Electric planers, which have been on the market since the mid-20th century, have become indispensable for craftsmen processing lumber. Their popularity is due to the presence of a number of advantages compared to conventional hand planes. When using power tools, the labor intensity of the process is reduced, labor productivity increases, and the quality of workpiece processing is improved. In addition to planing, specialists perform quarter cutting, chamfering and other operations using tools. To achieve a high-quality result, you need to know how to operate an electric planer correctly and follow safety rules.

Basic parameters and classification

The parameters by which drill cutters intended for wood processing are divided into various categories are:

Basic geometric parameters of a wood cutter

Types by purpose

Today, many tools are used to perform milling work on wood using an electric drill, since technological operations with this material can be different. Depending on the main purpose, the following types of wood cutters are distinguished.

Using such a tool, the corners of wood products are rounded.

These cutters are used to cut V-shaped grooves on flat wood surfaces. Using such a tool, you can make various patterns and inscriptions on the product, as well as process edges.

These are wood cutters, with the help of which grooves and grooves of various widths and depths are cut out on the surface of the workpiece.

Such cutters are similar in purpose to disk cutters, but they allow you to create wider grooves on the surface of the product. Cutters of this particular type are used in window production, where they are used to cut grooves in wooden frames to accommodate glass.

Using cutters of this type, semicircular grooves can be created at the end of the workpiece. Wood fillet cutters equipped with a support bearing are used for the manufacture of decorative furniture slats.

These are tools with a cutting part made in the shape of a reverse cone. With their help, you can create dovetail grooves in wood products. It is these grooves that are used to create open and hidden tenon joints between two or more parts made of wood.

These wood cutters are designed for processing the edges of wooden products. The design of the edge cutter may contain a bearing, which, resting against the edge of the workpiece, ensures its correct position and limits the depth of its cut.

Wood cutters of this type can be made with straight or helical cutting edges. Using such tools, flat surfaces are processed.

These cutters are also designed for flat surface processing. Unlike cylindrical ones, they have cutting teeth on the end part.

Using these cutters, chamfers are removed from the edges of the workpiece. Such a wood cutter, used for installation on a drill, can also have a thrust bearing in its design, which limits the depth of the tool’s cut into the wood.

These wood cutters are used to create complex grooves and recesses on the surface of the workpiece.

These are cutters used to form elements with a complex configuration on the surface of a wood product.

Types by design

Milling tools used in conjunction with drills can have different designs. Thus, there are solid and prefabricated wood cutters, which should also be selected depending on the characteristics of the material to be processed.

Basic techniques for quarter sampling

After the block is securely fastened, you need to stand in such a way that it is convenient to move while moving the electric planer. The body should not be overly tense, and the sleeves and hems of clothing should not interfere with movement.

Selecting a quarter begins with turning on the instrument. Before carrying out the procedure for removing a quarter, the electric planer should work a little without load to allow the tool knives to reach maximum speed. Only after this can you bring the power tool to the workpiece and perform the first approach. In this case, the sole of the electric planer should always be parallel to the surface of the part.

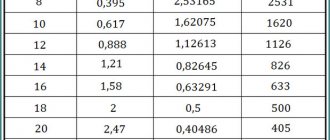

Table of main parameters of electric planers.

The electric planer is moved along the surface of the part very smoothly and evenly, making sure that no chips get under the sole. Sudden movements, stops, changes in speed or jerks will inevitably lead to surface deformation: pits or depressions will appear. It will no longer be possible to level the surface.

You also need to press the handles carefully while planing the plane. It is important to ensure that the force is the same. To avoid blockages, experts recommend slightly increasing the pressure on the front handle when starting planing, and on the rear handle when finishing.

When selecting a quarter, the sequence of work and the position of the hands will be slightly different. You need to advance the plane with one hand, and with the other you simultaneously press the side stop to the edge of the workpiece. The speed of movement should not be high: haste will only worsen the result. The optimal time for the first approach is up to 2 meters per minute, but not faster.

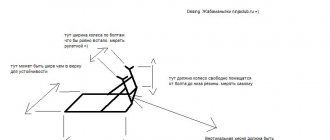

It is very important to ensure that the electric planer moves strictly along the intended path. As the depth increases, the side stop loses its importance. Gradually, after several approaches, the edge of the sample becomes a guide. The depth of the quarter is limited by the planer elements protruding from the side. They are slightly raised on one side, this makes it possible to make a quarter of great depth.

Peculiarities

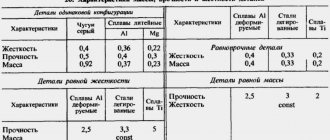

Computer numerical control equipment allows operator intervention to be kept to a minimum. After manufacturing, the part does not require additional processing.

Using machine tools, several types of processing can be performed:

There is also plasma treatment. But it is used less frequently than other types. Depending on the type of processing, there are both advantages and disadvantages. It is necessary to pay special attention to their consideration if you do not know which machine is better to choose.

The most suitable materials for work are sheet type materials. Of the listed types of manufacturing, the most popular is milling. on the machine ensures the production of parts with precise dimensions and smooth edges. Laser cutting is more suitable for cutting plywood.

When cutting, you must adhere to the rules for using the unit.

Using milling you can create almost all types of parts. Modern models are compact, so they can be placed in a room with a small area. Numerical control ensures easy operation. Thanks to this, you can handle plywood processing without any experience. When purchasing a machine, you will receive instructions that describe how to operate it.

Sampling a quarter using an electric planer

An electric planer is an indispensable tool for people who process lumber. Its widespread use is explained by a huge list of advantages compared to hand-held instruments. When using an electric planer, the labor intensity of work is significantly reduced, productivity increases, and the quality of material processing improves.

In addition to planing with an electric tool, you can perform a huge number of tasks: cutting quarters, chamfering. To get a high-quality result, you must strictly follow the processing rules and do not forget about safety precautions.

DIY milling machine from a drill

Considering the fact that a serial milling machine is an expensive piece of equipment, the question of how to make a small milling machine from a drill is very relevant. Such a machine, used in conjunction with wood cutters mounted on a drill, is indispensable in the construction and repair of a country house, as well as in performing many other works.

Homemade machine from a drill

When starting to make a homemade router, you must first make a table for it, which should be stable and reliable. For this, plywood is often used, the thickness of which should not be less than 12 mm. The supporting elements can be made from four wooden blocks. An important part of such a homemade device is the limiter pad, the task of which is to ensure the correct position of the cutter in relation to the surface being processed. You can make such a platform from a sheet of chipboard or thick plywood by cutting out a piece of the required size and rounding its corners. A hole is drilled in the center of the limiting pad, which is necessary for the wood cutter to exit.

Quarter selection sequence

- We adjust the reach of the saw blade so that the cutting depth is equal to half the thickness of the board being processed. The easiest way to do this is right on the spot. To do this, place the board on the side of the saw blade, as shown in the photo, and adjust the reach of the blade.

- We install a parallel stop on the machine so that the width of the cut is also equal to half the thickness of the board. We take into account the thickness of the disk itself. This completes the machine setup.

- We make longitudinal cuts on opposite sides of the board.

- We make cuts from the ends of the board. A quarter is ready. As a by-product we get glazing bead)).

Preparation

Before production, it is necessary to prepare the CNC machine for operation. Setting up the unit involves two stages. The first is represented by setting up tool blocks, and the second - by working mechanisms.

Setup is carried out step by step:

Additionally you need to check:

When serial processing with cutters, you should carefully monitor the processing of the first workpiece. With its help, you can determine whether there are errors after adjustment. If there are inaccuracies, additional corrections must be made. If there are several elements, the layout on the sheet saves plywood. After setup, there is no need to check the control program - it will produce parts according to similar parameters.

Select the number of revolutions

The rotation speed of the working attachment directly affects the quality of processing of a wooden workpiece. There is such a dependence: the higher the speed, the “cleaner” the gash. We strongly do not recommend purchasing a plane with a drum rotation speed below 12,000 rpm, as the quality of processing will be unsatisfactory.

For fitting building structures that do not require perfectly smooth surfaces, devices with a blade rotation speed of 12,000 - 13,000 rpm are suitable. By the way, if you already have a grinding machine at home, then, in principle, with planes of this speed you can obtain structures with ideal surface treatment.

For the manufacture of furniture, where high precision and quality of wood processing is required, units with an attachment speed of 14,000 - 18,000 rpm are suitable. In some cases, after planing with a high-quality electric planer, additional polishing may not even be necessary.

GROOTS CAN BE MADE EVERYWHERE

With a groove connection, the end of one part fits into a shallow groove cut across the grain of the other. This connection is an improvement on the simple butt connection. The groove shoulders provide decent strength. In fact, such a connection cannot be broken, for example, by pressing on a shelf. If it fits tightly, it can withstand oblique loads well, when the force is directed diagonally across the body. Installing back walls in cabinets or chests of drawers and bottoms in drawers further strengthens the entire structure. Finally, the groove makes assembly easier by defining the position of the parts and keeping them from slipping.

Using just two types of groove connections, you can make almost any body part. The main joint, where the groove engages the full thickness of the adjacent piece, allows for the assembly of bookcases, toy chests, wall shelves, or any other cabinets in which the side walls extend beyond the adjacent pieces (Figure 1).

. Main groove connection. Rice. 2

. Modified groove/tenon connection.

If these "through" angles are unsuitable or unsightly, use a modified joint (Figure 2) called mortise/tenon.

Description of the tool

Knowledge of the structure and operating principle of an electric planer is necessary for everyone who wants to use this tool. It will help not only to use the device correctly, but also to repair it yourself if necessary.

Device

The design of the tool has remained virtually unchanged since the release of the first model.

Only some additional functions and electrical control have appeared.

The engines also became more advanced: they reduced weight and gained more power.

The design of an electric planer includes the following parts:

- Frame;

- Electric motor block;

- Handle for support;

- Chip collection bag;

- Rubber pad;

- The sole, which acts as a support, consists of an adjustable and fixed part;

- A pipe for removing generated debris;

- Button to turn on;

- Lock button;

- Regulator for setting planing depth;

- Drum with cutting knives (from 1 to 3 pieces);

- Side limiter;

- Transmission mechanism.

For home use, it is enough to buy a model that will contain only one knife. On more expensive planes, an electronic unit is also installed to control the number of working revolutions. With its help, the speed of shaft torsion is controlled, depending on the volume of the load. But the size of the sole is very important. It controls the stability of the plane while performing work. The length can vary from 30 to 40 cm.

Principle of operation

Various models of electric planes operate according to the same principle:

- When power is supplied to the starter windings, the electric motor rotor begins to rotate.

- Then, using a transmission mechanism, the torque is transmitted into the drum to the blades.

- They, in turn, rotate in a circle. When the blades come into contact with wood, part of the surface of the material is removed. The amount of wood cut is adjusted manually. Using the pipe, excess chips are ejected.

- When the power is turned on or off, the electric motor starts and stops not instantly, but gradually. This helps to avoid overload during work.

Alternative methods

As mentioned, a stationary circular saw is very convenient for selecting quarters. (There is a separate article on our website about the types of circular saws and the features of their choice.) But it is not always in the master’s arsenal, and sometimes it is physically impossible to use it.

If you need to cut quarters out of thick, long boards, you can use a hand-held circular saw. The manufacturing principle and sequence of operations are the same. The difference is that in this case the board being processed and the tool change places. The board is fixed motionless, and the master moves the circular saw with a parallel stop along it manually.

If you don’t have a circular saw or a hand-held circular saw at hand, you can use a grinder with a wood blade or a hand router with a suitable cylindrical cutter. Both methods are very slow and are not suitable for large volumes of work. In addition, choosing a quarter with an angle grinder is inconvenient, dangerous and turns out uneven.

Read also: Welding inverter helper 140 diagram

Another way is to use an electric plane. However, most modern plane models are not suitable for this due to their design features. Watch the video that shows just this method of choosing a quarter.

How to choose on a board using an Interskol plane

Not all models of electric planers of this brand are equipped with the quarter sampling option. It is available on the Interskol R-82 710 710 W model. It is carried out in exactly the same way as described above.

But there are two features of the model.

- The stop bar for selecting the quarter is mounted on one screw with a thumb for tightening by hand. All fastenings are on the same axis - a little “spinner”, so the fastening is unreliable, goes to the left or right from parallel with the body.

- The model is equipped with a stand for operation in stationary (inverted) mode. A quarter can also be selected in two ways - by moving the plane over the workpiece, or by moving a small workpiece along the plane in a stationary mode.

The depth of the quarter on this model is 15 mm.

BASIC CONNECTION IN GROOVE

Cutting grooves on a tabletop circular saw with a set of groove discs is much faster than manually. But long or wide pieces are difficult to maneuver around the table. A pendulum saw solves this problem, but it has a drawback - usually its console is not enough to cut across wide parts.

A router helps solve this problem. But this also has its drawbacks.

First, if you are selecting more than one pair of grooves, setting the ruler for each side can be time consuming. Therefore, use an insert with a width equal to the distance from the rib of the router base to the cutter. To install the ruler, slide the insert along the marked shoulder line on the work piece (Figure 4).

. Insert for router.

Second, the thickness of the workpiece is almost never matched to the cutter to ensure a tight-fitting joint. Solid wood parts can be planed or sanded, but plywood parts are difficult to trim. Cutting a groove to fit is more clear. But this requires two passes with a router - one for each shoulder.

Faced closely with the selection of grooves, you can make a simple device (photo A).

What does drying out lead to?

A typical case: you made a shed at your dacha to store household equipment and for other needs. They did it for themselves, so they pulled together the boards from which the walls were made, carefully, without the slightest crack. Two or three months pass; the boards dry out and the entire wall glows with cracks. In winter, snow blows through them; in summer, the wind blows dust inside the barn.

Shrinkage reaches 10-13% of the linear size. That is, a board with a width of 100 mm after drying is reduced to 88 mm.

To prevent this from happening, you need to use quarter boards for wall cladding. A wall covered with such boards will never have through gaps. With their quarters, neighboring boards overlap each other and when they dry out, through cracks no longer appear.

Unfortunately, lumber is very rarely sold with a quarter finished. Therefore, an amateur craftsman should know the ways in which boards can be modified if necessary.

GROVING DEVICE

The device consists of two rulers (one for each groove shoulder) and two strips that rest on the edges of the workpiece. One ruler and one strip are T-shaped fastened at right angles. Gaps along the other strip and ruler allow you to install boards up to 300mm wide and select grooves up to 38mm wide. Two clamps in an adjustable bar rest against the workpiece and lock the fixture in place.

To operate, you need a set of guide bushings for the router. With bushings, the rulers should be slightly offset to the side relative to the width of the groove itself.

The device is made of poplar, but Karelian birch plywood or MDF is also suitable. The T-nuts and MB screws are recessed, so the router can slide along the rules without hindrance.

Having finished manufacturing, you need to make inserts for installing the rulers. Plane a piece of cutting board approximately 450 mm long, 150 mm wide and 20 mm thick to the same thickness along the entire length. It all depends on the size of the sleeve and the cutter. Leave the jig in place while you make and fit four inserts, each approximately 50mm long, about 25mm wide and equal to the thickness of the gaps. Ideally, the thickness of the inserts should be equal to half the difference in the diameters of the cutter and sleeve.

Precise adjustment of the inserts is accomplished by using them with rulers installed when routing on a short piece that has been sawed off previously. Loosen the adjustable ruler, place the scrap between the rulers and two inserts on each side.

Tighten the screws. Remove the inserts and trim and mill the groove. If the trim does not fit into the groove, adjust the thickness of the inserts.

How much device power is needed?

Models on sale range from 450 to 2250 W. The power of the device directly affects the depth of cut and the density of wood that can be processed. Low-power devices will not be able to cope with hard wood, for example, ash or acacia, as the knives will “stick” and the quality of the processing will be poor. On the other hand, if you have to work mainly with pine or linden, then a powerful device will simply waste extra energy. Here is the approximate dependence of the power of the device on the density of wood:

- 450 – 600 W – suitable for soft wood with a wood density of up to 540 kg/m 3, for example, pine, chestnut, linden, poplar, alder and juniper.

- 600 – 1000 W – suitable for medium-density species from 540 kg/m3 to 730 kg/m3, for example, apple, birch, maple, larch, etc.

- 1000 – 1500 W – suitable for species with high wood density from 730 kg/m3 and above, for example, oak, ash, acacia, hornbeam, iron birch, etc.

Higher power models will only be needed if you are going to use an electric planer for production purposes, for example, if you are opening your own sawmill. In our rating of electric planes, we took exclusively models for household use, not exceeding a power of 1500 W.

Making planks with grooves at home

Often you have to make furniture or make repairs at home, using the simplest methods and what is at hand.

If you need to make a groove in the board with your own hands, be patient and have the necessary tools:

Making a groove with a circular saw.

The optimal materials are wooden boards, bars and the like. The price of raw materials is minimal; in extreme cases, what is available on the farm is used. The most successful solution is a through, single open straight end connection.

The joint will be strong and reliable:

The photo shows a groove being cut out with a drill.

The method is quite labor-intensive, but it can be called an alternative to the one described above. If you were unable to get a hand router, prepare a drill and chisel, ruler and pencil.

We invite you to familiarize yourself with How to beautifully make door frames

Making a transverse groove with a hacksaw.

Well-done markings will help a lot here.

Select a hacksaw blade that is smooth and durable:

TeremOK

House in Spain

Not far from Barcelona you can see a stylish house that integrates modern technologies to reduce energy consumption

Laser rangefinder Maka

Laser measuring instruments are increasingly popular and in demand in construction and repair work. Firstly, accuracy increases significantly.

Leak control system

A water leak in an apartment is a rather unpleasant event. And not only for your premises, but also for the neighbors below. Although the opposite happens.

Pipes for water heated floors

Warm floor water systems are very popular among owners of private houses and cottages. This is due to the fact that such heat is dispensed with.

New PVC profile KBE

As has been repeatedly pointed out, modern PVC windows are a complex and reliable design. And what would this “reliability” You did.

Roofing ICOPAL 3D

Everything flows and everything changes... This phrase is quite applicable to roofing materials. Today there is a roof for every taste, color, etc.

VEKA plastic windows

Have you decided to buy plastic windows? The idea is great and now all that remains is to make a choice. And as practice shows, the buyer chooses first.

House made of laminated timber

Glued laminated timber is a popular building material that is environmentally friendly and has high technological performance. Houses erected.

Construction of cottages

Building your own home is the dream of many of our citizens. But, the construction of a cottage or country house involves not only large material costs.

Turnkey wooden house

The construction of turnkey wooden houses is becoming more and more popular every year. And there are objective reasons for this. The most.

Block house

Block house is a popular finishing material, quite attractive in appearance, practical and versatile. Surface lined with block house.

Russian house made of timber

Country houses made of timber in a traditional Russian style are an excellent alternative to modern cottages made of blocks and bricks. What about internal amenities?

Lightweight foundation blocks

Lightweight foundation blocks are an excellent foundation option for the construction of such objects as frame-panel houses and houses made of timber.

Finnish wooden houses

Wooden houses made of timber are offered by POLAR LIFE HAUS. She has 100 years of experience in woodworking and is currently involved in construction.

Fiber cement siding CEDRAL

Most of us equate the concept of siding with vinyl. However, with the development of construction technologies, new finishing technologies appear.

Champion replacement windows

It's time to think about replacing them with modern windows. Champion replacement windows — just those windows that give a number of advantages over.

Heated towel rail MARGAROLI

MARGAROLI - quality and elegance The heated towel rail in the bathroom performs two functions: firstly, it dries towels and clothes, and secondly, it plays.

Soft tiles IKO

Soft tiles IKO Flexible tiles IKO are identified with a guarantee of quality, proven by time and practice. It has long become an axiom &ndash.

Soft roof GAF

Soft roofing GAF Bituminous shingles of the American corporation GAF Materials Corporation is the flagship of roofing products.

Flexible tiles SHINGLAS

Flexible tiles SHINGLAS - harmony of price and functionality Flexible tiles SHINGLAS are just that roofing material.

OPERATING THE DEVICE

Marking the grooves is very simple. Determine the shoulder line for each groove by making a pencil mark on the face of the piece to be worked. You can put the two side walls together and mark all the grooves at once, or mark the second side wall after routing the first.

Once the jig is aligned and the cuts are marked, align the straight edge with the mark (photo C), lightly tighten the clamps and make a pass with the router, then move the jig to the next mark. A well-chosen groove should fit the tenon without gaps or backlash (photo D).

MILLING THE GROOVE/TENK JOINT

For large and wide parts of housings or long and narrow parts, milling grooves is relatively simple and safe. Select a cutter of the correct diameter, attach a ruler to the base of the router and make passes with it, moving the ruler along the end of the part (Fig. 8). Many routers are sold with a ruler, but to improve the quality of work, it must be pressed to the base with a clamp or screws.

The most accurate way to mill a tenon is to clearly set its thickness between the ruler and the cutter (Fig. 9). To support the base of the router, use a clamp to press a piece of thick board flush with the end of the workpiece.

HOMEMADE DEVICE FOR SELECTING GROOTS

Although the device looks complicated, it is quite easy to make (Fig. 10). Cut the workpieces to size, and then carefully plane the planes and edges. Then select a groove in the fixed bar for the fixed ruler using a few cuts on a circular saw. Then, to ensure a tight fit and square edges, use a sharp chisel to trim its shoulders. The half-wood connection on the adjustable ruler is made so that its upper surface is in the same plane as the fixed ruler.

Milling a pattern on plywood with an edge router

I decided to write a short master class on milling. This master class will help in implementing ideas for making interesting decorative elements using budget woodworking tools. After completing it, you will not have to turn to carpentry specialists for help. Because the lesson will help you master the skill of figure milling. In order to start studying this direction you will need: - a sheet of plywood; - pencil; — an edge router, any that weighs little and fits comfortably in the hand (usually the weight does not exceed 2 kg); — a cutter or several cutters of different diameters; - a little imagination; — work space (it will be dusty); — safety glasses; — protective headphones; - respirator (optional). First, find or buy a sheet of plywood. Usually a sheet of plywood has dimensions of more than 1.5 by 1.5 meters; find a hypermarket or store that could cut this sheet for you into smaller pieces so that you can easily transport it to your home or place of work, if necessary. . To work at the learning stage, you need a small sheet, even 30 cm by 50 cm, with a thickness of at least 1 cm (10 mm), is enough. Let's assume there is a leaf. At this stage you will need imagination, draw the sheet with any lines: straight, oblique, curved, in the form of balls, squares, perhaps these will be illustrations or stencils of leaves, insects, trees, etc., keep in mind that the smaller the size of the drawing, the You will need less of a cutter to select a design stencil from the plywood. Since the router makes a very loud noise when milling, and also generates a large amount of dust and gouging emissions from work, you will have to find and use glasses, headphones, and a respirator, the latter is optional. Below is my photo, which shows a sheet of lined plywood. A simple drawing was chosen, which I made in one minute. The photo shows that the milling cutter has already slightly selected part of the pattern and a kind of depression has been created. Please note that it is best to set the milling depth to the minimum possible, so the cutter will easily move along the surface of the plywood. If you set the milling depth to be greater than the thickness of the plywood, then it will be possible cut out objects and separate them from the general sheet, but that's another story.

Yes, and be careful, although the router is small, the number of revolutions per minute is about 30,000, which is very fast. Pieces of wood bouncing off the workpiece can accelerate to several tens, and maybe hundreds of kilometers per hour.

After about 40 minutes of work, you will get the result, well, someone may work slower or faster, it all depends on the complexity of the drawing. In general, working with an edge router is a great pleasure. This is what happened. The technique is not new, but you can depict something, especially if your imagination and hands are good. The choice of materials for work in this direction is possible with any wood; it can be any solid board, planed log, board, tabletop, steps. Regarding MDF, I don’t know how it will work, but you can try it if you want.

Source

Basic techniques for quarter sampling

After the block is securely fastened, you need to stand in such a way that it is convenient to move while moving the electric planer. The body should not be overly tense, and the sleeves and hems of clothing should not interfere with movement.

Selecting a quarter begins with turning on the instrument. Before carrying out the procedure for removing a quarter, the electric planer should work a little without load to allow the tool knives to reach maximum speed. Only after this can you bring the power tool to the workpiece and perform the first approach. In this case, the sole of the electric planer should always be parallel to the surface of the part.

Table of main parameters of electric planers.

The electric planer is moved along the surface of the part very smoothly and evenly, making sure that no chips get under the sole. Sudden movements, stops, changes in speed or jerks will inevitably lead to surface deformation: pits or depressions will appear. It will no longer be possible to level the surface.

You also need to press the handles carefully while planing the plane. It is important to ensure that the force is the same. To avoid blockages, experts recommend slightly increasing the pressure on the front handle when starting planing, and on the rear handle when finishing.

When selecting a quarter, the sequence of work and the position of the hands will be slightly different. You need to advance the plane with one hand, and with the other you simultaneously press the side stop to the edge of the workpiece. The speed of movement should not be high: haste will only worsen the result. The optimal time for the first approach is up to 2 meters per minute, but not faster.

It is very important to ensure that the electric planer moves strictly along the intended path. As the depth increases, the side stop loses its importance. Gradually, after several approaches, the edge of the sample becomes a guide. The depth of the quarter is limited by the planer elements protruding from the side. They are slightly raised on one side, this makes it possible to make a quarter of great depth.