A countersink is a special tool for metal cutting with several blades. The purpose of a countersink is to semi-finish holes in pre-drilled parts and workpieces in order to adjust the diameter to the required value and improve the quality of the resulting surface.

In general, countersinking is similar to drilling - rotating the tool around its axis with a translational movement. Countersinking should not be confused with countersinking, which is a separate type of metalworking.

Purpose of countersinking and equipment used

Countersinking allows you to improve the quality of the surface obtained during drilling to 9-11 quality accuracy and roughness Rz 2.5 microns. At the same time, all defects arising during casting, stamping and drilling of holes are eliminated, surface cleanliness and accuracy are increased, and alignment is increased. The advantage of a countersink over a conventional drill is its higher rigidity due to the cutting teeth, which ensures high precision in the direction of movement of the tool.

The main purpose of the countersink:

- Improves accuracy and surface finish of holes before tapping or reaming.

- Sizing pre-drilled holes for studs, bolts and other types of fasteners.

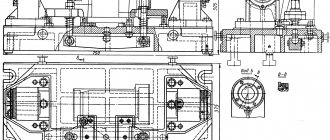

Countersinking is a machine operation and is performed on:

- drilling machines of all types;

- lathes;

- boring machines;

- aggregate machines, as an operation in an automatic line;

- horizontal and vertical milling machines.

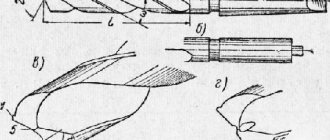

Design and principle of operation of countersinks for metal

Design:

- Cutting part. Consists of a calibration part and cutting teeth.

- Working part. It has cutting edges arranged in a spiral.

- Neck. Transition between the shank and the working part.

- Shank. This part is fixed in the chuck of a power tool or industrial equipment.

- Lamp. The end of the shank. It is needed to transmit torque from the drive.

After the electric motor starts, the equipment begins to rotate, cutting off the metal layer with sharp edges and teeth. Gradually it goes deeper into the metal part, processing the surface of the hole.

Countersink with a working diameter of 16 mm.

Types of countersinks

In modern metalworking, various types of countersinks are widely used. Depending on the purpose, the instrument is divided into two numbers:

- Countersink N1 - has an allowance and is used for semi-finishing holes before reaming.

- Countersink N2 – has an accuracy rating of H11 and is used mainly for finishing.

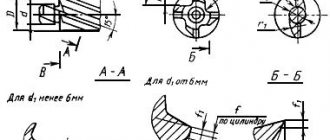

The most commonly used are two main types of countersink design - machine-made solid and mounted. The former have a Morse taper or metric taper shank, a one-piece design with cutting teeth and grooves for chip removal. Mounted countersinks have an internal hole for mounting on a mandrel. Prefabricated countersinks, welded ones, and tools with plates made of hard metal-ceramic alloys are also used.

In the photo: Countersink with carbide plates

The material of the cutting part of the solid countersink is high-speed steel P18 or P19. Tools with carbide inserts differ in the material of the workpiece. For working with cast iron parts, the plates are made of ceramic-metal alloys VK4, VK6 or VK8, for working with steel products - from T15K6. The use of carbide inserts ensures higher performance and longer tool life.

Basic definitions

A countersink is a special cutting tool that allows you to make canonical or cylindrical holes. It is used to process finished holes in order to chamfer the center hole.

A countersink is a tool consisting of a certain number of blades designed for cutting. Designed to improve the quality of the hole and expand existing holes, creating holes of cylindrical or canonical shape. Machining holes using a countersink is called countersinking. Countersinking refers to semi-finishing metal processing.

You can come across the wrong concept when they say that a countersink and a countersink are the same thing. Using a countersink, the technical quality of the hole is improved. And it is not intended for making recesses.

Countersinking holes is the removal of chips or irregularities from a drilled hole. Countering holes is the process of deepening a canonically shaped hole in order to hide the head of a bolt or self-tapping screw. You can also come across the definition of hiding a self-tapping screw in a pattai.

Countersinking a hole

Countersinking of holes - processing of drilled holes for the heads or heads of bolts, screws, hardware.

Application of countersinks

When using any type of countersink for working with steel products, it is recommended to use coolant. For cast iron and non-ferrous metals, the use of lubricant is not necessary. It is very important to choose the right tool for the operation. This takes into account:

- The material of the part and the nature of the processing, as well as the location of the hole and the planned number of operations.

- Depending on the mounting method on the machine, the design of the countersink is selected.

- The choice of tool material depends on the material of the part, the intensity of work, as well as some other factors.

Design

The conical countersink consists of two main elements - the working part and the shank. The working part has a cone with a standard range of angles at the apex from 60 to 120°. The number of cutting blades depends on the diameter of the tool and can be from 6 to 12 pieces.

A cylindrical countersink is similar in design to a drill, but has more cutting elements. At the end there is a guide pin necessary for fixing the position of the tool during processing. The limiter can be removable or be part of the body of the instrument. The first option is more practical, as it expands processing capabilities. A cutting attachment can also be installed.

If it is necessary to drill several holes to equal depths, a tool with holders with a rotating or fixed stop is used. Before processing, the countersink is fixed in the holder so that the cutting part protrudes from the stop at a distance equal to the required depth of hole processing.

This is interesting: Steel alloying - elements, classification, application, grades

The tool is made from tool alloy, carbon, high-speed and carbide steel grades. For processing cast iron parts, carbide steels are most often used; for ordinary steels, high-speed and tool steels are used.

Cone countersink design

This device is intended for passing cone-shaped openings of small depth. The main feature in the design of the element is the presence of straight teeth and an absolutely flat outer base. The number of cutting elements, in accordance with calibration, can vary from 6 to 12 units.

Countersinking holes is considered a manual procedure, carried out through a turning unit on which the countersink is mounted. The workpiece is clamped in the machine's grip, and its correct location in the recess is checked.

The axial centers of the electric spindle and the rear assembly of the machine must be at the same level. This reduces the risk of the technically movable sleeve (quill) flying out. The tip of the tool is inserted into the hole to be finished manually.

To obtain an opening of the required diameter after the countersinking operation, an allowance of 2-3 mm is made during drilling. The exact allowance values depend on the calibration of the recess in the workpiece being processed. It is more difficult to implement the countersinking process for forged and dense products. To simplify your task, you should bore the countersunk hole by 5-9 mm in advance.

Countersinking can be done in cutting order. In this situation, the tool feed is doubled than when drilling, but the travel speed remains the same.

The cutting recess with a countersink is laid at approximately 50 percent of the allowance for the diameter. Countersinking of holes with a tool is carried out using cooling materials.

The mechanism made of hard alloys does not require the introduction of auxiliary coolant.

When processing openings, a countersink guarantees high accuracy, but defects cannot be avoided at all. The most common processing defects are:

- Increased opening diameter. The main reason for the occurrence of such a defect is considered to be the use of a device with incorrect sharpening.

- Reduced diameter of the recess. It happens that the wrong tools were chosen for the job or a damaged countersink was used.

- Defiant purity. This flaw can be caused by a number of reasons. Usually, a decrease in cleanliness lies in poor sharpening of the device. In practice, the cause of the defect can also be excessive viscosity of the product material. Therefore, the element sticks to the tool belts. Damage is also caused by the error of the turner, who made an incorrect feed and acceleration of the cut.

- Partial processing of the opening. This reason usually occurs as a result of incorrect fixation of the part or an incorrect countersink allowance saved after drilling.

Design features

- Working body. The main part of the element, which essentially performs the countersinking operation. It contains cutting edges - there can be a different number of them. There is also a base - a cylindrical part where the incisors converge from the top of the cone.

- The shank is an important part of the element. With its help, the cutter is fixed in the equipment chuck. The shanks are also different: in some the body is shaped like a cylinder, in others it looks like a truncated cone.

- There is a small isthmus between the shank and the working area - this is also a countersink element. The isthmus is the weakest part of the instrument. It has a smaller diameter than the shank and working head. Its purpose is to act as a fuse in case the cutter jams in the workpiece; in this case, it should simply burst and prevent larger-scale destruction.

In addition to all-metal countersinks, there are tools with insertable blades.

In this case, the blade material is made of a stronger grade of steel than the base of the element. This design allows you to have a high-quality cutter, but at the same time, the cost will not exceed that of popular products. Another cutter design has high-strength tipped cutting edges. These cutting elements are good for processing hard alloys or cast iron.

Geometric parameters

To choose the right countersink for a specific task, you need to know what metal it will work with and what parameters the main elements of the countersink have. For all-metal cylindrical elements, the following standards are provided for geometric parameters when processing specific materials:

- For parts made of structural steel with holes up to 40.0 mm in diameter, the latter are processed with a tool with a working part diameter of 40 to 10 mm and a number of cutting edges of 3–4 units. If the diameter reaches 80 mm, then the cutter should be in the range of 32–80 mm.

- For parts made of metal that has been hardened, the holes are machined with 4- and 3-blade countersinks with a cross-sectional size from 50 to 14 mm.

- For parts made of cast iron or non-ferrous metal, the countersinking operation for blind holes is carried out with a stylus tool.

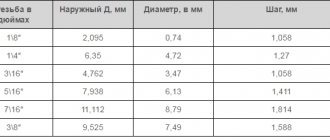

This is interesting: Inch threads - dimensions, table, GOST with diameters and pitch, designations in mm

Recommendations for the application of conical elements to the type of metal that must correspond to a certain geometric shape of the cone (meaning angle) are as follows:

- An angle of 20 to 15 degrees can be used when processing soft grades of steel and alloys is necessary.

- An angle of 10 to 8 degrees is suitable for work, which involves countersinking metals with medium hardness or parts for steel castings.

- An angle of 5 degrees and below is suitable for countersinking workpieces made of cast iron or high-alloy steel.

When finishing a product is carried out using a countersink, the diameter of the diameter of the tool must coincide with the diameter that should be obtained in the end!

The difference between counterbore and other metalworking operations

Countering is a finishing operation that follows after countersinking and usually before reaming. The process eliminates minor defects from previous processing. The master removes roughness from the surface of the hole and gives it the correct geometry. When counterbore, conical and cylindrical recesses are cut out for the heads of fasteners and a smooth surface is obtained for high-quality contact of the part with them.

The lateral surfaces of the cylindrical recesses for bolts must comply with the dimensions and quality requirements established in the drawings. The process of their processing is called reverse counterbore. It uses countersinks with a large number of cutting edges, sometimes their number reaches fourteen.

The parameters set on the machine during processing are calculated and determined according to current industry standards and product drawings. These include: feed, depth and cutting speed, effective and required power, as well as the efficiency factor calculated for the selected operating mode.

Countersink. Finishing holes

In many cases, a pre-drilled hole (especially using a hand drill) is not of high quality: in addition to end burrs, there may also be axis non-perpendicularity. Therefore, after drilling, the next transition is often used - countersinking; for this operation we need a countersink.

Types and application of countersinks

When processing parts on drilling and lathes, metal countersinking is used for:

- Formation of conical or cylindrical recesses of the required length in pre-prepared holes.

- Formation of reference planes near the holes.

- Removing chamfers in holes.

- Processing holes for fasteners.

You can often come across the term “counterbore”, which is the name of a tool designed for drilling out cylindrical recesses and supporting planes.

According to the configuration of the cutting part, the following types of countersinks are found:

- Cylindrical configuration.

- Conical countersinks.

- Face tools.

Based on the diameter of the machined holes, countersinks are divided into:

- Simple (from 0.5 to 1.5 mm).

- For holes with diameters from 0.5 to 6 mm. Available with or without safety cone.

- Countersinks with a tapered shank. Used for holes with a diameter of 8 to 12 mm.

Cylindrical

An operation of this type is often used in almost any type of production. The result is a cylindrical recess. It is an ideal choice for screws and bolts. And these fasteners in standard format are common in almost all designs. In fact, this is the most popular and current type of countersinking holes in metal.

Flat and end

This method is sometimes called countersinking. A special final type of operation. Used in ready-made recesses. So that the caps themselves and other hardware for concealment fit tightly and without gaps. To do this, the surface is cleaned. And this is where we need these varieties.

In fact, counterbore and countersink are a small difference. It’s just that this is a narrower activity, which has this name only for flat or end stripping.

Metal processing rules

For countersinking at home, you can also use a regular drill, which must first be fixed in a hand or electric drill. In production, countersinking is a more complex operation that requires the use of special equipment:

- drilling;

- turning;

- aggregate;

- boring;

- milling (horizontal and vertical).

When machining a hole in a cast workpiece, it is recommended to first bore it with a cutter so that the countersink can take the correct direction.

When working with steel products, it is advisable to use special liquids for cooling and lubrication. Countersinking of non-ferrous metal alloys and cast iron does not require cooling. When choosing a tool for this procedure, you should pay attention to a number of factors:

- The type of device is selected depending on the nature of the processing and the material from which the part is made. The serialization of processes and the location of the hole should also be taken into account.

- Guided by the accuracy, diameter and depth of processing, the most suitable countersink is selected.

- The design of the tool is determined by the method of fixation in the machine.

In addition, a prerequisite for high-quality countersinking is compliance with allowances.

That is, the diameter of the tool must necessarily correspond to the final diameter of the hole made. If after processing you need to ream, then you should take a tool whose diameter is 0.15-0.3 mm smaller. If rough boring or pre-counter drilling is planned, then an allowance of 0.6 to 2 mm should be left aside. Countersinking is a much more effective procedure than processing using cutters. The cutting speed of a countersink is comparable to drilling, and the feed speed is even several times higher.