The welding station is a specific “office” of the welder, equipped with all the necessary equipment, accessories and devices necessary for the uninterrupted performance of welding work. The organization of the welding station and all work associated with its arrangement must be carried out in accordance with labor protection and life safety requirements. When planning such areas that carry out technological processes, one should be guided by the requirements for production premises and placement of equipment, transportation of materials, as well as requirements for personnel and the use of personal protective equipment.

In this case, we will talk about arranging a workplace for performing electric arc welding operations (manual, argon arc, semi-automatic).

Stationary and mobile welding stations: types and sizes

In essence, welding stations are workplaces where conditions have been created for safe and comfortable work.

Depending on the energy source, they come in gas and electric welding types. Gas welding workplaces are subject to increased air exchange requirements. Electric welding stations provide reliable protection against electric shock. Classification by design is divided into stationary and mobile types. The first ones are equipped in a designated area for welding small-sized workpieces, since the area of the workbench tabletop is limited. The latter are made in the form of frames on wheels with installed equipment. The mobility of the workplace is convenient for welding complex objects.

Welder workplace equipment options

Welding stations are divided into two types:

- stationary – designed mainly for working with small metal workpieces;

- mobile - most often installed at large manufacturing enterprises, used when laying pipelines and prefabricated construction structures.

General requirements for the welder's workplace

- The area must be sufficiently illuminated (minimum 80 Lux). It is recommended to simultaneously use natural light and electric lighting devices for welding stations.

- All types of electrical equipment must be grounded.

- The flooring on the site should be made of brickwork or concrete.

- Specialized pockets for storing documentation and consumables.

- A mandatory requirement is the organization of high-quality ventilation of welding stations to remove harmful gases.

- Working surface made of cast iron, steel with power cable.

- The welder must have a rubber mat under his feet.

- To perform seated work, there must be a special metal chair with a dielectric seat.

When arranging a site on the street, a canopy must be made that will protect from precipitation. To protect from direct sunlight, special folding shields are equipped.

Classification of welding stations

Welding work stations are divided into two categories: stationary and mobile. They are used for different types of work and have different designs.

The stationary post and all its equipment is an open cabin at the top, which contains everything necessary for work. In these posts you can weld small-sized metal products. But they are not suitable for processing large products; here you will need a mobile welding station. It is used to make pipes, install large structures and much more.

Mobile welding station

A professional mobile welding station is organized for high-quality welding work and the production of large-sized metal structures. Such a workplace is most often organized in an open area, so a canopy must be made for it, which will protect it from solar radiation and precipitation. The main material used in the manufacture of mobile post canopies is warehouse panels.

For the convenience of storing electrodes, auxiliary tools, special equipment, and other available tools, the gas welding station is equipped with special cabinets. In this case, a ventilation system is not provided, since the work is carried out in the open air, and the harmful gases released during the work quickly dissipate on their own.

Basic requirements for organizing a mobile post

- Lighting should minimize the load on the worker’s visual organs resulting from the light flux.

- Lighting fixtures are most often placed above the desktop tabletop, next to it.

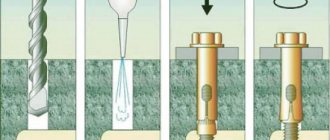

- The gas welding station must have a grounding device.

- For high-quality exhaust ventilation in a natural way, gaps of about half a meter are left between the floor base and the walls.

Equipment

Since there are several types of welding, the workplace will have to be equipped differently. The only things that remain unchanged are grounding, safety requirements for the welding station, lighting and auxiliary devices for the convenience of the welder.

- Welding with non-consumable electrodes in shielding gases requires organizing a place for gas cylinders or a compressor.

- Mechanized welding or cutting of metals is an additional unit for supplying consumables or cutting tools.

- Using three-phase voltage means installing a contactor of the required size.

- The workplace of an electric welder operating on alternating current is additionally equipped with an oscillator. Its purpose is to stabilize the electric arc.

Equipping a place where a gas or electric welder works is a serious and responsible matter. The basic and important rule here is to ensure maximum safety during welding work. Therefore, systems such as ventilation, grounding and lighting receive increased attention.

Proper provision of a welding station for manual welding is not only reducing the risk of employee illness, but also preserving his health, which is very important. This is an increase in the quality of work, plus a reduction in order completion times.

Features of the welding station

If necessary, welding equipment is moved to an open area. Therefore, posts are divided into two types - stationary and mobile (mobile). Welding transformers will be located at the workplace to carry out welding with alternating current, or a rectifier for direct voltage. Welding stations often include:

- Switch.

- Power network.

- Electric holder.

- Welding cables.

- Power supply.

- Exhaust probe.

The post cabin must also have its own specific dimensions: 1.5 m and at least 2 meters in height. Inside it is equipped with a metal table; an exhaust probe must be installed in the upper part. The table has one or more drawers for storing any tool. You should never forget about personal protective equipment; this includes overalls, which must be issued to the welder.

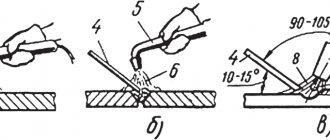

Post device for manual arc welding

All necessary materials, tools and welding equipment must be available at each welding station. In short, everything that a welder needs to work. This is a welding machine of the required type, electrodes and holders for them, grounding means, a power source, as well as a minimum set of metal furniture.

The welding post can be stationary or mobile, depending on its purpose and location.

Stationary welding station for manual welding

This is a workplace that is equipped on a permanent basis. Its dimensions depend on the size of the products being welded. As a rule, this includes a metal table and a chair that is adjustable in height. The power is supplied directly to the table, and the welder

works without leaving the table. All products are delivered to his workplace. Instead of a table, a special tilter is often used, which makes it easy to move and rotate parts as needed by the welder.

Electric welder station equipment

When equipping a welding station (stationary or mobile) for electric welding, the following conditions must be met:

- grounding is connected to the desktop and equipment housings;

- good illumination of the desktop surface (a combination of artificial light and natural light is allowed);

- floor made of fire-resistant material;

- table cover made of steel or cast iron, at least 20 mm thick, with a connected ground cable;

- drawers or pockets for storing tools, electrodes, technical documentation;

- stool with seat made of insulating material for welding while sitting;

- the presence of a rubber mat on the floor near the table.

When welding is carried out outdoors, the workplace is covered with a canopy or awning made of waterproof material to protect from rain, snow, and sun.

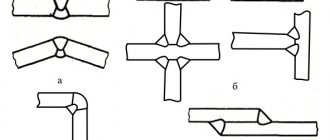

Stationary

Stationary welding stations are made in the form of booths without an upper ceiling.

When arranging, take into account the requirements of regulatory documents:

- The area is not less than 3 m², the walls are 2 m high. A screen made of tarpaulin or non-flammable plastic is hung at the entrance.

- Ventilation gaps of at least 50 mm in size are left from the floor to the bottom edge of the walls. When working with inert gas, the gap is increased to 300 mm. The gaps are covered with a metal mesh with small cells.

- Install a table with a tabletop of at least 1 m². For working in a sitting position, its height is 60 - 70 cm, for welding standing from 85 cm.

- The walls are made of sheet iron, asbestos-cement slabs or non-combustible materials treated with a fire-resistant composition.

- A lamp is installed above the table.

- The walls are covered with light gray paint that has the ability to absorb ultraviolet radiation (zinc-based compositions or titanium white).

- An exhaust hood is installed or, when organizing a welding station in the workshop, it is connected to a centralized supply and exhaust air exchange system.

- The floor is poured with concrete or laid with bricks.

- A switch is installed inside the cabin to quickly turn off electrical equipment if an emergency occurs.

Stationary post

It is an open-top cabin raised above floor level. In such posts, small and medium-sized parts are welded; it is not suitable for large units and metal structures. The cabin is usually made of metal sheets, which are subsequently coated with zinc-containing paints or other coatings that are resistant to high temperatures and infrared radiation (for example, titanium-based white or yellow chromium-lead salt paint, other modern substances).

The floor must be concrete (or screed). PVC coverings, wooden floors on joists and other flammable materials are not allowed. The entrance/exit is covered with a tarpaulin, or metal double-leaf doors with corrugated glass are provided.

Some requirements for a welding booth:

- Sufficient lighting for comfortable work, the presence of light sources that illuminate the post in general and the table on which all manipulations are carried out, in particular.

- The area of the post is at least 3 m2, the height of the metal walls is 1.8 - 2 m, they must be raised above the floor to a height of 20-25 cm; the ceiling height of the room in which the cabin is installed is, accordingly, more than 2 m for free air circulation.

- A table for working in a sitting position should be 50-60 cm high. The table is assembled from metal. It is advisable that a copper sheet be laid on the table cover (including at the point of contact of the ground terminal). The lid itself is made of steel or cast iron up to 2.5 cm thick. The table should have metal drawers for storing tools, fixtures, electrodes, drawings, etc.

- There must be a special hood above the table. If you are creating a post in a garage, you can build an exhaust fan into one of the walls of the garage; in this case, you will need to take care of the presence of an air supply during the winter season. In industrial conditions, a point hood has recently been often installed, the flexible “trunk” of which can be installed directly at the welding site.

Air exchange in the room is at least 40 m3/hour according to regulatory documentation. Let us remind you that with insufficient air exchange, toxic elements contained in welding smoke (aerosol) will accumulate in the lungs of welders, which will eventually lead to the occurrence of occupational diseases.

- There should be a rubber mat under your feet.

- All equipment must be grounded (some welders use RCDs).

- The welder's work chair must rotate around its axis for ease of work. The materials from which the chair is made must be heat-resistant and non-conductive. The seat and backrest can be made, for example, of wood.

- For convenient work, you should have a manipulator (or rotator) and a foot pedal at hand, which simplifies its control. The manipulator is used for welding bodies of rotation.

Varieties

There are two types of welding stations: stationary and mobile. Stationary stations are located in the workshop and are designed to work with small parts, since the working surface of welding tables is often limited. Mobile posts can be located both inside the workshop and outside. These can be small frames on wheels into which the equipment is built, or a special cart.

Let's take a closer look at each post type.

Stationary post

Below is a diagram of a stationary type welding station. In most cases, the stationary post is located in a separate cabin without a roof, but with closing screens. The area of such a cabin must be at least 3 m2.

A stationary welding station must be made of non-flammable materials, so the screens are made of polymers, and the frames are made of metal. The height of the cabin itself must be at least 2 meters. The interior walls of the cabin are coated with a fire-resistant compound that does not support combustion.

Each stationary post has not only equipment, but also a welding table. Its size is determined by the nature of the work. If welding is done in a sitting position, then the height of the table should be about 60-70 cm. If in a standing position, it should be from 85 and above. The size of the working surface must be at least 100x100 cm.

A separate requirement is good ventilation for the welding station. Local ventilation during welding can be either natural or forced. Forced ventilation is preferable. Local suction from the welding station is also necessary to quickly remove metal shavings, dust from grinding, etc.

Mobile post

The welding station for manual arc welding can be mobile or portable. Often, a mobile welding station can be set up with less effort, since it does not require compliance with many rules. There is no need to organize ventilation, observe the size of the working area, etc.

But what is worth doing is a canopy over the mobile station so that the welder can work in bad weather or under the sun. Also, the mobile post should have comfortable wheels so that even heavy equipment can be transported without much difficulty.

The mobile post must have compartments and niches for storing components. If this is a mobile gas welding station, then there must be space for a gas cylinder. Ventilation of the welding station can be natural, since work in most cases takes place outside.

Electric welding arc

During electric arc welding, the air is contaminated with impurities that can cause poisoning of the human body or damage to the lungs, leading to pulmonary diseases. Impurities that cause poisoning of the body include oxides of copper, lead, zinc, manganese, fluoride compounds, carbon monoxide and nitrogen monoxide. Oxides are formed during the oxidation of copper, lead, zinc, and manganese vapors released during the welding process. Copper and zinc can be part of the electrode and base metal. Manganese can be part of the base metal, electrode metal, as well as in coatings and fluxes.

Lead oxides are formed when it is welded using a carbon or graphite electrode method. Air pollution with fluoride compounds is observed during welding using coatings and fluxes containing cryolite, fluorspar or other substances containing fluorine. Carbon monoxide is produced when welding using this method, as well as when welding with electrodes whose coating contains carbon compounds or pure carbon. Nitrogen oxides are formed in all cases of manual arc welding and to a greater extent when welding with thin-coated electrodes. The content of the listed impurities should not exceed thousandths of a milligram per liter of air.

Impurities that cause lung disease include oxides of iron, silicon, aluminum, particles of free carbon and other dust released during manual electric arc welding. These impurities, when inhaled for a long time, cause damage to the bronchi, resulting in pulmonary diseases.

To prevent air pollution by impurities, it is necessary to provide thorough ventilation of the rooms where manual electric arc welding stations are installed. Ventilation can be general or local. General ventilation should be flow-exhaust. Clean air must be supplied directly to the welding areas. In winter, this air must be heated by air heaters.

According to the Academy of Medical Sciences of the USSR, when welding with metal electrodes with TsM-7 and UONII coatings, the amount of clean air supplied to the workshop should be about 4000-5000 m3 per 1 kg of molten electrodes.

Supply and exhaust ventilation must be provided in all manual arc welding rooms. Local ventilation is installed when welding stations are located in certain places. In this case, exhaust hoods are installed above the welding tables. Vessels must be provided with local supply and exhaust ventilation when welding is performed in them. In these cases, supplying air directly under the shield or mask gives good results. In this case, the amount of air should be about 25 m3/hour.

Air supply directly under the welder’s shield or mask should also be used in the case of welding non-ferrous metals: copper, brass, bronze, lead, aluminum and its alloys. The need to supply clean air is due to the fact that when welding non-ferrous metals, a significant amount of harmful metal oxides, as well as harmful gases, are released.

Places where welding work must be sufficiently well illuminated by daylight or artificial light. Good lighting of workplaces reduces eye fatigue for workers and is one of the conditions for increasing labor productivity. Illumination of workplaces should be at least 50-100 lux. To reduce the absorption of light by the walls of the cabins, they are painted in light matte colors. It is recommended to use zinc white, crown yellow, and titanium white. The listed dyes absorb ultraviolet rays well.

- Back

- Forward