The wide variety of shapes and sizes of file notches has led to the fact that it has become very difficult for a non-specialist to understand for what purposes one or another tool should be used. To improve the situation, a classification of files was developed. This classification, gradually modified and supplemented with new types of instruments, is still in effect today.

Diagram of the file structure.

File appearance

Even in the age of space technology, most metal or wood work cannot be done without a file. Despite the very respectable age of the tool, its purpose remains the same - by layer-by-layer grinding the surface of the part to form it into the desired size and shape.

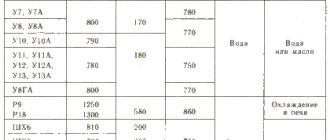

Domestic files are produced from two groups of high-quality tool steels - alloyed chromium steel grades ШХ15 and 13Х or unalloyed improved steel grades У10А - У13А.

A file is classified as a cutting tool. In appearance, a file is a bar made of a special grade of steel, the surface of which is cut according to a special pattern. Most files have a rectangular, triangular or round cross-section, although other options are possible.

A wooden or plastic handle is attached to the tapered shank of the file. It serves solely for the convenience of the user working with the tool, and has no effect on the quality of the tool itself. Therefore, it is stupid to throw away a tool with a broken handle; it can easily be replaced with another one.

Numbering of notches

Notch numbering table.

The use of files is largely determined by the type of cut applied and the configuration of its teeth. To apply teeth, the method of notching, milling, cutting, broaching and turning can be used. The most common files today are those with teeth cut on special machines.

In the vast majority of files, the cut is single or double. A single notch allows you to remove sawdust equal to the size of the teeth. It is very difficult to work with such a tool, so it is mainly used for processing soft metals, plastics and wood.

A double (cross) notch is obtained by combining a main, deeper one, and an auxiliary, shallower one, made at an angle to the main one. Intersecting notches grind the chips formed during operation. This type of cut is used for processing hard metals and alloys.

The size of the file teeth depends on the size of the notches per 1 cm of the length of the bar - the fewer notches, the larger the tooth. According to the size of the teeth, files come from 0 to 5 numbers (there are 6 in total), and according to the shape of the applied notches, they distinguish between single, cross (double) and rasp notches.

The largest notch teeth are designated No. 0 and No. 1. Such files are used when you need to quickly remove a fairly large layer of material (0.05 - 0.10 mm). The main disadvantage of tools with such a notch is the low accuracy of processing parts - it does not exceed 0.1 - 0.2 mm.

Scheme of working with a file.

A tool with teeth No. 2 and No. 3 is used when it is necessary to remove a layer of material within 0.02 - 0.06 mm. The accuracy of their work is 0.02 - 0.05 mm.

For finishing parts, a tool with a processing accuracy of 0.01 - 0.005 mm is used, with serration teeth No. 4 and No. 5 (they are popularly called velvet teeth).

They can remove a layer of material no more than 0.01 - 0.03 mm.

Types of notches on the surface of the tool

Based on the nature of the notches, it is customary to speak of a single or double design.

Single execution is more common with rough instruments. Here the tooth has a long cutting edge. Its length corresponds to the width of the file. To make it easier to penetrate into the thickness of the metal being processed, the notch is made inclined at an angle of 25⁰. The result is cutting with some displacement. It makes it easier to penetrate deeper into the part. The effort is slightly reduced.

The double design of the notches is made at an angle to each other. The second cut is made at an angle of 45⁰. Now the cutting teeth are limited in length. Where the lines intersect, places where chips break are formed. Consequently, such files require less physical effort during operation (no need to waste effort on twisting long shavings).

Types of files

According to their purpose, files are divided into several large groups:

- general purpose;

- special purpose;

- machine;

- rasps;

- files.

General purpose files are used for general metalworking work. The notching for instruments of this group is carried out using the notching method, equipping them with a double (cross) notch. They can be of different lengths (from 100 to 450 mm), have different bar shapes and almost all notch numbers.

Bench files for special work are used mainly in industrial settings, since their purpose is to eliminate large allowances when fitting grooves and different curvatures of surfaces; they can be used for processing non-ferrous metals. Depending on the work performed, they can be flat, lumber, grooved, double-ended and other shapes.

The most numerous group of needle files - there are as many as 11 types of them: flat, round, semicircular, square, triangular, oval, hacksaw, etc. Needle files can be distinguished by the short length of the bar (40, 60 or 80 mm) and the highest class 5 notch.

Needle files are mostly equipped with a double notch, although the edges of flat files can also have a single notch. They are used primarily for processing small parts or bottlenecks that cannot be reached with conventional plumbing tools.

Rasps are divided into three types: shoe rasps, hoof rasps and general purpose rasps. Their distinctive feature is their long length (from 250 to 350 mm) and large notch teeth - it is never smaller than No. 1 for rasps. Typically, rasps come in round or semi-circular shapes, as well as flat ones with blunt or sharp noses.

Use of files of various shapes

The shape of the bar is very important; it can be used to immediately determine the scope of application of the tool. Files according to the method of application are:

- flat or flat pointed, designed for processing interior or exterior flat surfaces;

- square, designed for sawing rectangular, square and polygonal holes;

- triangular, designed for processing in grooves, holes and grooves, as well as on the outside of parts with sharp (from 60º) corners;

- semicircular, designed for processing large holes and concave surfaces with a significant radius of curvature;

- round, designed for processing small round or oval holes or small radius concave surfaces;

- rhombic, designed for working with gear parts;

- hacksaws, designed for cutting narrow grooves, grooves, for processing internal corners, as well as planes in square, diamond-shaped or rectangular holes.

Read also: What is a drilling machine spindle

Such a variety of tools of the same type can confuse even a specialist. If you do not professionally work on metal or wood, but use a file occasionally, then it is not at all necessary to purchase tools of all sizes and shapes for your home workshop. Most operations can be performed with only three types of files - flat, triangular and round, but it is necessary that these types be of all three main groups: general-purpose metalworking files, needle files and rasps. When they are in your workshop, you will be able to handle any task.

The service life of the tool is directly dependent on the brand of material, its heat treatment and the quality of the notch.

When choosing a file in a hardware store, be sure to pay close attention to its appearance.

Professionals advise choosing a tool that has a uniform steel surface color, a clearly visible notch without the slightest sign of defects. If you find stains, traces of rust or oil stains on the surface, then it’s definitely better not to take such a tool; you won’t be using it for a long time anyway.

On the surface of the file there are sharp teeth called serrations, which determine the type of file.

The notch (picture below) can be single (simple) or double (cross).

| File cuts |

a - single; b - double.

Single-cut files cut metal with wide chips equal to the length of the entire tooth, so it is difficult to work with such files. They are mainly used to file soft metals and alloys (copper, brass, aluminum, lead).

Double-cut files are used to process hard metals (steel, cast iron). In double-cut files, the bottom cut is called the main cut, and the top cut is called the auxiliary cut.

The cross cut breaks up the chips, making work easier.

The lower notch is usually made at an angle of 55°, and the upper one at an angle of 70°.

Depending on the size of the notch tooth and the number of teeth per 10 mm of length, 6 classes of files are distinguished: 1st class - bastard files, which have 5-13 teeth per 10 mm of length (large notch); used for rough (rough) filing, when it is necessary to remove a large layer of metal.

2nd class - personal files, which have 13-25 teeth per 10 mm of length (medium notch); used after the main layer of metal has already been removed with a bastard file; used for surface finishing.

3, 4, 5 and 6 classes - velvet files - there are 25-60 teeth per 10 mm of length (the smallest notch); used for fitting parts, finishing and grinding surfaces.

Questions

- What kind of cut do files have?

- What metals can be processed with a single cut file?

- What class does the pugnacious file belong to?

- How to determine the class of a file?

Exercise

Using the training manual, set the number of main notches per 10 mm of file length: 200, 300, 400 mm long for basal file; personal length 150, 250, 350 mm; velvet length 150, 200, 250 mm. Write your answers in the table, the form of which is given below.

| Type of file | Number of notches per 10 mm length | File class |

| … | … | … |

“Plumbing”, I.G. Spiridonov, G.P. Bufetov, V.G. Kopelevich

Curvilinear surfaces of machine parts are divided into convex and concave. Typically, filing such surfaces involves removing significant allowances. Before you begin processing, you should carefully mark the workpiece and choose the easiest way to remove excess metal. In one case it is necessary to first cut with a hacksaw, in another - to drill, in the third - to knock out. Excessively large allowance for filing...

Cylindrical rods sometimes have to be filed to reduce their diameter. It also happens that a cylindrical part is obtained from a square section by filing. Long blanks of rods from which a large layer of metal must be removed are clamped in a vice in a horizontal position and filed by swinging the file in a vertical plane and frequently turning the workpiece. Filing a long rod A short workpiece (rod) is clamped...

Before filing, the workpiece is clamped in a vice so that the surface to be processed is horizontal and protrudes 5-8 mm above the jaws of the vice. First, file one wide surface with a cross stroke, taking it as the main base. The sawn workpiece is removed. See the picture - Filing with a cross stroke. The quality of the processing is checked with a ruler, installing it along, across and diagonally...

The conductor is a copying device. Using a jig It is possible to reproduce the contour of a part with an accuracy of 0.1 to 0.05 mm. The working sides of the jig must be precisely machined and hardened. They are filed along the jig when producing a large number of identical parts. The workpiece (plate) to be processed is inserted into the jig and clamped together with it in a vice. The protruding part of the workpiece...

According to their purpose, there are ordinary files, special files, rasps and needle files. Common files include flat (blunt and pointed), square, triangular, semicircular, round and diamond-shaped files. Files differ from each other not only in the number of notches, but also in the cross-sectional profile and length. This is due to the fact that workpieces of different shapes and sizes have to be processed. The file must be longer than the surface being filed...

Various types of files have been known to the world since the 3rd century BC.

Today, the range of applications of this oldest hand-held device is practically unlimited.

Various types of tools are used to polish parts and achieve the required surface cleanliness.

Thanks to modern technology, mechanical files have been supplemented by a range of electric and cordless tools.

Instrument care

The file is quite fragile and quickly deteriorates if handled carelessly, so proper care is very important. During processing, metal filings get stuck in the recesses, which is why the properties of the tool are reduced, and it begins to slide over the surface - it “does not grip” it.

For bastard files, they sell a special blade made of soft iron. For the rest, a regular brush with steel bristles will do. Cleaning should only be done in the direction of the notch to prevent it from becoming dull.

It is worth familiarizing yourself with other rules for caring for a file.

- Do not hit the tool against hard objects. This applies not only to work, but also to storage. Therefore, it is better to put the tools separately in a box or case with sockets,

- Do not place it on metal to avoid damaging the teeth. Therefore, even before work, you should take care of a stand for the file - preferably made of wood,

- store in a dry place to avoid rust,

- do not remove scale with a file - this will lead to rapid damage to the instrument (or remove it with one you don’t mind),

- “load” the file gradually - you should not file hard metals immediately after purchase. It’s better to start with soft ones and gradually move on to hard ones - this way the teeth will become less dull,

- If the file gets dirty in oil, charcoal will help - you should rub the tool with it, and then use a brush with steel bristles (all movements are made along the teeth).

Craftsmen on the Internet even sharpen files on their own using ferric chloride, vinegar or citric acid.

What is a file and what is it for?

This is one of the most popular types of metalworking tools for manual processing of a wide variety of materials: metal, wood, plastic, bones, glass and others.

Each application has its own type of tool, with the appropriate file elements for the task at hand.

As general functions, it is designed to perform the following operations:

• sharpening of cutting edges; • grinding and deburring; • surface cleaning to a certain level of roughness; • layer-by-layer filing of the surface; • cutting of blanks; • adjustment of sizes; • making grooves, chamfers, radii, splines, grooves, etc.; • giving structural elements the desired shape.

Read also: How to properly place a file on a manual jigsaw

The corrugated surface is capable of providing a high level of accuracy and cleanliness of the processed elements at low physical costs.

A nail file can rightfully be classified as one of the varieties of this tool.

Appearance and shapes of files

Externally, it is a multi-bladed block consisting of a metal strip with sharp teeth of various angles.

Typically, the main elements of a file are the blade and the shank for attaching the handle.

According to the shape of the work area, tools can be:

• in the form of a flat rectangle; • round; • semicircular; • oval; • rhombic; • in the form of an equilateral or obtuse triangle.

Some varieties are produced without a shank, while other types use an extension of the steel blade as a handle.

As a rule, the length of the working blade ranges from 100 to 400 mm.

Some types, taking into account the specifics, are produced in large sizes.

Where and at what price to buy

A file can be found at any hardware store. They are not always put on display due to low demand and slight markup, in which case it is worth checking their availability with the seller. Their prices are quite affordable: from 100 rubles for one tool to 700 for a whole set of six diamond-coated needle files, with a storage case and production in Switzerland.

Deciding which files are best for you is easy - you don’t have to think about power, speed and other characteristics of power tools. All that is required is to know what material you will be working with, its shape, and how accurate the result should be.

Operating principle

The principle of operation of a file is to remove the top layer from the workpiece by means of friction.

The teeth of the bar determine the quality of the cut, and the depth depends on the effort applied by pressing the tool and the speed of movement.

A coarser and larger notch allows you to work much faster, but at the same time the quality of processing decreases.

Fine or diamond edges provide an almost perfect surface.

In many ways, the results of the work depend on the characteristics of the material and the correctly selected type of file.

Features of choice and rules of care

When purchasing files, in addition to technical characteristics and dimensions, you should pay attention to the quality of the tool. He must have:

- uniform color of the working surface;

- clearly defined notch;

- a comfortable, ergonomically shaped handle that is securely fixed and does not slip.

To extend the service life of files, you must follow the rules of operation and storage. Firstly, it is undesirable to use a new tool to work with parts and workpieces covered with a thick layer of rust. Before starting treatment, it should be removed using a grinder or metal brushes. In addition, you must:

- Choose the right type and density of notches, taking into account the hardness of the materials and the characteristics of the parts being processed.

- Protect the tool from impacts and moisture, sanding dust, oils and aggressive substances.

- Clean up chips in a timely manner.

- The new tool should be used first for processing soft metals, which will ensure the removal of burrs without compromising cutting properties.

Classification of files

The main classification of files, according to state standard GOST 23726-79, is carried out by type of use and divides tools into 5 main groups:

• for plumbing work; • special purpose; • needle files; • rasps; • machine and tape.

Also, types of files are distinguished by their notch - they are assigned numbers according to classes from 0 to 5.

Marking

The marking reflects the necessary data characterizing the purpose of the instrument.

This is a class from 1 to 6 and a length that is designated by the Latin letter L.

And also types of file cuts numbered from 0 to 5.

Such an important parameter as tooth hardness is denoted by the abbreviation HRC in combination with a two-digit number - for example, HRC 55.

Also, the type of steel can be indicated, for example: 13X or U13A.

CM designations are applied to tools intended for processing non-ferrous metals.

Types of notches and their numbering

Types of file cuts are the most important performance indicator by the nature of which the tool is classified.

The abrasive coating can be:

1. Simple single

A simple single-type cut is used for processing soft metals and other materials, as well as for the production of specialized files.

2. Double

This notch enhances the impact on the surface of the workpiece.

These types of files are used for rough processing of cast iron, bronze, and steel.

3. Krestovy

The cross cut consists of teeth for rough processing, and the fine cut is auxiliary for grinding the material.

This ensures better processing.

4. Spot

A point or rasp cut consists of small burrs and is ideal for processing soft wood, leather, rubber, etc.

5. Arc milling

Thanks to its special shape, this notch contributes to achieving high productivity and good quality of the processed product.

It is used when working with non-ferrous metals and wood.

As mentioned above, file types differ in cut numbers from 0 to 5.

Numbers 0 and 1 are distinguished by large, sparse teeth from 4 to 12 pieces per 10 mm.

Numbers 2 and 3 have 13-24 teeth per 10 mm.

Notches No. 4 and 5 are characterized by the largest number of teeth - more than 24 per 10 mm.

Types of files and their purpose

Types of files by class and shape determine the main scope of application.

Class 1 includes tools with a notch numbered from 0 to 1.

This is a rough file; its main task is rough surface finishing.

The second class includes tools with abrasives No. 2 and 3.

This is a less coarse file, it is called a personal file, and is used primarily for finishing, because... it leaves a smoother surface.

Tools of classes 3,4,5 and 6 have a notch of 4 and 5 numbers.

They are better known as “velvet” or jewelry files and are used for finishing.

Types of files by shape

Classification by form subdivides the scope of application in more detail.

1. Flat, blunt-nosed files are considered universal tools because... They are designed for working on metal and wood.

They can easily handle flat and convex surfaces. They have a single notch on one of the side faces.

2. Flat pointed blades are used for processing external or internal flat surfaces; they are also used for sawing slots and grooves.

3. Square products have a sharp nose; they are used for sawing square and rectangular holes and narrowed surfaces.

4. The triangular shape is available in two versions - for layer-by-layer cutting of materials, processing internal corners of various shapes, triangular holes for filing small grooves and wedge-shaped grooves.

This type is also used for sharpening wood saws, which is why they are also called hacksaws.

5. Round shape - this type, like the triangular one, has two different subtypes.

For processing round grooves, holes, layer-by-layer sawing and for sharpening wood saws and saw chains.

6. The semicircular type classifies the tool as a universal one, as it combines the advantages of flat and round files.

Ideally performs processing of spherical and flat surfaces, has a pointed nose.

7. The rhombic shape makes it possible to effectively process materials with complex surface configurations, including working with gears, sprockets, wheels, and disks.

Files intended for specialized operations are called special purpose tools, these include diamond coatings and other cutting surfaces of higher hardness intended for non-ferrous alloys, metal, tiles or ceramics and other materials.

Read also: Where to get x12MF steel in everyday life

Types and sizes of notches

The nature of the notch determines the main types of files.

The profile and size of a file's teeth depend on the machine used to apply the cutting surface.

Typically used for production:

— saw-cutting machines with chisels; — milling machines; — grinding machines with special wheels; — gear cutting and broaching machines.

Regardless of the production method, all teeth have specified parameters for the angle of location, sharpening and cutting.

The more notches per 1 cm of working area, the smaller the notch teeth.

The ratio of the height to the pitch of the main notch must be at least 0.5.

File material

According to Russian and international standards, files are made from carbon tool steel.

These include the most common brands:

- U 10,12, 13; — At 10, 12, 13 A; — ShKh15 UA; — 13X and their foreign analogues.

Roughness removers

A simple device called a “file” has been familiar to every man since school labor lessons. It is found in almost every tool box, pushed onto the mezzanine or under the table. The more or less handy home craftsman will have a whole collection of files of different sizes. In short, in the sublunary world this is perhaps one of the most common hand tools - of course, after the hammer and saw.

The file has been used as a metalworking and carpentry tool for about a thousand years. In general, this is a hand-held cutting tool with many blades (teeth) formed on the surfaces of the working part in the form of a notch. The working part ends with a shank for attaching the handle, and its front side is called the toe and can have an elongated, tapering shape. The processing of workpieces to obtain specified geometric parameters and roughness is called filing; it is performed using a file in cases where machine processing is impossible or economically unprofitable. In any case, this is almost the only way to accurately adjust the mating surfaces of parts when assembling individual units or entire products. For manual filing, files are used, which have many varieties - from rasp to riffle.

All files are conventionally divided into:

•

garnish, personal, semi-personal and velvet - according to the cleanliness and accuracy of filing practically achieved with their help;

•

rasps, files themselves, files and riffles - according to design (including the nature of the notch), while rasps, in turn, are divided into flat (sharp-nosed and blunt-nosed), round, semicircular, shoe rasps (straight or curved, double-sided and single-sided; without a shank and pens) and ungulates;

•

flat, square, triangular, round, semicircular, multi-convex and knife-shaped - according to the cross-sectional shape of the working part. It is at least unwise to use the first file that comes to hand for filing. It is better to choose the most suitable option in accordance with the material, the specified accuracy, the allowance left, the size and configuration of the surface being processed, which will allow you to achieve the desired result without applying unnecessary effort. Here it makes sense to remember some basic parameters and numbers - there are not many of them.

To obtain a processing accuracy within 0.2–0.5 mm, a bastard file is sufficient; an accuracy of 0.02–0.15 mm will require a personal tool, and 0.005–0.01 mm will require a velvet file. Accordingly, the allowance for a bastard file should be 0.5–1.0 mm, for a personal file – 0.1–0.3 mm, and for a velvet file – 0.025–0.05 mm. When filing metal during a working stroke (usually from yourself), a bastard file removes a layer 0.08–0.15 mm thick, a personal file – 0.02–0.08 mm, and a velvet file – 0.005–0.01 mm.

The length of the working part of the file must correspond to the size of the part being filed; if the tool is chosen incorrectly, productivity and, what is much worse, quality suffers: a device that is too long is difficult to hold in a horizontal plane, which is why you can “overwhelm” the surface being processed. Centuries of experience show that for parts up to 50 mm in length, files with a working part of 160–250 mm are best suited; for workpieces 50–100 mm in size, files of 250–315 mm are required, and for larger analogues (over 100 mm) use the longest files are 315–400 mm. The typical length of the working part of general purpose files can be 100, 125, 150, 200, 250, 300, 350, 400 and 450 mm, and for needle files it is 50, 60 and 80 mm, respectively.

For the manufacture of metalworking files, high-carbon and alloy steel grades are used (for example, U12, U12A, U13, U13A, 13X, and for materials that are more difficult to process - 14HF, 13X and high-speed varieties). Such devices are hardened to high hardness (GOST 1465–80 prescribes three values on the Rockwell scale: 58, 60 and 62), while for the shank this parameter should not exceed 36 HRC.

Notch

Equally important is the correct choice of notch, and specifically its shape, depth and pitch. One of the main parameters of a file is the notch pitch (the number of teeth per 1 cm of the length of the working part) or its number (corresponding to a certain interval of pitch values). It is by step/number that the tool in question is classified. For ordinary varieties, the notch can have a number from 0 (maximum) to 5 (minimum), for needle files there are more gradations - from 00 to 8. For a rasp notch, the number of teeth per 1 cm2 of the working surface is taken into account. On round files, a spiral single cut with an inclination angle of about 70° can be used.

Brussels files used for rough filing have a cut number of 0–1 or a pitch of 4.5–12. Thinner analogs used for preliminary filing are called semi-file and personal, their numbers are 2–3, and the notch pitch is from 13 to 26. Finish filing, fine finishing and finishing are performed with velvet files with numbers 4–5 and a notch pitch of 42–80 .

By the way, the Swiss style is distinguished by a small angle of inclination of the teeth, the number of which per 1 cm of the length of the working part of the file determines the number of the notch, which differs from the similar parameter of the German style: they coincide only for 20 teeth/cm, which corresponds to number 00. Swiss number 4 (the most thin cut) coincides with the German number 5 - this is 56 teeth/cm.

The notch is formed primarily by cutting with chisels on a specialized machine, but can be done by milling and other methods. The shape of the teeth depends on the purpose of the tool. For a rasp, these are individual small teeth with a semicircular cutting edge (the so-called rasp notch). For metalwork files and needle files, the notch is made in the form of straight blades and is usually double: the main part is located at an angle of 65° to the axis of the working part, and the auxiliary part is located at an angle of 45°, and it divides the main part into many triangular teeth that increase productivity. Due to the different pitch of the main and auxiliary notches, each subsequent tooth is shifted relative to the previous one relative to the longitudinal axis of the working part of the file, which makes it possible to achieve a lower surface roughness of the workpiece. There is also an arc cut, when the cutting surface has the shape of an arc of a fairly large radius.

For filing soft metals (copper and copper alloys, aluminum and its alloys), files with sharper teeth are better suited, while for aluminum a special tool with a large and deep single cut is produced. However, in everyday life, few people purchase separate files for each type of material being processed, so they have to use the same tool for both soft non-ferrous metals and hard parts made of steel and cast iron. In this case, it is reasonable to use a new file, the cut of which has not yet become dull, for copper, brass and aluminum, and subsequently, when the tool “sits down” a little, to work with it on steel and cast iron. For very soft metals and alloys (lead, babbitt, tin), specialized files are produced with very sharp teeth formed by milling and large space for chips to exit (single cut, not prone to clogging), but you can also use a regular personal tool with cut No. 2.

And finally, it is worth mentioning the regulatory documents and standards that determine the parameters, quality and properties of files:

•

ISO 234/I-83 and ISO 234/II-82;

•

DIN File Standards;

•

BS498:1990;

•

US Fed. Spec. GGG-F-325b/GGG-F-331b;

•

GOST 1465-80 “Files. Technical specifications" (applies to general purpose metalworker's files);

•

GOST 1513-77 “Needles. Technical conditions";

•

GOST 6476-80 “Files for sharpening wood saws. Technical conditions";

•

GOST 6876-79 “Rasps. Technical specifications" (rasps for processing soft metals, bone, leather, wood, rubber).

The most common types

Flat and square files are used to process flat and convex surfaces of parts. Triangular and diamond-shaped ones are used mainly when processing internal sharp corners, slots and grooves, while the edges of the tool must be sharp. Round files are useful for filing round or oval-shaped holes, and hacksaw files are useful for grooves and narrow grooves. Half-round files can be used to work both on concave surfaces and round holes of large diameter, as well as on flat or convex surfaces, i.e. they are quite versatile. Less common are differently convex files: as you might guess from the name, the two sides of their working part have different radii of curvature. Such devices are used for filing rounded internal surfaces.

During the filing process, you should press on the file only during the working movement (forward relative to the handle), but when moving in the opposite direction, it is not necessary to press the tool from above, and it is pointless: this will make it more likely to become dull, and the user’s hands will get tired faster. As the working surface moves forward, vertical pressure must be smoothly redistributed from the toe to the handle, this is called balancing. This method best allows you to maintain the plane of the treated surface.

Needles and riffles

Needle files are used for the most delicate work, mainly jewelry and patterns. This tool basically has a double cut (main at 25° and auxiliary at 45°) - however, on the narrow sides of flat and hacksaw varieties, on the oval side of groove files, as well as on round and oval files, the notch is made single. On round files a spiral single cut with an angle of 20° can be used. In addition to the transverse profile found in regular files, needle files also have an oval profile. The working part of these devices is hardened to 54–60 HRC.

A not very common type of needle file is riffle. They are distinguished by a short, curved working part and are designed for filing concave surfaces and the internal parts of hollow parts. In tool stores there are many options for riffles with different profiles and bending radii of the working surface. This type of file is made only from ferromagnetic materials: it is used primarily in jewelry, so the particles of riffle material crumbled during the work must be separated from the filings of precious metals, which is easiest to do with a magnet.

Diamond needle files are designed for filing particularly durable materials, ceramics and glass, except tempered glass. These are, in fact, rather thin narrow steel strips, on the surface of which small diamond chips are fixed using a binder (we are mainly talking about artificial, technical diamonds). The sharp edges slightly protruding above the coating play the role of a notch, removing the finest chips from the workpiece being processed.

Rare files

The cross section of a knife file is an isosceles triangle with a very acute angle between the two cut surfaces. It is used for filing narrow slots and multi-faceted holes with sharp corners.

For files for sharpening wood saws, the angle of inclination of the main and auxiliary notches is 60° relative to the axis of the working part.

To sharpen cutting tools such as lawn mower blades, universal sharpening files are used that have a flat working part with a double-sided notch, and narrow smooth edges are made in the shape of a semicircle.

Machine files are produced for use in filing (sharpening) machines. A contact file is needed for cleaning contacts and contact pairs; it can be used to process narrow grooves and cracks. The working part of this tool is flat with a double-sided notch, very narrow and thin. Horse riding enthusiasts often use a special file for horseshoes. Its two flat sides are milled differently - with small and large teeth, which allows you to file both horseshoes and hooves with the same device.

To process concave surfaces of parts with a sufficiently large radius made of wood and plastic in hard-to-reach places, a rather exotic carpentry rasp is used, reminiscent of an open bracelet with a rasp notch on the outer semicircular side.

A specialized turning file will help remove irregularities and burrs on rotating parts during turning. Its double-sided notch is made in such a way that a flat tool pressed against a rotating part moves from the chuck to the headstock, making the operation safe.

Intended for finishing of sheet metal and plastic materials, body files are distinguished by the fact that their teeth are milled on a whole steel bar. Due to this, special sharpness of the teeth and a significant volume of chip chambers are achieved, and the slightly convex shape of the working part spreads the cutting edges out of one plane, reducing the force required for filing and increasing productivity. In addition, in cross-section, the wide part of the file is not completely flat: from the ribs to the center line it has a very small (several tenths of a millimeter) convexity, which avoids contact between the edges of the tool and the surface being processed, respectively, preventing the appearance of scratches. Body files are available with a shank for a handle and without a shank, for a special holder resembling a hand plane.

There is a rather rare type of body file - a plane designed for fine processing of varnished surfaces of a small area. It is fixed in a plastic holder, which allows the bending of the blade of a special convex shape to be adjusted within small limits, preventing scratching of the surface being processed by the edges of a tool with very sharp teeth. For filing materials of high hardness, files made of hard alloys are used, which are used only with holders. Such devices are made with a one-sided notch, having a shape that is convex in cross section and curved in the longitudinal direction. The uniqueness of this radial convex cut ensures high performance.

Handles for files and needle files

A typical file handle is made of hardwood (beech or birch) or plastic, but occasionally a kind of ersatz made of pressed paper is found. The wooden handle must have a steel tightening ring that protects it from cracking when placed on the tool shank. The length of this element should be chosen so that it is one and a half times longer than the file shank, therefore, typical sizes of wooden handles are 90, 100, 110, 120, 130 and 140 mm.

The cross-section of the handle can be round or oval, and in the second case the tool is not prone to rolling off the workbench, moreover, the position of the working surface of a flat file can be determined by touch, without looking. Needle files are usually supplied without handles and their shank is shaped like a long, thin cylinder. Here they usually use plastic handles with a collet clamp, which, however, are often replaced with ordinary wine stoppers, into which the file shank is simply stuck without drilling.

Rules of care

Very hard high-carbon steel does not withstand impacts and bending deformation well, so you should not use a file as a lever or hammer, and it is also weak as a chisel. A knife made from a file turns out to be so-so, too fragile, but the scraper comes out excellent: you just need to remove the notch on the toe of the triangular device with sandpaper.

Steel corrodes easily, so long-term contact with water is contraindicated for files. First of all, rust destroys the notch, dulling the teeth and making the tool unsuitable for work. By the way, it also deteriorates from contact with oil, i.e. you don’t need to grab the work surface with oily hands or throw it onto an oily workbench. However, the oil-covered working surface of the file can be cleaned with a piece of charcoal, and then with a wire brush, remove the remaining shavings that have clogged into the notch. This device does not tolerate possible contact with hardened steel (for example, with another file) or hard stone. If these simple rules are followed, the file will last for many years and even decades.

Revival of the stupid and resuscitation of the downtrodden

Over time, the file teeth may become dull, become clogged with sawdust from the material being processed (i.e., become greasy), and become covered with thin (or not so thin) spots of corrosion. A thrifty craftsman is in no hurry to throw away such a tool; in many cases, it can be put in order. An experienced user also tries to prevent such problems from arising. For example, dusting the working surface with talc or chalk or wetting it with water will help to somewhat reduce the clogging of a velvet file when processing soft materials (however, then after finishing the work you will have to thoroughly dry the tool). You can clean the notch from wood, plastic or bone shavings by holding the file in boiling water for 15–20 minutes, then treating it with a steel brush and drying thoroughly. The brush also helps to get rid of metal filings, but, of course, there is no need to soak the tool before doing this. You can use a regular mechanic's brush, but it is better to use a special one made specifically for cleaning the notches on files. An infrequently used chemical method for restoring a device that is dull, rusty, or greasy with metal filings is based on etching in an acid solution. The tool must first be degreased, for example, using any detergent and cleaned with a steel brush. By the way, short boiling in a soda solution degreases very well. Rust is removed with a chemical rust converter (this “magic” composition is familiar to all motorists) or simply with a 20% solution of sulfuric acid. Finally, after degreasing and eliminating corrosion, the file is placed in a reducing aqueous solution containing 8% nitric and 6% sulfuric acid. This combination of acids preferentially etches only the recesses between the teeth, weakly affecting the points themselves, so the result is a sharpening of the notch. After processing, the remaining acids are washed away with running water, the file is dried and again becomes ready for use. You can protect the tool from the reappearance of corrosion by “boiling” it for 15–20 minutes in machine oil at a temperature of 100–120 °C.

Choosing the right file

As already mentioned, a file is selected and purchased for specific types of work. The above article describes the classes and varieties of such tools for various purposes, so first the user needs to decide what he is going to file. When there is clarity on this issue, you can move on to the stage of rejecting the proposed models, paying attention to the following features:

•

the working part of a high-quality file should have a uniform gray color, without streaks and traces of corrosion or oil: streaks indicate a violation of the hardening regime, but with rust, oil and other contaminants everything is clear;

•

the tool must have the correct shape without bends: the presence of the latter indicates violations of the heat treatment process;

•

the notch should be uniform along the entire length of the working part, without gaps. And a couple more tips. A high-quality file has teeth slanted towards the toe; they look, and even more so, feel sharp. When you lightly hit a metal object with a tool, the sound should be clear: rattling notes indicate the presence of cracks that make the device unsuitable for work.

Text:

Ivan Kalashnikov

What is a needle file and its purpose?

Products of small sizes, the main purpose of which is engraving, patterning and jewelry; they are also used for grinding in hard-to-reach places; short sections of profile, corners or holes; for ceramics, hard alloys, finishing of cutting tools - called needle files.

Bench files and needle files come in different shapes.

According to the type of notch, the latter are produced under numbers from 1 to 5 and, depending on the type, have from 20 to 112 teeth.

The production of needle files is regulated by GOST 1513-67.

According to the standard, the length of products can be 80, 120 and 160 mm.

Abrasive notches are not located on the entire working surface, but at a length of 40, 60 and 80 mm. The main working area is covered with a cross cut, and the narrow side is covered with a single cut.

Files

File

— a cutting tool for processing materials using the method of layer-by-layer cutting (filing). It is a steel strip (blade), on the working surfaces of which a “notch” is created - cutting elements (sharp teeth). A handle is attached to the cone-shaped shank of the file. According to their intended purpose, files are

:

File length

Rasp

The rasp is designed for processing soft metals, rubber, leather, wood, bone and similar materials.

According to GOST, there are three main types of tools:

— general purpose; - shoe (shoe) - ungulates.

General purpose rasps are available with a sharp and blunt nose, flat type, or round and semicircular with notches 1 and 2.

A characteristic feature of this type is the large size of the teeth and spacious grooves in front of each tooth.

What is a calibrated file

A calibrated file serves as a kind of standard for determining the hardness of hardened metal parts and workpieces on the Vickers scale or the Rockwell “C” scale.

Hardness testers allow you to quickly and cheaply determine the nature of a material in everyday life and industry, as well as in hard-to-reach places where it is not possible to use stationary or portable tools.

For this purpose, sets are produced in which the tools, depending on the standard of their hardness, differ in color:

1. Black HRC65 2. Blue HRC 60 3. Dark green HRC 55 4. Light green HRC 50 5. Yellow HRC 45 6. Red HRC 40

Traces of scratches on the control product show that the tested surface is softer than the determinant.

Tests are carried out until the hardness of the object is higher than the hardness of the tester and is between the average values of both instruments.

What types of files are there?

Modern production cannot always be satisfied with the results of manual labor, so manufacturers offer tools such as an electric or pneumatic file.

The latter are characterized by low productivity, but benefit in weight and size.

Network tools have high performance, are heavier and larger than the first ones, but do not require additional air supply.

With the development of autonomous technologies, a new type has appeared - a cordless tape file, which allows you to work without being tied to a power point.

Despite the fact that pneumatics are gradually being forced out of store shelves, there are models that best meet consumer requirements.

One such popular option is the pneumatic band file.

It does an excellent job of cleaning metal surfaces from traces of welding, corrosion and other things in small metalworking enterprises, private auto repair shops, production and assembly shops.

DIY file handles

Real craftsmen equip their existing tools with handles made by themselves. With the advent of plastics, there was a wider choice of materials for homemade products.

If you have a lathe, then the handle can be turned from hardwood: walnut, birch, ash. There are quite a lot of drawings on the Internet, using which a suitable handle is made.

Some craftsmen use epoxy resin to make unusual handles.

- First, possible porous materials that can be impregnated with epoxy resin are selected. Most often, fabrics of different colors are used. Micarta is created - a multi-layer fabric impregnated with epoxy.

- They are placed in the desired sequence.

- The epoxy resin is diluted according to the attached recipe.

- Wet each layer.

- Lay in the chosen sequence and place under a press.

- After polymerization is completed, a new material is formed - micarta.

- A file handle is made from micarta.

Video: “Cuban” files.

How to choose a file

When choosing a certain type of hand file, professionals recommend paying attention to the materials processed and performance characteristics.

Among the significant parameters is the quality of the teeth.

The efficiency of work directly depends on it.

In addition, it is worth considering:

— Type of notches; — Shape of the working fluid; — Length; — Features of the handle or shank.

The dimensions must correspond to the dimensions of the parts being processed.

For large parts, use the maximum length - from 22 to 350 mm, and for small parts - from 150 to 180 mm.

The handle should be reliable and comfortable.

Wooden handles are considered less reliable; plastic and rubber are more convenient.

Also, tools are often offered without a handle.

Indicators such as the distribution of hardness and viscosity are very important.

Viscosity is minimum at the surface and maximum at depth, while hardness is the opposite.

Insufficient hardness leads to a rapid loss of tooth sharpness, and low viscosity threatens the destruction of the notch during operation.

Surface hardness is regulated depending on the purpose.

The average figures for manufacturers are the following values for files of various types:

1. Carpentry and metalworking purposes – from 64 to 66 HRc;

2. Grinding type – from 65 to 67 HRc;

3. Rasps – from 53 to 56 HRc.

The actual quality is only verified during use.

Classification by section shape

The form determined the name and purpose of the files, and the main classification was created on it. Depending on the profile of the surface being processed, the cross-section of the tool is selected. Manufacturers of files suggest using special hand tools with the following sections:

- Flat – files of this shape are suitable for processing flat and rounded (protruding) surfaces. This is the most common cross-section for such a tool.

- Square files are used for processing rectangular and square holes. They grind rectangular grooves on the surface.

- Round - they are used to process internal cavities and holes, remove sagging from welds and flash from castings. The desired configuration is achieved by finishing elliptical surfaces inside the part.

- Triangular - in cross-section they represent a regular triangle with an angle of inclination of the surfaces of 60 ⁰ to each other. Most often, such a tool is used to sharpen the teeth of another tool, for example, a hacksaw for sawing wood.

- Special - at some enterprises, specially shaped files are made in tool shops. For example, in the manufacture of air-cooled two-stroke internal combustion engines, the inlet ports must be modified. The blanks are produced by casting, but finishing is done manually (cheaper than using a specialized machine).

- Oval or semi-cylindrical files are used for processing cylindrical or conical cavities.

Depending on the size of the parts being processed, hand tools are made in different lengths. When steam locomotives were used, each crew of drivers had a file 720 mm long. Used to clean soot and other contaminants from the surface of steam boiler pipes.

Modern files are rarely made longer than 500 mm (the size is determined by the length of the working part where the teeth are). For small jobs, for example, watchmakers use needle files with a working length of about 50 mm.

There is an accepted rule: the larger the tooth, the longer the working part. The explanation is quite simple. The work is performed in a forward motion. By moving the working part further, we achieve deeper removal of the layer when grinding.

Large teeth leave deep marks on the treated surface. To achieve a better surface, allowance is left to obtain a high-quality surface. It is obtained by processing using files with smaller teeth.