The evolution of tools has led to the fact that hand-held instruments have been replaced by electric ones. Some assistants have not changed their appearance over many years of use; such a tool can be considered a file, with which you can perform various operations.

What is being processed with a file?

Flat files are used to process (figure below) flat external and internal surfaces, as well as external convex surfaces. a - outer flat surface; b - internal flat surface. Square files (picture below) are used to process the walls of square and rectangular holes.

Interesting materials:

How to pin messages in Viber? How to cover foam on windows? How to close a 1 by 1 elastic band with a needle in a circle? How to close your Odnoklassniki page forever? How to close your second AdSense account? How to add liquid to a Vape? How to Tin a soldering iron with a metal tip? How to replace the processor on the motherboard? How to replace cotton wool in Jul? How to close an object into a component in AutoCAD?

What types of files are there?

There are several dozen types of files, differing in their performance characteristics.

The purpose of this tool is to remove a layer of material, which could be, for example, wood, metal or plastic. Each file consists of a working part and a handle. A special notch is applied to the body of the tool, due to which it is possible to remove layers of material from the surface of the product. The type of a particular file and its name are determined precisely by the size of the notch. Files are a general name for a whole line of tools, which includes rasps and needle files. Such a tool can have different sizes and profiles. Most often, craftsmen have to work with files with a flat or square section. There is a tool whose working part has a round, oval, diamond-shaped or triangular profile. Having an arsenal of files of different types and sections, a mechanic can process parts of a very complex configuration.

What should a set of rasps consist of?

It is worth considering that for high-quality work, a whole set of rasps is required. The classic set is represented by a combination of the following options:

- Flat.

- Round.

- Semicircular.

Classification is also carried out according to the type of notches applied into two classes, only if both are available it is possible to carry out work with high accuracy. The semicircular rasp of the second number has more notches on the surface, which ensures higher efficiency in use.

Most often, a metal rod is made using steel grade U7, in some cases U8 and U10. By increasing the hardness and sharpness of the cutting edge, the degree of engagement with the surface being processed significantly increases at the time of processing.

Only two types of tools are produced abroad: regular and grooved. The teeth of such designs, as a rule, have standard sizes.

How to use a file?

Working with any tool requires skills and abilities from the master, the most important thing is compliance with safety precautions. Before work, you should decide what shape of tool you need to take to process a specific surface: a flat, round or diamond file. It is most convenient to clamp the workpiece in a vice so that it does not move, apply markings and then begin grinding. To process large surfaces, movements with a file should be alternated, moving it back and forth, left and right, and diagonally.

Types and purpose

The master’s kit should contain several types of rasps, differing in their shape and technical characteristics:

- Flat - designed for processing concave surfaces. They allow you to effectively remove burrs and trim workpieces made of non-ferrous metals or wood. Modern models are equipped with comfortable two-component handles, the design of which includes holes for hanging. For the manufacture of the working part, high-strength tool steel is used, which is resistant to severe wear. Depending on its configuration, the product may have a straight or narrowed shape.

- Round - used for processing soft materials and uneven surfaces. Such tools are often used in many plumbing jobs. The presence of an ergonomic handle provides additional convenience.

- Semicircular - used for cleaning and sawing flat surfaces. In addition, tools of this type allow you to process holes with a large diameter. The handle of such devices is often coated with an anti-slip coating. Depending on the purpose and features of the model, the degree of rounding of the working part may vary significantly.

Marking of files

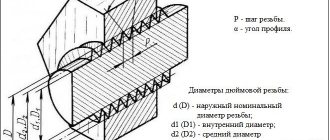

It is difficult to entrust fine processing of workpieces to machines, but with a set of files, you can cope with this task. The marking of the tool must comply with GOST; it must reflect the main characteristics of the tool:

- Class

– from 1 to 6. - Length

– looks like the number after the Latin letter L. - Type of notch

– from 0 to 5. - Tooth hardness

is double digit after abbreviation HRC. - Type of steel

– U, if the tool is made of carbon alloys, ШХ, if the file is made of alloy steel.

The needle file and its functions

The needle file has a completely different purpose. It is used for precise and finishing machining of small parts. In production and in everyday life, there are very often situations when it is necessary to give a finished look to a metal product of complex shape, to turn or process a tiny part. This is where the needle file comes to the aid of the mechanic. This small, finely cut file can get into the most difficult to reach areas.

The shape of the working body of the needle file can be completely different. Experienced craftsmen prefer to have sets of several such files in their household, using them individually or sequentially, one after another. A double notch – main and auxiliary – helps needle files process parts effectively. The notch number is usually marked on the handle of the tool.

How to restore a file at home?

Many novice craftsmen believe that a tool with traces of paint or covered with rust cannot be restored, and they throw it away. Any metal files can be cleaned, sharpened and used for a long time. After work on restoring the metal rod, you can also update the handle; it is recommended to carefully remove the old one if it is cracked and has defects. A new one will last a long time if it is treated with special wood products, varnished or painted.

How to clean a file?

Many craftsmen have encountered a problem when files become covered with rust and cannot be used. You can clean both straight and triangular files, as well as other options, using improvised materials at home.

- Pour hot water into the container where the entire file is placed and clean the surface of the tool with an old toothbrush and dishwashing detergent.

- Drain the soap solution, dry the file, prepare a liquid for cleaning the surface of the tool, consisting of 1 tbsp. hot water and 2 heaped teaspoons of citric acid. Pour the prepared solution into the file and leave it in it for 12 hours.

How to sharpen a file?

Frequent use of a file can cause the tool to become dull. Working with copper, aluminum and stainless steel often causes small metal particles to get stuck between the teeth. A rough file becomes clogged, its surface loses its functions, and its cutting part needs to be sharpened. There are several options that can return the file to its original appearance.

- The chemical method

is fast and effective. Before sharpening, the tool must be cleaned, degreased and dried. The solution into which the file is then placed consists of water (86%), nitric acid (8%) and sulfuric acid (6%). In 10 minutes. After immersion, the instrument must be removed and washed thoroughly. - The electrochemical method

is similar to the previous one. The proportions of the solution in it are slightly different; water (80%), nitric acid (9%) and sulfuric acid (11%) are taken. The file must be dipped into the prepared mixture and a low frequency current must be passed through using aluminum plates. - The mechanical method

of sharpening tools requires a special device - a milling machine. First, the file is fired in a special furnace at a temperature of about 800°C, after which its surface is ground on a machine. Using a chisel, notches are formed on a smooth file. To harden the tool, place it in a solution consisting of water (50 l), salt (2 kg) and hydrochloric acid (1 l). For hardening small instruments, the proportions are reduced. - The sandblasting method

of sharpening files requires the ability to work with special tools. The cutting surface is restored using fine sand, which is passed through a nozzle under pressure. - Folk methods of sharpening

tools are widely used by home craftsmen. Experts recommend using different compounds to restore the working surface of files: citric acid, ferric chloride, vinegar.

Choosing a file with a notch size - what is important to consider

To choose a tool, you must first decide what work you plan to perform with its help. Removing a layer of material is the main purpose of files. Based on the purpose of the tool, devices with the appropriate notch are selected.

- To remove a layer of metal from 0.1 mm, tools with notches numbered 0 and 1 are used

- Fine work with removal of a metal layer up to 0.06 mm is carried out with devices number 2 and 3

- The most precise actions to remove the minimum layer are carried out using velvet-type files (4 and 5)

Table of file shapes and sizes

To eliminate the possibility of making a mistake in choosing the appropriate tool, you need to know the following information:

- The grade of steel from which the tool is made. Counterfeits can be easily identified by their poor build quality and low cost. If the device has diamond coating, this indicates the possibility of its use for grinding hard steels, as well as ceramic products - tiles and tiles

- The length and width of the device - it all depends on what kind of workpieces you plan to process (their size)

- Type of cut and tooth size

- Handle type - the best options for handles on devices are fiberglass. It is distinguished by increased performance indicators, but at the same time it is more expensive than wooden

- The shape of the metal base, which depends on the implementation of the planned work

Today files are produced by different manufacturers - domestic and foreign. Which is better to choose? It all depends on the amount of money you are willing to spend to purchase tools. Foreign files are more expensive than domestic ones, but the quality of these tools is almost the same. Whether it is worth overpaying for the purchase of a file from a foreign brand is a matter for everyone to decide for themselves.

This is interesting!

How long do files last? This question is of interest to many, and few people know that the notches wear out over time. If the tool is used correctly, it will last a very long time, but if cast iron or bronze is processed with a bastard tool, the teeth will wear out quickly.

Types of files

Manual processing of metal blanks is carried out using a variety of files. It is necessary for a home craftsman to understand their types, understand how they differ, what they are and what they are intended for.

- A rough file

is a tool with a large notch; it is used for final, finishing grinding of the surface. - The personal file

has a medium cut size and is used as an intermediate option when processing surfaces. - A velvet file

with the smallest notch is necessary for finishing parts and sanding them.