A router is often used in conjunction with accessories to accurately complete a planned job. Various additional devices for such electric tools are available on the market. One of them is the rip fence for the router. Read on and find out the purpose of such a device, how it is modernized for milling a curved surface. Let's also consider options for professionally manufacturing a wooden rip fence. Let's talk more about frequently used factory models.

One of the variants of a proprietary parallel stop for milling tools Source 220-volt.ru

Briefly about the main thing

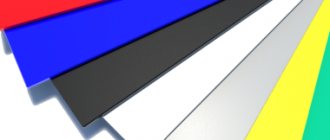

The parallel stop for a manual electric router is designed for precise execution of straight cuts. It simplifies the processing of edges of wooden workpieces and facilitates the creation of grooves in parts. A stop fixture for an electric router is produced by many tool manufacturers. Craftsmen often use models such as Kreg PRS1015, DeWalt DE6913-XJ, Keepwork 800X110 mm.

Carpentry specialists often make stops for a hand router for a specific type of work. They are created mainly from wooden parts. Metal elements are also used, but in smaller quantities. So that a stop device for a manual router can be used to process curved surfaces, it is supplemented with a wooden block with a recess that is shaped to fit the plane being processed.

Factory rip fences

Not a single qualified craftsman refuses the opportunity to buy a parallel fence. Nowadays, many manufacturers manufacture additional devices for routers, some of which are well known to builders, carpenters and other craftsmen. Popular brands include Bosch, Makita, Kreg, Interskol and so on. Let's look at some commonly used models.

Keepwork 800Х110 mm

This model is a side support with an anodized aluminum base. Aluminum corners are used to fix it on the milling table. Exactly in the center of the device there is a hole created specifically for the operation of the cutter. Chips are still removed through it. The design also contains brushes. For their manufacture, the manufacturer used MDF. The brushes have holes through which they are attached to the thrust device. This parallel fence is sold together with a connection for connecting the dust extraction hose.

Description and purpose of the rip fence for an electric router

It would be more correct to call such an additional device an auxiliary device for a milling table. It is usually always available in workshops where work is performed by real professionals. However, the fence can be used not only on the router table. It can be used on any base surface. That is why many milling cutter models initially include a parallel stop, which makes it possible not to purchase it separately. Although on the market such add-ons are presented in different versions from various manufacturers of power tools, including world-famous companies.

The rip fence is an auxiliary device for making straight cuts. The base surface for it can be not only a specially designed and manufactured table from one of the brands. When performing work, it is often used as the side edge of the workpiece being processed or even slats, which are guides for the router.

Option for using a metal guide Source mebpilot.ru

Important! A rip fence is a bar that is used when milling edges and processing grooves on parts.

In the standard version, the router stop device consists of the following parts:

- two metal rods with a round cross-section, which are fixed in special holes in the milling power tool;

- screw for fixing the rod in the required position;

- support elements, which are pads for resting the device on the base (manufacturers produce modifications of parallel stops with the ability to adjust the gap between these pads);

- a screw to fine-tune the location of the cutter axis relative to the base flat support - more often in the workshops of highly qualified joiners and carpenters, the surface of a milling table is used as this support.

The design of a factory rip fence often includes a fine-tuning screw Source ftool.ru

See also: Catalog of companies that specialize in the reconstruction and rebuilding of houses

A stop device for a hand router, which is manufactured in a factory, is first prepared for use, and only then used for its intended purpose. Such an additional device cannot be used immediately as soon as it is removed from the package. To use it, you must do the following:

- insert the rods into the holes specially designed for them in the base of the electric milling tool;

- secure the rods in the desired position using a locking screw element;

- loosen the stopper;

- adjust the gap between the reference plane and the axis of the cutting blades of the cutter by turning the fine adjustment screw.

This is interesting! Experienced craftsmen equip the persistent factory fixture with an additional element of a simple design. With sufficient experience, it allows you to use a rip fence to quickly perform not only high-quality straight cuts, but also precise curved cuts in wooden workpieces.

Once modified, the rip fence can be used to make curved cuts Source amazon.com

An addition to the factory milling tool fence is a block of wood. Its craftsmen make it with one straight side edge. On its second side, a recess is created, which can have an angular or round shape. This block is placed between the curved surface of a wooden blank and the supporting overhead elements of the factory fixture.

This addition is installed in such a way that its straight, even edge rests against the lining of the straight stop, and the side with a round or angular recess is in contact with the curved plane of the workpiece. At the same time, experts note that it is necessary to work with the improved stop device as carefully as possible due to the unstable position of the milling hand-held power tool. For this reason, milling rounds or corners of various wooden parts is entrusted exclusively to experienced craftsmen.

Milling roundness is entrusted only to an experienced craftsman Source klasstrueda.ru

Professional manufacturing of rip fence for milling power tools

Craftsmen who professionally perform carpentry and carpentry work sometimes make a stop for the router themselves. The reasons for this may be different. In some cases, craftsmen do not have the opportunity to buy a device in a specialized store, since it simply is not nearby, and the work needs to be completed urgently. In other situations, some woodworkers and carpenters find that making them themselves produces a better rip fence. With its help, it will be possible to carry out the specific work for which it was created as conveniently as possible.

Experienced specialists in carpentry are able to quickly produce a stop device for a router. They begin its creation by preparing a base with a flat surface. This part is located parallel to the cutting line of the blades of the milling power tool. Any oblong object is used as a thrust element.

A professional can quickly produce a rip fence Source zone-outillage.fr

On a note! The design of a rip fence for an electric router may include one or two rods. Experienced craftsmen usually choose the second version of the device because it is more reliable. After this, they thoroughly think through the strong fastening of the rods.

Custom router jigs are often made from lumber. Typically, when creating parts for a thrust device, craftsmen use bars, MDF, plywood or chipboard. A common wooden rip fence design consists of the following parts:

- base 20 mm thick – 1 pc.;

- vertically fixed part 254*70*25 mm – 1 pc.;

- screw size 4.2*38 with a countersunk head – 2 pcs.;

- metal rods with a diameter of 8 mm – 2 pcs.;

- furniture bolt class M8 with a length of 75 mm – 1 pc.;

- bottom strip with recesses for two steel rods – 1 pc.:

- washer 8 mm – 1 pc.;

- top bar with recesses for metal rods – 1 pc.;

- flywheel nut size M8 – 1 pc.

Manufacturing drawing of a wooden parallel stop for an electric milling tool Source orgstanki.ru

On a note! A hole with a diameter of 8 mm is made in the center of the lower and upper planks, which allows them to be connected to each other using a furniture bolt and a flywheel nut.

To make a fixture for a wood router, a slightly different pattern can be used. In this case, to create it use:

- plywood measuring 900*125 mm;

- melanin, the dimensions of which are 900*125 mm;

- another piece of plywood 900*75 mm.

Melanin is used as a lining. The rail is placed on it in the same way as fixing the guide to the table surface. The plywood is then joined together using adhesive and nails. Then, using a special attachment for a screwdriver or electric drill, one through hole is made through three workpieces at once. Its diameter should correspond to the same size of the vacuum cleaner port. Next, this element from the vacuum cleaner is placed in the hole made. Its fixation is also carried out using an adhesive composition.