark it.

- The cut should be made along a line inside the side that will then be separated.

- For a circular saw, the instructions recommend a blade width of 2-4 mm.

- Sawing in the middle of the marked line removes 1-2 mm of excess, since two grooves are made on each plank.

Note! To prevent the workpiece from being damaged, make cuts along the inner sides of the drawn lines. In this case, a visual correction is made for the thickness of the canvas.

- If you need to join two parts at a 90º angle, cut the pieces at 45º at the ends.

- For an end-to-end open miter connection (single straight), mark the cut locations on the oblique cuts of the planks.

- Before removing the groove from the board, double-check that the cut is correct on all sides.

- For an angular single connection that is not through the eye, an eye is made instead of a groove. In this case, the width of the tenon is left unchanged, and the length will be 0.3-0.8 of the width of the board being attached.

- Since the circular saw rounds the edges of the eye, leaving the shape of the tenon unchanged, it is advisable to refine the corners by turning them with a rasp.

Groove using a drill

The photo shows a groove being cut out with a drill.

The method is quite labor-intensive, but it can be called an alternative to the one described above. If you were unable to get a hand router, prepare a drill and chisel, ruler and pencil.

- Select a drill with a diameter corresponding to the width of the future groove.

- To guess the depth of the groove, you can make a mark on the drill itself (for example, draw it with bright paint).

- Draw two parallel lines along the block at the required distance from each other.

- Having secured the workpiece in a vice, drill a furrow, carefully monitoring the vertical position of the drill and maintaining the depth.

- When finished, remove all excess with a sharp chisel and sand with emery cloth.

Note! It happens that a furrow with a concave bottom and a spike with a convex end are required. Before making the moon groove in the board completely, drill to a depth slightly less than required. Subsequent processing and adjustment can be conveniently done with coarse sandpaper or a round file.

Using a hacksaw on wood

Making a transverse groove with a hacksaw.

Well-done markings will help a lot here.

Select a hacksaw blade that is smooth and durable:

- To avoid mistakes, draw two lines along the length of the board, on opposite sides. The distance from the top plane to them will be the depth.

- Securely secure the block and begin sawing.

- It is important to monitor, checking the lines, how far the canvas fits into the wood.

- If the tool is skewed, you can ruin everything, so periodically watch the hacksaw’s entry into the material from the side angles.

- With a wide groove and a thin blade, it is more effective to make two cuts, again along the inner sides of the cut.

- All excess is carefully removed with a chisel and cleaned.

What does drying out lead to?

A typical case: you made a shed at your dacha to store household equipment and for other needs. They did it for themselves, so they pulled together the boards from which the walls were made, carefully, without the slightest crack. Two or three months pass; the boards dry out and the entire wall glows with cracks. In winter, snow blows through them; in summer, the wind blows dust inside the barn.

To prevent this from happening, you need to use quarter boards for wall cladding. A wall covered with such boards will never have through gaps. With their quarters, neighboring boards overlap each other and when they dry out, through cracks no longer appear.

Unfortunately, lumber is very rarely sold with a quarter finished. Therefore, an amateur craftsman should know the ways in which boards can be modified if necessary.

Useful DIY crafts

In order to make something useful, for example, a box, it is not necessary to have a whole arsenal of complex equipment and expensive tools. You can get by with a minimum of tools and mechanisms. To perform carpentry work you will need:

You can use absolutely anything as a material - for example, scraps of parquet boards, pieces of plywood and waste chipboards, but always at right angles. To simplify the work, you need to make a simple milling table. To process workpieces, you will need a large-diameter straight groove cutter. The process looks something like this. On a makeshift table, plan the ends of parquet board scraps. Mark the sides of the box and use a jigsaw to remove all excess.

You can connect the sidewalls together with a mustache. To do this, you need to mill the ends of the sidewalls with a conical cutter with an angle of 90 degrees. This can be done using a router. Thus, the ends of the sidewalls have the same bevels of 45 degrees. Next you need to make grooves in the sides for the bottom. For this, an end mill with a diameter of 6 millimeters is used, equal to the thickness of the plywood.

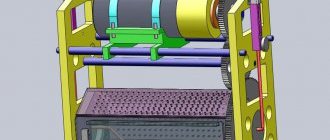

In order to make a tool box, it is necessary to strengthen the carpentry joint of the sides by inserting additional tenons. The operation is called cutting tenons with a hand router. It is very difficult to do it manually, so you need to make a simple device - a milling table. The principle of its manufacture is simple:

We invite you to familiarize yourself with the DIY headrest for a bath, dimensions

One of the most commonly performed carpentry operations is making paneling. It is performed with a special cutter. To perform the work efficiently, it is necessary to make a simple device for the tabletop of the milling device. To do this, you will need thick-layer plywood measuring 500 x 300 x 10 millimeters.

To exit the cutter, a hole with a diameter of 100 millimeters is cut. The parallel stop is attached to the table with clamps. The cutter is set taking into account the distance from the table surface to the sharp edge of the cutting tool of one millimeter. All sides of the workpiece are processed sequentially. The thickness of the panel is adjusted by lifting the cutter.

Using a hand router, it is very easy to create a furniture facade on the doors. To do this, you will need a shaped end mill, a copy sleeve and a plywood template. The technological process is very simple:

The result is a neat design of the furniture facade.

Making a device for picking out a tenon

When parts are processed manually, the milling cutter itself does not have additional spatial fixation. But the overall result of the work and the accuracy of the connection itself in the future depend on this.

To assemble the simplest design that can cope with the task, you will need to use:

- Several guides that remain stationary. They should be side and top or bottom.

- The length of the sample is adjusted through the use of an appropriate movable bar.

For manufacturing, the following sequence of actions is used:

- A plywood sheet is taken, from one edge of which the side elements are mounted in a vertical plane. It is necessary to create appropriate cutouts in the center of the material.

- The sides are equipped with guides. The base of the hand cutter moves along them later.

- The side strips are fixed on the upper guides. Then the movement of the working milling cutter associated with these parts becomes limited.

- The plywood sheet, which became the basis for the installation, also serves as a surface for installing the moving element. Then the amount of edge overhang for the future workpiece is easier to control under any circumstances. Fixation is ensured with ordinary screws and other types of fixing devices.

There are several points during manufacturing that require special consideration:

- The upper guides have a height corresponding to the sum of the thickness for the part under processing and a small gap at which the wedge involved in fixation is installed.

- The forming tenon has a certain length, which is taken into account when determining the vertical thickness of the cutouts in the side elements.

When such devices are used, the work is carried out with the participation of hand-held milling cutters of any modern model.

Fixtures are made in the following way if dovetail connections are required.

- A hole is created inside a sheet of plywood with several layers. The cutting part at the cutter itself protrudes from this part.

- A plywood sheet is prepared in advance, on the bottom of which the manual router itself is fixed. Clamps and screws are perfect for doing the job, as are other types of fastenings.

- The board, 2.5 centimeters thick, is attached to a plywood sheet, which subsequently participates in the movement of the prepared part. The function of the guides is taken over by the design. Boards are consumables with one-time use.

How to choose a groove with a router?

The solution to the problem depends on where the grooves are located and what size they are. Here are some recommendations for home craftsmen:

- The use of open grooves involves securing it to the tabletop and guiding the workpiece along the cutter.

- Accuracy is determined by the height of the cutter and the location of the bar.

- It is recommended to use wood waste for trial operations. This allows you to avoid mistakes.

- Sampling is carried out in stages, with several passes being carried out.

Cutting a tenon with a router

If you have a lot of tenons to cut (or if you just like working with machines), a table router is the ideal tool. If the large size of the workpiece does not allow it to be placed on the milling table, it is better to press it with clamps to the workbench and process it while holding the router in your hands. Set the fence to the length of the tenon and the router to the desired height, then, holding the workpiece firmly against the fence, remove the excess wood in several passes. When the end of the tenon rests against the stop, turn the workpiece over and repeat the procedure on the other side. If you stop before the cutter reaches the shoulder line, trim the tenon with a chisel.

Cutting a tenon with a router

SAWING A GROOVE/TENK CONNECTION ON A CIRCULAR

Since this is a very simple connection, it is easier and faster to combine marking and installation. Check the settings on the scrap boards (Fig. 6 and 7).

It's easier to fit the tenon to the mortise, so make the mortise first. Set the depth of the cut by measuring or by eye, pressing the disc against the part in which the groove will be. Then set a ruler to cut out the inner shoulder of the groove (Fig. 6, step 2), make a cut in all parts with grooves, rearrange the ruler and cut out the second shoulders.

Narrow parts, such as the sides of bookcases, can be sawed using a dividing head, keeping the end of the work piece in contact with a straightedge as you work. You can also attach a limiter to a ruler in front of the disk so that the end of the part rests against it.

The most accurate way to select a groove on a circular saw is to place the workpiece on the table and, pressing it against the ruler, cut out the shoulder. Then place the part on the end and cut out the thickness of the tenon. This method allows you to accurately control the thickness of the tenon, but it is inconvenient for long parts or those that are sawed across. It is better to make tenons on these parts using several horizontal cuts. After sawing the shoulder, press the piece against the ruler and use a dividing head to cut out the excess wood in several passes. Unlike the first method, here the thickness of the tenon depends on the thickness of the workpiece.

No matter how carefully the tenons are made, there is usually some variation in their size, especially when sawing into solid wood. Here we can advise you to cut the tenons a little thicker, and then, when fitting, trim them with a plane for the shoulders. The blade of a shoulder plane runs across its entire narrow sole, so you can cut right into the corner of a tenon shoulder.

GROOTS CAN BE MADE EVERYWHERE

With a groove connection, the end of one part fits into a shallow groove cut across the grain of the other. This connection is an improvement on the simple butt connection. The groove shoulders provide decent strength. In fact, such a connection cannot be broken, for example, by pressing on a shelf. If it fits tightly, it can withstand oblique loads well, when the force is directed diagonally across the body. Installing back walls in cabinets or chests of drawers and bottoms in drawers further strengthens the entire structure. Finally, the groove makes assembly easier by defining the position of the parts and keeping them from slipping.

Using just two types of groove connections, you can make almost any body part. The main joint, where the groove engages the full thickness of the adjacent piece, allows for the assembly of bookcases, toy chests, wall shelves, or any other cabinets in which the side walls extend beyond the adjacent pieces (Figure 1).

Rice. 1

.

Main groove connection. Rice.

2 . Modified groove/tenon connection.

If these "through" angles are unsuitable or unsightly, use a modified joint (Figure 2) called mortise/tenon.

Drawers are also boxes. They are easily made using a basic mortise joint and a mortise/tenon joint (Figure 3). Example ZA is the strongest of them; in examples ZV and ZS, you can weaken the front wall. If you want to hide the ends of the drawer sides shown in 30, cover them with a false front or use a quarter joint as shown in 30, reinforced with nails or dowels.

Rice. 3

. Grooves in drawers.

Types of groove boards

Many users have no idea how to choose a groove in a board, believing that the store will offer them only one option for connection and material.

This is far from true; there you will be greeted by a large assortment:

- Symmetrical groove. This is the simplest type. In it, the lengths of the upper and lower shelves are the same, and they protrude at the same distance.

- Asymmetrical groove. Here the upper shelves are longer than the lower ones.

- Block house, used mainly for finishing walls and ceilings. The planks often imitate the relief of timber and have a semicircular or shaped profile on the front side.

- Euro lining, like block house, is often supplied with a relief pattern.

- Decking boards, made of wood and polymer, also have tongues and grooves that simplify installation.

Note! If you plan to mount walls that are not level, have protrusions and dents without a groove board, do not expect good quality from the result. The cladding will not lie flat, height differences and cracks are inevitable.

Lumber processing options

Let's figure out how to choose a quarter on the board with your own hands. We buy grade 2 board and process it in a convenient way. How can you do something like this:

- electric planer;

- circular;

- manual milling cutter;

- Bulgarian

First, you need to make a cut from the end of the board, with a depth of half the height, and then in the center of the end. Then we set the width of the working part of the board and saw another fragment. Here the depth should be 1.5 times greater than half the height to make it more convenient to remove the sawn-off part. In this way, you can create a finished product with your own hands that is twice as expensive as the original one.

Despite the production from second-grade raw materials, the quarter has excellent characteristics:

- strength;

- thermal insulation properties;

- visual appeal;

- possibility of decorative use;

It is possible to use this material for external cladding.

A circular saw

The work scheme is not fundamentally different from the previous ones, the only difference is that wood processing is carried out with a circular saw.

Electric planer

They are convenient for cutting boards and giving them shape. The process of obtaining a quarter board is no different from working with other equipment, but a plane is better because of its convenient operation. This device provides an open view of the working surface of the board.

In the absence of a circular saw and a plane, a grinder with a wood disc or a hand router on which a cylindrical cutter has been previously installed will be suitable for work. But both options are characterized by low productivity, that is, they are unlikely to be suitable for processing large volumes of material due to their low speed.

Curved cuts

A curved cut can be made with an electric hacksaw, jigsaw or band saw. The hacksaw is good for large radius cuts and thick wood, when the cutting line goes away from the edges.

Curved cut

Hacksaws are equipped with rotating bases that change the cutting angle, and depending on the type and thickness of the material, different saw blades should be used. For curved cuts of small radius and with wood thickness less than 50 mm, use a jigsaw or jigsaw.

Jigsaw machine

Install the new file and tighten it until it rings when you click it with your finger. If you need to cut an opening, you can do two things: either start cutting from the edge, or, if you do not need to touch the edge, first drill a hole in the part to be removed, then release one end of the file, pass it through the hole made and clamp and tighten again.

This saw makes it easy to make cuts at any angle. Place the cutting blade on the frame at the required angle (90, 45, 36, 22.5 or 15°) and fix it. Set the depth gauge to the desired mark. Place the workpiece on the saw table, press it against the fence, and then make the cut using smooth back and forth movements.

The sawing machine works neatly and quickly

When it comes to choosing grooves, rebates or tongues, all workshop workers first of all think about the sawing machine. As a rule, it takes less time to install the groove disk and set up than it does to prepare the router. In addition, I like the fact that the saw machine quickly copes with such work and it is convenient to work with boards and panels of different widths and lengths.

Grooving discs come in two types: dialed and adjustable (so-called “drunk”). We prefer compositors that make square, clean cuts. Of course, the most expensive type-setting disks cut cleaner, and the bottom of the cutting turns out to be flat, and the side surfaces are parallel and without chips. However, most set-up discs leave small triangular grooves in the bottom corners, caused by the beveled edges of the teeth on the outer discs. Adjustable (“drunk”) discs are attractive due to their low price and speed of adjustment, but they have a serious drawback - the bottom of the disc turns out to be concave, and the corners are not straight, and after working with them you have to resort to cleaning.

You can also do all three types of cuts with a 40- or 50-tooth combination saw blade. When choosing a groove or tongue, make the outermost cuts first, and then remove the material between them in several passes. Small irregularities at the bottom of the sample can be smoothed out with a sharp chisel or milling cutter.

In the same way, it is possible to cut folds, but we prefer to make them using two cuts. First, a cut is made to form the shoulder of the rebate. Then a high overlay (150-200 mm depending on the width of the workpiece) is fixed to the longitudinal (parallel) stop, the overhang of the disk is adjusted and a second cut is made at a right angle to the first. To avoid kickback when the blade jams and ejection of cuttings, make sure that the cuttings are not caught between the blade and the fence.

Tool that can be used

Let's consider what devices can help you when carrying out work:

| Fraser | There can be two options here - either a full-fledged machine that can perform any work, or a manual milling machine, with which you can quickly perform some operations right at the construction site. |

The first solution is used by professionals, since the price of the machine is high; the second type of tool is also suitable for home use

Specialists use special machines for longitudinal profiling of timber

Driving screws

You have a choice of mild steel, stainless steel, brass or aluminum screws with straight or Phillips slots and countersunk or pan heads. Semicircular heads stand out clearly on the surface of the wood, countersunk heads are either flush with the surface, or edged with brass washers, or hidden by wooden plugs. The screws are screwed in with a hand screwdriver, a drill with an appropriate attachment, or a screwdriver.

Driving screws with a drill or screwdriver

When using a drill, install the locking mechanism so that the screw is screwed in to the required depth. If the wood is soft, the installation hole can be made with an awl; if it is hard, drill it with a drill of a smaller diameter.

The installation hole can be made with an awl

To be able to hide the screws under the wooden plugs, you will have to drill a hole for the plug with a countersink drill and a corresponding cutter for the plug. Don't use steel screws on oak - they react with the wood and moisture and cause stains. Instead, choose plated steel, brass, or stainless steel screws.

Creativity without limits

Milling equipment is indispensable when processing wood. With its help, you can turn a wooden blank into an elegant decorative product. This equipment is most often used by professionals, but experienced amateurs can also master it. Using mechanisms is not an easy task , so before you start working with them, you need to ensure your comfort and safety. Organization of the workplace is very important. The home craftsman must remember that during work there is a possibility of damage not only to the cutter or mechanical device, but also to health.

Woodworking is not only about working at the machine , but also about preparing the workplace and planning the sequence of work performed. Before you start milling, you need to select the appropriate type of cutter for a specific task, taking into account its shape and size. You should select the speed of the machine and the cutting depth and do not forget that the material being processed must be securely attached to the table.

Depending on the specific type of milling device, the rules for their use are different in many aspects. Today, vertical milling machines in which the spindles are located above the work table are widely used. They have proven themselves to be excellent in operations such as wood milling, processing the edges of shelves and round tabletops, making a groove, and joining wooden parts. When processing round structures, an indispensable addition is a special compass with a support plate, which ensures precision processing.

When working with a router, you need to learn how to move it calmly and smoothly. The key is to move the material being processed correctly and safely. This should not be done too slowly, as burn marks may appear on the wood, which can lead to damage to the material.

Chips appear when milling woodworking against the direction of the wood grain. In one pass it is necessary to mill to a depth of up to 8 mm; some models allow adjustment with an accuracy of 0.1 mm. Deep grooves and quarters need to be milled in several passes.

Hazardous factors

Milling machines require complete safety and high qualifications of the worker. When using electric machines, accidents may occur due to material ejected during milling. Therefore, the performer of the work must have special work clothes.

If heavy dust is generated during the milling process, you must wear safety glasses. Maximum safety in this situation is provided by special clamps and vices that effectively hold the workpiece, preventing it from being thrown out. Do not hold the workpiece in the rotation zone of the cutter with your hands or directly touch the rotating tool. It is necessary to use special clamping devices to advance the part during milling.

It is easy for a home craftsman to figure out how to make a tenon and groove using hand routers. Tools used, detailed instructions on how to select a groove with a router.

an engineer will help - Milling grooves in wood

Both the groove and the notch can pass through, that is, through the entire surface of the product, or not reach one edge or both edges. There are many methods to ensure the accuracy of the work, but the operation of the machine remains more or less the same.

Making a through groove

Lower and lock the router's vertical movement mechanism. Place the base of the machine on the workpiece without touching the cutter to the wood, then turn on the engine. Move the machine forward evenly along the workpiece until the cutter exits the material at the other edge of the part. Turn off the engine and wait until the cutter has come to a complete stop before putting the tool down.

Making a no-go groove

Before turning on the router with a vertical movement mechanism, lower the cutter onto the surface of the workpiece and place it exactly at the beginning of the groove. Raise the cutter, turn on the motor, and slowly lower the cutter to the set maximum depth. Bring the cutter to the end of the intended groove and release the vertical movement mechanism and turn off the engine. Using a chisel, trim the ends of the groove. Making a groove parallel to the edge Most grooves are cut parallel to and close to the edge.

Included with any router, manufacturers supply side rulers (stops) with bolted screw fastenings, which can be adjusted to set the router to the required distance from the edge. If you have them, then place the router on the workpiece and align the cutting edge along one side of the groove marked on the surface. Adjust the straight edge so that it touches the edge of the piece and tighten its clamp screws. Make the groove by pressing the ruler against the workpiece throughout the process.

Processing of wooden parts

The first thing you need to learn is to correctly set the milling depth. To do this, you need to set the zero point. It is impossible to set it rigidly, because it changes every time the cutter is changed. The zero point is the position of the tool when the end of the cutter touches the material and is fixed with a special device called a clamp.

It is necessary to pay attention to the fact that each router has a different position when fixed. To control the depth of immersion of the cutting tool into the body of the material, a stop pin with a coarse adjustment scale is used.

When milling with an end mill, the counterforce from the cutting force moves the router to the side. To prevent this from happening, you need to use a rip fence. The milling process is as follows. Place the cutter along the marking line and secure the position of the stop with a special screw. Set the milling depth and turn on the machine. If the rip fence is installed on the left side, you need to pull the router towards you, when on the right side - away from you.

How to make a groove in a board - All about timber and woodworking

Knowing how to make a tenon and groove with a hand router, you can even at home make not only beautiful but also reliable furniture, but also various wood structures characterized by excellent load-bearing capacity. The tongue-and-groove system connects not only elements of various furniture (tables, chairs and shelves), but also frames of low-rise buildings that experience significant loads during operation.

A tongue-and-groove joint made by hand

In order to make a tenon on a wooden beam using a hand router, several conditions must be met:

- securely fix the workpiece and correctly orient it in relation to the guide sole of the router;

- set the height of the working part of the cutter so that the tool removes a layer of material of the required thickness from the surface of the workpiece.

HOMEMADE DEVICE FOR SELECTING GROOTS

Although the device looks complicated, it is quite easy to make (Fig. 10). Cut the workpieces to size, and then carefully plane the planes and edges. Then select a groove in the fixed bar for the fixed ruler using a few cuts on a circular saw. Then, to ensure a tight fit and square edges, use a sharp chisel to trim its shoulders. The half-wood connection on the adjustable ruler is made so that its upper surface is in the same plane as the fixed ruler.

Mill out all the cracks in the planks and rulers using a ruler pressed to the base of the router (Fig. 8). First, releasing the cutter approximately 3 mm in each pass, mill narrow through slots in several passes. Next, mill out pockets for the screw heads and T-nuts.

Small clamps are used as clamps. The pressure pad is a T-shaped nut at the end of the screw. The locknut prevents the pad from coming loose when it presses against the workpiece. Select the grooves in the adjustable bar so that the clamps can hide behind its edge. Rice. 10

. Device for making grooves.

A hand router is a universal mechanical tool in the home workshop. To use it correctly, you need to get basic lessons in working with a wood router. There are many Chinese-made milling cutters on the market, they are all of the same design and differ only in engine power. Experts recommend purchasing a more powerful tool, since the list of work performed will expand significantly. The craftsman will be able to cut out a pattern, make a quarter cut, cut tenons and perform other operations related to the manufacture of furniture.

Drill saw

Neither a hand saw nor an electric hacksaw will help if you need to cut a small hole in the workpiece - less than 10 cm in diameter. A jigsaw may also be useless if the workpiece is large. In this case, the most suitable tool is a drill saw. With its tip it bites into the wood like a drill and thus makes a “starting” hole for further cutting. Externally, the saw is similar to a round file with the difference that its shaft is surrounded by a spiral around the cutting edge.

Drill saws are available with interchangeable attachments of various diameters, designed for processing both soft and hard wood, as well as a variety of materials made from it.

The working body of a drill saw is a metal rod with a cutting tip, like a gimlet, and a cutting edge that goes around the rod in a spiral.

This is what the narrowest of hand saws looks like. Thanks to the fastening unit, the blades in the hacksaw can be changed depending on the nature of the material being processed.

Drill attachment

One of the most popular and convenient options for cutting a hole is a special attachment for a drill. It is made in the form of a crown comb and has a rounded shape. With this attachment, cutting holes occurs quickly, and they turn out quite smooth.

drill bit for holes

Nozzles come in different diameters, which allows you to cut a hole of the required diameter. If you have already prepared a hole, we can advise you to try your hand at options trading.

Drill

You can also cut a large hole using a drill. To do this, it is necessary to pre-mark the outline of the hole to be drilled. Next, use a small drill to drill through holes along the contour prepared in advance. Next, using a jigsaw or a very sharp knife, we cut off the holes, thereby connecting the holes. After which you can smooth the circle using sandpaper of various grain sizes.

Chisel

You can also cut the required hole using a chisel. It is enough to remove the wood layer by layer along the contour. This option is the least suitable for interior decoration. The hole must be smooth, which cannot be achieved by using improvised and unsuitable materials for the job. The best option would be to use a drill bit. The hole is even and has smooth edges.

Thus, to summarize, it becomes clear that you need to choose a tool for cutting a hole based on your goals. If you need a high-quality cut, then you cannot do without a special tool.

Selection options

When choosing one or another method of milling wood, first of all you should pay attention to the possibility of installing a milling attachment on a drill. To do this, the power tool must have a cylindrical neck, in the extension of which a chuck is installed

In the absence of one, it is not recommended to use a specific drill model for milling. If it is installed on a specialized drill device intended for milling, then you can select cutters. First of all, you should pay attention to the type of work. The milling tool is not universal, so each operation will require its own model of equipment. The diameter of the shank must allow clamping in a specific drill chuck. It is not recommended to use large cutters, as they can require significant spindle power.

It is also necessary to take into account processing modes. Many wood tools require high RPMs that are unattainable with drills. It should be remembered that any electric drill is not designed for long-term loads. Therefore, it is not recommended to apply great effort to it and perform work continuously for a long time.

What does drying out lead to?

A typical case: you made a shed at your dacha to store household equipment and for other needs. They did it for themselves, so they pulled together the boards from which the walls were made, carefully, without the slightest crack. Two or three months pass; the boards dry out and the entire wall glows with cracks. In winter, snow blows through them; in summer, the wind blows dust inside the barn.

To prevent this from happening, you need to use quarter boards for wall cladding. A wall covered with such boards will never have through gaps. With their quarters, neighboring boards overlap each other and when they dry out, through cracks no longer appear.

Unfortunately, lumber is very rarely sold with a quarter finished. Therefore, an amateur craftsman should know the ways in which boards can be modified if necessary.

Rallying in a quarter

Rallying in a quarter

gives a tighter connection than butt jointing. Longitudinal side cuts (quarters) are made in the boards to be joined using a hand router, electric planer or circular saw. The depth and width of the quarter should be equal to half the thickness of the board. This type of connection leaves no cracks or gaps. Quarter bonding is useful for cladding external and internal surfaces. For example, to hide unevenness or defects in walls, insulation and flooring.

1. For an example of cutting a quarter with a circular saw, take 3 identical boards (photo 1).

2. At the beginning of work, mark 1/4 of their width on the boards on both sides. Prepare the circular saw. To do this, adjust the reach of the saw blade so that the cutting depth is equal to half the thickness of the board (photo 2).

3. For the required distance (half the thickness of the board) of the cut from the edge of the board, we adjust the parallel stop of the saw (photo 3).

4. We secure the workpiece on the work table with clamps and make a longitudinal cut with a circular saw (photo 4).

5. After this, we make longitudinal cuts on the back sides of the board (photo 5).

6. Again, secure the workpiece with clamps on the work table (photo 6.1) and make transverse cuts equal to half the thickness of the board (photo 6.2-6.4).

7. In this way we make 2 more blanks (photo 7).

8. Place the workpiece on 2 perpendicular boards (photo 8).

9. We nail the prepared blanks to their base (photo 9.1, 9.2).

10. When nailing the next workpiece, press it tightly against the previous one and fix it with nails using a hammer (photo 10).

11. The quarter joint is ready (photo 11).