The use of natural wood products in interior design remains highly popular. Modern manufacturers and individual craftsmen use various types of wood for these purposes, from very dense and hard to soft and brittle. Each such part is processed on appropriate machines. The different composition and density of wood requires an individual approach to the selection of cutting tools. Cutters for a wood lathe are made from special grades of tool steel. To produce exclusive products, professionals try to make such an instrument themselves.

Purpose of turning tools

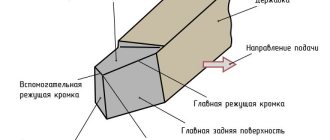

Any cutting tool performs two functions: processing the surface of a part with a given accuracy and cutting the bar into pieces of a given size. To solve these problems, the structure of a turning cutter has the following characteristics:

- geometric dimensions (they determine the shape of the turning tool);

- sharpening angle of the cutting edge.

The head of the turning cutter is made of a special shape. This is necessary to solve the assigned tasks. Its geometric parameters are set based on the type and structure of the processed wooden workpiece and the steel used for its manufacture. The selected grade of steel will determine the strength and durability of the tool.

When choosing the right turning tool, the workpiece is processed quickly and with high quality.

Types of turning tools

A wide range of tasks that arise when creating structures made of wood requires a large number of turning devices for various purposes. Modern manufacturers offer a wide variety of such products. Any turning tool is tasked with performing certain practical tasks. Each lathe cutter consists of two parts: the working part that performs processing or cutting and fastening elements. Approximately 20 centimeters from the entire length of the metal workpiece are allocated to the working part. This size provides freedom of maneuver for the tool, which guarantees the accuracy of the required operations. The length reserve allows you to process the cutting part many times. The length of the tail is determined by the length of the future handle. It must ensure safe operation.

Despite the wide variety of similar tools, all types of turning tools can be classified according to the following criteria:

- the nature of the tasks performed;

- the material from which it is made;

- tip shape and sharpening angles.

This classification of turning cutters allows you to accurately determine their scope of application. Depending on the nature of the tasks being solved, they can be cutting or processing. Steel grades with increased hardness are chosen as the material for their manufacture. This creates a good cutting leading edge.

Turning cutters are divided into the following types:

- cutting;

- chisels;

- scrapers.

Chisels are divided into two groups. The first is intended for rough processing or cutting. The second is used for final or finishing processing.

They mainly have four cutting edge shapes:

- straight or flat;

- radius;

- in the form of a bracket;

- corner

The width of the chisel is selected depending on the size of the workpiece. It varies from four to thirty millimeters. The main group of turning chisels has a blade that allows you to turn the necessary shapes on a flat surface. To give a certain corrugation, special chisels are made. These include:

- semicircular rayer (its name is determined by the shape of the blade. It is used to pre-process the prepared workpiece);

- Meisel has a double-edged cutting edge, the angle of convergence of the edges reaches 25 degrees. It is ideal for turning indentations of various sizes, making grooves, cutting out shapes and designs. With its help, surface finishing is carried out;

- chisel-hook (designed for making various recesses in the surface, Their size depends on the diameter of the hook);

- comb chisel - allows you to cut threads on the outer and inner sides of a wooden product (it is used to make wooden hardware for subsequent fastening of individual parts);

- chisel-scraper - used for finishing parts with a cylindrical surface.

- cranberries (these include corner chisels. They are used for cutting complex and three-dimensional designs, ornaments, bas-reliefs or various decorative ornaments on the surface of a product);

- rivets (used for fine finishing of a relief surface. It is especially useful for making complex images and sampling wood in hard-to-reach places).

Therefore, chisels can be flat or shaped. The main characteristics on the basis of which the cutters are classified are the shape of the future product and its artistic design. The work with chisels is done manually. The quality of the resulting product largely depends on the quality of the turning tool, the density of the wood and the qualifications of the craftsman.

Finishing is carried out using turning tools with a sharpening angle to the right or left. The experience of the work carried out has shown that the most acceptable angle is 70-75 degrees. For finishing cleaning, turning products are used, sharpened at an angle of 20-25 degrees.

A separate type is the cutting cutter. Their blade is made of the most unusual shape. It may look like a spoon, cup or other semicircular shape. It is quite difficult to list all types of incisors. This is due to the constant improvement of forms and methods of processing wood products. In addition, modern carpentry uses wood of various types and textures.

To solve more complex (non-standard) problems, shaped cutters are used. These include turning products with a cutting part in the shape of a semicircle.

The variety of turning cutters offered for sale and the possibility of self-production allows you to choose a tool that will allow you to solve the most complex problems and create unique parts with the most intricate patterns from any type of wood.

How to properly operate a wooden lathe

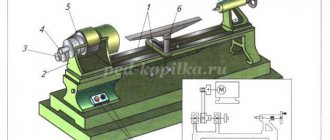

A wooden lathe is widely used in the manufacture of furniture and decorative elements. The device differs in size grid, thanks to which the dimensions of the machine are determined depending on the purpose. You can choose a machine for a small project or choose a massive device for turning balusters, which are used in the manufacture of staircase railings or furniture elements.

When choosing a machine, you should pay attention to the length of the bed, which allows you to determine the maximum length of the bar that can be used when turning the workpiece. The diameter of the turning above the bed indicates the permissible value of the diameter of the wooden block. The horsepower value determines the power of the motor, thanks to which the maximum permissible weight of the product is selected without load on the machine and cutter. Engine speed should be taken into account when determining tasks for the machine. At low speed, a product having a continuous shape can be processed. Machines with a large number of full revolutions will polish the product at the final stage of processing in a matter of minutes.

Lathes vary in size from amateur models that are suitable for use on a workbench, to industrial ones weighing hundreds of kilograms

The weight of the machine determines the mobility of the device. Models made of a steel frame and cast iron bed are characterized by a fairly robust design and a strong platform for work, but require a stationary position. For high-quality and efficient operation of the machine, it is important to choose the right wood cutters, which should be easy to use and effective for a specific task.

How to make wood turning tools yourself

Many people who like to work with wood themselves prefer to make homemade cutters for a wood lathe in their workshop. Having certain metalworking skills, making a turning chisel or rake according to your own drawings is not difficult. To do this you need:

- select a workpiece from a suitable metal;

- carry out pre-processing to give it the required geometric shape;

- sharpen the cutting part in compliance with all sharpening angles and directions;

- make a handle;

- assemble the entire structure.

The blank for a wood turning tool is selected from various grades of steel. The main requirement for them is the required level of rigidity and strength. The most commonly used are blanks made of carbon tool steel. Its carbon content does not exceed 0.7%. These include: U8, U10 and U12. In terms of their physical and mechanical characteristics, they fully satisfy the requirements.

In addition to pre-prepared blanks, improvised material is used, which can be found quite easily. These products include used steel tools. For example, sheets of automobile springs, files that have lost their characteristics, trimmed sheet metal. Some products have increased strength and are quite difficult to process (especially those that have undergone thermal hardening during manufacturing, especially in large-scale production conditions). To reduce labor costs, it is advisable to choose a workpiece whose geometric shape is closest to the configuration of the future product. This will eliminate the need to use complex technologies.

To work with workpieces, turning tools, made of steel grades with increased strength, it is necessary to preheat. Using the properties of the metal, give the future product the required shape. Then the cutting edge is processed to a given level. After all operations are completed, the finished cutter is hardened. The hardening procedure involves heating the cutting edge of a turning tool, followed by rapid cooling. Such heating can be done in a home workshop using a gas burner or blowtorch. Rapid cooling is carried out in a container with liquid: for example, water or machine oil. It turns out to be a kind of home heat treatment workshop.

Cooling of turning tool blanks made of high-alloy and high-carbon steels should not be done in water. This causes increased internal stress at various levels of the metal. Ultimately leads to the appearance of serious defects. After making a turning tool, I first test its capabilities on wooden blanks of simple shape, preferably made of soft wood. This will help to identify all the shortcomings and shortcomings that arose during the production process and avoid damage to the main products.

What is needed to make cutters?

Manufacturing turning tools of this class is not particularly difficult if you have three components: suitable material, sharpening equipment and certain metalworking skills.

The required grade of metal is selected from those offered for sale or used steel products are used. For example, spanners, files, or any other used tool.

To give the product a given shape and create a high-quality cutting edge, a sharpening machine or grinding machine is needed. In both cases, it is necessary to have several abrasive wheels of different grain sizes. The final finishing is done manually, fixing the cutter in a vice using files or needle files. At the initial stage, a stone with the largest grain is used, which makes it possible to outline the main contours of the future cutting edge. Next they move on to the stone with the finest grain. All tools must be checked and stones carefully secured.

Most often, professionals use sharpening in several stages. At the initial stage, the manufacture of the cutter is carried out on a grinding wheel. Then they gradually move on to more precise processing. To prevent overheating during processing, the metal part is poured with machine oil.

Rules and algorithm

Sequence of work for making a wood cutter for a lathe:

- processing the material on a grinding machine to create the shape of the working head;

- primary sharpening of parts;

- hardening of the metal by heating to the highest possible degrees and cooling in machine oil, which will allow the cutter to subsequently process workpieces of varying degrees of hardness;

- final sharpening;

- handle attachment.

To perform high-quality work with a future tool, you must adhere to simple rules:

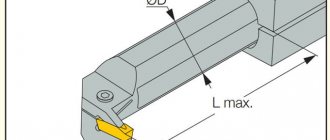

- the length of the working tool must be at least 20 cm, but not more than 40 cm, which contributes to high-quality work, ensures convenient grip by the master and allows, if necessary, installation on a work surface;

- the cutter shank must be of sufficient size to ensure reliable fastening of the metal part to the handle of the wood cutter for the turning mechanism, otherwise the working head will be pulled out;

- special attention must be paid to the thickness of the tool; a sufficient diameter will increase its impact resistance;

- The wooden handle of the cutter should be more than 25 cm, which will allow the master to hold the chisel firmly in his hands and perform the necessary work efficiently.

Do-it-yourself sharpening of cutters

The quality of the resulting surface and its configuration depends on the correct sharpening of the tool used. The final sharpening (finishing) of the cutting edge of a turning tool must be carried out not only for tools made independently or used, but also for new ones. The sharpening operation must be performed in the following cases:

- after acquisition, if there is no confidence in the quality of this instrument;

- as a result of prolonged use;

- reduction in the quality of the resulting surface and the accuracy of the processed parts;

- after long-term storage (especially in unfavorable conditions).

When carrying out this operation, it is necessary not only to achieve the sharpness of the cutting edge, but to fulfill all the requirements for its inclination and the required angles. Sharpening cutters for a wood lathe requires strict adherence to the entire sequence of the operation. Professionals advise drawing up a technological map before sharpening. It must indicate all the required angles of the tool being sharpened. However, experienced carpenters advise making adjustments based on the worker’s qualifications. If you lack experience, you should reduce the sharpening angle to 30 degrees. With advanced training, you can increase the angle to 45 degrees. This will allow you to process hard wood with high quality. An acute sharpening angle requires constant checking and periodic fine-tuning. Determine the plane from which they must be measured.

To properly prepare a cutting edge for wood, you will need the following tool:

- a sharpening machine with an abrasive wheel, the grain of which is in the range from 25 to 40 with a hardness of SM-1;

- if you don’t have a machine, you can use a household grinding machine using appropriate turning wheels;

- Finishing after mechanical sharpening should be done using small files or needle files (this will help to more accurately process the cutting edge and obtain its desired shape.

It is advisable to carry out final finishing using a sharpening stone. Upon completion of the sharpening operation, each cutter should be thoroughly wiped with a dry cloth. This will remove residual machine oil, adhering chips and dirt, preventing a decrease in the quality of the treated surface.